Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Practical Instructions General

Caricato da

Sani TipareCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Practical Instructions General

Caricato da

Sani TipareCopyright:

Formati disponibili

MEENA INTERNATIONAL

JJJ;;EENA

Page 1 of 10

INTERNATIONAL

Ultrasonic Testing Practical Instructions : General

1. Linearity

of time base:

General:

This check may be carried out of a standard calibration block e.g. V1 and a Compression wave

probe. The Linearity should be checked over a range at least equal to that which is to be used in

subsequent testing.

Method:

1. Place the probe on the 25mm thickness of the IIW V1 Block and adjust the controls to

display 10 back wall echoes.

2. Adjust the controls so that the first and last back wall echoes coincide with the scale

marks at 1 and 10.

3.

Increase the gain to bring successive back wall echoes to 80% full screen Height. The

leading edge of each echo should line up with the appropriate graticule line.

4.

Record any deviations at approximately half screen height. Deviations should be

expressed as a percentage of the range between the first and last echoes displayed

(i.e. 225mm).

Tolerance:

Unless otherwise specified by the testing standard, a tolerance of 2% is considered

acceptable.

Frequency

of checking:

Document: UT-01 Instruction:

The check shall be carried out at least once per week.

General Issued 15/07/2009

MEENA INTERNATIONAL

JJJ;;EENA

Page 2 of 10

INTERNATIONAL

Ultrasonic Testing Practical Instructions : General

2. Linearity of equipment gain:

General:

This is a Check on both the Linearity of the amplifier within the set and the calibrated gain control.

It can be carried out on any calibration block containing a side drilled hole and should be done

using the probe to be used in subsequent testing. RejecUSuppression controls shall be switched

off

Method:

1.

Position the probe on a calibration block to obtain a reflected signal from a small reflector e.g.

1.6 mm side drilled hole in the V1 block.

2.

Adjust the gain to set this signal to 80% full screen height and note the gain setting (dB).

3. a)

Increase the gain by 2dB and record the amplitude of the signal.

b)

Remove the 2dB and return the signal to 80% FSH.

c)

Reduce the gain by 6dB and record signal amplitude.

d)

Reduce the gain by further 6dB (12 in total) and record signal amplitude

e)

f)

Reduce the gain by further 6dB (18 in total) and record signal amplitude

Reduce the gain by a further 6dB (24 in total) and record signal amplitude.

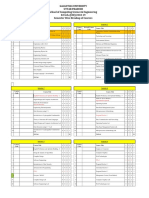

Tolerance: (See table below)

Recorded Amplitude

Gain dB

Expected Amplitude % of

Full Screen Height

+2

101%

80%

-6

40%

-12

20%

-18

10%

'i!, ';:

- 24

5%

Vis.\:b\e

i66"/

<b 0 'I

3~ '/

1 ~ '/

Acceptable Limits

Not less than 95%

(Reference Line)

37% to 43%

17% to 23%

8% to 12%

Visible, below 8%

Frequency of checking: The check shall be carried out at least once per week.

Document: UT-01 Instruction: General Issued 15/07/2009

MEENA INTERNATIONAL

IlTr:1EENA

Page 3 of 10

INTERNATIONAL

Ultrasonic Testing Practical Instructions : General

3. Probe index and Beam Alignment:

General:

The check for probe index applies only to shear wave probes, and is the first probe characteristic

to be checked on a shear wave probe. The probe index may be checked on the standard V1

calibration block.

Method:

1. Position the probe on the appropriate

quadrant.

2.

3.

side of the block to obtain a reflection from the

Move the probe backwards and forwards to maximize the amplitude of the reflected signal.

When the signal is at maximum, the probe index will correspond to the engraved line on the

block. Mark this position on the side of the probe.

Tolerance:

Tolerance will depend on application but for plotting of defects, it is recommended that probe index

is accurate to within 1mm.

Frequency of checking:

When a probe is in continuous use, it is recommended

hours: otherwise, a daily check is recommended.

that the check be carried out every few

Beam Alignment (Squint):

With the probe still in position, a check on a beam alignment can be performed. If the probe beam

is correctly aligned, the edge of the probe will be parallel to the edge of the block. If this is not the

case, the squint angle between the two edges. Tolerance depends upon the accuracy of defect

plotting required. The check should be carried out once per week.

Document: UT-01 Instruction:

General Issued 15/07/2009

MEENA INTERNATIONAL

fll(;;EENA

Page 4 of 10

INTERNATIONAL

4.

Ultrasonic Testing Practical Instructions : General

Beam Angle

General:

Beam angle can be checked on several calibration blocks e.g. V1 or lOW. The beam angle check

shall preferable be made on a probe in conjunction with the flaw detector to be used in subsequent

testing.

Method:

1. Place the probe in such a position as to receive a reflected signal from the selected transverse

hole in the calibration block (e.g.19mm deep hole in the AS block).

2. Maximise the signal from the hole and mark the index point of the probe on the block.

3. Measure the distance from the marked point on the block to the edge of the block. Knowing the

position of the drilled hole will allow the beam angle to be calculated (see below).

*Note. If only a rapid check is required, maximize the signal from the SOmm hole in the V1 block.

The angle can then be assessed by visual interpolation between the references marking on the

block.

Tolerance:

The accuracy by the described method is

1.So.

*The accuracy in this case can only be assumed to be 3.

Frequency

of checking:

When a probe is in continuous use, it is recommended that the check be carried out at least every

few hours: otherwise, a daily check is recommended.

Document: UT-01 Instruction: General Issued 15/07/2009

MEENA INTERNATIONAL

I'JK;EENA

Page 5 of 10

INTERNATIONAL

5. Sensitivity

Ultrasonic Testing Practical Instructions : General

and signal-to-noise

ratio:

General

The main objective of this check is to provide the operator with a simple method, which will allow

deterioration in sensitivity of the probe and flaw detector in combination to be identified.

Method

1. Place the probe on the A2 calibration block and adjust its position to maximize the signal from

the 1.5mm diameter hole.

2. Adjust the gain control to set this signal to 20% FSH, and note the dB setting.

3. Increase the gain until the overall system noise (electronic noise and grain structure grass) at

the same range as the target hole reached 20% FSH, and note the new dB setting.

4. The first gain measurement noted provides a check on the sensitivity of the probe and flaw

detector, and the difference between the first and second measurements (dB) gives the signalto-noise ratio.

Note 1: A demonstration of the sensitivity of probe and flaw detector on a calibration block does

not guarantee that the same size of reflector could be detected in the work piece.

Note 2: If it is desired to check the sensitivity as a function of range, the use of the standard A5

block is recommended for longer ranges.

Tolerance: Tolerance will depend on application. Any deterioration in the sensitivity value will

indicate a problem with the probe or flaw detector. A low signal-to-noise ratio would be typical of a

coarse-grained material. The tolerances are usually end user specified.

Frequency

of checking:

Unless otherwise agreed, the check shall be carried out once per probe

per day.

Document: UT-01 Instruction: General Issued 15/07/2009

MEENA INTERNATIONAL

IJl(;tEENA

Page 6 of 10

INTERNATIONAL

Ultrasonic

Testing

Practical

Instructions

: General

6. Pulse Duration General:

This check on the probe and flaw detector in combination, measures the effect on the displayed

signal of probe damping, amplifier bandwidth, built-in suppression and smoothing circuits. The

standard V1 calibration block may be used for this check.

Method:

1. Calibrate the time base in millimeters to a range that is to be used in subsequent testing.

2. Maximise the signal from the 1.5mm side drilled hole for shear wave probes or a back wall

echo for compression wave probes, and set its peak to 100% screen height.

3. Measure the width of the signal in millimeters at the 10% screen height position.

4.

If desired, the measurement in millimeters can be converted into microseconds by dividing it by

the relevant sound velocity.

Tolerance:

Tolerance will depend upon application. A long pulse duration will limit range resolution and

indicate the need for a resolution check*, and a short pulse duration may indicate the flaw detector

has built-in suppression that could prevent the observation of small signals. The tolerances are

usually end user specified.

A resolution check is described in clause NO.7

Frequency

of checking:

Unless otherwise agreed, the check should be carried out daily.

Document: UT-01 Instruction: General Issued 15/07/2009

MEENA INTERNATIONAL

/l7;;EENA

Page 7 of 10

INTERNATIONAL

Ultrasonic Testing Practical Instructions : General

7. Resolving

Power (Resolution):

General:

This check determines the ability of an ultrasonic flaw detection system to give separate indication

of discontinuities situated close together and simultaneously within the sound beam.

Method

1. Calibrate the time base to a range of 0-100 for either the compression wave probe or the shear

wave probe.

2. Place the probe so that the axis of the beam impinges upon the 2mm step in the A7 calibration

block for shear wave probes, or the 3mm step for compression wave probes.

3. Adjust the position of the probe so that the echoes from the two targets are of the same height

and approximately half-full graticule height.

4. The steps are said to be resolved when their echoes are clearly separated at half maximum

echo height or lower.

*Note. The 3mm step between the 9mm and 3mm drilled holes in the A6 calibration block may also

be used when checking compression probes.

Frequency

of checking:

The Check shall be carried out monthly, or when too long a pulse

duration is suspected.

Document: UT-01 Instruction:

General Issued 15/07/2009

MEENA INTERNATIONAL

IlJ(;EENA

INTERNATIONAL

Page 8 of 10

Ultrasonic Testing Practical Instructions : General

8. 20 dB Beam Spread Profile Plot:

1. Check and mark index point on the probe

2. Calibrate the angle probe for 100 mm range

3. Select 4 holes at a range of depths from the lOW calibration block (e.g .. 13, 25, 32 & 43

mm)

4. For hole 1 maximize the echo from the hole and adjust to full screen height (100% FSH)

5. Mark the index point on the block

6. Move the probe back until the echo is reduced to 10% of FSH (1/10th or 1 graticule height)

7. Mark the index point on the block

8. Move the probe forward through the maximum echo position until the echo again is reduced

to 10% of FSH (1/10th or 1 graticule height)

9. Mark the index point on the block

10. Measure the standoff distances on the block and record

11. Repeat steps 4 to 10 for other 3 hole depths

12. Transfer the measurements

devise.

Document: UT-01 Instruction:

for hole depth and standoff distance to a relevant plotting

General Issued 15/07/2009

J7K1EENA

INTERNATIONAL

MEENA INTERNATIONAL

Page 9 of 10

Ultrasonic Testing Practical Instructions : General

9. Preparation of Distance Amplitude Correction (DAC) Curves:

1. Calibrate the time base to accommodate the full testing range to be used.

2. Select the target holes to be used for the DAC curve and adjust probe position to obtain

maximum echo height from the hole giving the highest amplitude. (Not necessarily shortest

range echo).

3. Adjust the gain to give an 80% full screen height echo from this hole, and either mark the

position of the echo tip on the screen or plot the echo height and beam path range on a

separate graph.

4. Without altering the equipment gain, adjust the probe position to obtain maximum amplitude

from each of the holes in turn and either mark the echo tip on the screen or plot on a

separate graph.

5. Join the marked points on the screen, or on the graph, to obtain the DAC curve for that

particular probe. (See Figure 1).

6. Record the sensitivity at which the DAC curve was plotted by reference to the gain setting

and echo height from a suitable test block, e.g. the 100mm radius of A2 block. This will

enable the sensitivity to be easily reset to the DAC level without the use of the special DAC

test block.

Document: UT-01 Instruction: General Issued 15/07/2009

MEENA INTERNATIONAL

fll(;;EENA

INTERNATIONAL

Page 10 of 10

Ultrasonic

Testing

Practical

Instructions

: General

10. Penetration Check: (Ability to penetrate different material)

Experiment to be carried out using IIW V1 or BS A 1 block:

Step-1: Using a normal beam transducer on the 25 mm face of the steel portion calibrate the

display for 50 mm range by obtaining two back wall echoes.

Step-2: Now place the normal beam transducer on the face of the 23 mm Perspex without altering

the calibration.

Step-3: Observe the reading on the display system

Note: Sound travels at a lower velocity in Perspex when compared to steel. Hence 23 mm Perspex

will give reading which is equivalent to that of 50 mm steel and only one back wall echo at 50 mm

steel equivalent will appear on the screen.

Document: UT-01 Instruction:

General Issued 15/07/2009

Potrebbero piacerti anche

- Curriculam Vitae: Post Applied For RT Technician Abhay Pratap SinghDocumento5 pagineCurriculam Vitae: Post Applied For RT Technician Abhay Pratap SinghSani TipareNessuna valutazione finora

- Dme 20Documento5 pagineDme 20Sani TipareNessuna valutazione finora

- Abroad News Paper 11 MayDocumento6 pagineAbroad News Paper 11 MaySani TipareNessuna valutazione finora

- 10.kotti Update CVDocumento3 pagine10.kotti Update CVSani TipareNessuna valutazione finora

- App L3 Kuwait 2016 22 Final FinalDocumento11 pagineApp L3 Kuwait 2016 22 Final FinalSani TipareNessuna valutazione finora

- UT Level III Exam Paper 2012Documento2 pagineUT Level III Exam Paper 2012Sani Tipare100% (1)

- EPOCH600 EN 201409 WebDocumento8 pagineEPOCH600 EN 201409 WebSani TipareNessuna valutazione finora

- Interval Velocity ModelDocumento36 pagineInterval Velocity ModelSani TipareNessuna valutazione finora

- Prakash Patel NDT CV 101Documento5 paginePrakash Patel NDT CV 101Sani TipareNessuna valutazione finora

- Abs Mpi TestDocumento7 pagineAbs Mpi TestSani TipareNessuna valutazione finora

- Raytrace Modelling: Rays and ModelsDocumento11 pagineRaytrace Modelling: Rays and ModelsSani TipareNessuna valutazione finora

- Coherency InversionDocumento16 pagineCoherency InversionSani TipareNessuna valutazione finora

- 00FRONT2Documento5 pagine00FRONT2Sani TipareNessuna valutazione finora

- Velocity Definitions: T T XV XV T +Documento8 pagineVelocity Definitions: T T XV XV T +Sani TipareNessuna valutazione finora

- Depth Conversion of Time Interpretations Volume ModelsDocumento53 pagineDepth Conversion of Time Interpretations Volume ModelsSani TipareNessuna valutazione finora

- Key References For Further ReadingDocumento11 pagineKey References For Further ReadingSani TipareNessuna valutazione finora

- Data Courtesy of ARCO British Ltd. 17.25Documento3 pagineData Courtesy of ARCO British Ltd. 17.25Sani TipareNessuna valutazione finora

- Objective:: - Objective of Course - Basic Concepts - Outline of The CourseDocumento16 pagineObjective:: - Objective of Course - Basic Concepts - Outline of The CourseSani TipareNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Imabalacat DocuDocumento114 pagineImabalacat DocuJänrëýMåmårìlSälängsàngNessuna valutazione finora

- Caterpillar Cat C7 Marine Engine Parts Catalogue ManualDocumento21 pagineCaterpillar Cat C7 Marine Engine Parts Catalogue ManualkfsmmeNessuna valutazione finora

- Universitas Tidar: Fakultas Keguruan Dan Ilmu PendidikanDocumento7 pagineUniversitas Tidar: Fakultas Keguruan Dan Ilmu PendidikanTheresia Calcutaa WilNessuna valutazione finora

- AIIMS 2015 Solved PaperDocumento436 pagineAIIMS 2015 Solved PaperSurya TejaNessuna valutazione finora

- SG110CX: Multi-MPPT String Inverter For SystemDocumento2 pagineSG110CX: Multi-MPPT String Inverter For SystemKatherine SmithNessuna valutazione finora

- CISF Manual Final OriginalDocumento17 pagineCISF Manual Final OriginalVaishnavi JayakumarNessuna valutazione finora

- Case Study - Suprema CarsDocumento5 pagineCase Study - Suprema CarsALFONSO PATRICIO GUERRA CARVAJALNessuna valutazione finora

- Pediatrics: The Journal ofDocumento11 paginePediatrics: The Journal ofRohini TondaNessuna valutazione finora

- A Comparative Study of Public Private Life Insurance Companies in IndiaDocumento5 pagineA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalNessuna valutazione finora

- CA21159 MG 8 Digital BookletDocumento5 pagineCA21159 MG 8 Digital BookletcantaloupemusicNessuna valutazione finora

- Noise and DB Calculations: Smart EDGE ECE Review SpecialistDocumento2 pagineNoise and DB Calculations: Smart EDGE ECE Review SpecialistLM BecinaNessuna valutazione finora

- SW OSDocumento11 pagineSW OSErnest OfosuNessuna valutazione finora

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesDocumento2 pagineGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiNessuna valutazione finora

- Magic Bullet Theory - PPTDocumento5 pagineMagic Bullet Theory - PPTThe Bengal ChariotNessuna valutazione finora

- The Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalDocumento6 pagineThe Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalMahad Abdi100% (1)

- Gis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaDocumento9 pagineGis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaGrantNessuna valutazione finora

- FHWA Guidance For Load Rating Evaluation of Gusset Plates in Truss BridgesDocumento6 pagineFHWA Guidance For Load Rating Evaluation of Gusset Plates in Truss BridgesPatrick Saint-LouisNessuna valutazione finora

- DJ Crypto ResumeDocumento1 paginaDJ Crypto ResumeNitin MahawarNessuna valutazione finora

- Contemporary Strategic ManagementDocumento2 pagineContemporary Strategic ManagementZee Dee100% (1)

- Research FinalDocumento55 pagineResearch Finalkieferdem071908Nessuna valutazione finora

- COK - Training PlanDocumento22 pagineCOK - Training PlanralphNessuna valutazione finora

- Mathmatcs Joint Form TwoDocumento11 pagineMathmatcs Joint Form TwoNurudi jumaNessuna valutazione finora

- 8 A - 1615864446 - 1605148379 - 1579835163 - Topic - 8.A.EffectiveSchoolsDocumento9 pagine8 A - 1615864446 - 1605148379 - 1579835163 - Topic - 8.A.EffectiveSchoolsYasodhara ArawwawelaNessuna valutazione finora

- Quotation of Suny PDFDocumento5 pagineQuotation of Suny PDFHaider KingNessuna valutazione finora

- Sample Learning Module As PatternDocumento23 pagineSample Learning Module As PatternWilliam BulliganNessuna valutazione finora

- Boom-Block Gambit: Redemption'S RiseDocumento44 pagineBoom-Block Gambit: Redemption'S RiseNone OfyourbuisnessNessuna valutazione finora

- Smart Door Lock System Using Face RecognitionDocumento5 pagineSmart Door Lock System Using Face RecognitionIJRASETPublicationsNessuna valutazione finora

- SilmaDocumento12 pagineSilmanobleconsultantsNessuna valutazione finora

- Information Systems and Supply Chain ManagementDocumento2 pagineInformation Systems and Supply Chain Managementvipinkandpal86Nessuna valutazione finora