Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pressure Reducing & Sustaining Valve

Caricato da

neversigCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pressure Reducing & Sustaining Valve

Caricato da

neversigCopyright:

Formati disponibili

92-01

MODEL

(Full Internal Port)

692-01

(Reduced Internal Port)

Combination Pressure Reducing

& Pressure Sustaining Valve

Accurate Response to Slight Pressure Changes

Check Feature Available

Completely Automatic Operation

Drip-Tight, Positive Seating Action

Operation is Fully Hydraulic

The Cla-Val Model 92-01/692-01 Combination Pressure Reducing

and Pressure Sustaining Valve automatically performs two

independent functions. It maintains a constant downstream

pressure, regardless of fluctuating demand and sustains the

upstream pressure to a pre-determined minimum.

The pressure reducing control responds to slight variations in

downstream pressure and immediately repositions the main valve

to maintain the desired downstream pressure. The pressure

sustaining control is normally held open by the upstream pressure,

but modulates should the pressure drop to the control set point.

This, in turn, modulates the main valve to sustain the desired

upstream pressure.

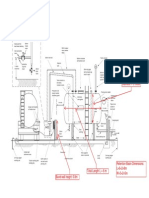

Schematic Diagram

Item

1

2

3

4

5

If a check feature is added, and a pressure reversal occurs, the

downstream pressure is admitted into the main valve cover

chamber and the valve closes to prevent return flow.

Description

Hytrol (Main Valve)

X44A Strainer & Orifice

CRD Pressure Reducing Control

CRL Pressure Relief Control

CV Flow Control (Opening)

Optional Features

Item

B

C

D

F

P

V

Description

CK2 (Isolation Valve)

CV Flow Control (Closing)*

Check Valves With Isolation Valve

Remote Pilot Sensing

X141 Pressure Gauge

X101 Valve Position Indicator

* The (optional) closing speed control on this valve should

always be open at least three (3) turns off its seat.

Typical Applications

A Combination Pressure Reducing and Pressure Sustaining

Valve is typical used to automatically reduce pressure for the

downstream distribution network and sustain a minimum

pressure in the high pressure main regardless of distribution

demand.

Model 92-01 (Uses Basic Valve Model 100-01)

B (Diameter)

Dimensions

(In inches)

Pressure Ratings

(Recommended Maximum Pressure - psi)

Flanged

ASTM A536

Material

Pressure Class

Valve Body & Cover

Grade

100-01

Ductile Iron B16.42

300

Class

End

Details

250

400

400

400

ASTM A216-WCB Cast Steel B16.5

285

400

400

400

ASTM B62

225

400

400

400

Bronze

B16.24

Threaded &

Flanged

X

C

(MAX)

Grooved Threaded

ANSI

150

300

Standards* Class Class

Inlet

Outlet

G

GG

GGG

F

FF

D

DD

DDD

Inlet

A

AA

AAA

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

Materials

Component

Standard Material Combinations

Body & Cover

Ductile Iron

Available Sizes

1" - 36"

Disc Retainer &

Diaphragm Washer

Cast Iron

Cast Steel

1" - 16"

Cast Steel

Bronze

Disc

100-01

Grooved

Bronze

Bronze is Standard

Stainless Steel is Optional

Trim: Disc Guide,

Seat & Cover Bearing

B (Diameter)

1" - 16"

CC

(MAX)

Buna-N Rubber

Diaphragm

Nylon Reinforced Buna-N Rubber

Stem, Nut & Spring

Outlet

Inlet

Stainless Steel

EE

GGGG

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Inlet

Model 92-01 Dimensions (In Inches)

Valve Size (Inches)

A Threaded

AA 150 ANSI

AAA 300 ANSI

AAAA Grooved End

B Dia.

C Max.

CC Max. Grooved End

D Threaded

DD 150 ANSI

DDD 300 ANSI

DDDD Grooved End

E

EE Grooved End

F 150 ANSI

FF 300 ANSI

G Threaded

GG 150 ANSI

GGG 300 ANSI

GGGG Grooved End

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Wt. Lbs.

X Pilot System

Y Pilot System

Z Pilot System

1

7.25

5.62

5.50

3.25

1.12

1.88

.375

.25

.375

0.4

15

11

9

9

1 1/4

7.25

5.62

5.50

3.25

1.12

1.88

.375

.25

.375

0.4

15

11

9

9

AAAA

1 1/2

2

2 1/2

3

4

6

8

10

12

14

16

18

7.25 9.38 11.00 12.50

8.50 9.38 11.00 12.00 15.00 20.00 25.38 29.75 34.00 39.00 41.38 46.00

9.00 10.00 11.62 13.25 15.62 21.00 26.38 31.12 35.50 40.50 43.50 47.64

8.50 9.00 11.00 12.50 15.00 20.00 25.38

5.62 6.62 8.00 9.12 11.50 15.75 20.00 23.62 28.00 32.75 35.50 41.50

5.50 6.50 7.56 8.19 10.62 13.38 16.00 17.12 20.88 24.19 25.00 39.06

4.75 5.75 6.88 7.25 9.31 12.12 14.62

3.25 4.75 5.50 6.25

4.00 4.75 5.50 6.00 7.50 10.00 12.69 14.88 17.00 19.50 20.81

4.25 5.00 5.88 6.38 7.88 10.50 13.25 15.56 17.75 20.25 21.62

4.75

6.00 7.50

1.12 1.50 1.69 2.06 3.19 4.31 5.31 9.25 10.75 12.62 15.50 12.95

2.00 2.50 2.88 3.12 4.25 6.00 7.56

2.50 3.00 3.50 3.75 4.50 5.50 6.75 8.00 9.50 10.50 11.75 15.00

3.06 3.25 3.75 4.13 5.00 6.25 7.50 8.75 10.25 11.50 12.75 15.00

1.88 3.25 4.00 4.50

4.00 3.25 4.00 4.00 5.00 6.00 8.00 8.62 13.75 14.88 15.69

4.25 3.50 4.31 4.38 5.31 6.50 8.50 9.31 14.50 15.62 16.50

3.25

4.25 5.00

.375 .375 .50

.50

.75

.75

1

1

1

1

1

1

.25

.50

.50

.50

.75

.75

1

1

1.25 1.5

2

1.5

.375 .375 .50

.50

.75

.75

1

1

1

1

1

1

0.4

0.6

0.7

0.8

1.1

1.7

2.3

2.8

3.4

4.0

4.5

5.1

15

35

50

70

140 285 500 780 1165 1600 2265 2982

11

13

14

15

17

29

31

33

36

40

40

43

9

9

10

11

12

20

22

24

26

29

30

32

9

9

10

11

12

20

22

24

26

29

30

32

DDDD

20

52.00

53.62

45.00

41.90

15.00

16.50

16.50

1

1.5

1

5.63

3900

47

34

34

24

61.50

63.24

53.16

43.93

30.75

31.62

17.75

19.25

19.25

22.06

22.90

1

1.5

1

6.75

6200

68

39

39

30

63.00

64.50

56.00

54.60

21.31

22.50

24.00

2

2

2

7.5

7703

79

40

42

36

76.00

76.00

66.00

61.50

24.56

25.60

25.60

2

2

2

8.5

11720

85

45

47

Note: The top two flange holes on valve size 36 are threaded to 1 1/2"-6 UNC.

Model 692-01 (Uses Basic Valve Model 100-20)

Dimensions

(In inches)

Pressure Ratings

(Recommended Maximum Pressure - psi)

Pressure Class

Valve Body & Cover

Flanged

Grade

Material

ANSI

Standards*

B (Diameter)

150

Class

300

Class

ASTM A536

Ductile Iron

B16.42

250

400

ASTM A216-WCB

Cast Steel

B16.5

285

400

ASTM B62

Bronze

B16.24

225

400

100-20

Flanged

K

C

(MAX)

Outlet

Inlet

F

FF

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

Valves for higher pressure are available; consult factory for details

A

AA

Materials

Component

Body & Cover

Inlet

E

EE

D

DD

Standard Material Combinations

Ductile Iron

Cast Steel

Bronze

3" - 48"

3" - 16"

3" - 16"

Cast Iron

Cast Steel

Bronze

Available Sizes

Disc Retainer &

Diaphragm Washer

Bronze is Standard

Stainless Steel is Optional

Trim: Disc Guide,

Seat & Cover Bearing

Disc

Buna-N Rubber

Diaphragm

Nylon Reinforced Buna-N Rubber

Stem, Nut & Spring

Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Model 692-01 Dimensions (In Inches)

Valve Size (Inches)

10

12

14

16

18

20

24

30

36

42

48

A 150 ANSI

10.25

13.88

17.75

21.38

26.00

30.00

34.25

35.00

42.12

48.00

48.00

63.25

65.00

76.00

94.50

AA 300 ANSI

11.00

14.50

18.62

22.38

27.38

31.50

35.75

36.62

43.63

49.62

49.75

63.75

67.00

76.00

94.50

B Dia.

6.62

9.12

11.50

15.75

20.00

23.62

27.47

28.00

35.44

35.44

35.44

53.19

56.00

66.00

66.00

C Max.

7.00

8.62

11.62

15.00

17.88

21.00

20.88

25.75

25.00

31.00

31.00

43.94

54.60

61.50

61.50

D 150 ANSI

6.94

8.88

10.69

CF*

CF*

CF*

CF*

CF*

CF*

CF*

DD 300 ANSI

7.25

9.38

11.19

CF*

CF*

CF*

CF*

CF*

CF*

CF*

E 150 ANSI

5.50

6.75

7.25

CF*

CF*

CF*

CF*

CF*

CF*

CF*

EE 300 ANSI

5.81

7.25

7.75

CF*

CF*

CF*

CF*

CF*

CF*

CF*

F 150 ANSI

3.75

4.50

5.50

6.75

8.00

9.50

11.00

11.75

15.88

14.56

17.00

19.88

25.50

28.00

31.50

31.50

FF 300 ANSI

4.12

5.00

6.25

7.50

8.75

10.25

11.50

12.75

15.88

16.06

19.00

22.00

27.50

28.00

H NPT Body Tapping

.375

.50

.75

.75

J NPT Cover Center Plug

.50

.50

.75

.75

1.25

1.25

K NPT Cover Tapping

.375

.50

.75

.75

Stem Travel

0.6

0.8

1.1

1.7

2.3

2.8

3.4

3.4

4.5

4.5

4.5

6.5

7.5

8.5

8.5

Approx. Ship Wt. Lbs.

45

85

195

330

625

900

1250

1380

1500

2551

2733

6500

8545

X Pilot System

13

15

27

30

33

36

36

41

40

46

55

68

79

85

86

Y Pilot System

10

11

18

20

22

24

26

26

30

30

30

39

40

45

47

Z Pilot System

10

11

18

20

22

24

26

26

30

30

30

39

42

47

49

*Consult Factory

12450 13100

Note: The top two flange holes on valve sizes 36 thru 48 are threaded to 1 1/2"-6 UNC.

100-01 Pattern: Globe (G), Angle (A), End Connections: Threaded (T), Grooved (GR), Flanged (F) Indicate Available Sizes

92-01

Valve

Selection

Basic Valve

100-01

Suggested

Flow

(gpm)

Suggested

Flow

(Liters/Sec)

Inches

114

112

212

10

12

14

16

18

20

24

30

36

mm

25

32

40

50

65

80

100

150

200

250

300

350

400

450

500

600

750

900

G, A

G, A

G, A

G, A

G, A

G, A

G, A

G, A

G, A

G, A

G, A

G, A

G, A

G, A

End Detail

T, F,

Gr*

T, F,

Gr

T, F,

Gr*

T, F,

Gr

F,

Gr

F,

Gr*

F,

Gr*

Maximum

55

93

125

210

300

460

800

1800 3100 4900 7000 8400 11000 14000 17000 25000 42000 50000

Maximum

Intermittent

68

120

160

260

370

580

990

2250 3900 6150 8720 10540 13700 17500 21700 31300 48000 62500

Minimum

10

15

35

50

70

95

120

150

Maximum

3.5

13

19

29

50

113

195

309

442

530

694

883

1073 1577 2650 3150

Maximum

Intermittent

4.3

7.6

10

16

23

37

62

142

246

387

549

664

863

1104 1369 1972 3028 3940

Minimum

.03

.03

.03

.06

.09

0.13

0.25

0.63

0.95

2.2

3.2

4.4

6.0

Pattern

7.6

9.5

275

17.4

For Lower Flows Consult Factory

100-01 Series is the full internal port Hytrol.

450

28.4

650

41.0

*Globe Grooved Only

100-20 Pattern: Globe (G), Angle (A), End Connections: Flanged (F) Indicate Available Sizes

692-01

Valve

Selection

Basic Valve

100-20

Inches

10

12

14

16

18

20

24

30

36

42

48

mm

80

100

150

200

250

300

350

400

450

500

600

750

900

1000

1200

Pattern

G, A

G, A

G, A

End Detail

Suggested

Flow

(gpm)

Maximum

260

580

1025

2300

4100

6400

9230

9230

16500

16500

16500

28000

33500

33500

33500

Minimum

10

15

35

50

50

95

95

95

275

450

450

450

Suggested

Flow

(Liters/Sec)

Maximum

16

37

65

145

258

403

581

581

1040

1040

1040

1764

2115

2115

2115

Minimum

.06

.13

.25

.63

.95

2.2

3.2

3.2

6.0

6.0

6.0

17.4

28.4

41.0

41.0

100-20 Series is the reduced internal port size version of the 100-01 Series.

Pilot System Specifications

Adjustment Ranges

Downstream:

2 to 30 psi

15 to 75 psi

20 to 105 psi

30 to 300 psi*

Materials

Upstream:

0 to 75 psi

20 to 200 psi*

100 to 300 psi

*Supplied unless otherwise specified

Other ranges available, please consult factory.

Temperature Range

Water: to 180F

Standard Pilot System Materials

Pilot Control: Bronze ASTM B62

Trim: Stainless Steel Type 303

Rubber: Buna-N Synthetic Rubber

Optional Pilot System Materials

Pilot Systems are available with

optional Aluminum, Stainless Steel or

Monel materials.

For Lower Flows Consult Factory

When Ordering, Please

Specify

1. Catalog No. 92-01 or No. 692-01

2. Valve Size

3. Pattern - Globe or Angle

4. Pressure Class

5. Threaded or Flanged

6. Trim Material

7. Adjustment Range

8. Desired Options

9. When Vertically Installed

Note: Available with remote sensing control.

CLA-VAL

P.O. Box 1325 Newport Beach, CA 92659-0325 Phone: 949-722-4800 Fax: 949-548-5441 E-mail: claval@cla-val.com Website cla-val.com

Copyright

Cla-Val 2013 Printed in USA Specifications subject to change without notice.

E-92-01/692-01 (R-1/2013)

Potrebbero piacerti anche

- Pressure Reducing Valve PDFDocumento3 paginePressure Reducing Valve PDFneversigNessuna valutazione finora

- Detailed Chemical Characterization of Petroleum Middle Fractions by Chemometrics Analysis of Their Ultraviolet SpectrumDocumento18 pagineDetailed Chemical Characterization of Petroleum Middle Fractions by Chemometrics Analysis of Their Ultraviolet SpectrumneversigNessuna valutazione finora

- OLGA 2015.1.2 Release Notes PDFDocumento51 pagineOLGA 2015.1.2 Release Notes PDFamine bcNessuna valutazione finora

- Pathway HVAC CatalogDocumento40 paginePathway HVAC CataloggeotsimbNessuna valutazione finora

- Pressure Reducing Valve PDFDocumento3 paginePressure Reducing Valve PDFneversigNessuna valutazione finora

- Pressure-Temperature Diagram Analysis of Liquefied PDFDocumento5 paginePressure-Temperature Diagram Analysis of Liquefied PDFneversig100% (1)

- Closed Refrigerated Ventilated Display Cube ProfessionalDocumento1 paginaClosed Refrigerated Ventilated Display Cube Professionalneversig100% (1)

- Typical Storage of Flammable Liquid (Gasoil)Documento1 paginaTypical Storage of Flammable Liquid (Gasoil)neversigNessuna valutazione finora

- TIA 222 - Mass Min Basic Wind Speed PDFDocumento1 paginaTIA 222 - Mass Min Basic Wind Speed PDFneversigNessuna valutazione finora

- Eexd Iic T6: Hazardous Location Rating Systems For Interlock SwitchesDocumento4 pagineEexd Iic T6: Hazardous Location Rating Systems For Interlock SwitchesPrakash AyappanNessuna valutazione finora

- Ts102 Easement Standard Distribution NetworksDocumento31 pagineTs102 Easement Standard Distribution NetworksneversigNessuna valutazione finora

- Instrument Junction BoxDocumento12 pagineInstrument Junction Boxshabbirtechnical100% (1)

- High Efficiency Compressed Air Dryers: Adsorption Dryers Classical SystemDocumento8 pagineHigh Efficiency Compressed Air Dryers: Adsorption Dryers Classical Systemneversig100% (1)

- SpecDocumento2 pagineSpecneversigNessuna valutazione finora

- Pipe Fittings Catalogue - Jan2011 - Lo Res (2) - FBDocumento38 paginePipe Fittings Catalogue - Jan2011 - Lo Res (2) - FBsparkie900Nessuna valutazione finora

- Gas/Liquid Separation Technology: Sulzer ChemtechDocumento24 pagineGas/Liquid Separation Technology: Sulzer ChemtechneversigNessuna valutazione finora

- Eexd Iic T6: Hazardous Location Rating Systems For Interlock SwitchesDocumento4 pagineEexd Iic T6: Hazardous Location Rating Systems For Interlock SwitchesPrakash AyappanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Types of Water Closet: Siphon-VortexDocumento2 pagineTypes of Water Closet: Siphon-VortexMherlieNessuna valutazione finora

- Plumbing ReviewerDocumento46 paginePlumbing ReviewerYsabelle Marie FuentesNessuna valutazione finora

- Sanitary Drainage ReportDocumento18 pagineSanitary Drainage ReportLeonard MalateNessuna valutazione finora

- Mcalpine Section 3Documento12 pagineMcalpine Section 3KOMATSU SHOVELNessuna valutazione finora

- Boiler CalculationDocumento11 pagineBoiler Calculationahmed abdohNessuna valutazione finora

- Coeficiente de Descarga para VertederosDocumento59 pagineCoeficiente de Descarga para Vertederosspmatus100% (1)

- Data Sheet Lockshield Valve Type RLV - With Facility For Connection To Drain TapDocumento4 pagineData Sheet Lockshield Valve Type RLV - With Facility For Connection To Drain TapZeljko RisticNessuna valutazione finora

- Fundamentals of Hydraulic TransientsDocumento13 pagineFundamentals of Hydraulic TransientsyousefNessuna valutazione finora

- W268.01 DLV Package A Basic Design WWTP N Effl DisposalDocumento62 pagineW268.01 DLV Package A Basic Design WWTP N Effl DisposalAdrianus HindradjajaNessuna valutazione finora

- Seattle Plumbing CodeDocumento243 pagineSeattle Plumbing CodeAouina Chokri100% (2)

- DDOT PayItemsDocumento117 pagineDDOT PayItemshighwayNessuna valutazione finora

- SS20220727NDocumento2 pagineSS20220727NIsrael AdegboyegaNessuna valutazione finora

- Surface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedDocumento22 pagineSurface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedandrzemaNessuna valutazione finora

- Hydraulic CircuitsDocumento13 pagineHydraulic CircuitsklashincoviskyNessuna valutazione finora

- Manual Formacion 430Documento112 pagineManual Formacion 430Valoys Miranda100% (4)

- ,previewDocumento57 pagine,previewhoàng đình sơn60% (5)

- Accessoires Adapters and Pressure GaugesDocumento29 pagineAccessoires Adapters and Pressure GaugesTuyota CaserNessuna valutazione finora

- Water Engineering and Management SET AITDocumento2 pagineWater Engineering and Management SET AITGustavo AtuncarNessuna valutazione finora

- FINALE GFDO 6202 4b Allgemein iJOINTDocumento6 pagineFINALE GFDO 6202 4b Allgemein iJOINTMohammed sabatinNessuna valutazione finora

- Table PD957, BP220Documento4 pagineTable PD957, BP220Anne CadizNessuna valutazione finora

- Hardhatengineer Com Pipe FittingsDocumento20 pagineHardhatengineer Com Pipe FittingsPrashant Kumar mishraNessuna valutazione finora

- Hamworthy - STP Retrofit STA-C and ST-C SeriesDocumento2 pagineHamworthy - STP Retrofit STA-C and ST-C SeriesRAJESH GANESANNessuna valutazione finora

- 2012 Plumbing Code UpdateDocumento87 pagine2012 Plumbing Code UpdateSusheel GuptaNessuna valutazione finora

- Boiler Fulton PDFDocumento84 pagineBoiler Fulton PDFHector VelazquezNessuna valutazione finora

- Process Optimisation of An Upflow Sludge Blanket Clarifier Through The Installation of Tube SettlersDocumento8 pagineProcess Optimisation of An Upflow Sludge Blanket Clarifier Through The Installation of Tube SettlersToni PhamNessuna valutazione finora

- Hydraulics & Electrics: (24 February 2010)Documento189 pagineHydraulics & Electrics: (24 February 2010)Marius Solca100% (2)

- Reference Information: Copper TubeDocumento9 pagineReference Information: Copper TubeFitsum BulloNessuna valutazione finora

- CV Agus Nugraha For IndII-SMECDocumento6 pagineCV Agus Nugraha For IndII-SMECAgus NugrahaNessuna valutazione finora

- Urban Drought Bookchapt14 - Kapil Gupta and Vinay NikamDocumento14 pagineUrban Drought Bookchapt14 - Kapil Gupta and Vinay NikamSameer PhadtareNessuna valutazione finora

- Content The STP Guide - Design, Operation and Maintenance Content The STP Guide - Design, Operation and MaintenanceDocumento1 paginaContent The STP Guide - Design, Operation and Maintenance Content The STP Guide - Design, Operation and MaintenanceBenadict JoshuaNessuna valutazione finora