Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Viscoelasticity - Rheological

Caricato da

saltyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Viscoelasticity - Rheological

Caricato da

saltyCopyright:

Formati disponibili

Section 10.

10.3 Rheological Models

In this section, a number of one-dimensional linear viscoelastic models are discussed.

10.3.1

Mechanical (rheological) models

The word viscoelastic is derived from the words "viscous" + "elastic"; a viscoelastic

material exhibits both viscous and elastic behaviour a bit like a fluid and a bit like a

solid. One can build up a model of linear viscoelasticity by considering combinations of

the linear elastic spring and the linear viscous dash-pot. These are known as rheological

models or mechanical models.

The Linear Elastic Spring

The constitutive equation for a material which responds as a linear elastic spring of

stiffness E is (see Fig. 10.3.1)

(10.3.1)

The response of this material to a creep-recovery test is to undergo an instantaneous

elastic strain upon loading, to maintain that strain so long as the load is applied, and then

to undergo an instantaneous de-straining upon removal of the load.

E

Figure 10.3.1: the linear elastic spring

The Linear Viscous Dash-pot

Imagine next a material which responds like a viscous dash-pot; the dash-pot is a pistoncylinder arrangement, filled with a viscous fluid, Fig. 10.3.2 a strain is achieved by

dragging the piston through the fluid. By definition, the dash-pot responds with a strainrate proportional to stress:

1

(10.3.2)

where is the viscosity of the material. This is the typical response of many fluids; the

larger the stress, the faster the straining (as can be seen by pushing your hand through

water at different speeds).

Solid Mechanics Part I

292

Kelly

Section 10.3

Figure 10.3.2: the linear dash-pot

The strain due to a suddenly applied load o may be obtained by integrating the

constitutive equation 10.3.2. Assuming zero initial strain, one has

o

t

(10.3.3)

The strain is seen to increase linearly and without bound so long as the stress is applied,

Fig. 10.3.3. Note that there is no movement of the dash-pot at the onset of load; it takes

time for the strain to build up. When the load is removed, there is no stress to move the

piston back through the fluid, so that any strain built up is permanent. The slope of the

creep-line is o / .

t

stress

applied

stress

removed

Figure 10.3.3: Creep-Recovery Response of the Dash-pot

The relationship between the stress and strain during the creep-test may be expressed in

the form

(t ) o J (t ), J (t )

(10.3.4)

J here is called the creep (compliance) function ( J 1 / E for the elastic spring).

10.3.2

The Maxwell Model

Consider next a spring and dash-pot in series, Fig. 10.3.4. This is the Maxwell model.

One can divide the total strain into one for the spring ( 1 ) and one for the dash-pot ( 2 ).

Solid Mechanics Part I

293

Kelly

Section 10.3

Equilibrium requires that the stress be the same in both elements. One thus has the

following three equations in four unknowns1:

1

,

E

2 ,

1 2

(10.3.5)

To eliminate 1 and 2 , differentiate the first and third equations, and put the first and

second into the third:

Maxwell Model

(10.3.6)

This constitutive equation has been put in what is known as standard form stress on

left, strain on right, increasing order of derivatives from left to right, and coefficient of

is 1.

Figure 10.3.4: the Maxwell Model

Creep-Recovery Response

Consider now a creep test. Physically, when the Maxwell model is subjected to a stress

0 , the spring will stretch immediately and the dash-pot will take time to react. Thus the

initial strain is (0) o / E . Using this as the initial condition, an integration of 10.3.6

(with a zero stress-rate2) leads to

1

If one considers an actual spring of length L1 and a dashpot of length L2 as in Fig. 10.3.4, and

corresponding elongations d1 and d2 due to strains 1 and 2, the total elongation would be

( Ls Ld ) s Ls d Ld , which is not quite the same as Eqn. 10.3.5c. It is best to think of the Maxwell

model as: the total strain at a material particle can be decomposed additively according to Eqn. 10.3.5c,

with the separate strains being linear elastic and viscous; Fig. 10.3.4 is simply an attempt to visualise this

concept.

2

there is a jump in stress from zero to o when the load is applied, implying an infinite stress-rate .

One is not really interested in this jump here because the corresponding jump in strain can be predicted

from the physical response of the spring. One is more interested in what happens just "after" the load is

applied. In that sense, when one speaks of initial strains and stress-rates, one means their values at 0 , just

after t 0 ; the stress-rate is zero from 0 on. To be more precise, one can deal with the sudden jump in

stress by integrating the constitutive equation across the point t 0 as follows:

( E / ) (t ) dt (t ) dt E (t ) dt

( E / ) (t ) dt ( ) ( ) E ( ) ( )

In the limit as 0 , the integral tends to zero ( is finite), the values of stress and strain at 0 , i.e. in

the limit as 0 from the left, are zero. All that remains are the values to the right, giving

Solid Mechanics Part I

294

Kelly

Section 10.3

(t )

o

t C

(10.3.7)

1

1

(t ) o t

E

The creep-response can again be expressed in terms of a creep compliance function:

(t ) o J (t ) where J (t )

1

E

(10.3.8)

When the load is removed, the spring again reacts immediately, but the dash-pot has no

tendency to recover. Hence there is an immediate elastic recovery o / E , with the creep

strain due to the dash-pot remaining. The full creep and recovery response is shown in

Fig. 10.3.5.

The Maxwell model predicts creep, but not of the ever-decreasing strain-rate type. There

is no anelastic recovery, but there is the elastic response and a permanent strain.

0

E

0

E

stress

applied

t

stress

removed

Figure 10.3.5: Creep-Recovery Response of the Maxwell Model

Stress Relaxation

In the stress relaxation test, the material is subjected to a constant strain 0 at t 0 . The

Maxwell model then leads to {Problem 1}

(t ) o E (t ) where E (t ) Ee t / t , t R

R

(10.3.9)

Analogous to the creep function J for the creep test, E (t ) is called the relaxation

modulus function.

(0 ) E (0 ) , as expected. One can deal with this sudden behaviour more easily using integral

formulations or with the Laplace Transform (see 10.4, 10.5)

Solid Mechanics Part I

295

Kelly

Section 10.3

The parameter t R is called the relaxation time of the material and is a measure of the

time taken for the stress to relax; the shorter the relaxation time, the more rapid the stress

relaxation.

10.3.3

The Kelvin (Voigt) Model

Consider next the other two-element model, the Kelvin (or Voigt) model, which consists

of a spring and dash-pot in parallel, Fig. 10.3.6. It is assumed there is no bending in this

type of parallel arrangement, so that the strain experienced by the spring is the same as

that experienced by the dash-pot. This time,

1

1

1 , 2 , 1 2

E

(10.3.10)

where 1 is the stress in the spring and 2 is the dash-pot stress. Eliminating 1 , 2

leaves the constitutive law

Kelvin (Voigt) Model

(10.3.11)

E

1

Figure 10.3.6: the Kelvin (Voigt) Model

Creep-Recovery Response

If a load 0 is applied suddenly to the Kelvin model, the spring will want to stretch, but

is held back by the dash-pot, which cannot react immediately. Since the spring does not

change length, the stress is initially taken up by the dash-pot. The creep curve thus starts

with an initial slope o / .

Some strain then occurs and so some of the stress is transferred from the dash-pot to the

spring. The slope of the creep curve is now 2 / , where 2 is the stress in the dashpot, with 2 ever-decreasing. In the limit when 2 0 , the spring takes all the stress

and thus the maximum strain is o / E .

Solving the first order non-homogeneous differential equation 10.3.11 with the initial

condition (0) 0 gives

Solid Mechanics Part I

296

Kelly

Section 10.3

(t )

o

E

1 e

( E / )t

(10.3.12)

which agrees with the above physical reasoning; the creep compliance function is now

J (t )

1 e t / t R , t R

E

E

(10.3.13)

The parameter t R , in contrast to the relaxation time of the Maxwell model, is here called

the retardation time of the material and is a measure of the time taken for the creep

strain to accumulate; the shorter the retardation time, the more rapid the creep straining.

When the Kelvin model is unloaded, the spring will want to contract but again the dash

pot will hold it back. The spring will however eventually pull the dash-pot back to its

original zero position given time and full recovery occurs.

Suppose the material is unloaded at time t . The constitutive law, with zero stress,

reduces to 0 E . Solving leads to

(t ) Ce ( E / )t

(10.3.14)

where C is a constant of integration. The t here is measured from the point where "zero

load" begins. If one wants to measure time from the onset of load, t must be replaced

with t . From Eqn. 10.3.12, the strain at t is ( ) ( o / E ) 1 e ( E / ) . Using

this as the initial condition, one finds that

(t )

o

E

e ( E / ) t e( E / ) 1 , t

(10.3.15)

The creep and recovery response is shown in Fig. 10.3.7. There is a transient-type creep

and anelastic recovery, but no instantaneous or permanent strain.

stress

applied

stress

removed

Figure 10.3.7: Creep-Recovery Response of the Kelvin (Voigt) Model

Solid Mechanics Part I

297

Kelly

Section 10.3

Stress Relaxation

Consider next a stress-relaxation test. Setting the strain to be a constant 0 , the

constitutive law 10.3.11 reduces to E 0 . Thus the stress is taken up by the spring

and is constant, so there is in fact no stress relaxation over time. Actually, in order that

the Kelvin model undergoes an instantaneous strain of 0 , an infinite stress needs to be

applied, since the dash-pot will not respond instantaneously to a finite stress3.

10.3.4

Three Element Models

The Maxwell and Kelvin models are the simplest viscoelastic models. More realistic

material responses can be modelled using more elements. The four possible threeelement models are shown in Fig. 10.3.8 below. The models of Fig. 10.3.8a-b are

referred to as solids since they react instantaneously as elastic materials and recover

completely upon unloading. The models of Figs. 10.3.8c-d are referred to as fluids

since they involve dashpots at the initial loading phase and do not recover upon

unloading.

The differential constitutive relations for the Maxwell and Kelvin models were not to

difficult to derive. However, even with three elements, deriving them can be a difficult

task. This is because one needs to eliminate variables from a set of equations, one or

more of which is a differential equation (for example, see 10.3.5). The task is more easily

accomplished using integral formulations and the Laplace transform, which are discussed

in 10.4-10.5.

Only results are given here: the constitutive relations for the four models shown in Fig.

10.3.8 are

(a)

(b)

E1 E 2

E2

E1

E1 E 2

E1 E 2

E1 E 2

E1

(c)

(d)

1 2

E1 E 2

E2

1 2

E

1 2

E

1 2

E

(10.3.16)

The response of these models can be determined by specifying stress (strain) and solving

the differential equations 10.3.16 for strain (stress).

the stress required is (0) 0 (t ) , where (t ) is the Dirac delta function (this can be determined

using the integral representations of 10.4)

Solid Mechanics Part I

298

Kelly

Section 10.3

E ( 2)

E (1)

(a)

E (1)

(b)

(2)

1

(c)

2

E

(d)

Figure 10.3.8: Three-element Models: (a) Standard Solid I, (b) Standard Solid II, (c)

Standard Fluid I, (d) Standard Fluid II

10.3.5

The Creep Compliance and the Relaxation Modulus

The creep compliance function and the relaxation modulus have been mentioned in the

context of the two-element models discussed above. More generally, they are defined as

follows: the creep compliance is the strain due to unit stress:

(t ) o J (t ),

(t ) J (t ) when o 1

Creep Compliance

(10.3.17)

Relaxation Modulus

(10.3.18)

The relaxation modulus is the stress due to unit strain:

(t ) o E (t ),

(t ) E (t ) when o 1

Whereas the creep function describes the response of a material to a creep test, the

relaxation modulus describes the response to a stress-relaxation test.

Solid Mechanics Part I

299

Kelly

Section 10.3

10.3.6

Generalized Models

More complex models can be constructed by using more and more elements. A complex

viscoelastic rheological model will usually be of the form of the generalized Maxwell

model or the generalized Kelvin chain, shown in Fig. 10.3.9. The generalized Maxwell

model consists of N different Maxwell units in parallel, each unit with different

parameter values. The absence of the isolated spring would ensure fluid-type behaviour,

whereas the absence of the isolated dash-pot would ensure an instantaneous response.

The generalised Kelvin chain consists of a chain of Kelvin units and again the isolated

spring may be omitted if a fluid-type response is required.

In general, the more elements one has, the more accurate a model will be in describing the

response of real materials. That said, the more complex the model, the more material

parameters there are which need to be evaluated by experiment the determination of a

large number of material parameters might be a difficult, if not an impossible, task.

Generalized

Maxwell Model

E1

EN

Generalized

Kelvin Chain

E1

EN

Figure 10.3.9: Generalised Viscoelastic Models

In general, a linear viscoelastic constitutive equation will be of the general form

p o p1 p 2 p3 p 4 ( IV ) q o q1 q 2 q3 q 4 ( IV )

(10.3.19)

Solid Mechanics Part I

300

Kelly

Section 10.3

The more elements (springs/dashpots) one uses, the higher the order of the differential

equation.

Eqn. 10.3.19 is sometimes written in the short-hand notation

P Q

(10.3.20)

where P and Q are the linear differential operators

i

P pi i ,

t

i 0

n

i

Q qi i

t

i 0

n

(10.3.21)

A viscoelastic model can be created by simply entering values for the coefficients pi , qi ,

in 10.3.19, without referring to any particular rheological spring dashpot arrangement.

In that sense, springs and dashpots are not necessary for a model, all one needs is a

differential equation of the form 10.3.19. However, the use of springs and dashpots is

helpful as it gives one a physical feel for the way a material might respond, rather than

simply using an abstract mathematical expression such as 10.3.19.

10.3.7

Non-Linear Models

More realistic material responses can be achieved by using non-linear models. For

example, the springs of the previous section can be replaced with more general non-linear

stress-strain relations of the form:

E n

(10.3.22)

Various non-linear expressions for dash-pots can also be used, for example,

A n,

Ae /

0

(10.3.23)

Material data will certainly be better matched by such non-linear expressions; however,

of course, they will result in non-linear differential equations which will be more difficult

to solve than their linear counterparts.

10.3.8

Problems

1. Derive the Relaxation Modulus E (t ) for the Maxwell material.

2. What are the values of the coefficients pi , qi in the general differential equation

10.3.19 for

(a) the Maxwell model and the Kelvin model?

(b) The three-element models

Solid Mechanics Part I

301

Kelly

Potrebbero piacerti anche

- 10 Viscoelasticity 03 RheologicalDocumento13 pagine10 Viscoelasticity 03 RheologicalAvinash KawaleNessuna valutazione finora

- Rheological Models Explained in 10.3 SectionDocumento10 pagineRheological Models Explained in 10.3 SectionJuan Pablo EspinosaNessuna valutazione finora

- 10 Viscoelasticity 03 RheologicalDocumento13 pagine10 Viscoelasticity 03 RheologicalSaif LlNessuna valutazione finora

- Viscoelastic Behavior of Polymers PDFDocumento9 pagineViscoelastic Behavior of Polymers PDFchiuchan888Nessuna valutazione finora

- Chap. 6 MSMBM Design Sem IDocumento95 pagineChap. 6 MSMBM Design Sem IPrafulla PatilNessuna valutazione finora

- Rheological ModelsDocumento14 pagineRheological ModelsCHEENIE MAE SAGUNNessuna valutazione finora

- Viscoelastic hereditary integralsDocumento12 pagineViscoelastic hereditary integralsletter_ashish4444Nessuna valutazione finora

- ViscoelasticityDocumento11 pagineViscoelasticitymchilwesaNessuna valutazione finora

- Tschoegl1989 Chapter EnergyStorageAndDissipationInADocumento46 pagineTschoegl1989 Chapter EnergyStorageAndDissipationInAchopin.wlive.cnNessuna valutazione finora

- Dynamics of Structures and Soils: Deterministic Structural Dynamics. Random Stochastic or Random Structural DynamicsDocumento11 pagineDynamics of Structures and Soils: Deterministic Structural Dynamics. Random Stochastic or Random Structural Dynamicspanos2244662864Nessuna valutazione finora

- 15 ViscoelasticityDocumento30 pagine15 ViscoelasticityaderancNessuna valutazione finora

- Lecture 20Documento14 pagineLecture 20Martha Isabel SernaNessuna valutazione finora

- Tensors, Stress, Strain, ElasticityDocumento10 pagineTensors, Stress, Strain, ElasticitySiti Cweety MarryNessuna valutazione finora

- Theories of Elastic FailureDocumento15 pagineTheories of Elastic FailurejaishowNessuna valutazione finora

- CH 10Documento36 pagineCH 10LeonardoMadeira11100% (1)

- Maxwell ModelDocumento20 pagineMaxwell ModelJasleen Kaur HoraNessuna valutazione finora

- Eyring Equation PDFDocumento7 pagineEyring Equation PDFRana AnasNessuna valutazione finora

- Hysteretic Damping and ModelsDocumento12 pagineHysteretic Damping and ModelsnoussnoussaNessuna valutazione finora

- Creep DescriptionDocumento11 pagineCreep DescriptionGerry AnandaNessuna valutazione finora

- Drying Creep of Concrete in Terms of Age-Adjusted Effective Modulus MethodDocumento12 pagineDrying Creep of Concrete in Terms of Age-Adjusted Effective Modulus MethodDaniela Mihaiela BocaNessuna valutazione finora

- Generalized Maxwell ModelDocumento10 pagineGeneralized Maxwell Modelsalkan_rahmanovic810Nessuna valutazione finora

- Mechanics of Solids (MET-251) Columns & Struts notes (40Documento17 pagineMechanics of Solids (MET-251) Columns & Struts notes (40Gurpreet SinghNessuna valutazione finora

- Deformation, Stress, and Conservation Laws: I U U XDocumento31 pagineDeformation, Stress, and Conservation Laws: I U U XFelipe Carrasco DuránNessuna valutazione finora

- Articulo - Pendulo SimpleDocumento10 pagineArticulo - Pendulo SimpleeulalioaguilarNessuna valutazione finora

- Introducton To ThermodynamicsDocumento7 pagineIntroducton To Thermodynamicsdesi_parisNessuna valutazione finora

- Viscoelasticity: ReferencesDocumento21 pagineViscoelasticity: Referencesletter_ashish4444Nessuna valutazione finora

- Tensor Transformation FormulaeDocumento5 pagineTensor Transformation FormulaeAryce_Nessuna valutazione finora

- Experiment # 1: ObjectiveDocumento5 pagineExperiment # 1: ObjectiveHurair Tariq FOE-PermanentNessuna valutazione finora

- Stability of StructuresDocumento83 pagineStability of StructuresmchilwesaNessuna valutazione finora

- Elastic Stability of ColumnsDocumento11 pagineElastic Stability of ColumnsSayantan GhosalNessuna valutazione finora

- Polymer Mass: Principles of Product DesignDocumento27 paginePolymer Mass: Principles of Product DesignOladimeji AlabiNessuna valutazione finora

- Beam DeflectionDocumento14 pagineBeam DeflectionPrudvi Krishna MaladiNessuna valutazione finora

- Free Vibration of ParticlesDocumento19 pagineFree Vibration of ParticlesDavid AmachreeNessuna valutazione finora

- TP N°2 - Extracto CEB-FIP Model Code 1990Documento6 pagineTP N°2 - Extracto CEB-FIP Model Code 1990rlorefice6559Nessuna valutazione finora

- Sujets Physique SIS09 enDocumento6 pagineSujets Physique SIS09 enKlevis KasoNessuna valutazione finora

- 34 3 RSTD MotnDocumento9 pagine34 3 RSTD MotnEbookcrazeNessuna valutazione finora

- s11043-010-9122-9Documento11 pagines11043-010-9122-9Nam Huu TranNessuna valutazione finora

- Reference BooksDocumento23 pagineReference BooksIgor Gabriel Teixeira GómezNessuna valutazione finora

- CH10Documento39 pagineCH10Ajay Kumar SreeramaNessuna valutazione finora

- Couette FlowDocumento5 pagineCouette Flowphutd09100% (1)

- The Wave EquationDocumento34 pagineThe Wave EquationStephanie HaynesNessuna valutazione finora

- Chapter 8. Entropy: P P M ADocumento6 pagineChapter 8. Entropy: P P M AmarzinusNessuna valutazione finora

- Mechanics 3 Revision NotesDocumento45 pagineMechanics 3 Revision NotesDexter FungNessuna valutazione finora

- MIT2 080JF13 Lecture10Documento16 pagineMIT2 080JF13 Lecture10LeonardoMadeira11Nessuna valutazione finora

- M Aterial Subjected To Combine D Direct and Shear StressesDocumento4 pagineM Aterial Subjected To Combine D Direct and Shear Stressespmm05479Nessuna valutazione finora

- Design of Diagonal Cross Bracings - Part 1 Theoretical Study PDFDocumento5 pagineDesign of Diagonal Cross Bracings - Part 1 Theoretical Study PDFaapennsylvaniaNessuna valutazione finora

- Creep Behavior and Stress Relaxation Models for Advanced Mechanics of SolidsDocumento28 pagineCreep Behavior and Stress Relaxation Models for Advanced Mechanics of SolidsAbdul RahimNessuna valutazione finora

- 5.6 Unforced Mechanical Vibrations: Simple Harmonic MotionDocumento8 pagine5.6 Unforced Mechanical Vibrations: Simple Harmonic MotionHaridev MoorthyNessuna valutazione finora

- Mathematical modelling of skydivingDocumento14 pagineMathematical modelling of skydivingvarun varma100% (1)

- Subject: Arch315-Strength of MaterialsDocumento15 pagineSubject: Arch315-Strength of MaterialsAlyssa MadelNessuna valutazione finora

- Notes On Mechanical Vibrations: 1 Masses and Springs-The Linear OscillatorDocumento10 pagineNotes On Mechanical Vibrations: 1 Masses and Springs-The Linear Oscillatoramlandas08Nessuna valutazione finora

- Applications of Second ODEDocumento24 pagineApplications of Second ODEMuhammad Zariff 'Izzat Mohd Faudzi100% (1)

- Townsend, Quantum Physics, CHAP - 3, Schodinger EqDocumento24 pagineTownsend, Quantum Physics, CHAP - 3, Schodinger EqElcan DiogenesNessuna valutazione finora

- Beams and Framed Structures: Structures and Solid Body MechanicsDa EverandBeams and Framed Structures: Structures and Solid Body MechanicsValutazione: 3 su 5 stelle3/5 (2)

- Heat: The Nature of Temperature and Most Other PhysicsDa EverandHeat: The Nature of Temperature and Most Other PhysicsNessuna valutazione finora

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsDa EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsNessuna valutazione finora

- A Complete Course in Physics ( Graphs ) - First EditionDa EverandA Complete Course in Physics ( Graphs ) - First EditionNessuna valutazione finora

- Desmorat R Damage and FatigueDocumento95 pagineDesmorat R Damage and FatiguesaltyNessuna valutazione finora

- Energy Conversion and Management: Mohamed Lachheb, Mustapha Karkri, Fethi Albouchi, Foued Mzali, Sassi Ben NasrallahDocumento9 pagineEnergy Conversion and Management: Mohamed Lachheb, Mustapha Karkri, Fethi Albouchi, Foued Mzali, Sassi Ben NasrallahsaltyNessuna valutazione finora

- Applied Mathematical Modelling: X.T. Xiong, W.X. Shi, Y.C. HonDocumento15 pagineApplied Mathematical Modelling: X.T. Xiong, W.X. Shi, Y.C. HonsaltyNessuna valutazione finora

- Analysis of a cantilever beam with ABAQUSDocumento15 pagineAnalysis of a cantilever beam with ABAQUSsaltyNessuna valutazione finora

- Final ProjDocumento18 pagineFinal ProjsaltyNessuna valutazione finora

- JKR 2012 SITE INVESTIGATION SCHEDULE OF RATESDocumento0 pagineJKR 2012 SITE INVESTIGATION SCHEDULE OF RATESAjoy Zulfadhli0% (1)

- St. Mary's College Sta. Maria Ilocos Sur Inc.: ..Goodluck and GodblessDocumento6 pagineSt. Mary's College Sta. Maria Ilocos Sur Inc.: ..Goodluck and GodblessUrsula Sison Reyes DolorNessuna valutazione finora

- High-Performance Cold Work Tool Steel K110Documento2 pagineHigh-Performance Cold Work Tool Steel K110Greg SanjayaNessuna valutazione finora

- Geyser Mounting Horizontal Vs VerticalDocumento1 paginaGeyser Mounting Horizontal Vs VerticalRussell Collett0% (1)

- Computational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaDocumento7 pagineComputational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaAravind KumarNessuna valutazione finora

- Bernt - EC3 1 5Documento44 pagineBernt - EC3 1 5Rosario BlancaNessuna valutazione finora

- Singapore National Annexure To Eurocode 8 PDFDocumento21 pagineSingapore National Annexure To Eurocode 8 PDFPankaj MunjalNessuna valutazione finora

- Advanced Fluid MechanicsDocumento154 pagineAdvanced Fluid MechanicsMohammad irfanNessuna valutazione finora

- Torsion of A Circular Cylinder - f06 - RevisedDocumento24 pagineTorsion of A Circular Cylinder - f06 - RevisedCrystal WoodwardNessuna valutazione finora

- Offer Legrand SandwichBBT BMTC EV 02.04.2022Documento1 paginaOffer Legrand SandwichBBT BMTC EV 02.04.2022Darshit VyasNessuna valutazione finora

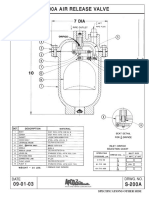

- APCO. S-200a Air Release ValveDocumento2 pagineAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- HVAC Systems Duct DesignDocumento39 pagineHVAC Systems Duct Designsardarmkhan100% (2)

- 5.01 Cold Water Plumbing Cold Water Pipe Sizing Testing and Commissioning PDFDocumento4 pagine5.01 Cold Water Plumbing Cold Water Pipe Sizing Testing and Commissioning PDFrhomadonaNessuna valutazione finora

- AWS90 Structural Nonlin Ch02 NonlinearDocumento94 pagineAWS90 Structural Nonlin Ch02 NonlinearVictor SanchezNessuna valutazione finora

- 3 Quarterly Exam: Eim 7 ExploratoryDocumento3 pagine3 Quarterly Exam: Eim 7 ExploratoryJulcon Avanceña Araiz100% (1)

- Causeway BOQDocumento7 pagineCauseway BOQSujan GhimireNessuna valutazione finora

- Almansoori Inspection Services: Travelling Block AssemblyDocumento2 pagineAlmansoori Inspection Services: Travelling Block AssemblyRanjithNessuna valutazione finora

- Reality Lighting 2022 灯饰目录Documento277 pagineReality Lighting 2022 灯饰目录qq1691492197Nessuna valutazione finora

- Lecture 1Documento24 pagineLecture 1SaurabhNessuna valutazione finora

- Overtime AccomplishmentDocumento9 pagineOvertime AccomplishmentKate PerezNessuna valutazione finora

- Astm A 403 / A 403M - 06Documento7 pagineAstm A 403 / A 403M - 06negg 348100% (1)

- Ansi b36.10 Seamless Pipe SizesDocumento2 pagineAnsi b36.10 Seamless Pipe SizesmohitNessuna valutazione finora

- Tricocat PDFDocumento44 pagineTricocat PDFJuan PabloNessuna valutazione finora

- 2000 IBC Handbook Seismic & WindDocumento11 pagine2000 IBC Handbook Seismic & WindcristinelbNessuna valutazione finora

- ACI 350 CalculationDocumento3 pagineACI 350 CalculationBoris GalindoNessuna valutazione finora

- 1 - Introduction To AggregateDocumento22 pagine1 - Introduction To AggregateFatin HazwaniNessuna valutazione finora

- SG653PB1 ADocumento5 pagineSG653PB1 ADANILO MEDINA OSORIONessuna valutazione finora

- Large-Scale Direct Shear Testing of Geocell Reinforced SoilDocumento6 pagineLarge-Scale Direct Shear Testing of Geocell Reinforced SoilnarutowhatsupNessuna valutazione finora

- Rolling ProcessDocumento17 pagineRolling ProcessRavichandran GNessuna valutazione finora