Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

NEW 1 of 56: Saudi Aramco Oil Company (Saudi Aramco) Yanbu Refinery Instruction Manual

Caricato da

maniTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

NEW 1 of 56: Saudi Aramco Oil Company (Saudi Aramco) Yanbu Refinery Instruction Manual

Caricato da

maniCopyright:

Formati disponibili

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

YRIM No.: 1156.00

Revision No.: 00

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

1 of 56

Saudi Aramco Loss Prevention Policy

Saudi Aramco will conduct its business in a manner which prevents incidents or accidents which cause

loss of life, bodily injury or illness, or damage to property, assets or the environment. As reflected in

Saudi Aramcos Corporate Values, the Company will continuously maintain the highest standards of

safety, security, health and environmental protection. Accordingly, the Company will:

Advise all employees and contractors of their loss prevention responsibilities and regularly

measure their performance;

Evaluate, identify and eliminate or manage safety risks prior to beginning any operation or activity

and continue to review such risks, complying with all applicable laws and regulations;

Communicate loss prevention objectives and procedures regularly to employees and all affected

parties;

Train employees and provide resources to maintain job competencies, including loss prevention

responsibility and accountability;

Design and construct Company facilities utilizing recognized best technology and practices to

safeguard property and people;

Operate and maintain Company facilities to assure safe operations;

Require that contractors, suppliers and others adhere to the Companys loss prevention policies,

procedures and goals;

Prepare for emergencies and other contingencies and respond promptly and effectively to any

incidents or accidents resulting from operations;

Report all incidents, review performance and communicate progress;

Promote off-the-job safety and community awareness, and

Review and improve the Companys loss prevention program and performance continuously.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

1.

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

2 of 56

Purpose & Objective

The objective of this process is to ensure compliance with all established company

inspection procedures/programs and maintain required level of asset integrity throughout

Yanbu Refinery facilities.

2. Owner or Champion: YRD Engineering Inspection unit is the owner of these

programs.

3.

Applicability

This comprehensive inspection document contains several inspection procedures/programs

which are applicable to YRD facilities.

4. Corporate Expectations: YRD follows all the guidelines as outlined in SMS Manual

Refer to YRD SMS website.

5.

Process Description

The main objective of this comprehensive inspection programs is to enable YRD inspection

team to comply with all corporate requirement for assets integrity and to highlight

deficiencies observed that require repair or action necessary to prevent further damage to

the equipment. Also this document specifies the responsibilities of all YRD personnel

pertaining to assets integrity. The area inspector shall use this document as a supplement to

the plant inspection index (00-SAIP-71). This document includes a section for each

inspection procedure/program which will include a brief description of the

procedure/program, a list of the related standards and engineering/inspection procedures, a

table which specifies the responsibilities and the required documentations and where it will

be filed.

6.

Responsibilities

a) YRD Inspection Unit Supervisor owns the overall responsibility for implementing the

periodic inspections at Yanbu Refinery facilities

b) YRD Inspection Unit Field Supervisor shall provide qualified inspection personnel to

conduct the inspection activities including tests. The Inspector will examine the system

during the inspection/test and issue a necessary test report per established

procedures after successful completion of each inspection/test. The inspection results

shall be retained as a record in the Inspection Filing System.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

3 of 56

c) The refinery Operation Foreman is responsible to ensure that all required inspection

programs are conducted in his plant limit as per inspection schedules.

d) The Supervising Operator of each unit shall be responsible to ensure that all proper

work permits have been issued.

e) The Area Maintenance/T&I engineer shall be responsible for providing the necessary

manpower and equipment (crane, man lift, scaffolding, etc) to perform the required

inspection activities and to rectify deficiencies.

f) The Area Process Engineer shall be responsible for preparing and distributing the

required procedures (hydrotest procedures, leak test, shutdown, start up etc) as

required to assist in conducting the inspection activities in accordance with relevant

company standard, or YRD internal procedures.

g) The detail responsibilities of all inspection programs are listed under in each program

7.

Training & Competency

YRD Engineering Inspection Unit shall provide required functional training to meet the

competencies required for conducting inspection activities per company established guidelines

and programs. YRD Inspection Unit is following the corporate training requirements to certify YRD

inspectors and all required courses and exams shall be fulfilled prior to certifying the inspectors.

8.

Documentation

The Engineering Inspection Unit shall complete, issue and distribute the inspection reports

including test information sheets per relevant Saudi Aramco inspection procedures to the

area Operations Foreman and area OME team. Records of all tests shall be maintained by

YRD Inspection Unit as will be detailed in the documents for each inspection

procedures/programs.

9.

References

All relevant references are indicated under each Procedure/Program in this document.

YRD SMS: Inspection Programs

NEW

Saudi Aramco:

[ X ] New Instruction

ELEMENT 5 ASSET INTEGRITY

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

10.

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

4 of 56

YRD List of Inspection Programs:

1- Relief valve installation, inspection and testing:

Refer to SMS # 5. (YRD E5 07) for more details.

2- Internal Inspection of Equipments (T&I) :

Procedure/Program Description

Internal inspection of all static equipments such as columns, vessels, drums, storage tanks,

heat exchangers, reboilers and boilers are conducted by visually inspecting them and by

using Non-Destructive Testing methods such as Magnetic Particle Testing, Dye Penetration

Testing and Radiography Testing for all internal welds, heat affected zone and base metals,

all attachment welds and nozzles. The internal inspection should also cover the internal

coating, refractory material and the mechanical integrity of the internal elements such as

trays and packing. In the other hand, the chemical material inside the vessels (Desiccant,

Sieve, catalyst, etc) should be inspected by the area process engineer and area operation

supervisor.

The final box up of static equipment in YRD is carried out as per the applicable SAESs and

SAEPs. The project inspector will perform the internal inspection for the static equipments

which are built by PMT along with YRD inspector. During T&I and up on request, YRD

inspector will perform the internal inspection of static equipments prior to signing the final

closure certificate. Deficiencies shall be reported to PMT/ YRD Maintenance to rectify prior to

signing the final closure certificate.

Referenced Standards/Procedures

SAEP-306 Assessment

SAEP-317 Testing & Inspection of Shell & Tube Exchangers

SAEP-325 Inspection

SAEP-1141

Industrial Radiation Safety

SAEP-1143

Radiographic Examination

SAEP-1144

Magnetic particle examination of welds and components

SAEP-1145

Liquid penetrant examination of weld and components

Saudi Aramco:

of the remaining strength of corroded pipes

requirements for pressurized equipment

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

YRIM No.: 1156.00

Revision No.: 00

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

NEW

Approved

Engineering Inspection Unit

SAEP-1146

SAEP-343 Risk Based Inspection (RBI) for In-Plant Static Equipment and piping.

00-SAIP-80

Guidelines for Process Equipment Inspection

32-SAIP-11

Inspection of Air cooled Exchangers

01-SAIP-02

Retirement thickness of In-plant Piping

SAES-C-001

SAES-D-001

Process Design of Trays and Packing

Design Criteria for Pressure Vessels

SAES-D-109

Design of Small Tanks

SAES-E-004

Design Criteria of Shell and Tube Heat Exchangers

SAES-E-007

Design Criteria of Air-Cooled Heat Exchangers

SAES-F-007

System Design Criteria of Flares

SAES-H-001

Selection Requirements for Industrial Coatings

SAES-N-110

Installation Requirements Castable Refractories

Saudi Aramco:

Page No.

5 of 56

API 510

Replaces

Manual Ultrasonic thickness testing

Pressure Vessel Inspection Code

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

6 of 56

Responsibilities:

Activities

Assigned to

Inspection

PMT/PID

Activities during

construction

period

Remark

Project inspector shall perform the following activities:

Inspects the static equipment during receiving and storing in

the yard.

Inspects the static equipment during installation.

Inspects the alignment of static equipment.

Inspects the static equipment for internal installation.

Inspects and witness the hydrotest and lay up of static

equipment if required.

PMT

PMT/PID/PROPONENT inspects the static equipment for final boxPID inspector up and signs the final box-up certification.

YRD inspector

Inspection

Activities(during

T&I and up on

request)

Area

inspector

Include performing the required NDT test and witnessing

hydrotest and leak test. Additional inspectors will be assigned as

needed to assist the area inspector during T&I

Maintenance

Activates

T&I engineer

Include providing the necessary manpower and equipment (crane,

man lift, scaffolding, etc) to perform the required T&I activities

Work Permit

Area

operation

supervisor

Include providing the necessary work permit and initiating

deviation letter to postpone the T&I.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Replaces

NEW

Engineering Inspection Unit

Procedures

(hydrotest, leak

test, shutdown,

start-up etc)

YRIM No.: 1156.00

Revision No.: 00

Approved

Page No.

7 of 56

Area process Prepare and distribute the required procedures if required

engineer

to assist in conducting the T&I in accordance with relevant

company standard, or YRD internal procedures

Inspect chemical Area process Inspect the internal chemical material (Desiccant, Sieve,

material

engineer /

Catalyst, etc) and provide the required specification if

Operation

replacement is needed.

supervisor

Documentations:

1. Approved SIS, Drawings, P&ID, SAIC and final box up certification

2. Pre-T&I Report Issued by the area inspector

3. Inspection Recommendations Issued by the area inspector

4. Post T&I Report Issued by the area inspector

5. Deviation Letter to postpone the scheduled T&I initiated by operation.

The area inspector shall document the above documentations in:

1. Equipment file

2. Equipment file in the shared folder

3. Update the SAIF program if required

3- External mechanical Inspection of Equipment, piping and components:

Procedure/Program Description:

External visual inspection of all mechanical equipments, piping and their components are

carried out as per the Inspection Schedule established as per the guidelines indicated in

SAEP-20 which specifies 24 months interval for onshore areas.

Referenced Standards/Procedures

00-SAIP-75

Saudi Aramco:

External Visual Inspection Procedure

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

8 of 56

SAEP-20 Equipment Inspection Schedule

Responsibilities:

Activities

Assigned

to

Remark

Inspection Inspection

Activities Unit

Supervisor

Area

inspector

Assigns inspector(s) to carry out external inspection of all YRD

facilities.

Ensure inspection worksheet(s) are issued to rectify deficiencies

reported in

the external inspection.

Ensure that all equipment within his area of responsibility is listed in the EIS

specifying inspection intervals as required by SAEP-20. A schedule of

twoyear external inspections shall be made available and is updated

regularly.

Perform two-year external inspection of all existing equipment within his

area listed in the approved EIS with the corresponding checklist(s);

per

attachments of 00-SAIP-75. Complete individual checklist for

pressure

equipment per SAEP-20, paragraph 5.5.8. Use the 00-SAIP-75 checklists

as

references only when inspecting piping if not individually listed in the

EIS.

Inspection of civil structure will be inspected (every two-year) by

the

assigned civil inspector while electrical equipment will be

inspected

(annually) by the assigned electrical inspector.

Prepare a detailed on-stream inspection report of the present condition

of

the equipment highlighting the deficiencies observed that require

repair or

action necessary to prevent further damage to the equipment and

issue

IWS or LBE if required.

Request engineering evaluation if deemed necessary.

Maintenan Maintena

Saudi Aramco:

Update the SAIF program

Include providing the necessary manpower and equipment (crane, man

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Replaces

NEW

Engineering Inspection Unit

ce

YRIM No.: 1156.00

Revision No.: 00

Approved

Page No.

9 of 56

lift,

scaffolding, etc) to perform the required inspection activities and rectify

the

highlighted deficiencies.

Activates

nce

Engineer

Work

Permit

Include providing the necessary work permit and initiating deviation letter

Area

to

operation postpone the T&I.

supervisor

Documentations:

1. Completed external check list survey

2. Inspection Worksheet highlighting the Inspection Recommendations

The area inspector shall document the above documentations in Equipment file and

Inspection unit shared folder

4- Inspection of Spring Support:

Procedure/Program Description:

Inspection requirement for spring supports for pipes and equipment during routine visual external

inspection. Inspections of spring support are required as per 00-SAIP-75. Inspection is required

to examine all items related to Spring support such as I beam support, beam attachment pin,

hanger attachment, integrity of clamps, eye-bolts & hanger rod, spring coil & housing, Hot/cold

load positions marked on tap plate, spring coil fully compressed, coating & galvanizing, safety

hooks availability, davits & lifting lugs in good condition and spring identification. Test results are

reviewed and any defect found shall be sent to Area operation foreman to rectify.

Referenced Standards/Procedures

00-SAIP-75

Visual external inspection procedure

Responsibilities:

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Activities

Replaces

NEW

Engineering Inspection Unit

Assigned to

YRIM No.: 1156.00

Revision No.: 00

Approved

Page No.

10 of 56

Remark

Inspection

Projects Inspector

Activities during

construction

period

Assure that all spring supports for new project are working

Inspection

Activities

Include the following:

Area inspector

Carry visual external inspection on spring support every

two years.

Make sure all spring mechanism are working, all parts

are free of corrosion and free of any deficiency

Issue recommendation for replacement as needed

Work Permit

Area operation

supervisor

Include providing the necessary work permit and inform

Maintenance to start maintenance activities.

Maintenance

Activates

Maintenance

Technician

Include providing the necessary manpower and equipment

(crane, man lift, scaffolding, etc) to perform the required

inspection activities and rectify the highlighted deficiencies.

Documentations:

The area inspector shall document the above documentations in:

1. Equipment file

2. Equipment file in the shared folder

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

11 of 56

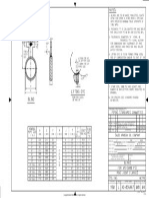

5- Inspection Of thermowell:

Procedure/Program Description:

Inspection is carried out on all thermowell that can be dismantled during plant T&I. Inspection

of all thermowells is conducted as per standard drawing AB-036019 and inspection results

are reviewed and any defect found shall be sent to Area operation foreman to rectify. All

results are recorded and filed along with the post-T&I reports.

Referenced Standards/Procedures

SAES-J-400

Temperature

SA-8020-418 Instrument Specification Sheet - Thermowell

AB-036019

CSD Technical Alert 05 issued on 5/17/1993

Thermowell Assembly and detailed

Responsibilities:

Activities

Inspection

Activities

during

construction

period

Saudi Aramco:

Assigned to

PMT & new

project design

reviewer

Remark

Assure that all thermowells are made of 316 SS. Other materials

shall be approved by CSD.

Assure the proper length of thermowell is installed.

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Inspection

Activities

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

12 of 56

Area inspector Include the following:

Inspect all thermowells in vibrating services. Thermowells

longer than 7.5 inches required more attention

Perform visual inspection thermowells for cracks scratch

Perform UT reading & PT on the thermowell during T&I

Issue recommendation for replacement if required.

Work Permit Area operation Include providing the necessary work permit

supervisor

maintenance to start maintenance activities.

Maintenance Maintenance

Activates

Technician

and

inform

Remove and re-install the thermowells which shall be marked prior

to removal. Make sure they are return to the same locations.

Documentations:

List of all thermowells inspected during each T&I. The area inspector shall file this documentation in:

1. Equipment file

2. Equipment file in the shared folder

6- Hydrostatic Testing for repaired

components Procedure/Program

Description:

Hydrostatic testing of equipment and piping is conducted after completing major repair,

renovation or alternation and replacement in kind of equipment and piping as per the

guideline given the following standards / procedures.

Referenced Standards/Procedures

SAES-A-004

General Requirements for Pressure Testing

SAES-L-150

Pressure Testing of Plant Piping and Pipelines

00-SAIP-06

Pressure Test Requirements

GI-0002.102

Pressure Testing Safely

ASME B31.1

Saudi Aramco:

Power Piping

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

13 of 56

ASME B31.3 Process Piping

ASME SEC VIII D1 & 2 Boilers and Pressure Vessel Code

NB 23

National Board of Inspection Code

Responsibilities:

Assigned

Activities

to

Inspection

Activities

Area

inspector

Remark

Include the following:

Request and witness pressure testing for all equipments/lines which

undergo a repair or alteration that affect the equipments/lines

integrity. The test shall be as per SAES-L-150 and in accordance with

the fabrication code. As a guideline for boiler hydrotest during T&I or

repair work, request and witness pressure test as per boiler data

sheet. For major repair, the pressure test shall be 1.3 X-DP. If no

repair was done, the test shall be up to the DP. This test is required to

check tube integrity. For shell and tube heat exchanger, request and

witness hydrotest for the shell and another hydrotest for the tube

after each T&I and before the exchanger is turn to operation.

The

tests shall be as per equipment data sheet and fabrication code.

Test media shall be approved by standards. Pneumatic test may be

subtitled if water cant be used provided that an approval from

inspection department and loss prevention is granted.

A hydrotest report shall be issued and filed in the equipment file for

each pressure test.

Area

Procedures process

(hydrotest, engineer

shutdown,

start-up

etc)

Work

Permit

Saudi Aramco:

Area

Prepare and distribute the hydrotest procedures to assist in

conducting the hydrotest in accordance with relevant company

standard, or YRD internal procedures

Include providing the necessary work permit and inform maintenance to

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

YRIM No.: 1156.00

Revision No.: 00

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

NEW

Approved

Engineering Inspection Unit

operation

supervisor

Replaces

Page No.

14 of 56

start maintenance activities.

Maintenanc Maintenanc Provide the necessary manpower and equipment to perform

e

e

the

Activates

engineer

required hydrotest. The maintenance crew shall be aware of GI

requirement and well trained to perform the hydrotest.

Documentations:

Pressure test report for each pressure test which shall be filed in the:

1. Equipment file

2. Equipment file in the shared folder

3. Update the SAIF program if required

7- Planning and Scheduling of Equipment Inspections in the plant:

Procedure/Program Description:

Inspection planning and scheduling of all equipment and piping in the plant is carried out as

per the guidelines indicated in SAEP-20. An Equipment Inspection Schedule should be

prepared for each group of equipments such as columns, drums, heat exchangers, boilers

and storage tanks indicating the initial T&I and subsequent T&I intervals. Based on the T&I

findings, the period for the next T&I will be determined by YRD inspection unit and the EIS

will be updated if required. YRD Inspection unit will initiate any revision to the approved EIS

and route it for approval. As required by SAEP-20, the revised EIS shall be approved by:

1. YRD Inspection Unit supervisor

2. YRD Engineering Superintendent

3. YRD Operation Superintendent

4. ID manager

5. YRD manager

Referenced Standards/Procedures

SAEP-20

Equipment Inspection Schedule

SAEP-309

Responsibilities:

Activities

Saudi Aramco:

Inspection of Community and Operations Support Facilities

Assigned to

[ X ] New Instruction

Remark

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

15 of 56

Prepare Original

EIS

PMT / Inspection PMT shall prepare and route for approval the EIS for

Unit supervisor

Equipment built by PMT. Inspection Unit supervisor shall

prepare and route for approval the EIS For equipment built

by YRD maintenance.

Maintaining the

EIS

Area inspector

Include filling the approved EIS, initiating any revision to the

approved EIS and updating the SAIF program.

Documentations:

The Approved EIS shall be filed by the area inspector in:

1. Equipment file located in the Inspection filling room

2. Update the SAIF program if required

Small Nipple inspection program:

Procedure/Program Description:

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

16 of 56

The small bore piping nipple inspection is intended to monitor the condition of in service

piping nipple of size 1 inches and smaller. Internal / external corrosion and welding defects

will be monitored. Each piping system will be categorized as per the corrosion severity and

classified as per the potential consequence on leaks. Based on corrosion category and piping

class, the inspection frequency will be fixed.

The piping inspection frequency is determined from the Nipple Inspection Intervals Matrix

provided in 01-SAIP-01. The subsequent nipple inspection will be adjusted based on the

inspection findings. Inspection frequency for injection points shall not exceed three years as

stipulated in 01-SAIP-02.

Radiography testing (RT) will be the primary inspection method for the internal or external

corrosion of the nipple, for all services including cryogenic service. If welding defects were found

during the inspection, the acceptance criteria provided in 01-SAIP-01 shall be utilized. Ultrasonic

Thickness (UT) inspection shall be utilized when RT is not conclusive. In addition to radiography,

MT or PT should be used to inspect for cracks in vibrating services or austenitic stainless steel

welds. Visual inspection should be performed on all pipe nipple systems to determine the need

for replacement or repairs due to external corrosion, threads not covered by seal weld, vibration

fatigue or possibility of overloading of the nipple.

The nipple shall be replaced when the retirement thickness is reached. The retirement thickness

shall be the lower of the minimum thickness by code and the structural minimum thickness. If the

retirement thickness has not been reached but there is metal loss, the remaining life shall be

calculated. The nipple shall be replaced if the remaining life is less than either the next inspection

interval or the next T&I. If the piping system cannot be shut down for nipple replacement, temporary

repair shall be considered until replacement in the next schedule T&I.

The nipple shall be replaced when the retirement thickness is reached. The retirement thickness

shall be the lower of the minimum thickness by code and the structural minimum thickness. If the

retirement thickness has not been reached but there is metal loss, the remaining life shall be

calculated. The nipple shall be replaced if the remaining life is less than either the next inspection

interval or the next T&I. If the piping system cannot be shut down for nipple replacement, temporary

repair shall be considered until replacement in the next schedule T&I.

All pipe nipples that have been identified as having incorrect metallurgy for the piping system

should be removed and replaced regardless of the remaining wall thickness. All alloy

replacement nipples, valves and welds should be evaluated using an approved Positive

Material Identification (PMI) instrument before installation.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

17 of 56

Nipples which are not braced and subjected to vibration should be adequately braced per

SAES-L-310, paragraph 20.2.3 and Saudi Aramco Standard Drawing AB-036521 to prevent

future fatigue failure.

Referenced Standards/Procedures

01-SAIP-01 Small Nipple Inspection Program

SAES-L-310 Design of Plant Piping

AB-036521 Bridge Weld and Typical Brace Seal Welded and Socket Welded Valves on

Process Lines

Responsibilities:

Activities

Assigned to

Remark

Inspection Activities

OSI Coordinator

Add Piping System to SAIF for nipple

Inspection

Corrosion Engineer and Determine Inspection Frequency

OSI coordinator

Area inspector

Schedule piping for inspection

NDT Technician

Conduct required Inspection

Work Permit

Area

supervisor

operation Include providing the necessary work

permit and inform maintenance to start

maintenance activities.

Maintenance Activates

Maintenance engineer Include providing the

necessary

manpower and equipment (crane, man

lift, scaffolding, etc) to perform the

required inspection activities and rectify

the highlighted deficiencies.

Documentations:

1. Piping Isometric

2. NDT Report

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

18 of 56

3. Nipple shall be added as additional OSI point

4. Update the SAIF program

The above documents (1 &2) shall be filed in the inspection unit filling room.

9- On-Stream inspection of equipment and piping:

Procedure/Program Description

Systematic monitoring program of piping, vessels and tanks for general loss of wall

thickness and localized metal loss in critical processes is established and carried out

as per the guidelines given in SAEP-1135 with the utilization of SAIF inspection

program.

Referenced Standards/Procedures

SAEP-1135

SAIF

On-Stream Inspection Administration

System Assurance & Inspection of FacilitiesOSI Module

Responsibilities (as per SAEP-1135)

Activitie

Assigned

s

to

Remarks

During

PMT

Saudi Aramco:

Project Management Team (PMT) or construction contractor shall:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

19 of 56

constructi

on

Assign TML locations as detailed in Appendix B of SAEP-1135 and conduct

baseline

survey to obtain original wall thickness of new equipment and piping as

required in

SAEP-122.

Inspection YRD

Assure the availability of an active OSI program and all unit personnel

have an

Activitie

s

Inspectio

n

Unit

Supervis

or

Corrosio

n

Engineer

and Area

Saudi Aramco:

access to the program for the required action.

Assure the availability of training program to maintain effective

administration of

the OSI Program.

Issue a quarterly OSI Progress Report to the plant management and

the annual

equipment condition reports to the plant maintenance and operation

superintendents.

Corrosion Engineer with assistance from the Process Engineer shall be

responsible for

the following:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Replaces

NEW

Approved

Engineering Inspection Unit

OSI

Coordinator

Inspection

Field

Supervisor

Planning and running of the OSI Program.

Issue the required OSI progress reports

and OSI TML overdue reports to the unit

supervisor.

Coordinate for NDT actions between the area

inspectors and the NDT technicians.

Issue report with for circuits where

corrosion rates greater than 5 mpy or

equipment with remaining life less than

twice the OSI interval to the Corrosion

Engineer

Assure all plant static equipment is

monitored by OSI program.

Review OSI data with the responsible

area inspector and advise accordingly.

Assure OSI program data is being reviewed,

analyzed, and added to the equipment per

T&I reports.

[ X ] New Instruction

Determine corrosion sectors from process

flow diagrams.

Assign corrosion circuits from P&IDs.

Estimate corrosion rates for each piping

corrosion circuit.

Assign TMLs to corrosion circuits so that

the quantity and location will match the

expected corrosion class.

Review of corrosion rates greater than 5

mpy or equipment with remaining life less

than twice the OSI interval.

Review of process changes for impact on

OSI Program and adjust the TML's or

intervals as required and determine

Inspection interval based on the corrosion

rate.

Area

Inspector

Page No.

20 of 56

Process

Engineer

Saudi Aramco:

YRIM No.: 1156.00

Revision No.: 00

Conduct baseline survey to obtain original

wall thickness measurement of new,

modified or previously unmonitored

equipment.

Obtain wall thickness measurement of the

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

21 of 56

monitored plant equipment as per OSI due

reports and prepare OSI isometric drawings

of added piping and equipment.

Work Permit

Maintenance Activities

NDT

Technician

perform the required UT reading for the

TML and record thickness

Operation

Supervisor

Provide the required Work Permit

Maintenance

Engineer

Include providing the necessary manpower and

equipment (crane, man lift, scaffolding, etc) to

perform the required inspection activities and

rectify the highlighted deficiencies.

Documentations:

1. OSI isometric drawings.

2. TML readings.

The OSI coordinator shall document the above documentations in SAIF OSI module.

10- Dead leg survey and monitoring in plant areas:

Procedure/Program Description:

Dead leg in the piping system is defined as the piping section where the flow is stagnant,

material has the potential for corrosion and when the length is longer than three times its

pipe diameter, or 1.22 m (4 ft) whichever is less. All dead legs shall be eliminated in the

design stage by modifying the piping system during project review. If the deal legs cannot be

eliminated at piping system, then YRD inspection Unit will monitor such dead legs through

the On- Stream Inspection (OSI) Program as per SAEP-1135.

For new projects and in case where a piping section is identified as dead leg and it is not

avoidable from a construction point of view, then it shall be added to OSI and a concurrence

letter shall be signed by:

-

Representatives from PMT (Project Manager)

Proponent (Engineering Division/Area Process Engineer)

Projects Inspection (Supervisor)

CSD Piping and Material Unit Supervisors.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

22 of 56

In normal operation, if a piping configuration is suspected to be a dead leg, then the plant

process engineer and YRD Corrosion engineer should be contacted to evaluate the case and

decide whether it is a dead leg or not. YRD has developed additional reference to help in

evaluating the dead leg conditions (Letter # KGP-92-09). If this piping configuration was

considered as dead leg, then the following activates will be made:

-

The dead leg will be added to OSI program.

The dead leg will be monitored every year for five (5) years.

After five (5) years of monitoring if no defect is found, then this dead leg can be

removed from OSI program.

If we found any metal loss even low corrosion rate, then the dead leg will be kept in

OSI program. In addition, this dead leg should be targeted for elimination if possible.

When pipe minimum thickness (tm) is reached, an inspection work sheet or logbook

entry shall be issued by area inspector to fix deficiency.

Referenced Standards/Procedures

SAES-L-310

Design of Plant Piping

SAEP-1135

On-Stream Inspection Administration

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

23 of 56

Responsibilities:

Activities

Assigned to

Design

Activities

PMT

& new Assure that dead legs are eliminated in the design stage by

project

design modifying the piping system during the project review.

reviewer

Engineering Area process

Activities

engineer

YRD corrosion

engineer

Inspection

Activities

Remark

Identify all lead legs in his plant.

Provide technical assistance to clarify the dead leg criteria and

the addition / removal of dead leg to the OSI program

YRD

inspection Include the following:

unit supervisor

Highlight any dead leg, during construction phase, to PMT in

order to eliminate it if possible.

Assure that an inspection programs for inspecting dead legs is

established and all dead legs are being inspected and

monitored.

Issue an Inspection Worksheet or logbook entry is issued as

needed.

Inspection Field

Supervisor

Field Supervisor shall be responsible for the following:

Assure all dead legs are monitored by OSI program or any

other inspection methods.

Review inspection data with the responsible area inspector

and advise accordingly.

Assure inspection data is being reviewed, analyzed, and

added to SAIF.

Area inspector /

OSI coordinator

Area inspector / OSI coordinator shall be responsible for the

following:

Ensure all identified dead legs are monitored by the On

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

24 of 56

Stream Inspection (OSI) program as per SAEP-1135.

Ensure appropriate inspection methods are used for each

dead leg.

Initiate an Inspection Work Sheet for any major findings and a

Logbook Entry for any minor findings.

Work

Permit

Area operation

supervisor

Maintenanc Maintenance

e Activates engineer

Include providing the necessary work permit

Include providing the necessary manpower and equipment

(crane, man lift, scaffolding, etc) to perform the required

inspection activities and rectify the highlighted deficiencies.

Documentations:

1. List of dead legs in the plant.

2. Dead leg worksheet or logbook issued by area inspector.

The area inspector shall document the above documentations in:

1. Equipment file

2. Equipment file in the shared folder

3. Upload the OSI reading for all identified dead leg into the SAIF program

11- Dummy leg survey and monitoring:

As the result of technical alert 002/01 dated 2/28/2001, all dummy legs in the plant, especially

in hydrocarbon service will be surveyed by the area inspector and any deficiencies will be

reported to area operations foreman for remedial action through IWS.

Referenced Standards/Procedures

ALERT-01-002 Deficiency of Dummy leg support elbows

Responsibilities:

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

YRIM No.: 1156.00

Revision No.: 00

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

NEW

Approved

Engineering Inspection Unit

Activities

Replaces

Assigned to

Page No.

25 of 56

Remark

Inspection

Activities

Area inspector

Perform the required survey and highlight any deficiency to

Area Operation foreman for implementation.

Maintenance

Activities

Area

Maintenance

engineer

Include providing the necessary manpower and equipment

(crane, man lift, scaffolding, etc) to perform the required

inspection activities and rectify the highlighted deficiencies.

Documentations:

1. Dummy legs survey for each plant.

2. Dummy legs worksheet or logbook issued by area inspector.

The area inspector shall document the above documentations in:

1. Equipment file

2. Equipment file in the shared folder

12- Chemical Injection Point Inspection:

Procedure/Program Description:

Due to the risk of process leaks as a result of accelerated or localized corrosion at or near chemical

injection points, an inspection program will be initiated to monitor each chemical injection points.

Injection points include those for injecting corrosion inhibitors, PH control, anti-foam and methanol.

Injection Circuits

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

YRIM No.: 1156.00

Revision No.: 00

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

26 of 56

For the purpose of monitoring, the Injection circuits shall begin at 300 mm (or 3D where D

is the nominal pipe diameter whichever is greater) upstream of the injection point and end at

the second change in the flow direction or 7.6 meters beyond the first change in flow

direction (whichever is less) downstream of the injection point.

Thickness Measurement Locations

The Thickness Measurement Locations (TML) within the injection circuits should be

located in the process piping at the below mentioned locations:

Beginning of the circuit upstream of the injection point.

Injection point 360 around the injection nozzle itself.

Impingement point on the process piping opposite the injection nozzle.

Downstream of the injection point defined as: D, 5D, 10D, midway between the

Injection point and the first change in direction (if they are more than 7.6 m apart).

First change in direction (elbow).

Connections (fittings) within the circuit.

At the end of the circuit downstream of the injection point as defined above.

Referenced Standards/Procedures

00-SAIP-04 Injection Point Inspection Program

SAIF

System Assurance & Inspection of FacilitiesOSI Module

Dcumentations:

1. OSI isometric drawings.

2. TML readings.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

27 of 56

The OSI coordinator shall document the above documentations in SAIF OSI module

Responsibilities:

Activities

Assigned to

Inspection YRD

Activities inspection

unit

supervisor

Remarks

The Inspection Unit Supervisor shall be responsible for:

Assigning inspectors/technicians to gauge pipe wall thickness at the

injection point Thickness Measurement Location (TML).

Approve repair, modification or replacement recommendations for the

injection points.

Assure that the OSI inspection program is implemented in YRD facilities.

OSI

Coordinator

On-Stream Inspection (OSI) coordinator shall be responsible for:

Tracking and monitoring all injection points on the OSI drawings.

Highlighting the areas that are approaching T-min or area of concerns to

the corrosion engineer, the area inspector, and the field supervisor.

Add or delete OSI circuits and update the inspection interval on the SAIF

Program as requested by corrosion engineer.

Coordinate between NDT technician and area inspector to perform the

required UT readings and enter the readings in the SAIF program

Corrosion

Engineer

Update the OSI drawings.

Plant corrosion engineer shall be responsible for:

Identifying all the injection points in the plant (coordinate with the plant

process engineer in this task).

Reviewing/recommending modifications or replacement of injection

points.

Determine Inspection interval based on the corrosion rate

Evaluate the need to add/delete TML locations based on the corrosion rate

of the circuits

Saudi Aramco:

Coordinate with the area inspector to issue IWS if pipe spools require

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

28 of 56

replacement due to internal corrosion

Area

inspector

Plant inspector shall be responsible for

Performing visual inspection as per 00-SAIP-75 guidelines.

Verifying the areas that are approaching T-min and issuing repair,

modification or replacement recommendations for review by the corrosion

engineer and the field supervisor and approval by the unit supervisor.

Assure that the OSI inspection program is implemented in his plant and

make sure that all OSI readings are updated in the SAIF program on

time(no Overdue)

NDT

Technician

Plant inspector/technician shall be responsible for:

Verifying the line number and location before taking the readings.

Taking the measurements as per the locations identified in this procedure.

Reporting any changes in the isometric drawing to the OSI coordinator.

Work

Permit

Operation

supervisor

Provide the required Work Permit

Maint.

Activities

Maintenance

Engineer

Include providing the necessary manpower and equipment (crane, man lift,

scaffolding, etc) to perform the required inspection activities and rectify

the highlighted deficiencies.

13- Corrosion Under Insulation Inspection and Repairs:

Procedure/Program Description:

Insulated equipment and piping systems which are susceptible to Corrosion Under

Insulation (CUI) at YRD shall be identified and checked frequently through CUI Program.

Inspection frequency shall be as per SAEP 20. Susceptible systems shall be carefully

inspected visually. Visual inspection shall identify any sign of damaged insulation,

jacketing or deviations. It should be noted that CUI might take place without any sign of it

on the external surface of the insulation. NDT may be used in lieu of insulation removal.

Method and extent of NDT shall be approved by Inspection Department.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

29 of 56

Criteria for CUI program for piping systems:

Insulated piping systems shall be included in CUI inspection program if any of the followings

conditions apply:

Piping systems made of carbon steel and operating temperature between 25F (-4C)

and 250F (121C).

Piping systems made of carbon steel and operating temperature above 250F (121C)

or below 25F (-4C) but in intermittent service.

Piping systems made of austenitic stainless steel and operate between 100F (38C)

and 400F (204C).

Piping located in areas exposed to mist overspray from cooling water towers.

Piping systems located in areas exposed to steam vents.

Piping systems exposed to deluge systems.

Piping systems subject to process spills, ingress of moistures or acid vapors.

Dead legs and protrusions from insulted piping that operates at different temperatures of

the main line.

Steam traced piping systems that may experience tracing leaks, especially at tubing

fittings beneath the insulation.

Piping systems with deteriorated coating and wrapping, damaged insulation cladding, or

insulation that might be damaged by piping vibration.

CUI vulnerable Location for piping systems:

The below specific locations in piping systems susceptible to CUI may be exposed to CUI

more than the rest of the piping systems.

All penetrations or breaches in the insulation jacketing such as dead legs (vents,

drains, instrument tapping and similar items), pipe hangers and supports and steam

tracing tubing penetrations.

Irregular insulation surfaces such as valves and fittings.

Bolted-on shoes.

Terminations of insulation at flanges and other piping components.

Damaged or missing insulation jacketing or when the seams of the insulating jacketing

are located on the top of horizontal piping.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

YRIM No.: 1156.00

Revision No.: 00

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

30 of 56

Termination of insulation in a vertical piping.

Caulking that has hardened, has separated or is missing.

Bulges or staining of insulation or jacketing.

Low points in piping systems that have a known breach in the insulation system,

including low points in long unsupported piping runs.

Carbon or low-alloy steel flanges, bolting and other components under insulation in

high-alloy piping systems.

UT measurement windows in the insulation jacketing.

CUI program for equipment:

Insulated equipment shall be inspected for CUI if any of the following conditions apply:

Equipment operating between 25F (-4C) and 250F (121C).

Equipment operating above 250F (121C) or below 25F (-4C), but in intermittent operation.

Equipment protected by deluge water system.

CUI Vulnerable Location for equipment:

Some locations of Insulated vessels and tanks that are susceptible for CUI may be

exposed to CUI more than the rest of the equipment. Examples of highly suspect areas

include, but not limited to the following:

Stiffening rings and insulation support.

Areas around nozzles and man ways.

Areas around protrusions; like lifting lungs and platforms supports.

Samples of the CUI Vulnerable of corrosion under insulation as described above and

locations of damaged insulation found through visual inspection of the system shall be

inspected by either NDT or insulation removal. Quantities of inspection samples are as

shown in Table 1. Piping classification is per section 6.2 of API-570. All vessels and

tanks are to be classified as class 1

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

31 of 56

Table1

Class

% of locations found with damaged

insulation to be inspected by NDT or

insulation removal

% of locations defined as susceptible

locations for CUI on this process to be

inspected by NDT or insulation removal

75%

50%

50%

33%

25%

10%

If the inspection of the selected locations revealed significant CUI, then the percentage of the

selected location shall be increased. If the system is known to have a good coating system,

or if the system has a good history from previous inspections for CUI, then the percentage of

the selected locations can be decreased up to 50% of the amounts given in Table 1.

Referenced Standards/Procedures

00-SAIP-74 Inspection of Corrosion under Insulation and Fire proofing

SAEP-20

SAEP-1135

On-Stream Inspection Administration

00-SAIP-75

External Visual Inspection Procedure

SAES-N-001

Basic Criteria, Industrial Insulation

API 570

Saudi Aramco:

Equipment Inspection Schedule

Piping Inspection Code

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

32 of 56

Responsibilities:

Activities

Assigned to

Inspection

Activities

YRD inspection Inspection unit supervisor shall be responsible for following:

unit supervisor Assure that an inspection programs for inspection CUI is

established and all susceptible systems for CUI are being

inspected and monitored.

Inspection

Field

Supervisor

Remark

Field Supervisor shall be responsible for the following:

Assure all susceptible systems for CUI are monitored.

Review inspection data with the responsible area inspector and

advise accordingly.

Assure inspection data is being reviewed, analyzed, and added

to SAIF.

Area inspector Area inspector shall be responsible for the following:

Assure that all identified susceptible systems for CUI are

monitored by the On Stream Inspection (OSI) program as per

SAEP-1135.

Ensure that the appropriate inspection methods are used for

each susceptible location for CUI as per the schedule.

Initiate a work sheet for any major findings and a logbook entry

for any minor findings.

Engineering

Activities

YRD corrosion Corrosion engineer shall be responsible for the following:

engineer

Identify all locations in the susceptible systems that are

susceptible for CUI.

Area process

engineer

Review all repair procedures and make sure that factors

promoting CUI are being eliminated if possible

Area process engineer shall be responsible for the following:

Verify if the existing insulation on piping or equipment is needed

either for energy conservation or personnel protection.

Work Permit Area operation Include providing the necessary work permit

supervisor

maintenance to start maintenance activities.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

and

inform

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Activates

engineer

Replaces

NEW

Engineering Inspection Unit

Maintenance Maintenance

YRIM No.: 1156.00

Revision No.: 00

Approved

Page No.

33 of 56

Include providing the necessary manpower and equipment (crane,

man lift, scaffolding, etc) to perform the required maintenance

activities.

Documentations:

1. List of Susceptible Systems for CUI.

2. CUI worksheet or logbook issued by area inspector.

The area inspector shall document the above documentations in:

1. Equipment file

2. Equipment file in the shared folder

3. Update the SAIF program if required

14- Thermograph inspection Survey of cold insulated equipment and piping

Procedure/Program Description

Thermograph Inspection of cold insulated drums, tanks and piping is carried out in order to

determine the damaged insulation and hot spots. These areas will be later added to T&I

scope to remove the insulation at the damaged areas and hot spot areas for visual and NDT

inspection and remedial action.

Referenced Standards/Procedures

None

Responsibilities:

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Saudi Aramco:

Replaces

NEW

Approved

Engineering Inspection Unit

Activities

YRIM No.: 1156.00

Revision No.: 00

Assigned

[ X ] New Instruction

Page No.

34 of 56

Remark

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

35 of 56

to

Inspection Activities

YRD inspection

unit supervisor

Include assuring that inspection unit has a qualified

inspector who can perform thermograph inspection

survey.

Inspection Field

Supervisor

Assure all susceptiblesystems for damaged

insulation are monitored.

Review inspection data with the responsible

Qualified Inspector and area inspector and

advise accordingly.

Assure inspection data is being reviewed,

analyzed, and added to shared files and

equipment file.

Work permit

YRD Qualified

Inspector

Include performing the Thermograph survey and

report any deficiency.

Area Operation

Include providing the necessary work permit and

inform maintenance to start maintenance activities.

Supervisor

Maintenance Activates

Area Maintenance Provide technical support as needed

Engineer

Provide the necessary manpower, material and

equipment (crane, man lift, scaffolding, etc) to

perform the required maintenance activities.

Documentations:

Thermograph inspection survey report. The inspector shall document this report in:

1. Equipment file

2. Equipment file in the shared folder

15- Cathodic Protection System Inspection

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

36 of 56

Procedure/Program Description:

YRD Operation/Inspection Unit will conduct monthly and annually surveys to monitor the

cathodic protection (CP) systems as specified in SAEP-333 and SAIP-02. The CP system

must be monitored to ensure that equipment or structures receive adequate protection.

Monitoring surveys for tank bottoms and in-plant buried piping will be conducted annually by

electrical inspection unit. The survey data shall be reviewed, analyzed and carried out

recommendations for corrective action.

Anode bed monitoring and maintenance:

Evaluate the performance of each anode bed annually prior to the scheduled annual potential

survey. The evaluation includes measuring the current output for each individual impressed

current/galvanic anodes and current in the negative cables. Measure the current output

From the voltage drops across the shunts if they are installed at the anode cable

terminals inside the anode junction boxes

By a DC clamp-on-ammeter, if no shunts are available

Calculate an estimate of the service life of the anode beds. For single or multiple

negative cables, measure the current in each cable as above.

For junction box, annually check will be conducted for all anode junction box connections

and fittings for cleanliness and tightness. During annually check, perform any required

maintenance as follows:

Take apart all connections and bolted fittings and clean with an approved safety solvent.

Apply Burndy Penetrox E oxide inhibiting compound (or equivalent) to all

cables and connections. When finished, reinstall them.

Seal or reseal all conduit openings with Duxseal compound.

Inspect, repair, or replace the door seals.

Record all anode bed readings during the annual check on the relevant data sheet show in

SAEP-333A, appendices FK.

Rectifier maintenance and monitoring procedures:

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

37 of 56

In YRD, there are two types of rectifiers oil cool and air cool rectifiers. Oil cool rectifier is

represented at DGA and air cool rectifier at Utilities. These rectifiers are required two types

of inspection monthly and annually inspections.

Monthly inspection:

Either Operations or Maintenance personnel who normally visit the site on a regular

basis for purposes other than those relating to cathodic protection can perform

these procedures.

Check rectifiers on a monthly basis and record the output volts and amps.

Record the rectifier output data on the attached data sheet.

Report immediately any abnormal rectifier operation to the Inspection Unit.

Annual inspection:

Record rectifier output volts and amps.

Verify the reading with a portable meter

Visually inspect the cabinet, terminals, and components for any damage.

For oil cool rectifier only, check the oil level, temperature and perform

sample check as follows:

1. Open the drain spout and collect approximately one liter of oil in a clear glass

container. If sediment, sludge, or water drains with the oil during sampling, continue

draining until the contaminant has been flushed out. Then collect approximately one

liter of oil. If the sediment has not been flushed out after four liters of oil have

drained, the rectifier should be completely drained and filled with new oil.

2. If the oil is dark or cloudy or appears to be full of suspended particles, it should be

replaced.

3. Dispose of old oil in an environmentally approved manner.

Adjust the rectifier sitting as required in order to ensure adequate protection.

Record all data taken during the annual rectifier check on the data sheet shown in

SAEP-333A, appendix J, pages 12.

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Approved

Engineering Inspection Unit

Page No.

38 of 56

Referenced Standards/Procedures

GI 428.003

SAES-X-600

SAEP-333 Cathodic

SAEP-333A

Cathodic Protection Monitoring Procedure

Cathodic Protection of In-Plant Facilities

Protection Monitoring Procedure

Cathodic Protection Monitoring Appendices FK

Documentations:

List of CP Systems at YRD:

CP systems monthly status reports.

annual CP survey report summarizes the CP status of all protected structures

The, all CP system performance, and includes recommendations to eliminate

deficiencies.

Issued CP worksheet or logbook.

Annual CP survey report to CSD.

The area inspector shall document the above documentations in:

1. Equipment file

2. Equipment file in the shared folder

3. Update the SAIF program if required

Responsibilities:

Activities

Saudi Aramco:

Assigned to

Remark

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Inspection

Activities

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

39 of 56

YRD inspection Inspection unit supervisor shall be responsible for the following:

unit supervisor Assure that an inspection programs for CP is established and being

inspected and monitored.

Area foreman Area foreman shall be responsible for the following:

Ensure that All CP systems are being checked.

Electrical

maintenance

supervisor

Ensure that CP system is in good operating condition.

Inform KGP inspection unit for any abnormalities.

Electrical maintenance supervisor shall be responsible for the

following:

Ensure that All CP systems are being monthly checked.

Ensure that all electrical technicians know how to obtain the

rectifier DC Volt/Ampere output readings at the area under his

authority.

Inform YRD inspection unit for any abnormalities.

Area electrical Area electrical technician shall be responsible for the following:

technician

Conduct the CP rectifier monthly check and record output data in

data sheet.

Report any abnormal rectifier operation to YRD inspection unit.

Forward the rectifier output reading to YRD inspection unit on a

monthly basis.

Area operator Area operator shall be responsible for the following:

Inspection

Field

Saudi Aramco:

Report any abnormal rectifier operation to Area foreman.

Field Supervisor shall be responsible for the following:

Assure all CP systems are monitored.

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

Replaces

NEW

Engineering Inspection Unit

Supervisor

YRIM No.: 1156.00

Revision No.: 00

Approved

Page No.

40 of 56

Review inspection data with the responsible electrical inspector

and advise accordingly.

Assure inspection data is being reviewed, analyzed, and added to

shared files, equipment file and SAIF.

Area electrical

inspector

Area electrical inspector shall be responsible for the following:

Conduct the CP rectifier, junction box and anode bed annually

survey and record output data in data sheets.

Report any abnormality on the CP rectifier, junction box and

anode bed.

Work Permit

Area operation Area operation supervisor shall be responsible for the following:

supervisor

Provide the necessary work permit and inform maintenance to

start maintenance activities.

Engineering

Activities

YRD corrosion

engineer

Review monthly and annually reports and recommend solutions for

any abnormalities.

Maintenance

Activates

Maintenance

engineer

Include providing the necessary manpower and equipment (crane,

man lift, scaffolding, etc) to perform the required maintenance

activities.

6- Monitoring of Corrosion Monitoring system (CMS)

Saudi Aramco:

[ X ] New Instruction

[ ] Complete Revision

[ ] Change

[ ] Addition

SAUDI ARAMCO OIL COMPANY (Saudi Aramco)

YANBU REFINERY INSTRUCTION MANUAL

Issue Date

SUBJECT: YRD Inspection Program

ISSUING ORG:

YRIM No.: 1156.00

Revision No.: 00

Replaces

NEW

Engineering Inspection Unit

Approved

Page No.

41 of 56

Procedure/Program Description:

Piping systems are generally subject to both internal and external corrosion. The internal

corrosion is considered to be challenging as well as expensive in practice. It has been

observed that internal corrosion could potentially reduce the pipe wall thickness much more

than external corrosion. In general, it becomes highly critical to mitigate internal corrosion

and reduce the risk of leakage in piping system. For that, YRD has installed corrosion

monitoring system to monitor internal corrosion and corrosion inhibitor performance inside

piping systems. COSASCO 2" corrosion monitoring assemblies are the CMSs, which are

installed in YRD. This CMS is designed to monitor corrosion behavior on line.

COSASCO 2" CMS can be installed and retrieved by using the following equipments:

1- RBSA retrievers

2- Service valves

3- Bleed valve and a pressure gauge to allow the operator to monitor the internal

pressure during use

These equipments are designed to install and retrieve the COSASCO 2" corrosion