Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Eea 60 1 2012 075 EN LP 000

Caricato da

kubikTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Eea 60 1 2012 075 EN LP 000

Caricato da

kubikCopyright:

Formati disponibili

75

Challenges in Nanotechnologies and Nanomanufacturing

Processes

Titu-Marius I. BJENESCU

Abstract

The tasks that have to be fulfilled by photonics and electronics, one-dimensional nanosystems, the

nanomanufacturing, and the worlds smallest transistor, phase change memory (PCM), and single-walled carbon

nanotubes (SWCNTs) are described. Nanoelectronics needs research tied to two features: barriers arising from

device implementations and utilization of unique properties correlated with nanostructure.

Keywords: nanotechnology, photonics, electronics, nanomanufacturing, nanotubes, reliability

1. Introduction

The first transistors built in 1947 were

over 1 cm in size; the smallest transistors

today are less than 30 nm long over three

hundred thousand times smaller. The results

of these efforts are billion-transistor

processors where a billion or more

transistor-based circuits are integrated into a

single chip. But this development cannot

continue for much longer. One of the

increasingly difficult problems that chip

designers are facing is that the high density

of components packed on a chip makes

interconnections increasingly difficult; and,

as conventional chip structures continue to

shrink; Moore's Law is on a collision course

with the laws of physics. The key to

fabricating a junctionless gated resistor is the

formation of a semiconductor layer that is

thin and narrow enough to allow for full

depletion of carriers when the device is

turned off. The semiconductor also needs to

be heavily doped to allow for a reasonable

amount of current flow when the device is

turned on. Putting these two constraints

together imposes the use of nanoscale

dimensions and high doping concentrations.

The key to success was the ability to

fabricate silicon nanowires with a diameter of

a few dozens of atomic planes, enabled by

the electron-beam writing techniques and

expertise available today. The electrical

current flows in this silicon nanowire, and the

flow of current is perfectly controlled by a

Titu-Marius I. BJENESCU, Prof. Eng., CFC, Switzerland.

'wedding ring' structure that electrically

squeezes the silicon wire in the same way

that you might stop the flow of water in a

hose by squeezing it. These structures are

easy to fabricate even on a miniature scale

which leads to the major breakthrough in

potential cost reduction. Another key

challenge for the semiconductor industry is

reducing the power consumption of

microchips. Minimizing current leakage is

one of the main challenges in today's

complex transistors. Junctionless devices

have near ideal electrical properties and

behave like the most perfect transistors.

Moreover, they have the potential of

operating faster and using less energy than

the conventional transistors used in todays

microprocessors.

The

new

smaller

junctionless transistor is now 30% more

energy efficient and outperforms current

transistors on the market. Nevertheless,

fabricating these junctionless transistors is

not without challenges. The main task is to

obtain ultrapure, defect-free silicon crystals

with a thickness and a width of a few atoms.

This requires the use and control of highprecision instruments like electron-beam

lithography equipment and highly skilled

operators [1][1a].

2. Combining photonics and

electronics

Combining ordinary electronics with light

has been a potential way to create minimal

computer circuits with super fast information

transfer. Researchers at Ume University in

Sweden and the University of Maryland in

76

ELECTROTEHNIC, ELECTRONIC, AUTOMATIC, 60 (2012), nr. 1

the U. S. are now showing that there is a

limit. When the size of the components

approaches the nanometre level, all

information will disappear before it has time

to be transferred [2]. The electronics we

know in our computers today is, as the name

suggests, based on the transfer of

information with the help of electrons. Using

electrons has allowed us to shrink the size of

computer circuits without losing efficacy. At

the same time, communication with the help

of electrons represents a rather slow means

of transmission. To alleviate this problem,

light can be used instead of electrons. This is

the basis of so-called photonic components.

While the transfer speed in photonics is

extremely high, the size of the components

cannot be shrunk to the same level as

ordinary electronics. For a number of years,

so-called plasmonic components have

proven to be a possible way around the

dilemma of electronics and photonics. By

combining photonics and electronics,

scientists have shown that information can

be transferred with the help of so-called

plasmons1. But difficulties arise when the

size of such components is reduced to the

nanometre level. At that point it turns out that

the dual nature of electrons makes itself felt:

the electrons no longer act like particles but

rather have a diffuse character, with their

location and movement no longer being

clearly defined. This leads to the energy of

the plasmon being dissipated and lost in the

transfer

of

information.

For

nanocomponents, this consequence cannot be

fully avoided, but the behaviour of the

plasmons might nevertheless be controlled

by meticulous component design that takes

into consideration the quantum nature of the

nanoscale.

3. The worlds smallest transistor

Researchers have used the world's

thinnest material to create the world's

smallest transistor, one atom thick and ten

atoms wide. Reporting their peer-reviewed

findings in the journal Science, Dr. Kostya

Novoselov and Prof. Andre Geim from the

School of Physics and Astronomy at the

University of Manchester show that

graphene can be carved into tiny electronic

circuits with individual transistors having a

1

Plasmons are surface waves, like waves in the ocean,

but here consisting of electrons, which can spread at

extremely high speeds in metals.

size not much larger than that of a molecule.

The smaller the size of their transistors the

better they perform. At the heart of the

problem is the poor stability of materials if

shaped in elements smaller than 10 nm in

size. At this spatial scale, all semiconductors

- including silicon - oxidise, decompose and

uncontrollably migrate along surfaces like

water droplets on a hot plate. Six years ago,

Geim and his colleagues discovered

graphene, the first known one-atom-thick

material which can be viewed as a plane of

atoms pulled out from graphite. Graphene

has rapidly become the hottest topic in

physics and materials science. The

Manchester team has shown that it is

possible to carve out nanometre-scale

transistors from a single graphene crystal.

Unlike all other known materials, graphene

remains highly stable and conductive even

when it is cut into devices one nanometre

wide. Graphene transistors start showing

advantages and good performance at sizes

below 10 nm - the miniaturization limit at

which the silicon technology is predicted to

fail. It is too early to promise graphene

supercomputers while unfortunately, no

existing technology allows the cutting

materials with true nanometre precision. But

this is exactly the same challenge that all

post-silicon electronics has to face [3].

4. Variation aware design

Presently, the scaling tendency is toward

higher speed, and lower power consumption,

resulting in cost reduction, but the cost

reductions cannot be expected without a

reduction in chip area using miniaturized

devices, when producing the same

functionality.

Process

and

material

developments as well as physical design are

big challenges in the development of nanocomplementary metal-oxide-semiconductors

(CMOS) large- and very large-scale

integration (LSI and VLSI). The circuit

operation is strongly affected by variations in

device performance, which become large

and the device size is miniaturized. Taking

measurements

and

achieving

understandings of such variation are the first

steps in developing a variation-aware circuit

design. Comprehensive work has been

undertaken by STARC [4], using a device

matrix array; research into understanding

performance variation resulted, for example,

in a new Vth variation plot called the

ELECTROTEHNIC, ELECTRONIC, AUTOMATIC, 60 (2012), nr. 1

Takeuchi plot. The scaling down of the

MOSFETs has increased the variability in

device characteristics, and the significance

of the problems has become increasingly

evident. Currently, such variability can be

explained by aspects of the device structure

such as surface edge-roughness, impurity

distribution, or distortion/stress. Among

these it was shown that the discrete

distribution of channel impurities causes

variability in threshold voltage Vth [5].

However, the origin of on-state drain current

(ION) variability has not been well

distinguished.

To discuss the semiconductor device

structures in relation to their electrical

characteristics,

various

measurement

methods can be considered. For instance,

scanning probe microscopy, such as atomic

force microscopy, seems effective. However,

the internal structure of the devices is difficult

to be measured since the interaction

between the probe and the sample surface is

used for imaging [6].

Nanosystems are devices that are in the

size range of a billionth of a meter (1 x 10-9)

and therefore are built necessarily from

individual atoms. The one-dimensional

nanosystems or linear nanosystems cover all

the nanosized systems which possess one

dimension that exceeds the other two

dimensions, i.e. extension over one

dimension is predominant over the other two

dimensions. Here only two of the dimensions

have to be on the nanoscale (less than 100

nanometers). It is considered a linear

nanosystem at a fixed moment of time, say

the present moment, and it is assumed that

the present state of the linear nanosystem

depends only on the present states of its

atoms [7].

5. Nanomanufacturing

Nanomanufacturing remains the essential

bridge

between

discoveries

of

the

nanosciences and real-word nanotechnology

products. Advancing nanotechnology from

the laboratory into high-volume production

requires careful study of manufacturing

system issues including product design

reliability and quality, process design and

control, shop floor operations and supply

chain management. Nanomanufacturing is

the controllable manipulation of materials

structure, components, devices/machines,

and systems at the nanoscale in one, two

77

and three dimensions for large-scale

reproducibility of value-added components

and

devices.

Nanomanufacturing

encompasses bottom-up directed assembly,

top-down

high

resolution

processing,

molecular

systems

engineering,

and

hierarchical integration with larger scale

systems. As dimensional scales of materials

and molecular systems approach the

nanoscale, the conventional rules governing

the behaviour and properties of these

components, devices, and systems change

significantly. As such, the behaviour of the

final product is enabled by the collective

performance of the nanoscale building

blocks. The critical challenges are the need

to control assembly of three-dimensional

heterogeneous

systems,

to

process

nanoscale structures in high-rate/highvolume applications without compromising

their inherent properties, and to ensure the

long-term reliability of nanostructures

through testing and metrics [8]. These

challenges reflect the need for research in

the characterization of nanomaterials and

nanoparticles as the building-blocks of

nanostructures and in the fabrication and

synthesis of both top-down and bottom-up

process. Further they require advanced

instrumentation to characterize and measure

nanostructures in order to provide predictive

simulation of nanostructures behaviour, and

to contribute to the design and integration of

nanodevices

and

systems.

Finally,

knowledge sharing and outreach is a

challenge to the overcome to enable

technology transfer and to contribute to

public awareness of nanotechnologies.

Areas

of

applications

for

nanomanufacturing include electronics and

semiconductor, energy and utilities, IT and

telecommunications,

automotive

and

aerospace industries, green technologies

and environmental remediation, pharmaceuticals, biomedical and biotechnology,

national security.

6. Phase change memory (PCM);

quantum phenomena; single-walled

carbon nanotubes (SWCNTs)

Integrated manufacturing processes must

achieve targeted product quality via

regulation of events at molecular and nano

length while controlling process variables at

macroscopic length scale. In order to

achieve sustainable levels of quality and

78

ELECTROTEHNIC, ELECTRONIC, AUTOMATIC, 60 (2012), nr. 1

reliability in manufacturing environments, the

target properties and performance must be

defined,

experimental

measurements

conducted, relevant models established, and

data analysed, with subsequent iterations for

optimization, and ultimately end-to-end

process

control.

Integrated

nanomanufacturing

processes

require

systematic integration of product design,

process design and control. Challenges2 to

resolve in achieving this goal are

methodologies for experimental design,

execution, and translation to control of

process variables, development of combined

statistical and physical models, and

ultimately control system structure, design,

and implementation.

Presently, the predominantly approach to

nanomanufacturing

process

control

incorporates experimental design in order to

establish viable models for process control.

With sufficient factorial design, and

appropriate definition of the process

objectives, statistical models and nonlinear

feedback can be effective in optimising

nanomanufacturing

processes.

Careful

selection of process variables, anticipated

responses

factorials,

and

sufficient

sophistication of sensors for experimental

data collection and analysis can result in

highly effective process control. The

shortcomings of the experimental design

approach to nanomanufacturing process

design include adaptability to new processes

and equipment, limited knowledge of the

physical mechanisms applied to the process

development and the time necessary to

conduct sufficient experiments to achieve the

desired process

performance. These

limitations are further complicated at the

nanoscale where novel physics and

materials are exploited to achieve new

products, requiring new sensors and

diagnostics to validate both the mechanistic

models3 and the results of experimental

2

These challenges include data acquisition, analysis and

information processing of multiscale variables with different

frequencies and categories.

Incorporation of mechanistic modelling of the underlying

physics, chemistry, or biology in combination with the

statistical models established through experimental design

leads to enhanced process control wherein improved

understanding of the products and processes is developed.

Such a model-based approach to process and controller

design uses first principles and system specifications for

model construction, thereby naturally accounting for

inherent process characteristics including nonlinearities,

spatial variations, and multiscale behaviour. For many

processes, large disparities exist in time and length scales

design [8].

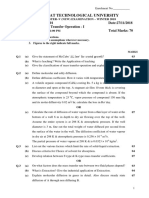

Gate

Phase change material

Source

Drain

SOI box

SOI Box

Figure 1. The schematic of phase change memory

(PCM).

Nanoelectronics based on nanoscience

and nanotechnology is prevailing in our lives

with satisfying our demand for faster, smaller

and ubiquitous devices. Nanoscience and

technology expects ~5 nm manipulated

dimensions adopting novel operational

principles, materials and structures. It was

encountered so many scientific challengespower, speed, design, multifunctions,

reliability and energy, etc., where ideas from

multiple disciplines must come together so

that efficiencies can be extracted at all levels

[9]. The initial effort for implementing

nanoelectronics is to confine electrons

allowed to tunnel to metallic leads, that is a

single electron transistor (SET) [10]. The

SET using quantum phenomena turns on

and off as a single electron is tunnelling into

islands surrounded by an insulator. Another

electronics

using

nanosciences

are

nanocrystal

(NC)

memory

devices

associated with quantum effects [11]. The

advent of nanocrystal memory has

accelerated the development of non-volatile

charge trapping memories such as SONOS

[12]. Recently, was reported a fast single

element non-volatile memory that employs

amorphous to crystalline phase change as

shown in Figure 1 [13]. The phase of a single

electronic element in confined geometry

transistors can be changed by thermal shot

or electric field. These devices need still

of phenomena occurring within the processes thereby

requiring the establishment of multiscale models coupled

through appropriate boundary conditions. Control of

nonlinear distributed systems is possible by combing

nonlinear models describing macroscale process control

with localized physical kinetic models. Combining this with

practical control and process feedback, facilitated by

optimal placement of sensors for real time analytical data,

an integrated nanomanufacturing capability can be realised

that is robust, scalable, and adaptable to a range of

processes and products.

ELECTROTEHNIC, ELECTRONIC, AUTOMATIC, 60 (2012), nr. 1

further study and challenges in materials,

principles, physics and analysis. As a

nanomaterial, carbon is a very useful

chemical

element

in

nanotechnology

applications. Some allotropes of carbon-0D

of buckyballs, 1D of carbon nanotube and

2D of graphene, are getting more focus to

explore novel composites/materials after

silicon era. Among these carbon forms,

graphene

overcomes

the

random

distributions occurring in carbon nanotubes

applications and the planar structure also

allows for the simple device implementations

and its integrations [14]. Now, most efforts

have been given to modify its properties to

apply it into electronics/systems with keeping

its own superior characteristics.

Nanoelectronic devices such as field

effect transistors and molecular electronic

devices have been currently demonstrated

by utilizing single-walled carbon nanotubes

(SWCNTs) with a shortened length provided

as connectors and components [16-18].

Considering the explosive growth of the

mobile device market and intrinsic attributes

of SWCNTs, one of expected applications of

SWCNTs is a non-volatile memory (NVM)

based on a CMOS process [19].

7. Future and reliability

Looking into the future, nanoelectronics

needs research tied to two features: barriers

arising from device implementations and

utilization of unique properties correlated

with

nanostructure.

Various

scientific

challenges and efforts can overcome these

barriers by using nano-material/structure and

new phenomena [15]. The general reliability

theory remains unchanged, but when it is

used at nano level, some adjustments must

be made. Reliability theory and physics of

failure of macro- and micro-world are only

partially applicable on the nanometer scale.

Physical processes not scaling linearly with

size and time dramatically change mass and

heat

diffusion,

electrical

conductivity,

reaction kinetics, corrosion processes, etc.

[20]. Fatigue, friction, damping, wear-out and

repair mechanisms have a different physical

meaning on atomic or molecular scales.

Redundancy and correlation of quantum

systems require quantum statistics of states

and entanglement of wave functions.

79

References

[1] http://www.nanowerk.com/spotlight/spotid=15

085. php

[2] http://www.sciencedaily.com/releases/2011/0

2/ 110202072214.htm

[3] http://www.sciencedaily.com/releases/2008/0

9/080 908201843.htm

[4] http://www.sciencedaily.com/releases/2008/0

4/080 417142452.htm

[5] Aoki, M., et al., Design Guidelines and

Process Quality Improvement for Treatment

of Device Variations in a LSI Chip, in IEICE

Trans. Electron., Vol. E88-C, No. 5, pp. 788795.

[6] Tsunomura, T., et al., Proceedings Symp.

VLSI Technology, Dig. Tech. Paper, 2009, p.

110.

[7] Shiano, Ono, et al., Three-Dimensional

Structure Analysis of Metal-Oxide-Insulator

Field Effect Transistors with Different

Electrical

Properties

by

Scanning

Transmission

Electron-Microscopy,

in

Applied Physics Express, 4(2011) 066601.

[8] Nader, Ebrahimi, Assessing a Linear

Nanosystem's Limiting Reliability from Its

Components, in J. Appl. Probab. Vol. 45, No.

3 (2008), pp. 879-887.

[9] http://eprints.internano.org/49/1/NMS_Works

hop_R eport.pdf

[10]Moonkyung Kim, Jo-won Lee, Challenges in

the

Future

Nanoelectronics,

http://asdn.net/ngc2011/raw_abstracts//attach

ed_abstracts/110411222057/abstract.pdf

[11]Lee, C. K., et al, Appl. Phys. Lett. 92,

093101, 2008.

[12]Tiwari, S., et al., Appl. Phys. Lett. 68; 1996,

p. 1377.

[13]Kim, M. K., et al., IEEE Trans. on

Nanotechnology, pp. 417-424, 2004.

[14]Kim, M. K. et al., IEICE Transactions on

Electronics, May 2011.

[15]Novoselov, K. S., et al., Science, 306, 666,

2004.

[16]http://www.sciencedaily.com/releases/2008/0

9/080 908201843.htm

[17]Tans, S. J., et al., Nature (London), 393, 49

(1998).

[18]Javey, A., et al., Nature (London), 424, 654

(2003).

[19]Wind, S. J., et al., Appl. Phys. Lett., 80, 3817

(2002).

[20]Seong-Wan Ryu, et al., Appl. Phys. Lett., 91,

063110 (2007).

[21]Bzu M., Bjenescu T., Failure Analysis. A

Practical Guide for Manufacturers of

Electronic Components and Systems, John

Wiley & Sons, Chichester, 2011.

Potrebbero piacerti anche

- Starting and Controlof Slip Ring Induction Motors PDFDocumento16 pagineStarting and Controlof Slip Ring Induction Motors PDFkubik100% (1)

- Rittal 3052000 Technical Details 3 2895Documento1 paginaRittal 3052000 Technical Details 3 2895kubikNessuna valutazione finora

- Product Data Sheet 6ES7326-1BK02-0AB0: Supply VoltageDocumento3 pagineProduct Data Sheet 6ES7326-1BK02-0AB0: Supply VoltagekubikNessuna valutazione finora

- Eea 61 1 2013 025 EN LP 000Documento6 pagineEea 61 1 2013 025 EN LP 000kubikNessuna valutazione finora

- Product Datasheet: Braking Resistor - 5 Ohms - 32 KW - IP23Documento3 pagineProduct Datasheet: Braking Resistor - 5 Ohms - 32 KW - IP23kubikNessuna valutazione finora

- Eea 60 4 2012 038 EN LP 000Documento6 pagineEea 60 4 2012 038 EN LP 000kubikNessuna valutazione finora

- Eea 61 1 2013 014 EN LP 000Documento5 pagineEea 61 1 2013 014 EN LP 000kubikNessuna valutazione finora

- Nickel Metal Hydride Battery Test Candidate For Future Electric Vehicle Under Different Scenario ConsiderationDocumento10 pagineNickel Metal Hydride Battery Test Candidate For Future Electric Vehicle Under Different Scenario ConsiderationkubikNessuna valutazione finora

- Reactive Power Compensation Using A Voltage Source GeneratorDocumento10 pagineReactive Power Compensation Using A Voltage Source GeneratorkubikNessuna valutazione finora

- Eea 60 3 2012 069 EN LP 000Documento6 pagineEea 60 3 2012 069 EN LP 000kubikNessuna valutazione finora

- Transportation System Based On Light Electric VehiclesDocumento7 pagineTransportation System Based On Light Electric VehicleskubikNessuna valutazione finora

- Eea 60 2 2012 072 EN LP 000Documento7 pagineEea 60 2 2012 072 EN LP 000kubikNessuna valutazione finora

- Eea 60 2 2012 084 EN LP 000Documento4 pagineEea 60 2 2012 084 EN LP 000kubikNessuna valutazione finora

- Piezoelectric Transducer For Fluid Viscosity Measurement: Electrotehnică, Electronică, Automatică, 60 (2012), Nr. 3Documento4 paginePiezoelectric Transducer For Fluid Viscosity Measurement: Electrotehnică, Electronică, Automatică, 60 (2012), Nr. 3kubikNessuna valutazione finora

- Parabola and Catenary Equations For Conductor Height CalculationDocumento7 pagineParabola and Catenary Equations For Conductor Height CalculationkubikNessuna valutazione finora

- Matlab Plots On Android Smartphones - Cloud ImplementationDocumento6 pagineMatlab Plots On Android Smartphones - Cloud ImplementationkubikNessuna valutazione finora

- Eea 60 2 2012 079 EN LP 000Documento5 pagineEea 60 2 2012 079 EN LP 000kubikNessuna valutazione finora

- Thermal Analysis of Shell-Structured Solar Collectors: István FEKETE, István FARKASDocumento6 pagineThermal Analysis of Shell-Structured Solar Collectors: István FEKETE, István FARKASkubikNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Coil BreaksDocumento6 pagineCoil BreaksTaciane Barbosa Silva Reis100% (1)

- 44CDocumento9 pagine44CTarunNessuna valutazione finora

- 07a30602 Metallurgical Thermodynamics and KineticsDocumento6 pagine07a30602 Metallurgical Thermodynamics and KineticsSharad Kumar AgarwalNessuna valutazione finora

- Solid State Physica - MCQDocumento31 pagineSolid State Physica - MCQVishnu RautNessuna valutazione finora

- Thesis FulltextDocumento495 pagineThesis FulltextChris Cmecs MagadiaNessuna valutazione finora

- Typical Properties - GRAFOIL® Grade GTBDocumento2 pagineTypical Properties - GRAFOIL® Grade GTBMamacintNessuna valutazione finora

- Introduction To Aspen Plus-2012Documento243 pagineIntroduction To Aspen Plus-2012D'Monthy José Salcedo Rosas100% (2)

- Bonding Forces and EnergiesDocumento3 pagineBonding Forces and EnergiesJaden BrownNessuna valutazione finora

- Controversial Electro ProblemDocumento16 pagineControversial Electro ProblemJorge AlcarazNessuna valutazione finora

- Nur Afiqah Binti Mohd Radzi (2019848282) - Assignment 1 FSG567Documento7 pagineNur Afiqah Binti Mohd Radzi (2019848282) - Assignment 1 FSG567Wsr HalilahNessuna valutazione finora

- Tutorial 3 Natural Convection Ansys CFXDocumento20 pagineTutorial 3 Natural Convection Ansys CFXsunilpatil.043827Nessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological UniversityShivam PanchalNessuna valutazione finora

- Note CHP 4 Material Science 281 Uitm Em110Documento52 pagineNote CHP 4 Material Science 281 Uitm Em110bino_ryeNessuna valutazione finora

- Chemical Engineering Thermodynamics Solution Manual PDFDocumento725 pagineChemical Engineering Thermodynamics Solution Manual PDFNaveen100% (1)

- Asphalt Plug JointDocumento103 pagineAsphalt Plug JointMahmood MuftiNessuna valutazione finora

- Topic 1 - ConcreteDocumento123 pagineTopic 1 - ConcreteFadlee WookieNessuna valutazione finora

- Chapter 22-Electric FieldDocumento38 pagineChapter 22-Electric Field0000003294 : Rawan Abdul Hakim SabhaNessuna valutazione finora

- Gas Laws Simulation Lab: Experiment One: Constant VolumeDocumento4 pagineGas Laws Simulation Lab: Experiment One: Constant Volumealan musselwhite100% (1)

- ASTM A710 Engineering Report Grade 50 Sheet Steel Formability Material For ClampsDocumento54 pagineASTM A710 Engineering Report Grade 50 Sheet Steel Formability Material For ClampsTony KrolikowskiNessuna valutazione finora

- 51CDocumento6 pagine51Cjhacademyhyd100% (5)

- Pure Substance LectureDocumento43 paginePure Substance LectureZesi Villamor Delos SantosNessuna valutazione finora

- Exp 05 - CavitationDocumento10 pagineExp 05 - CavitationhahaNessuna valutazione finora

- Electropolishing Parameters Optimization For Enhanced Performance of Nickel Coating Electroplated On Mild SteelDocumento8 pagineElectropolishing Parameters Optimization For Enhanced Performance of Nickel Coating Electroplated On Mild Steelqnk7Nessuna valutazione finora

- Combinatorial Exploration of B2-L21 Precipitation Strengthened AlCrFeNiTiDocumento17 pagineCombinatorial Exploration of B2-L21 Precipitation Strengthened AlCrFeNiTiAmigo AceNessuna valutazione finora

- ME 218 - Spring 2018 - Week02 HandoutDocumento15 pagineME 218 - Spring 2018 - Week02 HandoutHassan KhalidNessuna valutazione finora

- Q. Bank Pii/I, Ii T.Y.B.Sc. Sem VDocumento2 pagineQ. Bank Pii/I, Ii T.Y.B.Sc. Sem VNeelam KapoorNessuna valutazione finora

- Chemicals Zetag DATA Inverse Emulsions Zetag 8846 FS - 0410Documento2 pagineChemicals Zetag DATA Inverse Emulsions Zetag 8846 FS - 0410PromagEnviro.comNessuna valutazione finora

- Exercise - Optimisation Past Year ExamDocumento2 pagineExercise - Optimisation Past Year ExamAmirul AfiqNessuna valutazione finora