Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixer

Caricato da

lael00Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixer

Caricato da

lael00Copyright:

Formati disponibili

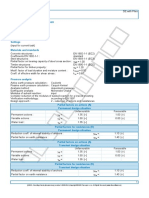

HIT-TZ injection adhesive anchor

Features:

- suitable for cracked concrete

- no cleaning of the hole in general

- less embedment, less drilling, fast curing

- also useable for diamond drilled holes

Material:

HIT-TZ:

HIT-RTZ:

Mortar:

Dispenser:

- galvanised, coating, grade 6.8

- stainless steel; 1.4404, 1.4401; EN 10088

- Hilti HIT HY 150, standard size 330ml and 500ml

- Hilti HIT HY 150, big size 1100 ml, 1400ml

- MD2000, BD2000, P3000 F, MD2500, P3500 F,

P5000 HY, HIT P-8000 D

HIT-HY 150 foil pack, mixer

HIT-TZ, HIT-RTZ

A4

316

Concrete

Tensile zone

Close edge

distance/

spacing

Corrosion

resistance

Fire

resistance

Hilti Anchor

programme

Basic loading data (for a single anchor): HIT-TZ

All data on this page applies to

concrete: See table below.

correct setting (See setting operations page 192)

no edge distance and spacing influence

steel failure

For detailed design method, see pages 194 199.

non-cracked concrete

cracked concrete

Mean ultimate resistance, Ru,m [kN]: concrete C20/25

Anchor size

Tensile NRu,m

Shear VRu,m

M8

20.8

11.6

M10

28.8

17.9

M12

42,3

26.3

M16

57.1

49.4

M20

89.2

76.7

M8

16.0

11.6

M10

23.9

17.9

M12

35.5

26.3

M16

50.0

49.4

M20

86.8

76.7

M8

9.0

11.0

M10

16.0

17.0

M12

20.0

25.0

M16

30.0

47.0

M20

40.0

74.0

M8

6.0

8.8

M10

10.7

13.6

M12

13.3

20.0

M16

20.0

37.6

M20

26.7

59.2

M8

4.3

6.3

M10

7.6

9.7

M12

9.5

14.3

M16

14.3

26.9

M20

19.1

42.3

Characteristic resistance, Rk [kN]: concrete C20/25

Anchor size

Tensile NRk

Shear VRk

M8

16.0

11.0

M10

20.0

17.0

M12

25.0

25.0

M16

43.0

47.0

M20

66.3

74.0

Following values according to the:

Concrete Capacity Method

Design resistance, Rd [kN]: concrete fck,cube = 25 N/mm2

Anchor size

Tensile NRd

Shear VRd

M8

10.7

8.8

M10

13.3

13.6

M12

16.7

20.0

M16

28.7

37.6

M20

44.2

59.2

Recommended load, Lrec [kN]: concrete fck,cube = 25 N/mm2

Anchor size

Tensile NRec

Shear VRec

M8

7.6

6.3

M10

9.5

9.7

M12

11.9

14.3

M16

20.5

26.9

M20

31.6

42.3

175

HIT-TZ injection adhesive anchor

Basic loading data (for a single anchor): HIT-RTZ

All data on this section applies to

concrete: See table below.

correct setting (See setting operations page 192)

no edge distance and spacing influence

steel failure

For detailed design method, see pages 194 199.

non-cracked concrete

cracked concrete

Mean ultimate resistance, Ru,m [kN]: concrete C20/25

Anchor size

Tensile NRu,m

Shear VRu,m

M8

23.8

11.6

M10

24.7

17.9

M12

38.3

26.3

M16

52.2

49.4

M20

94.8

76.7

M8

19.9

11.6

M10

25.1

17.9

M12

34.7

26.3

M16

47.0

49.4

M20

88.0

76.7

M8

9.0

11.0

M10

16.0

17.0

M12

20.0

25.0

M16

30.0

47.0

M20

40.0

74.0

M8

6.0

8.8

M10

10.7

13.6

M12

13.3

20.0

M16

20.0

37.6

M20

26.7

59.2

M8

4.3

6.3

M10

7.6

9.7

M12

9.5

14.3

M16

14.3

26.9

M20

19.1

42.3

Characteristic resistance, Rk [kN]: concrete C20/25

Anchor size

Tensile NRk

Shear VRk

M8

16.0

11.0

M10

20.0

17.0

M12

25.0

25.0

M16

43.0

47.0

M20

66.3

74.0

Following values according to the:

Concrete Capacity Method

Design resistance, Rd [kN]: concrete fck,cube = 25 N/mm2

Anchor size

Tensile NRd

Shear VRd

M8

10.7

8.8

M10

13.3

13.6

M12

16.7

20.0

M16

28.7

37.6

M20

44.2

59.2

Recommended load, Lrec [kN]: concrete fck,cube = 25 N/mm2

Anchor size

Tensile NRec

Shear VRec

M8

7.6

6.3

M10

9.5

9.7

M12

11.9

14.3

M16

20.5

26.9

M20

31.6

42.3

d0

HIT-TZ

Mxx*xx/xx

h ef

h1

h min

176

df

Setting details

t fixt

HIT-TZ injection adhesive anchor

Anchor size

Anchor rod

HIT-TZ M../ HIT-RTZ M..

M8

M10

M12

M16

M20

8x55/ tfix

10x65/ tfix

12x75/ tfix

16x90/tfix

20x120/ tfix

d0

[mm]

Drill bit diameter

10

12

14

18

22

h1

[mm]

Hole depth

60

70

80

95

125

hmin

[mm]

Min. thickness of base material

tfix

df

[mm]

[mm]

Min./Max. fixture thickness

Clearance hole

Tinst

[Nm]

Tightening torque

110

130

150

180

240

15 / 40

9

15 / 40

12

15 / 50

14

25/60

18

30/60

22

12

23

40

70

130

3.5

7.5

13.5

22.5

1

TECX 10/22

TE-TX 10/32

1.5

TECX 12/22

TE-TX 12/32

TECX 14/22

TE-TX 14/32

TE-C 18/32S

TE-T 18/32

6

TEC 22/27S

TE-T 22/32

ml

Filling Volume

Trigger pulls

Drill bit

Base material temperature

30C to 40C

25C to 30C

20C to 25C

15C to 20C

10C to 15C

+5C to 10C

less than +5C

Time available to

adjust anchor

(max)

Curing time befor

anchor can be fully

loaded:

tcure

(min)

2

40

2

45

2.5

50

3

60

5

75

8

90

Please consult your Hilti technical service.

The foil pack must be at least +5C.

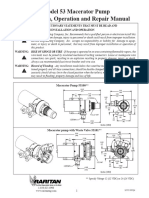

Installation equipment

A rotary hammer (TE5, TE 2, TE6A, TE15, TE-15C, TE-18M, TE35, TE55, TE76); dispenser ( MD2000,

BD2000, P3000 F, MD2500, P3500 F, P5000 HY, HIT P-8000 D)

Setting operations

Drill hole.

Insert rod.

Control

embedment depth.

Inject adhesive.

Wait for curing.

Adhesive amount

for dry and wet

conditions.

177

HIT-TZ injection adhesive anchor

dk

dw

Anchor geometry and mechanical properties

Prgung

HIT-TZ bzw. HIT-RTZ

SW

M.. x h ef /t fix, z.B. M12x75/50

l

Anchor size

M8

M10

M12

M16

M20

36.6

58.0

84.2

156.7

244.8

fuk [N/mm]

600

600

600

600

600

fyk

480

480

480

480

480

31.2

62.3

109

277

541

17.6

36.0

62.4

159.2

311.2

7,0

9.4

55

82/107

13

16

8.81

11.4

65

93/118

17

20

10.71

13.4

75

106/141

19

24

14.5

17.4

90

136/171

24

30

18.24

21.35

120

174/204

30

37

HIT-TZ/-RTZ:

As [mm]

Stressed cross-sectional area

under tensile and shear loading:

Nominal tensile

strength (point)

Nominal yield

[N/mm]

strength (point)

W [mm] Section modulus

MRd,s

Design bending

[Nm]

resistance

d [mm]

dk [mm]

hef [mm]

l [mm]

Sw [mm]

dw[mm]

1)

Shank diameter

Anchor end diameter

Actual anchorage depth

Anchor length

Width across flats

Washer outside diameter

The design bending resistance of the anchor rod was calculated using MRd,s = (1.2 W fuk)/Ms,b , where the partial safety factor Ms,b for

steel 1.25. Verification of safety is then given by MSk F MRd,s

176

HIT-TZ injection adhesive anchor

Detailed design method - Hilti CC

(The Hilti CC-Method is a simplified Version of ETAG Annex C)

Caution: In view of the high loads transferable with HIT-TZ, it must be verified by the user that the load on the

concrete structure including the loads introduced by the anchorage do not cause failure (e.g. cracking) of the

concrete structure.

TENSION

The tensile design resistance of a single anchor

is the lower of,

NRd,c : concrete cone/pull-out resistance

NRd,s : steel resistance

Nrec,c/s

s

NRd,p : Pull-out resistance

o

NRd,p = NRd

,p fB

N0Rd,p : Design pull-out resistance

Concrete compressive strength fck,cube(150) = 25 N/mm2

Anchor size

N0Rd,p1) [kN]

0

N

1)

2)

1)

Rd,p

[kN]

M8

M10

M12

M16

M20

non-cracked concrete

HIT-TZ, HIT-RTZ

10.7

13.3

16.7

cracked concrete

HIT-TZ, HIT-RTZ

6.0

10.7

20.0

26.7

The tensile design resistance is calculated from the tensile characteristic resistance N

safety factor Mc,N is 1.5.

not decisive

o

Rk,p

13.3

o

Rd,p

by N

o

Rk,p

=N

/Mc,N, where the partial

NRd,c: Concrete cone resistance

o

NRd,c = NRd

,c fB,N f A,N fR,N

N0Rd,c : Concrete cone/pull-out design resistance

Concrete compressive strength fck,cube(150) = 25 N/mm2

179

HIT-TZ injection adhesive anchor

Anchor size

M8

M10

M12

M16

M20

in non-cracked concrete

13.7

17.6

21.8

28.7

44.2

[kN]

in cracked concrete

9.8

12.6

15.6

20.5

31.6

[mm]

Actual anchorage depth

55

65

75

90

120

N0Rd,c1)

N0Rd,c1)

[kN]

hef

1)

The design tensile resistance is calculated from the characteristic tensile resistance N

factor Mc,N is 1.5.

o

Rk,c

o

Rd,c

by N

o

Rk,c

=N

/Mc,N, where the partial safety

fB :Influence of concrete strength

Concrete strength

designation

(ENV 206)

C20/25

C25/30

C30/37

C35/45

C40/50

C45/55

C50/60

Cylinder compressive

strength

fck,cyl [N/mm]

20

25

30

35

40

45

50

Cube compressive

strength

fck,cube [N/mm]

25

30

37

45

50

55

60

Concrete cylinder:

Concrete cube:

height 30cm, 15cm

side length 15cm

fB

1.0

1.1

1.22

1.34

1.41

1.48

1.55

fB =

fck,cube

25

Limits:

25 N/mm2 fck,cube(150) 60 N/mm2

diameter

Concrete test specimen geometry

fA,N: Influence of spacing

Spacing,

s [mm]

40

50

55

60

65

70

75

80

85

90

100

120

135

140

160

180

200

220

240

270

300

330

360

390

420

450

480

smin

for c>

180

M8

0.61

0.63

0.64

0.65

0.66

0.67

0.68

0.69

0.70

0.73

0.77

0.81

0.82

0.86

0.91

0.95

1.00

40

65

M10

0.62

0.63

0.63

0.64

0.65

0.66

0.67

0.69

0.73

0.76

0.77

0.81

0.85

0.88

0.92

0.96

60

85

Anchor size

M12

0.62

0.63

0.63

0.64

0.65

0.67

0.70

0.73

0.73

0.77

0.80

0.83

0.87

0.90

0.95

1.00

70

100

M16

0.61

0.62

0.63

0.64

0.67

0.69

0.69

0.72

0.75

0.78

0.81

0.83

0.88

0.92

0.96

1.00

80

100

M20

0.63

0.64

0.65

0.67

0.69

0.71

0.73

0.75

0.78

0.81

0.84

0.88

0.91

0.94

0.97

1.00

100

120

fA,N = 0.5 +

s

8 hef

Limits: smin s scr,N scr,N = 4hef

HIT-TZ injection adhesive anchor

fR,N: Influence of edge distance

Edge

distance,

c [mm]

50

55

60

65

70

75

80

85

90

95

100

105

110

115

125

135

145

155

165

175

185

205

225

240

cmin

for s>

Anchor size

M8

0.60

0.63

0.66

0.70

0.73

0.76

0.79

0.83

0.86

0.89

0.92

0.96

0.99

50

80

M10

0.60

0.63

0.66

0.69

0.71

0.74

0.77

0.80

0.82

0.85

0.88

0.91

0.96

60

120

M12

M16

0.61

0.63

0.65

0.68

0.70

0.73

0.75

0.77

0.80

0.82

0.87

0.92

0.97

M20

0.59

0.61

0.63

0.65

0.67

0.69

0.71

0.73

0.77

0.81

0.85

0.89

0.93

0.97

70

130

fR,N = 0.27 + 0.36

0.59

0.60

0.62

0.65

0.68

0.71

0.74

0.77

0.80

0.83

0.89

0.95

0.99

100

150

80

140

c

hef

Limits: cmin c ccr,N ccr,N = 2hef

NRd,s : Steel design tensile resistance

Anchor size

M8

M10

M12

M16

M20

1)

14.7

23.3

34.0

62.7

98.0

NRd,s

1)

[kN] HIT-TZ/HIT-RTZ

The design value of the ultimate state in tension is calculated using NRd,s= ASV fuk/Ms,N.

The partial safety factor, Ms,N is 1.5.

NRd : System design tensile resistance

NRd = lower of NRd,c and NRd,s

Combined loading: Only if tensile load and shear load applied (See page 31 and section 4 Examples).

181

HIT-TZ injection adhesive anchor

Detailed design method Hilti CC

(The Hilti CC-Method is a simplified Version of ETAG Annex C)

c2 >

1.5

c

SHEAR

V rec,c/s

s

c2 >

1.5

c

h>

1.5

c

The design shear resistance of a single

anchor is the lower of,

VRd,c : concrete edge resistance

VRd,s : steel resistance

Note: If the conditions shown for h and c2 cannot be

observed, please contact your Hilti sales representative.

VRd,c : Concrete edge design resistance

The lowest concrete edge resistance must be calculated. All near edges must be checked, (not only the edge in

the direction of shear). The direction of shear is accounted by the factor f,V.

0

VRd,c = VRd

,c f B,V f ,V f AR,V

V0Rd,c : Concrete edge design resistance

Concrete compressive strength fck,cube(150) = 25 N/mm2

at a minimum edge distance c min

Anchor size

V0Rd,c1)

V0Rd,c1)

cmin

smin

1)

[kN]

[kN]

[mm]

[mm]

M8

M10

M12

M16

M20

non-cracked concrete

3.4

4.7

6.5

8.8

13.8

cracked concrete

2.4

3.4

4.6

6.2

9.8

min. edge distance

50

60

70

80

100

min. edge distance

80

120

130

140

150

The design value of the ultimate state in shear is calculated from the characteristic anchor shear resistance, VRk,c, divided by

VRd,c= VRk,c/Mc,V, where the partial safety factor, Mc,V, is 1.5.

fB,V : Influence of concrete strength

Concrete strength

designation

(ENV 206)

C20/25

C25/30

C30/37

C35/45

C40/50

C45/55

C50/60

Cylinder compressive

strength

fck,cyl [N/mm]

20

25

30

35

40

45

50

Cube compressive

strength

fck,cube [N/mm]

25

30

37

45

50

55

60

Concrete cylinder:

Concrete cube:

height 30cm, 15cm

side length 15cm

diameter

Concrete test specimen geometry

180

fB,V

1.0

1.1

1.22

1.34

1.41

1.48

1.55

fB,V =

fck,cube

25

Limits: 25 N/mm2 fck,cube 60 N/mm2

HIT-TZ injection adhesive anchor

f,V : Influence of shear load direction

Angle []

f,V

0 to 55

60

1.1

70

1.2

80

1.5

90 to 180

Formulae:

V ... applied shear force

f,V = 1

f,V =

for 0 55

1

cos + 0.5 sin

for 55 < 90

f,V = 2

for 90 < 180

fAR,V : Influence of edge distance and spacing

Formula for single-anchor fastening

Influenced only by edge

f AR,V =

c

c min

c 2,1

c

c min

s n-1

Formula for a two-anchor fastening valid

for s < 3c

f AR,V =

3c + s

6c min

s3

results

tabulated

below

Single anchor with

edge influence

1.0

s/cmin

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

9.5

10.0

10.5

11.0

11.5

12.0

c

c min

h >1,5 c

Note:

3c + s1 + s 2 + ... + s n1

c

3nc min

c min

fAR.V

s1

c 2 ,2

General formula for n-anchor fastening (edge plus n-1 spacing)

only valid where s1 to sn-1 are all < 3c

f AR ,V =

s2

c/cmin

1.0 1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

It is assumed that only the row of anchors closest to

the free concrete edge carries the centric shear load

3.0

3.2

3.4

3.6

3.8

4.0

1.00 1.31 1.66 2.02 2.41 2.83 3.26 3.72 4.19 4.69 5.20 5.72 6.27 6.83 7.41 8.00

0.67

0.75

0.83

0.92

1.00

0.84

0.93

1.02

1.11

1.20

1.30

1.03

1.12

1.22

1.32

1.42

1.52

1.62

1.22

1.33

1.43

1.54

1.64

1.75

1.86

1.96

1.43

1.54

1.65

1.77

1.88

1.99

2.10

2.21

2.33

1.65

1.77

1.89

2.00

2.12

2.24

2.36

2.47

2.59

2.71

2.83

1.88

2.00

2.13

2.25

2.37

2.50

2.62

2.74

2.87

2.99

3.11

3.24

These results are for a two-.

Anchor fastening.

For fastening made with more

than 2 anchors, use the

general formulae for n

anchors at the top of the page.

2.12

2.25

2.38

2.50

2.63

2.76

2.89

3.02

3.15

3.28

3.41

3.54

3.67

2.36

2.50

2.63

2.77

2.90

3.04

3.17

3.31

3.44

3.57

3.71

3.84

3.98

4.11

2.62

2.76

2.90

3.04

3.18

3.32

3.46

3.60

3.74

3.88

4.02

4.16

4.29

4.43

4.57

2.89

3.03

3.18

3.32

3.46

3.61

3.75

3.90

4.04

4.19

4.33

4.47

4.62

4.76

4.91

5.05

5.20

3.16

3.31

3.46

3.61

3.76

3.91

4.05

4.20

4.35

4.50

4.65

4.80

4.95

5.10

5.25

5.40

5.55

5.69

3.44

3.60

3.75

3.90

4.06

4.21

4.36

4.52

4.67

4.82

4.98

5.13

5.29

5.44

5.59

5.75

5.90

6.05

6.21

3.73

3.89

4.05

4.21

4.36

4.52

4.68

4.84

5.00

5.15

5.31

5.47

5.63

5.79

5.95

6.10

6.26

6.42

6.58

6.74

4.03

4.19

4.35

4.52

4.68

4.84

5.00

5.17

5.33

5.49

5.65

5.82

5.98

6.14

6.30

6.47

6.63

6.79

6.95

7.12

7.28

4.33

4.50

4.67

4.83

5.00

5.17

5.33

5.50

5.67

5.83

6.00

6.17

6.33

6.50

6.67

6.83

7.00

7.17

7.33

7.50

7.67

7.83

8.00

183

HIT-TZ injection adhesive anchor

VRd,s : Steel design shear resistance

Anchor size

VRd,s

1)

1)

[kN]

HIT-TZ / HIT-RTZ

M8

M10

M12

M16

M20

8.8

13.6

20.0

37.6

59.2

The design shear resistance is calculated using VRd,s= VRk,s/Ms,V. The partial safety factor, Ms,V is 1.25.

NRd : System tensile design resistance

VRd = lower of VRd,c and VRd,s

Combined loading: Only if tensile load and shear load applied (See page 31 and section 4 Examples).

184

Potrebbero piacerti anche

- TD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)Documento5 pagineTD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)phamducquangNessuna valutazione finora

- 01Documento314 pagine01Melina BaluyotNessuna valutazione finora

- Geosynthetic Encased ColumnDocumento10 pagineGeosynthetic Encased Columnakdce01Nessuna valutazione finora

- Sheeting Structure Verification Input DataDocumento26 pagineSheeting Structure Verification Input DataanonimusazNessuna valutazione finora

- 187 NanoGrout EGDocumento2 pagine187 NanoGrout EGTristan Irvin Asi100% (3)

- Slope Stability Analysis Input Data: Project SettingsDocumento5 pagineSlope Stability Analysis Input Data: Project SettingsanonimusazNessuna valutazione finora

- Fhwa HRT 04 043Documento384 pagineFhwa HRT 04 043hana saffanahNessuna valutazione finora

- Project: Location: By: Date: Chk. By: Date: Clear Data Entry CellsDocumento1 paginaProject: Location: By: Date: Chk. By: Date: Clear Data Entry Cellsblackk7Nessuna valutazione finora

- ML-PRD01-EnG-CCAL-0113 - Rev 3 - Calculation Sheet For Pipe Support Wellpad ML-ADocumento114 pagineML-PRD01-EnG-CCAL-0113 - Rev 3 - Calculation Sheet For Pipe Support Wellpad ML-AZukri EmailNessuna valutazione finora

- SNiP 2.01.07-85 Nagruski I Vosdeystviy - Maps PDFDocumento8 pagineSNiP 2.01.07-85 Nagruski I Vosdeystviy - Maps PDFDmitriNessuna valutazione finora

- Industries: The Manila'S Expert EngineersDocumento12 pagineIndustries: The Manila'S Expert EngineersJohn Carlos Moralidad CriticaNessuna valutazione finora

- CEM Part VI Chap 5 Pt2Documento84 pagineCEM Part VI Chap 5 Pt2raly1Nessuna valutazione finora

- Guide For Maintenance of Concrete Bridge Members: ACI 345.1R-06Documento2 pagineGuide For Maintenance of Concrete Bridge Members: ACI 345.1R-06Arqowi Pribadi100% (1)

- Ruukki Load Bearing Sheet DrawingsDocumento56 pagineRuukki Load Bearing Sheet DrawingsРостислав ВасилевNessuna valutazione finora

- Slope Stability ImprovementDocumento43 pagineSlope Stability Improvementomar cNessuna valutazione finora

- MerantiDocumento1 paginaMerantiDipin Nediya ParambathNessuna valutazione finora

- Ancon CouplersDocumento32 pagineAncon CouplersNuno Telmo LopesNessuna valutazione finora

- PCI DH-Loss of PrestressDocumento5 paginePCI DH-Loss of PrestressCarlisle Flores-GarayNessuna valutazione finora

- Electra Sample Drawing 1Documento17 pagineElectra Sample Drawing 1stelios_yuhas4576Nessuna valutazione finora

- Cad Weld MSDSDocumento5 pagineCad Weld MSDSKatari Murthy NaiduNessuna valutazione finora

- Shop Drawing - 500 GPM at 8 Bar EDJ UL Listed End Suction-For Prasoon-ModelDocumento1 paginaShop Drawing - 500 GPM at 8 Bar EDJ UL Listed End Suction-For Prasoon-ModelSooraj VsNessuna valutazione finora

- Typical Fence DetailDocumento1 paginaTypical Fence DetailGelbert SilotNessuna valutazione finora

- Snow Load As Weight Per MM Calculation 330Documento1 paginaSnow Load As Weight Per MM Calculation 330Anonymous Iev5ggSRNessuna valutazione finora

- Floor Plate PDFDocumento2 pagineFloor Plate PDFdheenasweetNessuna valutazione finora

- Standard Penetration Test PDFDocumento13 pagineStandard Penetration Test PDFMohamedRaahimNessuna valutazione finora

- SurvCE V4 Instrument Setup Manual PDFDocumento113 pagineSurvCE V4 Instrument Setup Manual PDFCadastru IntabulareNessuna valutazione finora

- Defects ListDocumento2 pagineDefects Listfarukh azeemNessuna valutazione finora

- Ai-1113-Gb 15T Bitt Bollard Shop Drawing PDFDocumento1 paginaAi-1113-Gb 15T Bitt Bollard Shop Drawing PDFCarlos_CriticaNessuna valutazione finora

- PR RbiaDocumento25 paginePR RbiaDexter G. BatalaoNessuna valutazione finora

- Technical Specifications January 2019Documento7 pagineTechnical Specifications January 2019Sone Aung PyaeNessuna valutazione finora

- The Development of Design Guidance For Bridges in New Zealand For Liquefaction and Lateral Spreading EffectsDocumento142 pagineThe Development of Design Guidance For Bridges in New Zealand For Liquefaction and Lateral Spreading EffectsAndreas GiannakogiorgosNessuna valutazione finora

- Hilti-Fischer Anchor BoltDocumento2 pagineHilti-Fischer Anchor Boltpavitrakedar100% (1)

- Tandemloc Iso Container InfoDocumento4 pagineTandemloc Iso Container InfoDon LariviereNessuna valutazione finora

- Lintel BeamDocumento3 pagineLintel BeamJosephNessuna valutazione finora

- Specialisations - Conditions For Award of Specialisations - Aug12Documento9 pagineSpecialisations - Conditions For Award of Specialisations - Aug12lim kang haiNessuna valutazione finora

- Equivalent Moment Factor C1Documento2 pagineEquivalent Moment Factor C1baharfka7423Nessuna valutazione finora

- Materials PricelistDocumento4 pagineMaterials PricelistJeremy SaileNessuna valutazione finora

- Flyer Ostraadt Concrete FleximatDocumento2 pagineFlyer Ostraadt Concrete FleximatChristian BarNessuna valutazione finora

- Specifications For Driving Precast Concrete PilesDocumento4 pagineSpecifications For Driving Precast Concrete PilesArif NofiyantoNessuna valutazione finora

- Dead Man Sheet Pile Wall, SI Units (DeepEX 2015)Documento14 pagineDead Man Sheet Pile Wall, SI Units (DeepEX 2015)Moshiur RahmanNessuna valutazione finora

- Wind Calculation According To Bs Cp3 CH V Part 2Documento5 pagineWind Calculation According To Bs Cp3 CH V Part 2SAMER OSMANNessuna valutazione finora

- Calculation Note Sheet Pile PDFDocumento9 pagineCalculation Note Sheet Pile PDFDadi WahyudiNessuna valutazione finora

- 4.4.2 Technical SpecificationDocumento58 pagine4.4.2 Technical SpecificationSiji OktoberNessuna valutazione finora

- Estimating Guide For Woven Mesh GabionsDocumento3 pagineEstimating Guide For Woven Mesh GabionsJayson TeeNessuna valutazione finora

- DAIKIN VAM VRV HVE ModelDocumento5 pagineDAIKIN VAM VRV HVE ModelPads PrietoNessuna valutazione finora

- Fire Hydrant SystemDocumento4 pagineFire Hydrant SystemJoshua Gnanaraj100% (1)

- Metal Flooring, Stairways, Ladders, Platforms and Handrailing PDFDocumento16 pagineMetal Flooring, Stairways, Ladders, Platforms and Handrailing PDFDennis RangwetsiNessuna valutazione finora

- Ili Department of Public Works and Highways: - 097 13'Dpwh 10 20 202Fj.Documento2 pagineIli Department of Public Works and Highways: - 097 13'Dpwh 10 20 202Fj.Dyeri FloresNessuna valutazione finora

- Pier FootingDocumento2 paginePier FootingMathurathipan Rajendraseelan100% (1)

- Sikadur 732Documento2 pagineSikadur 732Hafidh Roiy100% (1)

- Boq For Road WorksDocumento6 pagineBoq For Road WorksFaisal KhanNessuna valutazione finora

- Timber Examples - TeddsDocumento19 pagineTimber Examples - TeddsTom KwoNessuna valutazione finora

- Technical Bid FormatDocumento4 pagineTechnical Bid FormatSunny Kumar GuptaNessuna valutazione finora

- Beam Design Summary: Material and Design DataDocumento2 pagineBeam Design Summary: Material and Design DatamalsrinivasanNessuna valutazione finora

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Documento12 pagineHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNessuna valutazione finora

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocumento10 pagineHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNessuna valutazione finora

- Hilti HVZ 1Documento13 pagineHilti HVZ 1Mihnea-Bogdan NicolaescuNessuna valutazione finora

- 44 - HVZ Adhesive AnchorDocumento14 pagine44 - HVZ Adhesive AnchorHuan VoNessuna valutazione finora

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Documento9 pagine2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNessuna valutazione finora

- Areas VarillasDocumento1 paginaAreas Varillaslael00Nessuna valutazione finora

- Desgin Column Base:-Sec. (1) Frame No.1: Hinged Column Bases (Under Q, N) : - 1) Base Plate Deminsion (BXL)Documento4 pagineDesgin Column Base:-Sec. (1) Frame No.1: Hinged Column Bases (Under Q, N) : - 1) Base Plate Deminsion (BXL)lael00Nessuna valutazione finora

- 2003 IBC SeismicDocumento1 pagina2003 IBC Seismiclael00Nessuna valutazione finora

- Ult IpsfusionDocumento5 pagineUlt Ipsfusionlael00Nessuna valutazione finora

- Bolted Beam Column ConnectionsDocumento16 pagineBolted Beam Column Connectionslael00Nessuna valutazione finora

- Stairwell Pressurization ChecklistDocumento2 pagineStairwell Pressurization Checklistmoh khNessuna valutazione finora

- Home Renovation Agreement TemplateDocumento10 pagineHome Renovation Agreement TemplateNasa MyjNessuna valutazione finora

- RA Bill FormatDocumento66 pagineRA Bill Formatdebajyoti dasNessuna valutazione finora

- Enesti Study PlansDocumento6 pagineEnesti Study PlansCooperante AnonimoNessuna valutazione finora

- LEED v4 For Interior Design and Construction ChecklistDocumento3 pagineLEED v4 For Interior Design and Construction Checklisttarek.abbas8598Nessuna valutazione finora

- Brochure UCL ENG 2018Documento12 pagineBrochure UCL ENG 2018ashumishra007Nessuna valutazione finora

- L552v1022 Macerator OM 0ff7a260Documento8 pagineL552v1022 Macerator OM 0ff7a260Beni SaputraNessuna valutazione finora

- Core CompetencyDocumento241 pagineCore CompetencyYeng LugtuNessuna valutazione finora

- MOS For Metallic Conduit InstallationDocumento23 pagineMOS For Metallic Conduit InstallationAhmed MhnaNessuna valutazione finora

- Hot Oil Expansion TankDocumento2 pagineHot Oil Expansion TankAnonymous 70lCzDJv100% (1)

- Addendum To Standard Bidding Document Procurement of Civil WorksDocumento29 pagineAddendum To Standard Bidding Document Procurement of Civil WorksvivekNessuna valutazione finora

- SamsdataDocumento296 pagineSamsdataSamuel AugustineNessuna valutazione finora

- Free LeadingGreen LEED GA Study Guide 3rd Ed PDFDocumento46 pagineFree LeadingGreen LEED GA Study Guide 3rd Ed PDFlexsNessuna valutazione finora

- Rodajes Miniatura NSKDocumento41 pagineRodajes Miniatura NSKenicolas2Nessuna valutazione finora

- Bolt Calculation According To VDI 2230:2014: InputsDocumento7 pagineBolt Calculation According To VDI 2230:2014: InputsSridhar TholasingamNessuna valutazione finora

- 4.2 Active and Passive Fire Fighting SystemDocumento16 pagine4.2 Active and Passive Fire Fighting SystemPUTRI ZAHEERANessuna valutazione finora

- KuwaitDocumento16 pagineKuwaitGualberto AlarconNessuna valutazione finora

- Verification 001Documento6 pagineVerification 001Med El Hadi AbidiNessuna valutazione finora

- European Technical Assessment ETA-20/0529 of 14 December 2020Documento12 pagineEuropean Technical Assessment ETA-20/0529 of 14 December 2020RadekNessuna valutazione finora

- ELECTRICAL WIRING PLAN DemoDocumento24 pagineELECTRICAL WIRING PLAN DemoTommy Dela CruzNessuna valutazione finora

- Spare Parts HMK 300 LC-3Documento1.173 pagineSpare Parts HMK 300 LC-3Bimbo Jimbo100% (1)

- 2011ARDocumento72 pagine2011ARMika AurelioNessuna valutazione finora

- Aitc Tn8 March 2010Documento3 pagineAitc Tn8 March 2010seagull70Nessuna valutazione finora

- Sobha Hartland Greens - Phase 02: InvestmentsDocumento1 paginaSobha Hartland Greens - Phase 02: InvestmentsrajatNessuna valutazione finora

- Chapter 4 GlassDocumento51 pagineChapter 4 Glassaman sudiNessuna valutazione finora

- MDD FormatDocumento6 pagineMDD FormatEngineeri TadiyosNessuna valutazione finora

- Tds - Emaco s66 CPDocumento2 pagineTds - Emaco s66 CPVenkata RaoNessuna valutazione finora

- Tube-To-Tube Sheet Joint RequirementsDocumento2 pagineTube-To-Tube Sheet Joint RequirementsWaqas WaqasNessuna valutazione finora

- HSEQ-QA-CMS0016-CIV-2914 CMS Pile Material ReceivalDocumento26 pagineHSEQ-QA-CMS0016-CIV-2914 CMS Pile Material ReceivalDoni TriatmojoNessuna valutazione finora