Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Steam 1

Caricato da

NaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Steam 1

Caricato da

NaCopyright:

Formati disponibili

Department of Facilities Services

Steam System Design Requirements Design Guidelines

7.4.2. The sealant shall be installed so as to provide full coverage of all concrete joint contact surfaces per

the manufacturers recommendations. Place sealant on parts to be joined prior to final positioning of the

pre-cast structures.

7.5. Waterproofing mastic

7.5.1. A heavy coat of non-asphalt, rubber/resin based mastic for underground use shall be applied a

minimum of 12 inches wide to all joints after the joint is made. The mastic shall be equal to Sandell

Special Nuflex Mastic as manufactured by Sandell Manufacturing Co., Inc.

7.6. Waterproofing Membrane

7.6.1. A waterproofing membrane shall be installed over the entire conduit system. The membrane shall

be polyvinyl chloride. The membrane shall have a nominal thickness of 20 mils, and have a minimum

tensile strength of 2300 psi.

7.6.2. The membrane shall be wide enough to drape over the conduit structure and lap over the foundation

on both sides in one piece. The membrane shall be extended axially along the conduit system from a large

roll so as to minimize the number of joints in the membrane.

7.6.3. The PVC membrane jacket shall be overlapped a minimum of 12 inches and sealed with a nonasphalt resin based sealant at membrane joints to produce a waterproof seal. The waterproofing

membrane shall be adhered to the concrete joints and to itself at overlaps. The entire conduit system shall

be made waterproof. All manufacturers installation recommendations shall be followed.

7.7. Waterproofing Backfill Protection

7.7.1. The waterproofing membrane shall be protected from backfill by a layer of nonwoven

polypropylene. The polypropylene protective layer shall have an approximate weight of lb. per square

yard. The polypropylene covering shall be equal to Terratex non-woven geotextile No. 8 as manufactured

by Webtec, Inc. At wrap joints the materials shall overlap a minimum of 12 inches. The wrap joints shall

not be coincident with waterproofing membrane joints. All manufactures installation recommendations

shall be followed.

7.8. Concrete Conduit Waterproofing Alternative

7.8.1. In lieu of the above membrane and mastic system, the same waterproofing system required for the

manholes may be used for the entire conduit system, so long as butyl resin sealants are applied to the precast joints as described in item 7.4.

8. Manholes

8.1. General Structure

8.1.1. Steam manholes shall contain only steam related systems (steam, condensate, heating hot water,

and occasionally hot domestic water). Absolutely no other utilities such as sewer, cold domestic water,

electrical duct banks, chilled water, etc. shall pass through the steam manholes, or steam conduit system.

8.1.2. Minimum manhole interior dimensions shall be L=10 x W=10 x H=8. Manholes shall be sized in

excess of this as required to provide adequate and safe movement within the finished manhole including

2013

Design Guidelines

6|P a g e

Department of Facilities Services

Steam System Design Requirements Design Guidelines

piping insulation. Free and open access to all operational components such as valves, drains, trap

stations, etc. shall be provided.

8.1.3. All steam and hot water manholes shall be constructed with a minimum of two egress paths, one on

each side of major obstructions such as through piping, and generally on opposite sides of the manhole.

Egress paths shall be coordinated withthe manhole ventilation design.

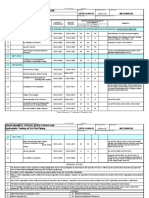

8.1.4. All steam manholes shall have a high-low natural ventilation system. The ventilation system shall

be designed to ventilate the manhole only, the conduit system will be blocked off with insulation from

drafting with the manhole. The low vent shall be on the opposite side diagonally from the high vent if

possible, or at a minimum on the opposite parallel side. The high vent can be common with a ladder

access point. The high vent shall be positioned such that rain drops do not drop on top of equipment and

piping. Typically, the low vent is constructed of 36 diameter ductile iron pipe adjacent to the manhole

with a penetration six (6) inches above the manhole floor. Alternately the down shaft can be cast

integrally with the manhole wall. The external ductile piping arrangement has proven to provide superior

ventilation because the exterior shaft with separation stays coolest. In all cases the down shaft shall be

exterior to the manhole, shall have a cross-sectional area equal to or greater than a 36 diameter pipe, and

shall penetrate the manhole six (6) inches above the floor. The penetration shall be sealed full wall

thickness with non-shrink grout and shall be water proofed according to the manhole water proofing

section of this document. The landscaping around the manhole shall prevent any surface water drainage to

any manhole opening or cover. The diagram below shows a down-shaft arrangement for the low vent.

2013

Design Guidelines

7|P a g e

Department of Facilities Services

Steam System Design Requirements Design Guidelines

8.1.5. The manholes shall have minimum of three (3) feet of cover, and the overall depth of manholes

shall be kept to a minimum. Consideration shall be given to accessibility and maintainability when

designing manholes.

8.1.6. The access points shall be a minimum of 30 inches in diameter. In non roadways use 36 square

HS-20 highway rated aluminum hinged doors. Even with such a rating, the aluminum doors are not

suitable for actual roadway use (repeated traffic crossing). In an actual roadway the doors shall be

standard 30 round cast iron manhole ring and covers. The accesses shall be designed for safety,

accessibility to the equipment, maintainability, operability, adequate ventilation, and must be large

enough to pass any equipment installed within. Regardless of installed location or type, all doors shall

carry a HS-20 highway rating.

8.1.7. All access doors shall have an aluminum or stainless steel, welded on, tag that bears the

identification number of the manhole. The letters shall be two (2) inches in height. The letters may be

field written with a stainless or aluminum welding bead in lieu of a fabricated tag. The tag shall have

the form STM-XXX where STM stands for steam, and XXX to be replaced with the Cogeneration

Systems manhole number.

8.1.8. Drains shall be provided in all manholes. Open drains shall be routed to the nearest storm sewer or

other suitable storm drainage location, as the purpose of these drains is simply to remove infiltrated rain

2013

Design Guidelines

8|P a g e

Department of Facilities Services

Steam System Design Requirements Design Guidelines

water. These drains shall have a minimum diameter of four (4) inches. Where gravity drains cannot be

installed,

sump pumps may be utilized. The sump pumps shall be Little Giant High Temperature Sump Pumps

only.

8.1.9. Whenever possible electrical switching equipment shall be located external to the manhole in an

adjacent building. In no case shall electrical equipment be located in a non-ventilated manhole. All

electrical equipment within manholes, including junction boxes, shall be suitable for continuous full load

operation in a 100%relative humidity, 200 degrees F ambient condition.

8.1.10. All electrical conduit in manholes and in steam conduits shall be aluminum only.

The only exception is naturally ventilated (with power assist) walk-able tunnels,

where the conduit may be rigid galvanized.

8.1.11. All wiring shall be rated for a minimum of 200 degrees C and sized appropriately

for the load. Referencing table 310-19 of the 1999 National Electric Code, the wiring shall be types, FEP,

FEPB, or PFA.

8.1.12. Steps leading into manholes shall be meet OSHA standards and shall be designed to withstand a

sustained temperature of 200F.

8.1.13. Ladders entering manholes shall be constructed of stainless steel, aluminum, or hot dipped

alvanized. Fabricated ladder risers shall be 2 inch by 3/8 inch flat bar. Fabricated ladder rungs shall be 1

inch re-bar. Smooth, round rungs will not be accepted. The rungs shall rest in drilled holes and be welded

in position. Similar pre-manufactured stainless steel, aluminum, or hot dipped galvanized ladders or

components may be used with the owners written approval of a shop drawing. The ladders shall be

anchored to the manhole wall using stainless steel only anchor bolts. Absolutely no individual step wall

anchored type ladders will be allowed. No carbon steel ladders will be accepted. If hot dipped material is

chosen, the ladder shall be dipped as a complete structure, not fabricated of individual pre-dipped

components.

8.1.14. Structural reinforcement shall be designed per the loading requirements by a licensed structural

engineer, but in no case shall be less than No. 4 reinforcing bar on twelve (12) inch centers. The

structural reinforcing steel shall meet the requirements in the steel reinforcement section of this

document.

8.1.15. The walls, roof, floor of the manholes shall be designed per the loading requirements by a licensed

structural engineer, but in no case shall be less than eight (8) inches thick.

8.2. Manhole Waterproofing Materials

8.2.1. The primary water proofing barrier shall be constructed of a sprayed on, or rolled on material that

meets or exceeds all of the following requirements.

8.2.1.1. Material shall be non-toxic.

8.2.1.2. Water based, and can be applied to green, un-cured concrete.

8.2.1.3. Final cure must occur within 48 hours.

8.2.1.4. Tensile strength shall not be less than 50 psf.

2013

Design Guidelines

9|P a g e

Department of Facilities Services

Steam System Design Requirements Design Guidelines

8.2.1.5. Elongation without failure shall be at least 1000%.

8.2.1.6. Resilience (elongation recovery) shall be at least 95%.

8.2.1.7. Moisture vapor transmission shall be no greater than 0.02 gm/sq.ft./hr.

8.2.1.8. Shall be impenetrable to water up to 30 psig.

8.2.1.9. Shall bond to the concrete with a pull off force not less than 820 psf.

8.2.1.10. Shall remain stable and bonded up to 240 degrees F.

8.2.2. The primary waterproofing backfill protection membrane shall be a high strength polyethylene

geomembrane slip sheet, and shall meet or exceed the following requirements.

8.2.2.1. Have a minimum thickness of 10 mils.

8.2.2.2. Have a minimum puncture resistance of 70 lbs.

8.2.2.3. Have a minimum tensile strength of 25 psi.

8.2.3. An example of these types of materials can be found at http://www.eproserv.com in the EcoLine-R,

EcoLine-S, and EcoShield-E line of products, as manufactured by EPRO Waterproofing Systems.

8.3. Manhole Waterproofing Methods

8.3.1. Manhole waterproofing shall be a three step process consisting of detailing cold joints and

penetrations, applying a sprayed on / rolled on membrane to provide overall waterproofing, and the

application of a backfill protection membrane.

8.3.2. The first, or detailing step consists of applying a roll on coat of the waterproofing compound to all

cold joints and penetrations at least 3 inches on either side of the joints and radial out from the

penetrations. While still wet, an embedding fabric shall be placed in the membrane coat. Then a second

coat shall be applied to the embedding fabric until saturated.

8.3.3. The second, or membrane application step is performed by rolling or spraying membrane material

to the manhole exterior surface in wet lifts until the material is not less than 60 mils thick on the concrete

surface. The surface shall be fully coated, and free of gaps and cracks.

8.3.4. The third, or protection layer is a process of applying a polyethylene geomembrane slip sheet that

will protect the waterproofing membrane from backfill. This membrane shall be applied such that the

overlaps are not less than 12, and are sealed with a roller compressed wet layer of water proofing

material. Waterproofing seal tape shall be applied to seam overlapping 2 inches on either side of the

seam.

8.3.5. In some circumstances there is a fourth process of applying a drainage membrane on the outside of

the protection membrane to aid in ground water drainage away from the structure. In most cases however, the

manhole is backfilled with a layer of pea-gravel which acts as the drainage mechanism.

2013

Design Guidelines

10 | P a g e

Potrebbero piacerti anche

- CompreDocumento3 pagineCompreNaNessuna valutazione finora

- Attachment B - Flange CheckDocumento1 paginaAttachment B - Flange CheckNaNessuna valutazione finora

- CompreDocumento3 pagineCompreNaNessuna valutazione finora

- A135810286 Compressor Stress Analysis PresentationDocumento25 pagineA135810286 Compressor Stress Analysis PresentationNaNessuna valutazione finora

- A88516875 Slug Flow AnalysisDocumento7 pagineA88516875 Slug Flow AnalysisNaNessuna valutazione finora

- Forces and Moments (Api-617Documento3 pagineForces and Moments (Api-617NaNessuna valutazione finora

- Static & Dynamic Analysis of Piping SystemDocumento105 pagineStatic & Dynamic Analysis of Piping Systemkarthikeashwar100% (4)

- Steam 1Documento5 pagineSteam 1NaNessuna valutazione finora

- LANL EngDocumento3 pagineLANL EngNaNessuna valutazione finora

- Evaluating Dynamic Stresses of A PipelineDocumento8 pagineEvaluating Dynamic Stresses of A PipelinejasminNessuna valutazione finora

- Steam 1Documento5 pagineSteam 1NaNessuna valutazione finora

- Steam 1Documento4 pagineSteam 1NaNessuna valutazione finora

- Steam 1Documento5 pagineSteam 1NaNessuna valutazione finora

- Steam 1Documento5 pagineSteam 1NaNessuna valutazione finora

- Steam 1Documento4 pagineSteam 1NaNessuna valutazione finora

- LANL EngDocumento4 pagineLANL EngNaNessuna valutazione finora

- LANL EngDocumento3 pagineLANL EngNaNessuna valutazione finora

- LANL EngDocumento3 pagineLANL EngNaNessuna valutazione finora

- LANL EngDocumento3 pagineLANL EngNaNessuna valutazione finora

- B4 Stress AnalysisDocumento5 pagineB4 Stress AnalysisNaNessuna valutazione finora

- LANL EngDocumento3 pagineLANL EngNaNessuna valutazione finora

- LANL EngDocumento3 pagineLANL EngNaNessuna valutazione finora

- Stress B4Documento7 pagineStress B4NaNessuna valutazione finora

- Code Requirements: Safe-Shutdown Earthquake (SSE), Which Is Defined As The Maximum PossibleDocumento4 pagineCode Requirements: Safe-Shutdown Earthquake (SSE), Which Is Defined As The Maximum PossibleNaNessuna valutazione finora

- Extracted Page From Stress B4Documento3 pagineExtracted Page From Stress B4NaNessuna valutazione finora

- Stress B4Documento5 pagineStress B4NaNessuna valutazione finora

- Stress B4Documento5 pagineStress B4NaNessuna valutazione finora

- Stress Analysis of Piping Systems: & PV Code, 1998. (Courtesy of ASME.)Documento5 pagineStress Analysis of Piping Systems: & PV Code, 1998. (Courtesy of ASME.)NaNessuna valutazione finora

- 2) Stress Analysis 2Documento30 pagine2) Stress Analysis 2Dennis Padec BwochengoNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Bituthene 3000-3000 HCDocumento2 pagineBituthene 3000-3000 HCRm1262Nessuna valutazione finora

- Mazzella WireRopeAtAGlance 0919Documento5 pagineMazzella WireRopeAtAGlance 0919Tarek HareedyNessuna valutazione finora

- MoRTH Circular Value Engineering 22.02.2023 PDFDocumento2 pagineMoRTH Circular Value Engineering 22.02.2023 PDFHimanshu PatelNessuna valutazione finora

- Bridge Superstructure DesignDocumento278 pagineBridge Superstructure Designmikefara100% (3)

- Fire Damaged Concrete StructuresDocumento11 pagineFire Damaged Concrete StructuresbarouniamineNessuna valutazione finora

- VRV AHU System: Standard Series Ahur-Cavj/Davj/Dabvj Outdoor Air Series Ahur-Calj/Dalj/DabljDocumento20 pagineVRV AHU System: Standard Series Ahur-Cavj/Davj/Dabvj Outdoor Air Series Ahur-Calj/Dalj/DabljPatrick SyNessuna valutazione finora

- Api 571 Damage Mechanism QuestionsDocumento27 pagineApi 571 Damage Mechanism QuestionsPadmanabhan Nataraj100% (12)

- Types of PumpsDocumento68 pagineTypes of PumpsVicky JeganNessuna valutazione finora

- List of Operational Control ProcedureDocumento1 paginaList of Operational Control ProcedureRam Naidu PenNessuna valutazione finora

- CC603 Topik 1Documento55 pagineCC603 Topik 1farrita95Nessuna valutazione finora

- Technical ManagerDocumento4 pagineTechnical ManagerSrini vasanNessuna valutazione finora

- Wa0040.Documento14 pagineWa0040.robert nick eusebio teheranNessuna valutazione finora

- Yamunaapartments 160117184123Documento34 pagineYamunaapartments 160117184123Ponvel KumaranNessuna valutazione finora

- Characteristics and Application of PolymersDocumento18 pagineCharacteristics and Application of PolymersQaz ZaqNessuna valutazione finora

- Multi ChemDocumento5 pagineMulti ChemKiran Kumar JhaNessuna valutazione finora

- Hilti HIT System - Rebar Hand OutDocumento34 pagineHilti HIT System - Rebar Hand Outmcwong_98Nessuna valutazione finora

- Is 2062 E350 - Fe 490 Steel Plate - Steel PlateDocumento4 pagineIs 2062 E350 - Fe 490 Steel Plate - Steel PlateAmit GauravNessuna valutazione finora

- Tabel Kekuatan BautDocumento94 pagineTabel Kekuatan BautJuweni 65100% (2)

- Marine Air Systems ManualDocumento32 pagineMarine Air Systems ManualKyaw MyoNessuna valutazione finora

- Adobe Scan 27 Sept 2023Documento1 paginaAdobe Scan 27 Sept 2023guha_tuhinNessuna valutazione finora

- Tension Stiffening and Crack Formation in Reinforced Concrete Members With Fiber-Reinforced Polymer SheetsDocumento8 pagineTension Stiffening and Crack Formation in Reinforced Concrete Members With Fiber-Reinforced Polymer SheetsMuhammad Fajrul FalahNessuna valutazione finora

- Saudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingDocumento10 pagineSaudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingAhdal NoushadNessuna valutazione finora

- EN - DRAA1621 - Spindle Replacement of The Milling Unit M1 - WebDocumento11 pagineEN - DRAA1621 - Spindle Replacement of The Milling Unit M1 - WebJPNessuna valutazione finora

- Grundfos CRDocumento48 pagineGrundfos CRharlyganNessuna valutazione finora

- Price List DT 10.09.20 PDFDocumento48 paginePrice List DT 10.09.20 PDFIshan Goel100% (1)

- Bamboo Joints and Joinery Techniques - Guadua BambooDocumento13 pagineBamboo Joints and Joinery Techniques - Guadua Bambooupendar reddy Mallu50% (2)

- LCT Shielded Primary UD Cable Jacketed: ApplicationsDocumento5 pagineLCT Shielded Primary UD Cable Jacketed: ApplicationsLuis MartinezNessuna valutazione finora

- Unit 2 QB Construction PracticesDocumento24 pagineUnit 2 QB Construction PracticesRajha RajeswaranNessuna valutazione finora

- A436-2020 Standard Specification For Austenitic Gray Iron CastingsDocumento5 pagineA436-2020 Standard Specification For Austenitic Gray Iron CastingsPablo C. T.Nessuna valutazione finora

- TAIPEI 101 Tall BuildingsDocumento10 pagineTAIPEI 101 Tall BuildingsAzam SufiNessuna valutazione finora