Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

42 Crmo 4

Caricato da

Shiva Kumar MDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

42 Crmo 4

Caricato da

Shiva Kumar MCopyright:

Formati disponibili

Quality

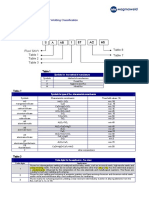

42CrMo4

Technical card

According to standards

Number

EN 10083-3: 2006

1.7225

Lucefin Group

Chemical composition

C%

Si%

Mn%

P%

S

max

max

max

0,38-0,45

0,40

0,60-0,90

0,025

0,035

0.02

+ 0.03

0.04

+ 0.005

+ 0.005

For 42CrMoS4 n 1.7227, S% 0.020-0.040 product deviations + 0.005

On request, it may be supplied Calcium (Ca) treated

Cr%

Mo%

0,90-1,20

0.05

0,15-0,30

0.03

Product deviations are

allowed

Temperature C

Hot-forming

Normalizing

Quenching

1100-850

870

air (HB ~ 190)

Isothermal

annealing

820 furnace cooling

to 670, then air

(HB 180-240)

860

850

oil or polymer water

Spheroidizing End quench

hardenability test

730-740

840

furnace cooling water

Soft annealing

720 cooling

15 C/h to 600,

then air

(HB max 241)

Quenching

Tempering

Stress-relieving

550-650

air

Pre-heating welding

50 under the

temperature of tempering

Stress-relieving

after welding

550 furnace cooling

MS

Mf

335

120

300

AC1

745

AC3

790

Mechanical and physical properties

Hot-rolled mechanical properties in quenched and tempered condition EN 10083-3: 2006

size d / t

Testing at room temperature (longitudinal)

mm

R

Rp 0.2

A%

C%

Kv

from

to

N/mm2

N/mm2 min.

min.

min.

J min.

16/8

1100-1300

900

10

40

16/8

40/20

1000-1200

750

11

45

35

40/20

100/60 900-1100

650

12

50

35

100/60 160/100 800-950

550

13

50

35

160/100 250/160 750-900

500

14

55

35

d = diameter t = thickness

HB

for information

331-380

298-359

271-331

240-286

225-271

Table of tempering values obtained at room temperature on rounds of 10 mm after quenching at 850 C in oil

HB

595

586

550

518

496

468

442

421

390

362

336

HRC

57

56.5

54.5

52.5

51

49

47

45

42

39

36

2

R

N/mm

2200 2180 2030 1910 1800 1700 1590 1480 1350 1220 1100

Rp 0.2 N/mm2

1520 1600 1620 1590 1560 1510 1440 1340 1230 1110 1000

A

%

7.0

9.5

10.0

10.0

10.0

10.4

11.0

12.0

13.5

15.8

Kv

J

24

27

28

27

26

26

26

27

31

42

75

Tempering at C 100

150

200

250

300

350

400

450

500

550

600

Data under fatigue +20 C

Fatigue strength coefficient, f

+N

1000

2 low cycle number

N/mm

+QT

1454

Fatigue strength exponent, b

+N

-0.11

low cycle number

+QT

-0.08

Fatigue ductility exponent, c

+N

-1.00

low cycle number

+QT

-0.72

2 50

100

2 40

2 30

95

90

2 20

2 10

2 00

85

190

180

75

80

70

170

Joule

Transition curve; LUCEFIN experience

Kv values obtained on hot-rolled 130 mm round

+QT induction for R 930 N/mm2 Rp 766 N/mm2 A% 18 C% 62

C

J

Lat. Exp. mm

Shear %

+20

97 101 - 99

1,10 - 1,10 - 1,17

40

0

94 96 - 93

0,97 - 0,99 - 1,00

50

-20

63 91 - 92

0,56 - 0,52 - 0,93

60

-40

66 58 - 86

0,73 - 0,77 - 0,94

60

-60

50 55 - 58

0,54 - 0,72 - 0,78

70

-80

38 29 - 35

0,27 - 0,35 - 0,26

90

264

27

880

710

21.5

135

700

160

65

150

60

140

55

130

50

120

110

45

100

40

90

35

80

30

70

60

25

50

40

20

15

30

10

20

10

0

-80

Temperature c

-6 0

-4 0

-20

20

Cleavagearea%

Data under fatigue +20 C

Cyclic yield strength, y

+N

328

2 low cycle number

N/mm

716

+QT

0.12

Cyclic strength exponent, n

+N

low cycle number

0.10

+QT

673

Cyclic strength coefficient, K

+N

N/mm2 low cycle number

+QT

1367

294

31

980

870

19.0

114

650

Lucefin Group

42CrMoS4 1.7227 EN 10277-5: 2008

Cold-drawn + quenching and tempering +C +QT

Hot-rolled annealed + peeled-reeled +A +SH

size

Testing at room temperature (longitudinal)

mm

R

Rp 0.2

A%

HB

R

Rp 0.2

A%

from

to

N/mm2

N/mm2 min min

for inform. N/mm2

N/mm2 min

min

5 b)

10

10

16

16

40

1000-1200

750

11

298-359

40

63

900-1100

650

12

271-331

63

100

900-1100

650

12

271-331

e) values valid also for +C+QT+SL

b) for thickness < 5 mm, mechanical properties should be agreed before order placement

e)

HB

max

241

241

241

Hot-rolled, quenched and tempered, cold-drawn +QT+C c) e)

Hot-rolled anneal + cold-drawn +A +C

size

Testing at room temperature (longitudinal)

mm

R

Rp 0.2

A%

HB

R

Rp 0.2

A%

from

to

N/mm2

N/mm2 min min

for inform. N/mm2 min

N/mm2 min

min

5 b)

10

1000-1200

770

8

298-359

10

16

1000-1200

750

8

298-359

16

40

1000-1200

720

9

298-359

40

63

900-1100

650

10

271-331

63

100

900-1100

650

10

271-331

c) for flats and special sections, tensile strength (R) may differ by 10% e) values valid also for +QT+C+SL

b) for thickness < 5 mm, mechanical properties should be agreed before order placement

HB

max

300

290

285

280

280

Forged quenched and tempered EN 10250-3: 2001

size d / t

Testing at room temperature

mm

R

Rp 0.2

A%

A%

from

to

N/mm2 min

N/mm2 min

min L

min T

250/160 750

500

14

10

250/160 500/330 700

460

15

11

500/330 750/500 600

390

16

12

L = longitudinal T = tangential Q = radial

d = diameter t = thickness

HB

min

225

213

178

Hardness after tempering; Lucefin experience

Tempering to 530 C

size mm

< 200

> 200 < 400

HB

320

300

A%

min Q

Kv +20 C

J min L

30

27

22

Kv +20 C

J min T

16

14

12

Tempering at 620 C

< 200

> 200 < 400

260

250

> 400

290

> 400

230

EN 10083-3: 2006 Jominy test HRC grain size 5 min.

mm distance from quenched extremity

min

max

1.5

11

13

15

20

25

30

35

40

45

50

53

61

53

61

52

61

51

60

49

60

43

59

40

59

37

58

34

56

32

53

31

51

30

48

30

47

29

46

29

45

Temperature

Testing at C

-100

0

20

100

200

300

400

500

600

Density +20 C

Kg/dm3

7.85

EUROPE EN

42CrMo4

Mod. of elasticity

E long.

GPa

217

213

230

207

199

192

184

175

164

Thermal

expansion

10-6 K-1

10.5

11.4

11.5

12.1

12.7

13.2

13.6

14.0

14.4

Specific heat

capacity

J/(KgK)

423

456

461

479

499

517

536

558

587

H

normal

Specific electric

resistivity

Ohmmm2/m

Thermal

conductivity

W/(mK)

0.231

0.284

0.358

0.448

0.552

0.671

0.806

45.1

45.1

44.1

41.9

39.4

36.9

34.4

Physical properties according to DIN SEW 310 (08/1992) standard

ITALY UNI

42CrMo4

CHINA GB

ML42CrMo

GERMANY DIN

42CrMo4

FRANCE AFNOR

42CD4

U.K. B.S.

708M40

RUSSIA GOST

38ChM

USA AISI/SAE

4140

Potrebbero piacerti anche

- Biology FullDocumento217 pagineBiology FullNaskaNessuna valutazione finora

- ISO 3755 Cast-Carbon-Steel-General-Engineering-PurposesDocumento9 pagineISO 3755 Cast-Carbon-Steel-General-Engineering-PurposesLe Van TamNessuna valutazione finora

- En10083 2Documento2 pagineEn10083 2Sezgin BayrakNessuna valutazione finora

- OSMB Technical Handbook Iss3Documento92 pagineOSMB Technical Handbook Iss3halder_kalyan9216Nessuna valutazione finora

- S For Quenching D Tentpering-: SteelDocumento28 pagineS For Quenching D Tentpering-: SteelDidier LZNessuna valutazione finora

- Alloy Guide PDFDocumento12 pagineAlloy Guide PDFArjed Ali ShaikhNessuna valutazione finora

- ISO - TC 17 - SC 11 - Steel CastingsDocumento2 pagineISO - TC 17 - SC 11 - Steel CastingsNilesh MistryNessuna valutazione finora

- Heat Resitant Steel Castings MaterialsDocumento2 pagineHeat Resitant Steel Castings MaterialssusisaravananNessuna valutazione finora

- d10 6-d10 6mPVDocumento6 pagined10 6-d10 6mPVDhanush Nair0% (1)

- 42 CR Mo 4Documento4 pagine42 CR Mo 4eduardomanar1224Nessuna valutazione finora

- Carbon Steels: Hot-Rolled Steel StripDocumento7 pagineCarbon Steels: Hot-Rolled Steel Stripwulfgang66Nessuna valutazione finora

- Week 5. Quenching and TemperingDocumento41 pagineWeek 5. Quenching and TemperingCheeragNessuna valutazione finora

- American Galvanizing Association PDFDocumento81 pagineAmerican Galvanizing Association PDFআসিফহাসানখানNessuna valutazione finora

- Cromax 42CrMo4Documento3 pagineCromax 42CrMo4ElMacheteDelHuesoNessuna valutazione finora

- WeldingDocumento21 pagineWeldingprabhatkumar_6657012Nessuna valutazione finora

- Diagramas TT de Ferro e Aço - Aço FerramentaDocumento141 pagineDiagramas TT de Ferro e Aço - Aço FerramentaFernando VenceslauNessuna valutazione finora

- 701 Steel InclusionRating DIN-50602 PDFDocumento1 pagina701 Steel InclusionRating DIN-50602 PDFbiancogallazzi0% (1)

- Astm e 2218 - 02Documento15 pagineAstm e 2218 - 02Jaime Rafael Patron PrioloNessuna valutazione finora

- AISI 410 Martensitic Stainless Steel: Gloria Material Technology CorpDocumento1 paginaAISI 410 Martensitic Stainless Steel: Gloria Material Technology CorppvdangNessuna valutazione finora

- Supraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilDocumento2 pagineSupraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilHugo RodriguezNessuna valutazione finora

- Astm e 112 Ebook - enDocumento46 pagineAstm e 112 Ebook - enyostar 232Nessuna valutazione finora

- Reaction Pathways and Mechanisms in Thermocatalytic Biomass Conversion IDocumento268 pagineReaction Pathways and Mechanisms in Thermocatalytic Biomass Conversion IPedro Milton Chibulacho100% (1)

- Welding Metallurgy and Weldability of Stainless SteelsDocumento6 pagineWelding Metallurgy and Weldability of Stainless SteelsoifhiudsnfNessuna valutazione finora

- Steel CleanlinessDocumento22 pagineSteel CleanlinessfondershellNessuna valutazione finora

- En 10088 Steel NumberDocumento3 pagineEn 10088 Steel Numberrvieira659Nessuna valutazione finora

- 42 CR Mo 4Documento2 pagine42 CR Mo 4niladriprasadrNessuna valutazione finora

- Welding - Ferritic Stainless Steel 1.4003Documento9 pagineWelding - Ferritic Stainless Steel 1.4003Danut RusNessuna valutazione finora

- Diagramas TT de Ferro e Aço - Aço de Alta ResistênciaDocumento111 pagineDiagramas TT de Ferro e Aço - Aço de Alta ResistênciaFernando VenceslauNessuna valutazione finora

- 30 CR Ni Mo 8Documento2 pagine30 CR Ni Mo 8Amy GriffinNessuna valutazione finora

- En 10140-2006Documento14 pagineEn 10140-2006KaanMertNessuna valutazione finora

- Macroetch Testing Steel Bars, Billets, Blooms, and Forgings: Standard Method ofDocumento5 pagineMacroetch Testing Steel Bars, Billets, Blooms, and Forgings: Standard Method ofislamakthamNessuna valutazione finora

- EN 760 (Flux-SAW)Documento2 pagineEN 760 (Flux-SAW)HoangNessuna valutazione finora

- Steel Grades HandbookDocumento6 pagineSteel Grades Handbookbhavin178Nessuna valutazione finora

- Advance StructuresDocumento6 pagineAdvance StructuresManju NishaNessuna valutazione finora

- Is 3930Documento19 pagineIs 3930IPSITNessuna valutazione finora

- Temper Embrittlement - J and X FactorDocumento2 pagineTemper Embrittlement - J and X Factorgovimano100% (2)

- Domex 100 XF Data SheetDocumento2 pagineDomex 100 XF Data Sheetzubblwump5063Nessuna valutazione finora

- C45 STD PDFDocumento2 pagineC45 STD PDFJeetu GosaiNessuna valutazione finora

- DIN EN ISO 9013 - Angular Deviation PDFDocumento1 paginaDIN EN ISO 9013 - Angular Deviation PDFflorinelvvNessuna valutazione finora

- SAW Flux StorageDocumento2 pagineSAW Flux StorageTrung Tinh HoNessuna valutazione finora

- Copper - Alloys - Properties and Applications - ChapterDocumento5 pagineCopper - Alloys - Properties and Applications - ChapterJavier RodenasNessuna valutazione finora

- IBR 73-80 Steel CastingsDocumento5 pagineIBR 73-80 Steel CastingsRajivharolikarNessuna valutazione finora

- Alloy286 - ASTM A453 660 DatasheetDocumento2 pagineAlloy286 - ASTM A453 660 Datasheetn1ghtfallNessuna valutazione finora

- Is Phosphorus Bad For SteelDocumento19 pagineIs Phosphorus Bad For SteelKarun Dev100% (1)

- Alloys DensityDocumento4 pagineAlloys DensityArnold Melissa CollettNessuna valutazione finora

- 304 DDQ SpecificationDocumento1 pagina304 DDQ Specificationdac_angelovNessuna valutazione finora

- Effect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 SteelDocumento5 pagineEffect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 SteelCường BéoNessuna valutazione finora

- 1 7335Documento5 pagine1 7335stamatsNessuna valutazione finora

- Interpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Documento10 pagineInterpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Nick pilipenkoNessuna valutazione finora

- MildSteel AISI 1018Documento2 pagineMildSteel AISI 1018ramanamurtytv7176Nessuna valutazione finora

- Corporate Overview Daniel I GroupDocumento34 pagineCorporate Overview Daniel I GroupRoccoFENessuna valutazione finora

- Alloy Process Data Sheet - 105-85Documento3 pagineAlloy Process Data Sheet - 105-85Ugur KayaNessuna valutazione finora

- LIBRO3Documento43 pagineLIBRO3Camilo LacoutureNessuna valutazione finora

- About En19Documento1 paginaAbout En19ramanamurtytv7176Nessuna valutazione finora

- S355 European Standard SteelDocumento7 pagineS355 European Standard SteelmaiquelernNessuna valutazione finora

- ASME SA213 T9 Seamless Alloy Steel TubesDocumento7 pagineASME SA213 T9 Seamless Alloy Steel TubesJayminNessuna valutazione finora

- Effect of Alloying Elements On Steel Properties (SubsTech)Documento2 pagineEffect of Alloying Elements On Steel Properties (SubsTech)hguptabhel100% (1)

- The Iron Puddler My life in the rolling mills and what came of itDa EverandThe Iron Puddler My life in the rolling mills and what came of itNessuna valutazione finora

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDa EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNessuna valutazione finora

- Print - Hardness Conversion ChartDocumento15 paginePrint - Hardness Conversion ChartShiva Kumar MNessuna valutazione finora

- Young Modulus of Elasticity For Metals and AlloysDocumento3 pagineYoung Modulus of Elasticity For Metals and AlloysShiva Kumar MNessuna valutazione finora

- Young Modulus of Elasticity For Metals and AlloysDocumento3 pagineYoung Modulus of Elasticity For Metals and AlloysShiva Kumar MNessuna valutazione finora

- 20 CR MoDocumento2 pagine20 CR MoShiva Kumar MNessuna valutazione finora

- HO1 Importance of Wood ChemistryDocumento2 pagineHO1 Importance of Wood ChemistryElla Rey67% (3)

- High Performance Liquid ChromatographyDocumento18 pagineHigh Performance Liquid ChromatographyNathan SueraNessuna valutazione finora

- An Introduction To Physical Organic ChemistryDocumento92 pagineAn Introduction To Physical Organic ChemistrymichaelNessuna valutazione finora

- 14 Pertumbuhan MikrobaDocumento24 pagine14 Pertumbuhan MikrobaNadia SNessuna valutazione finora

- Preregistration SeminarDocumento34 paginePreregistration Seminarchirag chawareNessuna valutazione finora

- Chem LabDocumento4 pagineChem LabSean M. InocencioNessuna valutazione finora

- Cruz - Bscpe - 1-1 - Task#4 The First Law of ThermodynamicsDocumento2 pagineCruz - Bscpe - 1-1 - Task#4 The First Law of ThermodynamicsJoshua CruzNessuna valutazione finora

- Solomon2021 Article CorrosionOfSulfurRemovalTanksUDocumento8 pagineSolomon2021 Article CorrosionOfSulfurRemovalTanksUSauravNessuna valutazione finora

- Research On Historical Bricks From A Baroque ChurchDocumento5 pagineResearch On Historical Bricks From A Baroque ChurchIS AANessuna valutazione finora

- Grundfos Oxiperm ProDocumento16 pagineGrundfos Oxiperm ProGrundfosEgypt100% (1)

- Fluorescence Spectroscopy and Its Applications: A Review: International Journal of Advances in Pharmaceutical AnalysisDocumento8 pagineFluorescence Spectroscopy and Its Applications: A Review: International Journal of Advances in Pharmaceutical AnalysisPriyanka KasturiaNessuna valutazione finora

- 7.016 Recitation 2 - Fall 2018: Summary of Lectures 2 (9/7) & 3 (9/10)Documento6 pagine7.016 Recitation 2 - Fall 2018: Summary of Lectures 2 (9/7) & 3 (9/10)Manish SarkarNessuna valutazione finora

- Chemistry Unit 1 Practice Exam 3Documento19 pagineChemistry Unit 1 Practice Exam 3AlyciaLeeNessuna valutazione finora

- Electrochemical BiosensorDocumento24 pagineElectrochemical BiosensorDyahrosa PranataNessuna valutazione finora

- Notes 6.1Documento3 pagineNotes 6.1LEE LEE LAUNessuna valutazione finora

- MSDS New CAUSTIC SODADocumento6 pagineMSDS New CAUSTIC SODAAlves EdattukaranNessuna valutazione finora

- Preparation of Nano Ferrite Particle by Chemical Way in High Static Magnetic Field (HSMF)Documento25 paginePreparation of Nano Ferrite Particle by Chemical Way in High Static Magnetic Field (HSMF)Blick ZitaNessuna valutazione finora

- Cert. Analisis KCL - EnglishDocumento1 paginaCert. Analisis KCL - EnglishmatiasNessuna valutazione finora

- Topic 1.3 Membrane StructureDocumento4 pagineTopic 1.3 Membrane Structurejasmine wibawaNessuna valutazione finora

- Intertek Testing Services LTD., Shanghai Ningbo BranchDocumento4 pagineIntertek Testing Services LTD., Shanghai Ningbo BranchKalpesh PatelNessuna valutazione finora

- Knowledge Sharing Session: Topic: AnodizingDocumento23 pagineKnowledge Sharing Session: Topic: AnodizingRaj Kumar GiriNessuna valutazione finora

- Phosphorimetry & FluorimetryDocumento21 paginePhosphorimetry & FluorimetryDeshan Wolfey100% (1)

- 11 - 19, 21-23, 24-25, 27Documento8 pagine11 - 19, 21-23, 24-25, 27Guile PTNessuna valutazione finora

- PASS Week 3 WorksheetDocumento3 paginePASS Week 3 WorksheetaskldhfdasjkNessuna valutazione finora

- Chemistry Investigatory Azo Dye Classification and PreparationDocumento28 pagineChemistry Investigatory Azo Dye Classification and Preparationdivyank tiwariNessuna valutazione finora

- Seminar Presentation Ce20214Documento13 pagineSeminar Presentation Ce20214Anji Reddy KommasaniNessuna valutazione finora

- IRP 1dandfblocksDocumento21 pagineIRP 1dandfblocksDhrutvan Reddy ReddiwaryNessuna valutazione finora