Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Welcome: Advanced Bulk Material Conveying Technologies in Cement Industry

Caricato da

1977julTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Welcome: Advanced Bulk Material Conveying Technologies in Cement Industry

Caricato da

1977julCopyright:

Formati disponibili

19-05-2015

Welcome

BEVCON AT A GLANCE

Very Promising professionals with well

planned Vision to achieve 500Crores by

2016.

Advanced Bulk Material Conveying

Technologies in Cement Industry

Three different manufacturing set-ups

with latest Technology two in Hyderabad

& one at Raipur are ISO Certified.

Only company in India to have all kinds

of

material

handling

products

manufactured under one common roof.

Marketing, Constructions & After Sales

Service Offices at all regions.

S.A.K.JEELANI

May 15th 2015

Export business with SAARC, E. Africa,

S. Africa, South East Asia & UAE.

19-05-2015

FOCUSSED AREAS

OUR PRESENCE

Bevcon Wayors is the industry leader in providing highquality and technologically advanced Bulk Material

Handling & Processing Solutions Crushing, Screening,

Conveying, Dust Extraction, Pneumatic conveying and

Special Conveying Systems.

BEVCON

Bevcon Wayors Leadership Areas:

Comprehensive Range of Bulk Material Handling &

Processing Solutions

Innovation Excellence & in-house Fabrication

Track Record & Credentials

World-Class Technology Partnerships

Vast Domain Expertise

ADVANCED CONVEYING SYSTEMS

A Total Solutions Provider to

Your business needs

Bevcon Wayors is engaged in

providing End to End solutions to

Power, Steel, Cement , Ports and

Mines with an experience of over

than 20 years on Turnkey basis

which include Design, Engineering,

Manufacturing, Installation and

Servicing.

Bevcon Wayors is the industry

leader in providing high-quality and

technologically advanced Bulk

Material Handling & Processing

Solutions

Advanced Conveying Systems

to

Simplify the Cement Plant Operations

Steep Angle Cleated Belt Conveyor

Overland Troughed Belt Conveyor

Overland Pipe Conveyor

Sandwich Belt Conveyor

19-05-2015

STEEP ANGLE CONVEYOR

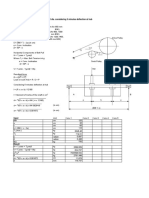

CONVENTIONAL / STEEP ANGLE CONVEYOR COMPARISON

STEEP ANGLE CONVEYOR

STEEP ANGLE CONVEYOR

FEATURES

INCLINE ANGLES UP TO 90 DEGREES.

LIMITATIONS

NO TRANSFER POINTS.

NO SPILLAGE.

LUMP SIZE IS SOMEWHAT LIMITED PARTICULARLY IN HIGH ANGLES OF INCLINE

MAXIMUM UTILISATION OF SPACE.

THE BELT IS MORE DIFFICULT TO CLEAN THAN STANDARD CONVEYOR BELTS.

MINIMUM MAINTENANCE, LONG BELT LIFE.

WIDE RANGE OF MATERIALS CAN BE HANDLED.

LOW POWER REQUIREMENT, QUIET AND SMOOTH RUNNING.

HIGH/MEDIUM CAPACITY, HIGH LIFTS CAN BE ACCOMPLISHED.

19-05-2015

JK Cement - Jhajjar

STEEP ANGLE CLEATED BELT CONVEYOR

Steep Angle (90o) Sidewall Cleated Belt Conveyor

Case Study JK Cement - Jhajjar

CASE STUDY JK CEMENT - JHAJJAR

19-05-2015

Case Study JK Cement - Jhajjar

Belt Width

2000mm

Capacity

1650TPH

Material

Clinker

Lift

19 Meters

Bulk Density

1700 kg/m3

Feed Size

: (-)50mm

Power Sector

Handling Ferro

Alloys at

Vatvedt

Technologies

SAC Installations

Handling

Dolomite,

Limestone & DRI

at Kamachi

Steel & Power

SAC Installations

Handling

Coal at

Malabon Oil & Soap

Handling

Coal

at Phoenix

Commodities

Handling

Ferro Alloys

at Kalyan Garuda

Handling Dolomite

& Lime mixture at

Viraj Profiles Ltd.

Handling

Municipal Solid

Waste at

Selco Intl.

Handling

Raw Sugar

at Silkroad Sugar

Handling Coal

& Husk at

Mylan

laboratories

19-05-2015

SAC Installations

Handling Granite

power at Restile

Ceramics

SAC Handling

Coal

OVERLAND PIPE CONVEYOR

Working Operation Process

Transition zone Loading / Unloading

Conventional belt and pipe conveyors are

loaded and unloaded in exactly the same

way; being opened for a conventional belt

feed system from the tail pulley and again

opening out at the head pulley for

discharging.

In the material loading area, the conveying

belt is open. The conveyed material is

supplied in the same way as in a

conventional belt conveyor. Then special

devices enclose the belt carrying the

conveyed material. The diameter of the

closed pipes can be selected depending

on the material conveying capacity.

At this point, the belt forms a sealed pipe for

the entire conveying line. Thus, the content

is protected against external influences

while the environment is protected against

any potential material losses.

At this point, the belt

opens on its own

before the material

discharge point and

the

material

is

discharged.

19-05-2015

Working Principle - Overland Pipe Conveyor

SUPERIOR FEATURES OF PIPE CONVEYOR

Dust free with minimal noise emissions.

Pipe Conveyor is as similar as conventional belt conveyor

system, and comprises a head and tail pulley, one of

which is driven, over which an endless conveyor belt is

spanned.

The belt is tensioned in a similar manner to conventional

belt conveyors. Beyond the loading point, the belt passes

through a series of pipe forming idlers which effect the

transition from conventional to rolled form. This transition

takes place over a distance calculated to minimize belt

stresses.

Once formed the pipe shape is maintained by six idlers set

in a hexagonal pattern at each idler frame. Idler frame

spacing depends on pipe diameter and ranges from 1 to

3.5 m

No spillage or scattering of material from loaded belt.

Any desired horizontal and vertical curves with

minimal radius upto 45 meters.

Material can be conveyed on the feed and as

well as on return belt even with different materials.

No build up on Idlers.

Can elevate vertically 50% more than conventional

conveyors.

Conveying angle up to 30 degree.

Has excellent belt edge damage control.

Unaffected by wind and rain thus requires no covers.

Reduced structural costs by eliminating walkways.

SHREE CEMENT -PIPE CONVEYOR

SHREE CEMENT -PIPE CONVEYOR

PROJECT HIGHLIGHTS

TYPE

Overland Pipe Conveyor

LOCATION

Khapradih, Raipur, CG

SYSTEM

3150TPH Limestone Handling System (Ongoing Project)

SCOPE OF WORK

Engineering, Manufacturing, Supply

EQUIPMENT Details

Material to be conveyed

Pipe Conveyor Length

Lift

Lump Size

Pipe Dia

Belt Width

Capacity

Belt Speed

STATUS

:

:

:

:

:

:

:

:

Limestone

1.4 Kms

10.5 Mtr

60 mm

600 mm

2100 mm

3190 TPH

3.5Mtr/sec

Under Commissioning Stage

19-05-2015

SHREE CEMENT -PIPE CONVEYOR

Sandwich Belt Conveyor

What is a Sandwich Belt Conveyor?

Simply, Sandwich Snake Belt Conveyor consists of two endless belt conveyors that share a

common load carrying path. The top and bottom belts are independently driven and

tensioned. Along the carrying path the top and bottom belts are alternately supported

against closely spaced toughing idlers. Radial pressure, due to belt tension and the curving

profile, continuously hugs the material that is Sandwiched between the two belts. Internal

friction is developed and bulk material can be conveyed at any high angle up to Vertical.

Sandwich Snake Belt Conveyor uses all and only conventional conveyor components and

smooth surfaced belts that can be continuously

scraped clean.

Sandwich Conveyor Profiles

Snakes are available in widely ranging profiles of C and S-Shape. In any case, a long

bottom belt approach is possible to the sandwich entrance, and discharge may be on the

high incline or may be after the extension of the carrying belt beyond the mouth of the

sandwich

Basic Profile

SANDWICH CONVETOR

FEATURES

Increased angle of lift including vertical lift.

Uses standard belting.

Some environmental protection.

Good for sticky material.

LIMITATIONS

Difficulty to handle large lumps, dry fines or spherical material.

Extended Profile

19-05-2015

Typical Layout

Installation

Dos Santos Sandwich Belt High Angle Conveyor, Majdanpek Copper Mine, Serbia.

Part of an IPCC (In-pit Crushing and conveying) system

Applications & Installations

Limestone Quarry, Midwest, USA

Material Density Size

Conveying Rate

STPH)

Conveying Angle

Belt Width

(42)

Belt Speed

(500 FPM)

Lift

Length

Drives

- Top Belt - Bottom Belt

HP)

Limestone

1.60 t/cu-m (100 PCF)

76 mm (3) minus

762 t/h (800

-

60 degrees

1067 mm

2.54 m/s

48,000 mm (158)

79,000 mm (258)

168 kW (125 HP)

168 kW (125

19-05-2015

Applications & Installations

Applications & Installations

Aceralia Steel Mill, Spain

Material

Density

Size

Conveying Rate Conveying Angle

Belt Width

Belt Speed

Lift

Length

Snake Drives

Top Belt

Bottom Belt

-

Coal

0.8 t/cu-m (50 PCF)

50 mm (2) minus

250 t/h (276 STPH)

75 degrees

1200 mm (47)

2.29 m/s (450 FPM)

35,100 mm (115)

45,065 mm (148)

30 kW (40.2 HP)

30 kW (40.2 HP)

DSI Snake Sandwich Conveyor Shiploader

for

Cortex Resources at Port Adelaide, Australia

Inflection 2

Inflection 1

Curve 2

Loading

Curve 1

Material

-Density

Conveying Rate

Conveying Angle

Belt Width

Belt Speed

Lift

Length

Snake Drives

- Top Belt

- Bottom Belt

- Titanium Ore

- 2.4 t/cu-m (150 PCF)

- 1000 t/h (1102 STPH)

- 50 degrees

- 1200 mm (47)

- 2 m/s (394 FPM)

- 21,805 mm (71.5)

- 56,656 mm (185.9)

- 55 kW (74 HP)

- 55 kW (74 HP)

Applications & Installations

Applications & Installations

Hamilton Ontario, Canada

Continental CN at INCO Voiseys Bay Proj

Material

- Pebble Ore

Density

- 2.25 t/cu-m (140

PCF)

Size

- 60 mm (2.4) minus

Conveying Rate

- 102 t/h (112 STPH)

Conveying Angle - 90 degrees

Belt Width

- 762 mm (30)

Belt Speed

- 1.02 m/s (200 FPM)

Lift

- 13,010 mm (42.7)

Length

- 23,500 mm (77.1)

Snake Drives

Top Belt

- 7.46 kW (10 HP)

Bottom Belt

- 7.46 kW (10 HP)

Steel Mill Project

SNAKE CONV. ELEVATION

Material

Density

Size

Conveying Rate

STPH)

Conveying Angle

Belt Width Belt Speed Lift

Length

Snake Drives

Top Belt

Bottom Belt -

Various

4.16 t/cu-m (260 PCF)

75 mm (3) minus

188 t/h (200

70 degrees

914 mm (36)

1.02 m/s (207 FPM)

35,235 mm (115.6)

48,768 mm (160.0)

18.64 kW (25 HP)

18.64 kW (25 HP)

10

19-05-2015

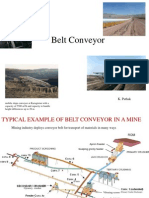

AN INTRODUCTION - OVERLAND TROUGHED BELT CONVEYOR

LATEST DEVELOPMENTS

Belt Conveyor and Pipe

Overland troughed belt conveyors (also known as long distance or cross country

conveyors) are belt conveyors that have been designed to carry high tonnage

loads over long distances. Overland conveyors can be applied in many different

industries and can range from just a few thousand feet to several miles in length.

Industries such as mining, power, paper, waste and cement require reliable

conveying of large quantities of material to long distances day in & day out.

Over land troughed belt conveyors have been proven to be an efficient method of

transporting bulk material over long distances and costs are often lower than with

truck & rail transportation.

These overland troughed belt conveyors can follow most terrains and have little or

no impact on the environment. Operating and maintenance costs are low and they

are extremely safe to operate and doesnt produce loud sounds.

Conveyor Systems

System Design

Energy Efficiency

Distributed Power

Analysis and

Simulation

Advanced Controls

11

19-05-2015

Model Project

Complex Overland Conveyor

Reference List

(Overland Troughed Belt Conveyor)

19.1km center-to-center length. 3 meter lift from head to tail

11 horizontal curves with radius ranging from 2100m to 3500m

Many Vertical Curves

Conveying ~1100 mtph of Lignite Coal

Real Installed Application

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

Material

Capacity (TPH)

Length (km)

Lift (m)

Belt Width (mm)

Belt Spec

Belt Speed (mps)

Power Attached (kW)

Drive Type

No of Drive

Intermediate

Take-up

Horizontal Curves

Radii (M)

Installation & Application

:

:

:

:

:

:

Aker Solutions

Peru Copper- Toromocho

Peru, South America

Under Construction (2012)

Designer

Surface Copper Mine

Client

Mine

Location

Commissioned

Role

Application

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Copper

10,292

4.93

+196, -276

1800

ST5200

6.00

10,000

CST

4x2,500

0

Winch

2

5000

Material

Capacity (tph)

Length(km)

Lift (m)

Belt Width (mm)

Belt Spec

Belt Speed (mps)

Power Attached (kW)

Drive Type

No of Drive

Intermediate

Take-up

Horizontal Curves

Radii (M)

:

:

:

:

:

:

Lycopodium

Rio Tinto- Western Turner Syncline

Western Australia

Pre-Feasibility Design in Progress

Design Auditor

Surface Iron Ore Mine

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Iron Ore

5,000

15.16

+106

1500

ST3800

4.00

8,000

VFD

5x1,600

1

Gravity

2

5000

12

19-05-2015

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

Consulting Engineer

Typical Project

Installed 2005, USA

19 km Centers

10 Horizontal Curves

Intermediate Drive

R10000

R6900

23

Head

R10000

31

5

14

R12000

R9750

Capacity: 1200 tph

Length: 62,791 ft

Lift: 11 ft

Belt Width: 36 in

Belt Speed: 1400 fpm

31

R8500

FREEPORT MCMORAN

Henderson PC-3

Climax, CO USA

1999

Design Team

Underground Molybdenum

Mine

Capacity (tph)

Molybdenum

2500

Length (km)

6.4

Lift (m)

76

Belt Width (mm)

1200

ST2500

R8000 R10000

R10000

:

:

:

:

:

:

Material

R12000

Tail

Installation & Application

Belt Spec

Belt Speed (mps)

4.5

Power Attached (kW)

3,000

No of Drive

2x1500

Drive Type

VFD

Intermediate

10

33

Take-up

Gravity

Horizontal Curves

1524

Radii (M)

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

:

:

:

:

:

:

Peabody Energy

NARM

Gillette WY, USA

2006

Designer

Surface Coal Mine

Material

Coal

6000

Capacity (tph)

Length(km)

3.70

Lift (m)

-14

Belt Width (mm)

1830

ST2500

Belt Spec

Belt Speed (mps)

4.87

Power Attached (kW)

4400

Drive Type

VFD

No of Drive

4x1100

Intermediate

Take-up

Gravity

Horizontal Curves

Radii (M)

NA

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

Material

Capacity(tph)

Length(km)

Lift (m)

Belt Width (mm)

Belt Spec

Belt Speed (mps)

Power Attached (kW)

Drive Type

No of Drive

Intermediate

Take-up

Gravity

Horizontal Curves

Radii (M)

:

:

:

:

:

:

Metso Brazil

Vale- Sossego

Brazil

2002

Designer

Surface Copper Mine

:

:

:

:

:

:

:

:

:

:

:

Copper Ore

3000

3.50

+65

1200

ST2500

4.80

1050

VFD

3x350

0

:

:

0

NA

13

19-05-2015

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

Material

Capacity(tph)

Length(km)

Lift (m)

Belt Width(mm)

Belt Spec

Belt Speed(mps)

Power Attached(kW)

Drive Type

No of Drive

Intermediate

Take-up

Horizontal Curves

Radii (M)

:

:

:

:

:

:

ThyssenKrupp Robins

Barrick- Cortez Hills Mine

Elko, NV, USA

2010

Designer

Surface Gold Mine

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Gold

1100

11.6

-216

900

ST1400

4.50

1200

VFD

2x600

0

Winch

1

5000

Installation & Application

Sichuan, China

7.8 miles (12.5 km) Long

1500 TPH Limestone

48 Belt Width

800 FPM

8 Horizontal Curves

Built by Beumer

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

Material

Capacity (tph)

Length(km)

Lift (m)

Belt Width (mm)

Belt Spec

Belt Speed (mps)

Power Attached (kW)

Drive Type

No of Drive

Intermediate

Take-up

Horizontal Curves

Radii (M)

:

:

:

:

:

:

Freeport McMoran

Henderson PC-2

Climax, CO USA

1999

Design Team

Underground

Molybdenum Mine

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Molybdenum

2500

16.8

474

1200

ST6800

6.0

10,000

VFD

4x2500

0

Gravity/Winch

0

NA

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

PC 3

PC 2

Material

Capacity (tph)

Length(km)

Lift (m)

Belt Width(mm)

Belt Spec

Belt Speed(mps)

Power Attached(kW)

Drive Type

No of Drive

Intermediate

Take-up

Winch/Storage Unit

Horizontal Curves

Radii (M)

:

:

:

:

:

:

Continental Conveyor England

UTE Guadarrama

Spain

2004

Designer

Tunnel Boring Much Removal

:

:

:

:

:

:

:

:

:

:

:

Muck

1150

13.4 and 15.0

-78

900

ST1000

3.55

1085 and 1280

VFD

7x160 and 8x160

3 and 3

:

:

4

800

14

19-05-2015

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

Material

Capacity (tph)

Length(km)

Lift (m)

Belt Width (mm)

Belt Spec

Belt Speed (mps)

Power Attached (kW)

Drive Type

No of Drive

Intermediate

Take-up

Gravity

Horizontal Curves

Radii (M)

:

:

:

:

:

:

Continental Conveyor Australia

Tiangin Port Authority

Tiangin, China

2003

Design Auditor

36

Coal Ship Loader

:

:

:

:

:

:

:

:

:

:

:

Coal

6000

8.98

8

1800

ST3500

5.6

6,000

VFD

3x2000

0

24

Head

R4000

R3000

Capacity: 6000 mtph

Length: 8980 m

Lift: 8 m

Belt Width: 1800 mm

Belt Speed: 5.6 mps

Tail

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

: 2

: 3000-4000

Material

Capacity (tph)

Length(km)

Lift (m)

Belt Width (mm)

Belt Spec

Belt Speed (mps)

Power Attached (kW)

Drive Type

No of Drive

Intermediate

Take-up

Gravity

Horizontal Curves

Radii (M)

:

:

:

:

:

:

Black Hills Energy

Wyodak

Gillette, WY, USA

2004

Designer

Surface Coal Mine

:

:

:

:

:

:

:

:

:

:

:

Coal

1950

1.0

12

1200

ST800

4.57

750

VFD

1x750

0

:

:

1

1500

Installation & Application

Client

Mine

Location

Commissioned

Role

Application

Material

Capacity (tph)

Length(km)

Lift (m)

Belt Width (mm)

Belt Spec

Belt Speed (mps)

Power Attached (kW)

Drive Type

No of Drive

Intermediate

Take-up

Horizontal Curves

Radii (M)

:

:

:

:

:

:

Hatch

Xstrata- Koniambo Nickel

New Calidonia

In Construction 2010

Design Auditor

Surface Nickel Mine

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Nickel Ore

700

11.41

-757

1050

ST1600

4.50

1575

VFD

5x315

0

Gravity

4

1500-2000

15

Potrebbero piacerti anche

- 2010 - Telescopic ChuteDocumento29 pagine2010 - Telescopic ChutesteelageNessuna valutazione finora

- Pipe Conveyor: Sheet 1 of 3Documento3 paginePipe Conveyor: Sheet 1 of 3Ravi KumarNessuna valutazione finora

- Sidewall Belt Conveyor PDFDocumento21 pagineSidewall Belt Conveyor PDFNyx RubyNessuna valutazione finora

- Japan Pipe Belt Conveyor Sy...Documento7 pagineJapan Pipe Belt Conveyor Sy...salkan_rahmanovic810Nessuna valutazione finora

- Conveying and StoringDocumento28 pagineConveying and StoringTin Nguyen100% (1)

- Bevcon Wayors Corporate Catalogue-1Documento4 pagineBevcon Wayors Corporate Catalogue-1Sheik MohideenNessuna valutazione finora

- Bulk Handling System and Engineered Systems - FlexiconDocumento36 pagineBulk Handling System and Engineered Systems - Flexiconfaja2004Nessuna valutazione finora

- Bevcon Wayors Product Range & InfrastructureDocumento58 pagineBevcon Wayors Product Range & InfrastructurerajanarenderNessuna valutazione finora

- Banda Conveyor PDFDocumento38 pagineBanda Conveyor PDFJorge Rios RNessuna valutazione finora

- Servicio de Fabricación E Instalación de Nuevos Chutes en Fajas OverlandDocumento18 pagineServicio de Fabricación E Instalación de Nuevos Chutes en Fajas OverlandRodolfo Humbert Zurita CruzNessuna valutazione finora

- Aa Spec 331001Documento13 pagineAa Spec 331001Mardi RahardjoNessuna valutazione finora

- 24941-100-30R-G01-00073 Tunra 6299 Report FinalDocumento96 pagine24941-100-30R-G01-00073 Tunra 6299 Report FinalcmahendrNessuna valutazione finora

- Gundlach Roll Crushers BrochureDocumento2 pagineGundlach Roll Crushers Brochurerajeevup2004Nessuna valutazione finora

- Draft VTUSA Conveyor Bridge Report v4Documento219 pagineDraft VTUSA Conveyor Bridge Report v4ken stanleyNessuna valutazione finora

- Design of Belt and Apron Feeders An Over PDFDocumento13 pagineDesign of Belt and Apron Feeders An Over PDFarsanioseNessuna valutazione finora

- Brochure ConveyorChainDocumento80 pagineBrochure ConveyorChainAmrie SarsidaNessuna valutazione finora

- Bucket ElevatorDocumento6 pagineBucket ElevatorbetojulioNessuna valutazione finora

- Double Roll CrusherDocumento3 pagineDouble Roll CrusherjtpmlNessuna valutazione finora

- Jaw Crusher Kinematics Simulation and AnalysisDocumento5 pagineJaw Crusher Kinematics Simulation and AnalysisInternational Journal of Research in Engineering and ScienceNessuna valutazione finora

- S3 Product Range - EnglishDocumento35 pagineS3 Product Range - EnglishJuan Esteban Luque ZegarraNessuna valutazione finora

- Pipe Conveyor SystemDocumento6 paginePipe Conveyor Systemsurajit81100% (2)

- Nepean Conveyors Projects CapabilityDocumento13 pagineNepean Conveyors Projects CapabilityFelipe RibeiroNessuna valutazione finora

- Importance of Dedusting Pipe LayoutDocumento4 pagineImportance of Dedusting Pipe LayoutManoj ThakurNessuna valutazione finora

- Heavy Duty Apron Feeder PDFDocumento2 pagineHeavy Duty Apron Feeder PDFNova HeriNessuna valutazione finora

- Drive-Non Drive Pulley Shaft Dia Calculation of Belt Feeder - IS 11592Documento1 paginaDrive-Non Drive Pulley Shaft Dia Calculation of Belt Feeder - IS 11592BISWAJIT DASNessuna valutazione finora

- Beumer Belt Bucket Elevator enDocumento8 pagineBeumer Belt Bucket Elevator enLev Maravi MandujanoNessuna valutazione finora

- CB Continental CatalogueDocumento69 pagineCB Continental CatalogueAina LikuntatiNessuna valutazione finora

- Diemme 2500x2500Documento8 pagineDiemme 2500x2500Cristian Mena HidalgoNessuna valutazione finora

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDocumento22 pagineFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramNessuna valutazione finora

- Sinter Plant Single Toothed Roll Crusher PDFDocumento14 pagineSinter Plant Single Toothed Roll Crusher PDFrmsh301Nessuna valutazione finora

- Pipe Conveyor Belts: With Steel Cord and Fabric ReinforcementDocumento5 paginePipe Conveyor Belts: With Steel Cord and Fabric ReinforcementEugenepaccelli Kolandai SamyNessuna valutazione finora

- AUMUND Chain Conveyors 2Documento12 pagineAUMUND Chain Conveyors 2NavidJalalianNessuna valutazione finora

- Eriez-Vibratory Feeders PDFDocumento16 pagineEriez-Vibratory Feeders PDFruben quedo salazarNessuna valutazione finora

- Formula calculates conveyor belt transition distanceDocumento8 pagineFormula calculates conveyor belt transition distanceRajaram JayaramanNessuna valutazione finora

- Extract From The Book Belt FeederDocumento93 pagineExtract From The Book Belt FeederPushp Dutt100% (1)

- BOF Plant Write UpDocumento20 pagineBOF Plant Write UpKalyan HalderNessuna valutazione finora

- Hms Drum PlantDocumento2 pagineHms Drum Plantrichard gutierrezNessuna valutazione finora

- Conveyor Chain Design GuideDocumento64 pagineConveyor Chain Design GuideAtacomaNessuna valutazione finora

- Pan ConveyorsDocumento24 paginePan ConveyorswereerNessuna valutazione finora

- Measuring Bulk Coal Friction on Wear PlatesDocumento8 pagineMeasuring Bulk Coal Friction on Wear PlatesWaris La Joi WakatobiNessuna valutazione finora

- Modern Technological Developments in The Storage and Handling of Bulk Solids - EditDocumento26 pagineModern Technological Developments in The Storage and Handling of Bulk Solids - Editpavan317Nessuna valutazione finora

- VibratingEquipmentBrochure PDFDocumento10 pagineVibratingEquipmentBrochure PDFWilliam VillamizarNessuna valutazione finora

- Cyanide DestructionDocumento11 pagineCyanide DestructionISMAEL RAMIREZNessuna valutazione finora

- CBG8144 en Solution Cement IndustryDocumento12 pagineCBG8144 en Solution Cement IndustryJavier TorresNessuna valutazione finora

- Renold Conveyor Chain Catalogue Designer GuideDocumento41 pagineRenold Conveyor Chain Catalogue Designer Guidedeep200Nessuna valutazione finora

- Filter & Size ReductionDocumento20 pagineFilter & Size ReductionMuhammad Putra RamadhanNessuna valutazione finora

- Sole PlatesDocumento12 pagineSole Platesjonodo89Nessuna valutazione finora

- Conveyor BeltDocumento13 pagineConveyor BeltRajesh KumarNessuna valutazione finora

- E1102m PDFDocumento283 pagineE1102m PDFBhawani Singh RajawatNessuna valutazione finora

- Coal Conveyor Belt Fault DetectionDocumento4 pagineCoal Conveyor Belt Fault Detectionc pawarNessuna valutazione finora

- Applications & Advantages of Pipe ConveyorsDocumento4 pagineApplications & Advantages of Pipe Conveyorsayaskant751001Nessuna valutazione finora

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Documento19 pagineKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNessuna valutazione finora

- Renold Chain CatalogueDocumento24 pagineRenold Chain CatalogueThang NguyenNessuna valutazione finora

- Thickeners and Clarifiers: Liquid / Solid SeparationDocumento6 pagineThickeners and Clarifiers: Liquid / Solid Separationyounes1980Nessuna valutazione finora

- Belt Conveyor by Alok VardhanDocumento30 pagineBelt Conveyor by Alok VardhanLOKENDRA9150% (2)

- ConveyorDocumento36 pagineConveyorapirakqNessuna valutazione finora

- 1 Conveyorppt Course 2010Documento36 pagine1 Conveyorppt Course 2010sk3146Nessuna valutazione finora

- Designing of Screw ConveyorDocumento6 pagineDesigning of Screw ConveyorErickk RoqueeNessuna valutazione finora

- 11.japan Pipe Belt Conveyor SystemDocumento9 pagine11.japan Pipe Belt Conveyor Systemshariq begNessuna valutazione finora

- Belt ConveyorsDocumento62 pagineBelt Conveyorsjayaraman3100% (1)

- #Powerof: Availability Centered MaintenanceDocumento14 pagine#Powerof: Availability Centered Maintenance1977julNessuna valutazione finora

- CFD Applications in Cement IndustriesDocumento33 pagineCFD Applications in Cement Industries1977julNessuna valutazione finora

- Strategic Energy Management PlanDocumento72 pagineStrategic Energy Management Plan1977julNessuna valutazione finora

- CMNT TS3 3Documento26 pagineCMNT TS3 31977jul100% (1)

- 38SAUNDocumento42 pagine38SAUN1977julNessuna valutazione finora

- OPE Model for Tyre Industry Process EffectivenessDocumento4 pagineOPE Model for Tyre Industry Process EffectivenessB6D4N0Nessuna valutazione finora

- PowderDocumento10 paginePowder1977julNessuna valutazione finora

- Chapter 3.7 Cooling TowerDocumento17 pagineChapter 3.7 Cooling TowerDeep DasNessuna valutazione finora

- Modefied Cooler2Documento71 pagineModefied Cooler21977jul100% (2)

- KN RaoDocumento34 pagineKN Rao1977julNessuna valutazione finora

- IEMTCModule9 FinalDocumento29 pagineIEMTCModule9 Final1977julNessuna valutazione finora

- Maag LGD Lateral Gear Drive For Horizontal MillsDocumento8 pagineMaag LGD Lateral Gear Drive For Horizontal Mills1977julNessuna valutazione finora

- Implementing Target CostingDocumento31 pagineImplementing Target CostingJonnattan MuñozNessuna valutazione finora

- Writing EmailsDocumento5 pagineWriting EmailsFiorella LeonNessuna valutazione finora

- Maag Cem Drive Built To PerformDocumento4 pagineMaag Cem Drive Built To PerformMuhammadNessuna valutazione finora

- 5 Why PDFDocumento14 pagine5 Why PDFjoni zulkarnainNessuna valutazione finora

- KPB Transmission Gear Units: For The Bucket Wheel Drive in ExcavatorsDocumento2 pagineKPB Transmission Gear Units: For The Bucket Wheel Drive in Excavators1977julNessuna valutazione finora

- Aspects of Raw Material HomogenizationDocumento25 pagineAspects of Raw Material Homogenization1977julNessuna valutazione finora

- Starting High Inertia Loads on Adjustable Speed DrivesDocumento6 pagineStarting High Inertia Loads on Adjustable Speed Drives1977julNessuna valutazione finora

- Robuschi BlowersDocumento23 pagineRobuschi Blowers1977jul100% (1)

- Feeder TypesDocumento54 pagineFeeder Types1977julNessuna valutazione finora

- Robuschi BlowersDocumento23 pagineRobuschi Blowers1977jul100% (1)

- Hr411 ReferenceDocumento3 pagineHr411 Reference1977julNessuna valutazione finora

- Maintenance in Cement PlantsDocumento11 pagineMaintenance in Cement PlantsAkshay Kadbe100% (1)

- VSM TemplateDocumento13 pagineVSM TemplatesigmasundarNessuna valutazione finora

- Advanced Manufacturing System (TPM)Documento9 pagineAdvanced Manufacturing System (TPM)1977julNessuna valutazione finora

- WPCA-Duke, How To Improve ESP Performance With Voltage Control and Rapper Control Settings, Roglieri, KC CottrellDocumento63 pagineWPCA-Duke, How To Improve ESP Performance With Voltage Control and Rapper Control Settings, Roglieri, KC Cottrell1977julNessuna valutazione finora

- OEEDocumento23 pagineOEEkayumanggiNessuna valutazione finora

- PVC Properties and UsesDocumento46 paginePVC Properties and UsesKuldeep PanchalNessuna valutazione finora

- Australia Oil & Gas Project Summary and Engineering RolesDocumento6 pagineAustralia Oil & Gas Project Summary and Engineering RolesPeter CollierNessuna valutazione finora

- KMS PresentationDocumento26 pagineKMS PresentationMarius CerbuNessuna valutazione finora

- Operations Management: For Competitive AdvantageDocumento23 pagineOperations Management: For Competitive Advantagevicky241989Nessuna valutazione finora

- Fosroc Fibreboard Jun06Documento2 pagineFosroc Fibreboard Jun06robzanaNessuna valutazione finora

- A. A B C D E F G H I: Bracket Base Springs (2) Clamps (4) Housing (2) Handle Casting Bearings (2) ShafDocumento4 pagineA. A B C D E F G H I: Bracket Base Springs (2) Clamps (4) Housing (2) Handle Casting Bearings (2) ShafRadinne Fakhri Al Wafa100% (1)

- TOP100 Automotive Suppliers in Germany FINALDocumento6 pagineTOP100 Automotive Suppliers in Germany FINALjohnNessuna valutazione finora

- Manual de Diseno Drywall RONDO PDFDocumento258 pagineManual de Diseno Drywall RONDO PDFYorbiCastilloNessuna valutazione finora

- Spec Automotive CustomerDocumento2 pagineSpec Automotive CustomeryantoniNessuna valutazione finora

- Logistics BoDocumento26 pagineLogistics BomanjupadmaNessuna valutazione finora

- Machine Shop Viva Voce QuestionsDocumento3 pagineMachine Shop Viva Voce QuestionsSachinNessuna valutazione finora

- Gee Gee ToolingDocumento6 pagineGee Gee ToolingNakul MasilamaniNessuna valutazione finora

- ManualDocumento8 pagineManualSherif AdelNessuna valutazione finora

- PFR Koyali-Ahmednagar PipelineDocumento4 paginePFR Koyali-Ahmednagar PipelineKalai SelvanNessuna valutazione finora

- Brazing DictionaryDocumento14 pagineBrazing DictionaryAriel GermainNessuna valutazione finora

- Street Furniture Factory and Prefabricated SystemsDocumento36 pagineStreet Furniture Factory and Prefabricated SystemsokisoundNessuna valutazione finora

- AAL-Meritor Operations Case Study For Naissance 2012Documento11 pagineAAL-Meritor Operations Case Study For Naissance 2012Gaurav GuptaNessuna valutazione finora

- Introduction To SAP Production Planning ModuleDocumento19 pagineIntroduction To SAP Production Planning ModuleM. N. M. Ashfaque HasanNessuna valutazione finora

- Halene P Technical Data Sheet for Polypropylene Homopolymer F110Documento1 paginaHalene P Technical Data Sheet for Polypropylene Homopolymer F110Dharmendrasinh ZalaNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolssierroNessuna valutazione finora

- The Industrial Revolution 1750-1850: Changes in Technology, Population, and Social StructureDocumento8 pagineThe Industrial Revolution 1750-1850: Changes in Technology, Population, and Social Structurerpatel13Nessuna valutazione finora

- Siempelkamp Ringwalze enDocumento4 pagineSiempelkamp Ringwalze enRia DevitasariNessuna valutazione finora

- Ring Spinning Frame GuideDocumento12 pagineRing Spinning Frame Guidepoojasol0% (1)

- TEXROPE Synchronous Drive Design Manual SH1 (PG 42, 46-47)Documento62 pagineTEXROPE Synchronous Drive Design Manual SH1 (PG 42, 46-47)Diego PovedaNessuna valutazione finora

- Case study-Toyota-JIT-SystemDocumento17 pagineCase study-Toyota-JIT-Systemdkumar881178% (9)

- Study on suppressing dark surface deposits in CuSi3 CMT brazingDocumento6 pagineStudy on suppressing dark surface deposits in CuSi3 CMT brazing木钢Nessuna valutazione finora

- Casting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesDocumento11 pagineCasting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesIOSRjournalNessuna valutazione finora

- NESMAN Manpower Utilization and Costs ReportDocumento55 pagineNESMAN Manpower Utilization and Costs ReportFaiq RehmanNessuna valutazione finora

- Sca-Pca RCC Design SeminarDocumento40 pagineSca-Pca RCC Design Seminarintimate4lifeNessuna valutazione finora

- Sludge Thickening: Design of Gravitational ThickeningDocumento8 pagineSludge Thickening: Design of Gravitational ThickeningugurNessuna valutazione finora