Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

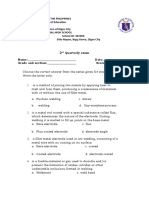

Workshop Objectives

Caricato da

Mansaf AbroDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Workshop Objectives

Caricato da

Mansaf AbroCopyright:

Formati disponibili

1.

A zinc diffusion process is called

A.

galvanising

B.

anodising

C.

parkerising

D.

sherardizing

2. The accuracy of micrometers, calipers, dial indicators can be checked by a

A.

feeler gauge

B.

slip gauge

C.

ring gauge

D.

plug gauge

3. The type of file used for a wood work is

A.

single-cut file

B.

double cut file

C.

rasp-cut file

D.

any one of these

4. A taper provided on the pattern for its easy and clean withdrawl from the mould is known as

A.

machining allowance

B.

draft allowance

C.

shrinkage allowance

D.

distortion allowance

5. In arc welding, the electric arc is produced between the work and the electrode by

A.

voltage

B.

flow of current

C.

contact resistance

D.

all of these

6. Which of the following welding process uses non-consumable electrodes?

A.

TIG welding

B.

MIG welding

C.

Manual arc welding

D.

Submerged arc welding

7. In a bilateral system of tolerance, the tolerance is allowed on

A.

one side of the actual size

B.

one side of the nominal size

C.

both sides of the actual size

D.

both sides of the nominal size

8. The temperature at which the new grains are formed in the metal is called

A.

lower critical temperature

B.

upper critical temperature

C.

eutectic temperature

D.

recrystallisation temperature

9. Thread rolling is restricted to

A.

ferrous materials

B.

ductile materials

C.

hard materials

D.

none of these

10. The temperature of oxy-hydrogen flame is __________ oxy-acetylene flame.

A.

same as

B.

less than

C.

more than

11. Which of the following methods can be used for manufacturing 2 metre long seamless metallic

tubes?

A.

Drawing

B.

Extrusion

C.

Rolling

D.

Extrusion and rolling

12. A saw which cuts wood during the return stroke of the saw is known as

A.

push saw

B.

pull saw or draw saw

13. The property of sand due to which it evolves a great amount of steam and other gases is called

A.

collapsibility

B.

permeability

C.

cohesiveness

D.

adhesiveness

14. The cross-section of a chisel is usually

A.

rectangular

B.

square

C.

hexagonal

D.

octagonal

15. In back-hand welding, the angle between the welding torch and the work is kept as

A.

30-40

B.

40-50

C.

50-60

D.

60-70

16. In submerged arc welding, an arc is produced between a

A.

carbon electrode and the work

B.

metal electrode and the work

C.

bare metal electrode and the work

D.

two tungsten electrodes and the work

17. In shielded arc welding

A.

large electrode is used

B.

welding rod coated with slag is used

C.

welding rod coated with fluxing material is used

D.

none of the above

18. In a hot chamber die casting machine

A.

melting pot is separate from the machine

B.

melting pot is an integral part of the machine

C.

melting pot may have any location

D.

high temperature and pressure is used

19. The electrodes used in spot welding have a tip of

A.

stainless steel

B.

aluminium

C.

copper

D.

brass

20. Blanking and piercing operations can be performed simultaneously in a

A.

simple die

B.

progressive die

C.

compound die

D.

combination die

21. Galvanizing is a

A.

zinc diffusion process

B.

process of coating zinc by hot dipping

C.

process used for making thin phosphate coating on steel

D.

none of the above

22. In __________ welding, the weld may be made either from left to right or from right to left.

A.

fore-hand

B.

back-hand

C.

vertical

23. Carburizing flame is used to weld

A.

steel, cast iron, copper, aluminum etc

B.

brass and bronze

C.

D.

hard surfacing materials such as satellite

all of these

24. Cores are used to

A.

form internal cavities in the casting

B.

improve mould surface

C.

form a part of a green sand mould

D.

all of these

25. A jolt machine is used to

A.

ram the sand harder at the pattern face with decreasing hardness towards the back of the

mould

B.

ram the sand harder at the back of the mould and softer on the pattern face

C.

produce uniform sand hardness throughout the mould

D.

produce uniform packing of sand in the mould

26. A file removes the metal during

A.

forward stroke

B.

return stroke

C.

both forward and return strokes

D.

none of these

27. Notching is the operation of

A.

cutting a sheet of metal in a straight line along the length

B.

removal of metal to the desired shape from the edge of a plate

C.

cutting a sheet of metal through part of its length and then bending the cut portion

D.

bending a sheet of metal along a curved axis

28. An oxidising process used for aluminium and magnesium articles is called

A.

galvanising

B.

anodising

C.

parkerising

D.

sheradising

29. The operation of straightening a curved sheet metal, is known as

A.

drawing

B.

squeezing

C.

coining

D.

planishing

30. A rip saw

A.

is a two man saw

B.

is used for cutting along the grains of wood

C.

has a narrow blade with two wooden handles

D.

all of the above

31. In electric resistance welding, voltage required for heating is

A.

1 to 5 volts

B.

6 to 10 volts

C.

11 to 20 volts

D.

50 to 100 volts

32. Most of the oxy-acetylene welding is done with

A.

neutral flame

B.

oxidizing flame

C.

carburizing flame

D.

all of these

33. The cutting edge of a chisel should be

A.

hardened

B.

tempered

C.

hardened and tempered

D.

case hardened

34. The oxy-acetylene gas used in gas welding produce a flame temperature of

A.

1800C

B.

2100C

C.

2400C

D.

3200C

35. The process extensively used for making bolts and nuts is

A.

hot piercing

B.

extrusion

C.

cold peening

D.

cold heading

Potrebbero piacerti anche

- 9 14 Pages MCQS CSWIP 3.1 Question Answers Solved Past Papers Cswip 3.1Documento14 pagine9 14 Pages MCQS CSWIP 3.1 Question Answers Solved Past Papers Cswip 3.1Mohammed Amjad Ali86% (21)

- Ch08Documento6 pagineCh08asma aslamNessuna valutazione finora

- Machine Design Examination 13Documento4 pagineMachine Design Examination 13SYBRELLE CRUZNessuna valutazione finora

- Meaning: Heat - Affected-Zone (HAZ) Is The Area of Base Material, Either A Metal orDocumento10 pagineMeaning: Heat - Affected-Zone (HAZ) Is The Area of Base Material, Either A Metal orLianne Sanchez50% (2)

- Elements Machine Shop PDFDocumento493 pagineElements Machine Shop PDFJaypes ManzanoNessuna valutazione finora

- Sindh GK CapsuleDocumento69 pagineSindh GK CapsuleSindh Jobs Helper100% (2)

- Rdso Bow String Girder-10411-9Documento1 paginaRdso Bow String Girder-10411-9a Rawat100% (1)

- FPC ManualDocumento15 pagineFPC ManualDavid SeeNessuna valutazione finora

- Workshop Technology PDFDocumento48 pagineWorkshop Technology PDFilamparithiNessuna valutazione finora

- Objective Questions MaterialDocumento14 pagineObjective Questions MaterialAshish AgarwalNessuna valutazione finora

- SMAW NC I Set B - 50 ItemsDocumento9 pagineSMAW NC I Set B - 50 Itemslouie gerasmia100% (1)

- Smaw 9 Summative Test Q1Documento2 pagineSmaw 9 Summative Test Q1Jose Intraboy Arais Tabugoc Jr.Nessuna valutazione finora

- A Flexible Hacksaw Blade Has A Tendency To: B. Buckle or Run Out of Line When Too Much Pressure Is Applied C. Cut Too Fast A. Snap EasilyDocumento84 pagineA Flexible Hacksaw Blade Has A Tendency To: B. Buckle or Run Out of Line When Too Much Pressure Is Applied C. Cut Too Fast A. Snap EasilyJom BautistaNessuna valutazione finora

- Ultimate 48 FinalDocumento5 pagineUltimate 48 FinalJape's EecaNessuna valutazione finora

- Elements in Machine Design (J.T.) Module 15Documento6 pagineElements in Machine Design (J.T.) Module 15allovidNessuna valutazione finora

- Production EngineeringDocumento15 pagineProduction EngineeringManav PriyadarshiNessuna valutazione finora

- A. B. Answer & ExplanationDocumento11 pagineA. B. Answer & ExplanationTemesgenNessuna valutazione finora

- GNHS Smaw 2ND QuarterDocumento8 pagineGNHS Smaw 2ND QuarterJymaer GeromoNessuna valutazione finora

- Objective ProductionDocumento6 pagineObjective ProductionM.ThirunavukkarasuNessuna valutazione finora

- 2nd Quarter Exam Smaw - Doc For PRINTDocumento5 pagine2nd Quarter Exam Smaw - Doc For PRINTSabas Quijada100% (3)

- SMAW NC I Set C - 50 ItemsDocumento9 pagineSMAW NC I Set C - 50 Itemslouie gerasmiaNessuna valutazione finora

- All ElementsDocumento392 pagineAll ElementsWilliam Bataluna100% (1)

- Cut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackDocumento100 pagineCut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackJade DigNessuna valutazione finora

- TestDocumento51 pagineTestNiaz KilamNessuna valutazione finora

- MCQs Chip FormationDocumento9 pagineMCQs Chip FormationMohsin QaziNessuna valutazione finora

- A. The Teeth Pointing Forward: 1 (MDSP 2)Documento22 pagineA. The Teeth Pointing Forward: 1 (MDSP 2)Dhin TolentinoNessuna valutazione finora

- MDSP T4Documento100 pagineMDSP T4Arnz BibosoNessuna valutazione finora

- Machine Design Examination 14Documento4 pagineMachine Design Examination 14SYBRELLE CRUZNessuna valutazione finora

- MP-II MCQ Unit IDocumento8 pagineMP-II MCQ Unit IMagnus CarlsenNessuna valutazione finora

- MC Design 3-1 PDFDocumento246 pagineMC Design 3-1 PDFVosotros Jun-JieNessuna valutazione finora

- A. Solid Stock B. Aluminum C. Cast Iron D. Any of The AboveDocumento100 pagineA. Solid Stock B. Aluminum C. Cast Iron D. Any of The AboveJade DigNessuna valutazione finora

- Ep Lap MCQ CivilDocumento4 pagineEp Lap MCQ CivilBhavani MurugesanNessuna valutazione finora

- Machine Design Examination 12Documento4 pagineMachine Design Examination 12SYBRELLE CRUZNessuna valutazione finora

- Dgca Question Module 6 and 7Documento29 pagineDgca Question Module 6 and 7Kusum chaurasiaNessuna valutazione finora

- Test 25: Machine Shop PracticeDocumento51 pagineTest 25: Machine Shop PracticeNiaz KilamNessuna valutazione finora

- Terms Enhancement 984 240 - 041823Documento984 pagineTerms Enhancement 984 240 - 041823Kurt Baylan100% (1)

- Elements Machine Shop PDFDocumento493 pagineElements Machine Shop PDFJaypes ManzanoNessuna valutazione finora

- Pre Test SMAW NC I 1Documento6 paginePre Test SMAW NC I 1Gaudencio BoniceliNessuna valutazione finora

- MD ElementsDocumento13 pagineMD ElementsJosue RicaldeNessuna valutazione finora

- 1st - Q - Exam - Grade 9 - Smaw - 25Documento4 pagine1st - Q - Exam - Grade 9 - Smaw - 25Jurie FernandezNessuna valutazione finora

- Elements of Machine DesignDocumento18 pagineElements of Machine DesignDexter Frank Virtucio CalderonNessuna valutazione finora

- Practice TestDocumento14 paginePractice TestRaviNessuna valutazione finora

- Manufactruing EngineeringDocumento6 pagineManufactruing Engineeringpervez khanNessuna valutazione finora

- After Grinding A Tool Bit, The Cutting Edge Should Be: A. Case-Hardened B. Rubbed With Emery ClothDocumento100 pagineAfter Grinding A Tool Bit, The Cutting Edge Should Be: A. Case-Hardened B. Rubbed With Emery ClothJom BautistaNessuna valutazione finora

- MD 01Documento100 pagineMD 01SiN XNessuna valutazione finora

- MCQ For Welding ShopDocumento6 pagineMCQ For Welding Shopsudhir guptaNessuna valutazione finora

- Paper IiDocumento93 paginePaper IiAviation WorldNessuna valutazione finora

- MD002Documento248 pagineMD002Christopher Lennon Dela CruzNessuna valutazione finora

- Prod ActionDocumento13 pagineProd Actionahmish kabbaxeNessuna valutazione finora

- Welding Questions 1Documento26 pagineWelding Questions 1dselvakuuNessuna valutazione finora

- Machine Design14Documento101 pagineMachine Design14Jm Beja100% (1)

- MDSP Miscellaneous Elements - 02Documento134 pagineMDSP Miscellaneous Elements - 02Ley MarNessuna valutazione finora

- Machine Design Examination 15Documento5 pagineMachine Design Examination 15SYBRELLE CRUZNessuna valutazione finora

- TestDocumento51 pagineTestNiaz KilamNessuna valutazione finora

- CSWIP 3.2 Multiple ChoiceDocumento10 pagineCSWIP 3.2 Multiple Choicerandhir kumar jha0% (1)

- MCQ On Advance Welding (Harshdeep Rai and Hassan Immam)Documento35 pagineMCQ On Advance Welding (Harshdeep Rai and Hassan Immam)Handu100% (1)

- Machine Design Elements14 - : God BlessDocumento101 pagineMachine Design Elements14 - : God BlessReynald de VeraNessuna valutazione finora

- Design 1Documento1.416 pagineDesign 1Edgar Ed100% (1)

- MDSPDocumento39 pagineMDSPNelson Naval CabingasNessuna valutazione finora

- Machine Design Examination 8Documento5 pagineMachine Design Examination 8SYBRELLE CRUZNessuna valutazione finora

- Production Engineering Questions and Answers Indo German Tool Room Ahmedabad by Sudhir ChauhanDocumento37 pagineProduction Engineering Questions and Answers Indo German Tool Room Ahmedabad by Sudhir ChauhanSUDHIR CHAUHAN91% (23)

- Cswip Paper 3.1Documento5 pagineCswip Paper 3.1Fran Bakkara100% (1)

- MD Elements 12Documento100 pagineMD Elements 12Garcia MaybelleNessuna valutazione finora

- Faculty of Science and Technology Hamdard Institute of Engineering & Technology, Hamdard UniversityDocumento4 pagineFaculty of Science and Technology Hamdard Institute of Engineering & Technology, Hamdard UniversityMansaf AbroNessuna valutazione finora

- Sindh GKDocumento7 pagineSindh GKMansaf AbroNessuna valutazione finora

- SDLKJSLDKJSDDocumento2 pagineSDLKJSLDKJSDMansaf AbroNessuna valutazione finora

- Course Outline TRWDocumento5 pagineCourse Outline TRWMansaf AbroNessuna valutazione finora

- Advt. No.9-2018 - 0 PDFDocumento7 pagineAdvt. No.9-2018 - 0 PDFMuhammad TayyabNessuna valutazione finora

- Ex.1:Find The Average of All Prime Numbers Between 30 andDocumento3 pagineEx.1:Find The Average of All Prime Numbers Between 30 andz1y280% (5)

- 1Documento2 pagine1Mansaf AbroNessuna valutazione finora

- Max. Marks 3 3 3 3 2 2 AssignmentsDocumento4 pagineMax. Marks 3 3 3 3 2 2 AssignmentsMansaf AbroNessuna valutazione finora

- Therm Outline 2Documento4 pagineTherm Outline 2Mansaf AbroNessuna valutazione finora

- ScheduleDocumento1 paginaScheduleMansaf AbroNessuna valutazione finora

- My DivDocumento3 pagineMy DivMansaf AbroNessuna valutazione finora

- Energy Conservation Power Point NewDocumento155 pagineEnergy Conservation Power Point NewMansaf AbroNessuna valutazione finora

- Eligibility Criteria: How To ApplyDocumento1 paginaEligibility Criteria: How To ApplyManzoor JanNessuna valutazione finora

- ThermodynamicsDocumento86 pagineThermodynamicsMansaf AbroNessuna valutazione finora

- IslamiatDocumento8 pagineIslamiatMansaf AbroNessuna valutazione finora

- Monthly Economic Affairs January 2015Documento40 pagineMonthly Economic Affairs January 2015Mansaf AbroNessuna valutazione finora

- Workshop MCQS... (Final Lab)Documento2 pagineWorkshop MCQS... (Final Lab)Mansaf AbroNessuna valutazione finora

- Nts Test Junior ClerkDocumento1 paginaNts Test Junior ClerkMansaf AbroNessuna valutazione finora

- Workshop Attendance and Job ProfileDocumento3 pagineWorkshop Attendance and Job ProfileMansaf AbroNessuna valutazione finora

- NextDocumento17 pagineNextMansaf AbroNessuna valutazione finora

- What Is The Nature and Function of Following AgenciesDocumento4 pagineWhat Is The Nature and Function of Following AgenciesMansaf AbroNessuna valutazione finora

- Nuclear Disarmament and NonDocumento2 pagineNuclear Disarmament and NonMansaf AbroNessuna valutazione finora

- Advt No 8-2015 FINAL PDFDocumento5 pagineAdvt No 8-2015 FINAL PDFshaubanalisolangiNessuna valutazione finora

- Constructing PolygonsDocumento25 pagineConstructing PolygonsJames DorfNessuna valutazione finora

- Application FormDocumento5 pagineApplication FormMansaf AbroNessuna valutazione finora

- Approved Colleges UniversitiesDocumento3 pagineApproved Colleges UniversitiesMansaf AbroNessuna valutazione finora

- NextDocumento17 pagineNextMansaf AbroNessuna valutazione finora

- How To Crack Compulsory PapersDocumento8 pagineHow To Crack Compulsory PapersMansaf AbroNessuna valutazione finora

- Vendor: Design Information: Gas BootDocumento2 pagineVendor: Design Information: Gas Boot124swadeshiNessuna valutazione finora

- Selected Formulary Book On Petroleum, Lubricants, Fats, Polishes, Glass, Ceramics, Nitrogenous Fertilizers, Emulsions, Leather and InsecticidesDocumento27 pagineSelected Formulary Book On Petroleum, Lubricants, Fats, Polishes, Glass, Ceramics, Nitrogenous Fertilizers, Emulsions, Leather and InsecticidesNatalieNessuna valutazione finora

- 08 3 PDFDocumento42 pagine08 3 PDFmakoi100% (1)

- Lloyds Approved Welding Consumables SuppliersDocumento16 pagineLloyds Approved Welding Consumables SuppliersadammzjinNessuna valutazione finora

- Asme B31.3Documento2 pagineAsme B31.3Juan ortega castellarNessuna valutazione finora

- Mmed Nit Srinagar SyllabusDocumento99 pagineMmed Nit Srinagar SyllabusdikshitbhatotiaNessuna valutazione finora

- Collie Welding Heat Input CalculatorDocumento6 pagineCollie Welding Heat Input CalculatorManohar SeetharamNessuna valutazione finora

- Pneumatic PLCDocumento109 paginePneumatic PLCragdapattice100% (1)

- Provided by UTHM Institutional RepositoryDocumento34 pagineProvided by UTHM Institutional RepositoryAlthaf MkNessuna valutazione finora

- ATOM User Manual AWE-16ADocumento12 pagineATOM User Manual AWE-16ARafaSNessuna valutazione finora

- Manufacturing of A Car Body: A Project Report For The Award of The Degree Bachelor of TechnologyDocumento23 pagineManufacturing of A Car Body: A Project Report For The Award of The Degree Bachelor of TechnologyDHRUV SINGHALNessuna valutazione finora

- Technology Multiple Choice Exam 1Documento8 pagineTechnology Multiple Choice Exam 1saifullah629Nessuna valutazione finora

- Ratnamani - Manufacturing RangeDocumento2 pagineRatnamani - Manufacturing RangeRenny DevassyNessuna valutazione finora

- GB 150 1 C 2011 PDFDocumento40 pagineGB 150 1 C 2011 PDFirfanlarikhotmailcomNessuna valutazione finora

- Efco Repair RecommendationsDocumento33 pagineEfco Repair RecommendationsSamy BarreraNessuna valutazione finora

- Introduction Basic Welding TechnologyDocumento17 pagineIntroduction Basic Welding TechnologyBenny Syahputra100% (1)

- Brochure LPG TankDocumento3 pagineBrochure LPG TankBagus Deddy AndriNessuna valutazione finora

- Aluminum Experience in ApplicationDocumento11 pagineAluminum Experience in ApplicationVelmohanaNessuna valutazione finora

- Ips C Pi 270 18 PDFDocumento1 paginaIps C Pi 270 18 PDFGERAILLYNessuna valutazione finora

- Design and Fabrication Multipurpose Agricultural EquipmentDocumento20 pagineDesign and Fabrication Multipurpose Agricultural EquipmentAbhay DesaiNessuna valutazione finora

- LONG QUIZ QuestionaireDocumento3 pagineLONG QUIZ Questionairejohn christian de leonNessuna valutazione finora

- POWERCUT-1500: Plasma Arc Cutting PackageDocumento48 paginePOWERCUT-1500: Plasma Arc Cutting PackageJose Miguel Dorado MenesesNessuna valutazione finora

- ADocumento2 pagineAJorge Manuel GuillermoNessuna valutazione finora

- Inet-Kemppi-Kit - nsf-DocsPlWeb-DS MasterTig MLS ACDC AD703 1218 EN - Pdf-$fileDocumento2 pagineInet-Kemppi-Kit - nsf-DocsPlWeb-DS MasterTig MLS ACDC AD703 1218 EN - Pdf-$fileJackNessuna valutazione finora

- Plastic WeldingDocumento9 paginePlastic WeldingTrecita BacoNessuna valutazione finora

- CBI Welding Journal Vert Plate Apr04Documento0 pagineCBI Welding Journal Vert Plate Apr04Mahendra RathoreNessuna valutazione finora