Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Roadwork Checklist 1

Caricato da

chinhonCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Roadwork Checklist 1

Caricato da

chinhonCopyright:

Formati disponibili

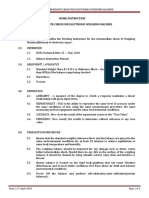

Appendix 1

QUALITY CONTROL TESTING REQUIREMENTS FOR ROAD ACCORDING TO SSRW

TEST IS TO BE PERFORMED

CONTROL ITEM

TESTS

Check

RECOMMENDED FREQUENCY

OF TESTS

(I) Atterberg Limits and Plasticity Index

REMARKS

Check

PASSING CRITERIA

PI<=55, LL<=80

Exisitng Ground

(ii) Organic Content

(I) Atterberg Limits and Plasticity Index

Embankment Fill

(I) Atterberg Limits and Plasticity Index

(II) BS1377 Compaction Test

(I) Atterberg Limits and Plasticity Index

(II) BS1377 Compaction Test

(I) Atterberg Limits and Plasticity Index

Subbase

90%

One Test for every 1500m3 and at

each change of source. Minimum

Frequency will be 1-2 tests per

KM

PI<=20, LL<=45

NA

5

One Test for every 300m2 of each

compacted layer

95%

One Test for every 1500m3 and at

each change of source. Minimum

Frequency will be 1-2 tests per

KM

PI<=55, LL<=80

NA

<= 2.5%

One Test for every 300m2 of each

compacted layer

One Test for every 750m3 of

materials or change of source

95%

PI<=6, LL<=25

(II) BS1377 Compaction Test

NA

(III) 4 days Soak CBR Test.

>=30

(IV) Aggregate crushing Value (ACV)

<=35

(V) Flakiness Index (FI)

<=30

(VI)Gradation Analysis

Grading curve; Table 4.1

SSRW

(VII) Fielde Density Test (FDT)

(I) BS1377 Compaction Test

Road Base

One Test for every 500m2

(III) Organic Content

(I) Field Density Test (FDT)

PI<=55, LL<=80

NA

(III) 4 days Soak CBR Test.

(IV) Field Density Test (FDT)

Earth Shoulder

One Test for every 1500m and at

each change of source

(II) BS1377 Compaction Test

(iii) Field Density Test (FDT)

Subgrade (top

300mm below

Formation Level)

<=2.5%

3

One Test for every 200m2 of each

compacted layer

One Test for every 750m3 of

materials or change of source

95%

NA

(II) 4 days Soak CBR Test.

>=80

(III) Aggregate crushing Value (ACV)

<=30

(IV) Sodium Sulphate Soundness Test

<=12%

(V) Flakiness Index

<=30

(VI)Gradation Analysis

grading curve; Table 4.3

SSRW

(VII) Fielde Density Test (FDT)

(I) water absorption of stockpiled

aggregates

(II) Flakiness Index of stockpiled

aggregates

(III) ACV of stockpiled aggregates

One Test for every 150m2 of each

compacted layer

1 test per stockpile per 2,500

tons (or 1,000 m3) of asphaltic

concrete produced

97%

<=2%

<=30

<=30

(IV) soundness of stockpiled aggregate

<=12%

(V) PSV Of stockpiled aggregate

>=40

(VI) Gradation analysis of aggregates in

mixing plant hot bins

(VII) Comprehensive Marshall Test

1 test per day of production

Grading curve; Table 4.8

SSRW

1 test per 200 tons of asphaltic

concrete produced

Stability: ACW 500 ;

ACB 450, Flow: 4.0

- 2.0; Stiffness: ACW

250; ACB 200

(VIII) Extraction of bitumen from Asphaltic

concrete

1 test per 200 tons of asphaltic

concrete produced

ACW = 4.5-6.5; ACB

= 4.0-6.0

(IX) Gradation analysis of aggregate

extracted from asphaltic concrete

(X) Determination of maximum specific

gravity of asphaltic concrete

(XI)Coring Test

1 test per 200 tons of asphaltic

concrete produced

1 test per 200 tons of asphaltic

concrete produced

1 sample per 500 m2 of mix laid

but not less than 2 samples for

the work completed in each

paving

(XII) Temperature of asphaltic concrete at

the time of laying

1 Test per every load delivered

for Paving

Asphaltic

Binder/Wearing

Course

Grading curve

Specified thickness

110-130 C

Check

TEST PLAN FOR CONCRETING WORKS

CONTROL ITEM

Steel Bars

Steel Fabric

TEST IS TO BE PERFORMED

Physical & Mechanical

Properties

Physical & Mechanical

Properties

FREQUENCY OF TESTING

At least Once or as directed by SO

At least Once or as directed by SO

Passing Criteria

T = 460 Mpa,

R=250Mpa

485 Mpa

Slump Test

Every ready mix truck or 4m3 of

production

As specified

Cubes

20m3 for beam, slab; 10m3 for

foundation and column

As per grade

Concrete

Appendix 1

REMARKS

Mill Certificate

Mill Certificate

Potrebbero piacerti anche

- Guideline For Operational Procedures For Building Projects - Pre Contract StageDocumento60 pagineGuideline For Operational Procedures For Building Projects - Pre Contract StagechinhonNessuna valutazione finora

- QAQC Testing Training Course - Post-Course AssessmentDocumento4 pagineQAQC Testing Training Course - Post-Course AssessmentchinhonNessuna valutazione finora

- CML In-House Training Course - Post-Course Assessment - Soil TestDocumento2 pagineCML In-House Training Course - Post-Course Assessment - Soil TestchinhonNessuna valutazione finora

- 5S Evaluation CHECKLISTDocumento2 pagine5S Evaluation CHECKLISTchinhonNessuna valutazione finora

- QC Tool - Control Chart Sieve Agg. 0.150mm 200diaDocumento3 pagineQC Tool - Control Chart Sieve Agg. 0.150mm 200diachinhon0% (1)

- Problem Solution - 5 Why's Analysis WorksheetDocumento1 paginaProblem Solution - 5 Why's Analysis WorksheetchinhonNessuna valutazione finora

- Risk Register Elongation IndexDocumento2 pagineRisk Register Elongation IndexchinhonNessuna valutazione finora

- Acemsbswut (Seminar) - 25 March 2014Documento3 pagineAcemsbswut (Seminar) - 25 March 2014chinhonNessuna valutazione finora

- WI - Intermediate Check For CalliperDocumento3 pagineWI - Intermediate Check For Calliperchinhon100% (3)

- ACEMSB (Seminar) - 12 December 2011Documento3 pagineACEMSB (Seminar) - 12 December 2011chinhonNessuna valutazione finora

- WI - Intermediate Check BalanceDocumento2 pagineWI - Intermediate Check Balancechinhon83% (6)

- Risk Register: Test Scope: Aggregate Crushing ValueDocumento2 pagineRisk Register: Test Scope: Aggregate Crushing ValuechinhonNessuna valutazione finora

- 5S Evaluation CHECKLISTDocumento2 pagine5S Evaluation CHECKLISTchinhonNessuna valutazione finora

- Summary of Quotation Construction and Completion of 1 Block of Makmal Komputer - M 2 at SK Simpang Kuda, Bau, Kuching DivisionDocumento1 paginaSummary of Quotation Construction and Completion of 1 Block of Makmal Komputer - M 2 at SK Simpang Kuda, Bau, Kuching DivisionchinhonNessuna valutazione finora

- Pavement Innovation by Bridging Public Sector Implementer and Higher Learning InstitutionDocumento2 paginePavement Innovation by Bridging Public Sector Implementer and Higher Learning InstitutionchinhonNessuna valutazione finora

- Building Design and Material Testing: Edutainment Ideas ImplementedDocumento1 paginaBuilding Design and Material Testing: Edutainment Ideas ImplementedchinhonNessuna valutazione finora

- Work Flow For Project QC Testing: No Event Action by Action On Record Duration (Day) RemarkDocumento2 pagineWork Flow For Project QC Testing: No Event Action by Action On Record Duration (Day) RemarkchinhonNessuna valutazione finora

- Control ChartDocumento9 pagineControl ChartchinhonNessuna valutazione finora

- QAQC Testing Training Course - Post-Course AssessmentDocumento4 pagineQAQC Testing Training Course - Post-Course AssessmentchinhonNessuna valutazione finora

- Authority and Responsibility Matrix For SI Works For Project Design by Consultant Stages Superintendent Authority Responsibility QA MeasureDocumento2 pagineAuthority and Responsibility Matrix For SI Works For Project Design by Consultant Stages Superintendent Authority Responsibility QA MeasurechinhonNessuna valutazione finora

- SPJ Sub Section 6.3: Road Marking: JKR/SPJ/2008-S4 SSRW 1988 Difference Remark Clause Description ClauseDocumento1 paginaSPJ Sub Section 6.3: Road Marking: JKR/SPJ/2008-S4 SSRW 1988 Difference Remark Clause Description ClausechinhonNessuna valutazione finora

- Personnel Competency Requirement For Testing Activities: Concrete Cube Compression TestDocumento1 paginaPersonnel Competency Requirement For Testing Activities: Concrete Cube Compression TestchinhonNessuna valutazione finora

- Project Quality List 311216 JKR KCHDocumento6 pagineProject Quality List 311216 JKR KCHchinhonNessuna valutazione finora

- Griptester Survey 50Km/H, 0.25Mm Water Film: Speed ChartDocumento4 pagineGriptester Survey 50Km/H, 0.25Mm Water Film: Speed ChartchinhonNessuna valutazione finora

- Course Assessment Form: Please Tick ( ) in The Following CriteriaDocumento2 pagineCourse Assessment Form: Please Tick ( ) in The Following CriteriachinhonNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Training ISO 50008Documento48 pagineTraining ISO 50008Ricardo AndresNessuna valutazione finora

- Concrete Fireproofing Analysis Evaluation and Repair StrategiesDocumento30 pagineConcrete Fireproofing Analysis Evaluation and Repair StrategiessvprskNessuna valutazione finora

- Harga Sewa Alat Terbaru Dan Berat AlatDocumento5 pagineHarga Sewa Alat Terbaru Dan Berat AlatSantiko SudihanotoNessuna valutazione finora

- Maintenance Engineering - LubricationDocumento23 pagineMaintenance Engineering - LubricationAhmed Zawad ShovonNessuna valutazione finora

- Specification For Lighting Columns: NotesDocumento9 pagineSpecification For Lighting Columns: Notessattar12345Nessuna valutazione finora

- Steam BlowingDocumento21 pagineSteam BlowingAbhishek JainNessuna valutazione finora

- Macho Laminador: M DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 Unc Asme B1.1Documento2 pagineMacho Laminador: M DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 Unc Asme B1.1emerson.mineiro100% (1)

- Avoiding Pressure Surge Damage in PipelineDocumento16 pagineAvoiding Pressure Surge Damage in PipelineFerlie IndrapatiNessuna valutazione finora

- Marine Brochure Pleasure BoatDocumento23 pagineMarine Brochure Pleasure BoatvrlinicNessuna valutazione finora

- Approval Document ASSET DOC LOC 570Documento2 pagineApproval Document ASSET DOC LOC 570Shibin PoulNessuna valutazione finora

- Mahendra Engineering College) : Internal Assessment - II, OCTOBER-2020Documento3 pagineMahendra Engineering College) : Internal Assessment - II, OCTOBER-2020ajithNessuna valutazione finora

- Danfoss - Valves - 2008 PDFDocumento39 pagineDanfoss - Valves - 2008 PDFVilius BukysNessuna valutazione finora

- QCP KOC-VME 1221006120-PART 1 Rev 3Documento49 pagineQCP KOC-VME 1221006120-PART 1 Rev 3Alireza Golpesar100% (1)

- 4.13.5 - 6 Simple Formula For Heat Loss Calculation PDFDocumento5 pagine4.13.5 - 6 Simple Formula For Heat Loss Calculation PDFSatria PurwantoNessuna valutazione finora

- Brick Dimension TablesDocumento5 pagineBrick Dimension TablesdavidongpongNessuna valutazione finora

- 4 - Bending of PlatesDocumento14 pagine4 - Bending of PlatesTushar Vinay MehtaNessuna valutazione finora

- Acura Spa Systems Inc ManualDocumento58 pagineAcura Spa Systems Inc Manualspartacusrocks100% (1)

- Ashiana Mulberry Presentation PDFDocumento23 pagineAshiana Mulberry Presentation PDFBharat ChatrathNessuna valutazione finora

- Cold Spray PTFEDocumento4 pagineCold Spray PTFEKewell LimNessuna valutazione finora

- Start Up System and Seperator Logics - 660MW (DHI Make) BoilerDocumento44 pagineStart Up System and Seperator Logics - 660MW (DHI Make) BoilerHemendra VermaNessuna valutazione finora

- Putalibazar-10 Ward OfficeDocumento18 paginePutalibazar-10 Ward OfficeRam Prasad AwasthiNessuna valutazione finora

- Ebook. Fluid Mechanics by Yunus A. Cengel, John M. CimbalaDocumento5 pagineEbook. Fluid Mechanics by Yunus A. Cengel, John M. CimbalaKiki DhanieNessuna valutazione finora

- Anexo 3 Seleccion Equipos Volumen Variable de RefrigeranteDocumento41 pagineAnexo 3 Seleccion Equipos Volumen Variable de RefrigerantepabloabelgilsotoNessuna valutazione finora

- Himani Report 2Documento20 pagineHimani Report 2Ram Kumar UttamNessuna valutazione finora

- Determination of Aggregate Crushing ValueDocumento10 pagineDetermination of Aggregate Crushing ValueArivalagan Revichandran100% (1)

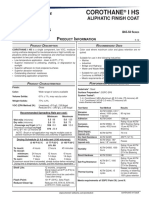

- Protective & Marine Coatings: Corothane IHSDocumento4 pagineProtective & Marine Coatings: Corothane IHSImam SitumeangNessuna valutazione finora

- Code of Practice For Installation and Maintenance of Power Cables Up To and Including 33 KV RatingDocumento1 paginaCode of Practice For Installation and Maintenance of Power Cables Up To and Including 33 KV RatingtceterexNessuna valutazione finora

- C955 09Documento4 pagineC955 09jacr27Nessuna valutazione finora

- Civil Work QuantitiesDocumento7 pagineCivil Work QuantitiesKarzan RwandziNessuna valutazione finora

- DW 30L278Documento4 pagineDW 30L278DeniRahayuYuniartoNessuna valutazione finora