Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MGMT 405 Operations and Production Management Answer Set 4 (Reference Chapters 8 - William J. Stevenson-2007, Ninth Edition) Problems and Answers

Caricato da

aurelioTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MGMT 405 Operations and Production Management Answer Set 4 (Reference Chapters 8 - William J. Stevenson-2007, Ninth Edition) Problems and Answers

Caricato da

aurelioCopyright:

Formati disponibili

Operations and Production Management

MGMT 405

Answer set 4

MGMT 405 Operations and Production Management

Answer set 4

(Reference chapters 8 William J. Stevenson-2007, ninth edition)

Problems and Answers

1. Green Valley Milis produces carpet at plants in St. Louis and Richmond. The

carpet is then shipp to two outlets, located in Chicago and Atlanta. The cost per

ton of shipping carpet from each of th two plants to the two warehouses is as

follows:

To

From

Chicago Atlanta

St. louis

Richmond

$ 40

70

65

30

The plant at St. Louis can supply 250 tons of carpet per week; the plant at

Richmond can supply 400 ton per week. The Chicago outlet has a demand of

300 tons per week, and the outlet at Atlanta. dernands 350 tons per week. The

company wants to know the nunher of tons of carpet to ship from each plant to

each outlet in order to minimize the total shipping cost. Solve this transportation

problem.

Answer:

To

From

St. louis

Richmond

Demand

Chicago Atlanta

$ 40

70

300

65

30

350

Supply

250

400

650\650

2010/11, Sami Fethi, EMU, All Right Reserved, McGraw-Hill, 2007, 9. Ed.

Operations and Production Management

To

From

St. louis

Richmond

Demand

To

From

St. louis

Richmond

Demand

Chicago

$ 40

70

300

(30)

Chicago

$ 40

70

300

(30)

MGMT 405

Atlanta

Answer set 4

Supply

65

30

350

(35)

250 (25)

400 (40)

Atlanta

Supply

65

30 /350

350/350

(35)

250

(25)

400/350 (40)

Richmond Atlanta =350*30=10500

To

From

St. louis

Richmond

Demand

Chicago

$ 40

70/50

300/50

(30)

Supply

250 (25)

50/50 (40)

Richmond Chicago =50*70=3500

To

From

Chicago

St. louis

$ 40/250

Demand

250

(30)

Supply

250 (25)

St. louis Chicago =250*40=10000

Total= $ 24,000

2010/11, Sami Fethi, EMU, All Right Reserved, McGraw-Hill, 2007, 9. Ed.

Operations and Production Management

MGMT 405

Answer set 4

2. Given a transportation problem wth the following costs, supply, and demand,

find the optimal solution:

To

From

A

B

C

Demand

(Cost)

1

2

$6

7

$5

3

$8

5

135 175

To

From

A

B

C

Demand

(Cost)

1

2

$6

7

$ 5 3/175

$8

5

135 175

(1)

(2)

3

4

6

7

170

supply

100

180

200

3

4

supply

100

180

200

480\480

ANSWER:

6

7

170

(2)

(2)

(2)

(2)

B 2 =175*3 =525

To

From

A

B

C

Demand

(Cost)

1

$6

$5

$8

135

(1)

3

4/100

6

7

170

(2)

supply

100

5

200

(2)

(1)

(1)

A 3 =100*4 =400

To

From

B

C

Demand

(Cost)

1

5/5

130/ 8

130

(3)

3

6

7/70

70

(1)

supply

5

200

(1)

(1)

2010/11, Sami Fethi, EMU, All Right Reserved, McGraw-Hill, 2007, 9. Ed.

Operations and Production Management

MGMT 405

Answer set 4

B 1 =5*5 =25

C 1 =130*8 =1040

C 3 =70*7 =490

Total= 2,480

3. A plant has four operators to be assigned to four machines. The time

(minutes) required by each worker to produce a product on each machine

is shown in the following table:

Operator

1

2

3

4

Machine (min.)

A

B

C

10

12

9

5

10

7

12

14

13

8

15

11

D

11

8

11

9

Determine the optimal assignment and compute total minimum time.

ANSWER

10

5

12

8

12

10

14

15

9

7

13

11

11

8

11

9

Row and Column

1

0

1

0

0

2

0

4

0

2

2

3

2

3

0

1

2010/11, Sami Fethi, EMU, All Right Reserved, McGraw-Hill, 2007, 9. Ed.

Operations and Production Management

1

0

1

0

0

2

0

4

0

2

2

3

2

3

0

1

0

1

0

3

0

1

2

2

2

2

0

0

MGMT 405

Answer set 4

2

0

2

0

C1=9

A2=5

B3=14

D4=9

Total=37 minutes

4. The Omega pharmaceutical firm has five salespersons, whom the firm

wants to assign to five sales regions. Given their various previous

contacts, the salespersons are able to cover the regions in different

amounts of time. The amount of time (days) required by each salesperson

to cover each city is shown in the following table:

Region

Days

Sales

person

1

2

3

4

5

A

17

12

11

14

13

B

10

9

16

10

12

C

15

16

14

10

9

D

16

9

15

18

15

E

20

14

12

17

11

Which salesperson should be assigned to each region to minimize total

time? Identify the optimal assignments and compute total minimum time.

2010/11, Sami Fethi, EMU, All Right Reserved, McGraw-Hill, 2007, 9. Ed.

Operations and Production Management

MGMT 405

Answer set 4

Answer

Row reduction:

A

7

3

0

4

4

1

2

3

4

5

B

0

0

5

0

3

C

5

7

3

0

0

D

6

0

4

8

6

E

10

5

1

7

2

Coloumn reduction:

A

7

3

0

4

4

A

7

3

0

4

4

B

0

0

5

0

3

B

0

0

5

0

3

C

5

7

3

0

0

C

5

7

3

0

0

D

6

0

4

8

6

E

9

4

0

6

1

D

5

0

4

7

5

E

8

4

0

5

0

D

6

0

4

8

6

E

9

4

0

6

1

Final step is as follows:

A

6

3

0

4

3

B

0

1

6

0

3

C

5

8

4

0

0

B 1

C 4

A 3

D2

E 5

2010/11, Sami Fethi, EMU, All Right Reserved, McGraw-Hill, 2007, 9. Ed.

Operations and Production Management

MGMT 405

Answer set 4

Total= 51 days

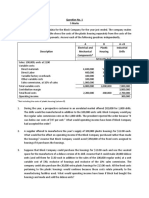

5. A company supplies three project A, B, and C in three different towns.

Construction plant engineers of the company estimated weekly

requirement truckloads as 72, 102, and 41 respectively. These projects

can be supplied by the three plants 1, 2, and 3 with available amount of

truckloads 56, 82 and 77 respectively. Conducting North west corner

method:

A

1

2

3

Plant

Projec

t

B

C

4

8

16

24

8

16

8

16

24

(a) Determine the dispatch program between the projects and plants.

(b) Calculate individual cost

(c) Calculate total minimum cost

ANSWER:

A

Plant

requirement

1

2

3

Projec

t

B

C

4

8

16

24

8

16

72

102

Capaci

ty

8

16

24

56

82

77

215/2

41 15

Capaci

Project

ty

A

B

C

1 Apr-56

8

8

56

16/16

Plant

2 *

24/66**

16

82

16/36** 24/41***

3

8 *

*

77

215/2

requirement

72

102

41 15

2010/11, Sami Fethi, EMU, All Right Reserved, McGraw-Hill, 2007, 9. Ed.

Operations and Production Management

MGMT 405

Answer set 4

41-41=0- this is the final step.

2010/11, Sami Fethi, EMU, All Right Reserved, McGraw-Hill, 2007, 9. Ed.

Potrebbero piacerti anche

- Assignment On TPDocumento5 pagineAssignment On TPabraha gebruNessuna valutazione finora

- Chapter 6Documento13 pagineChapter 6Paulin Joy Arce100% (1)

- MMB 522 Tutorial - 13 April 2016: AnswerDocumento9 pagineMMB 522 Tutorial - 13 April 2016: AnswerPansy Jaguar NjekwaNessuna valutazione finora

- Directions: Complete The Requirements Below and Submit Your Work in The Pigeon BoxesDocumento5 pagineDirections: Complete The Requirements Below and Submit Your Work in The Pigeon BoxesChin FiguraNessuna valutazione finora

- MGT 3332 Sample Test 1Documento3 pagineMGT 3332 Sample Test 1Ahmed0% (1)

- Transportation and Assignment ProblemDocumento67 pagineTransportation and Assignment ProblemRovick TarifeNessuna valutazione finora

- Complete Comparative Financial Statements and Notes to Financial Statements of Sakag-Kabuhi IncDocumento76 pagineComplete Comparative Financial Statements and Notes to Financial Statements of Sakag-Kabuhi IncLuigi Enderez BalucanNessuna valutazione finora

- New Microsoft Office Word DocumentDocumento5 pagineNew Microsoft Office Word DocumentTariq RahimNessuna valutazione finora

- Assign Students to Minimize Total Miles TraveledDocumento1 paginaAssign Students to Minimize Total Miles Traveledlyndy1969Nessuna valutazione finora

- Major Plant RenovationDocumento1 paginaMajor Plant RenovationgeorgecheboNessuna valutazione finora

- NetworkDocumento12 pagineNetworkDira Silvia IrvannyNessuna valutazione finora

- Assignment 1 PDFDocumento2 pagineAssignment 1 PDFHARINessuna valutazione finora

- Chapter 03 TP EndDocumento43 pagineChapter 03 TP EndMesfin MekuriaNessuna valutazione finora

- Estimation Methods Comparison for Cost AnalysisDocumento6 pagineEstimation Methods Comparison for Cost AnalysisCamila Miranda Kanda100% (1)

- Assignment 1 - Chapter 2Documento6 pagineAssignment 1 - Chapter 2Ho Thi Phuong ThaoNessuna valutazione finora

- Sample Test Questions For EOQDocumento5 pagineSample Test Questions For EOQSharina Mhyca SamonteNessuna valutazione finora

- Ilovepdf MergedDocumento100 pagineIlovepdf MergedVinny AujlaNessuna valutazione finora

- P3 - Basic Revision Q & A Selected TopicsDocumento96 pagineP3 - Basic Revision Q & A Selected TopicsZin Tha100% (1)

- Caterpillar Inc. 2016 Annual Report AnalysisDocumento27 pagineCaterpillar Inc. 2016 Annual Report AnalysisMuhammad Bilal KhanNessuna valutazione finora

- Case 3-2: Analyzing Server Purchase Options to Optimize Intranet RolloutDocumento11 pagineCase 3-2: Analyzing Server Purchase Options to Optimize Intranet RolloutKaren Kaye Pasamonte0% (1)

- End-Of-Chapter Answers Chapter 8 PDFDocumento16 pagineEnd-Of-Chapter Answers Chapter 8 PDFSiphoNessuna valutazione finora

- Taller OPT-SoluciónDocumento14 pagineTaller OPT-SoluciónMauricio Alejandro Buitrago Soto100% (1)

- Forecasting Topic 6Documento6 pagineForecasting Topic 6Ahmed Munawar100% (1)

- Chapter 3 Exercise SolutionsDocumento14 pagineChapter 3 Exercise SolutionsHoàng HuyNessuna valutazione finora

- Case Analysis Part 1Documento8 pagineCase Analysis Part 1CJ IbaleNessuna valutazione finora

- AMA Suggested Telegram Canotes PDFDocumento427 pagineAMA Suggested Telegram Canotes PDFAnmol AgalNessuna valutazione finora

- Weighted Average PDFDocumento3 pagineWeighted Average PDF'Ahmed Sabbir Tinku'100% (1)

- 2 - Sample Problem Set - ForecastingDocumento5 pagine2 - Sample Problem Set - ForecastingQila Ila0% (1)

- Dublin Shirt Case - SolutionDocumento7 pagineDublin Shirt Case - SolutionAbid Iqbal100% (1)

- MBA641 Managerial Accounting Case Study #3Documento3 pagineMBA641 Managerial Accounting Case Study #3risvana rahimNessuna valutazione finora

- Case Study - LocationDocumento3 pagineCase Study - LocationYuri MeigeniNessuna valutazione finora

- Question No 1Documento1 paginaQuestion No 1pammy3130% (1)

- Accounting Textbook Solutions - 34Documento19 pagineAccounting Textbook Solutions - 34acc-expertNessuna valutazione finora

- POM 1 Capacity and LocationDocumento5 paginePOM 1 Capacity and LocationAbdel Azim MohamedNessuna valutazione finora

- Pcoa 009 - Management Science Module 4: Waiting Line ModelsDocumento18 paginePcoa 009 - Management Science Module 4: Waiting Line ModelsGenesis RoldanNessuna valutazione finora

- Finance Assistant CV TemplateDocumento2 pagineFinance Assistant CV TemplateRizky WidiyantoNessuna valutazione finora

- Assignment 6-8Documento19 pagineAssignment 6-8Abhishek Satish WaghNessuna valutazione finora

- BA213 Test3 Review AnswersDocumento27 pagineBA213 Test3 Review AnswersnwuodiopdNessuna valutazione finora

- ABC Analysis Practice Problems Nov 2016Documento12 pagineABC Analysis Practice Problems Nov 2016manoj kumarNessuna valutazione finora

- OR Question BankDocumento29 pagineOR Question BankSuhas Mv50% (4)

- Strategic Plan Walt DisneyDocumento2 pagineStrategic Plan Walt DisneyRhea CastilloNessuna valutazione finora

- CORELAP Algorithm Layout Planning Relationship DiagramsDocumento6 pagineCORELAP Algorithm Layout Planning Relationship DiagramsSahil KumarNessuna valutazione finora

- Ibus Chapter 14Documento2 pagineIbus Chapter 14Chen Zhi HongNessuna valutazione finora

- Minimizing Costs with the Hungarian Assignment MethodDocumento37 pagineMinimizing Costs with the Hungarian Assignment MethodRajesh LambaNessuna valutazione finora

- CHAPTER 5 - Assignment SolutionDocumento16 pagineCHAPTER 5 - Assignment SolutionCoci KhouryNessuna valutazione finora

- Optimize Transportation Costs with Linear Programming ModelDocumento101 pagineOptimize Transportation Costs with Linear Programming ModelMeghna AdhikaryNessuna valutazione finora

- Group 4: Answer Questions Number 1 To 6 Using The Given DataDocumento4 pagineGroup 4: Answer Questions Number 1 To 6 Using The Given DataDame Chala100% (1)

- Class Exercise On Linear Programming PDFDocumento3 pagineClass Exercise On Linear Programming PDFKaran KakkarNessuna valutazione finora

- Chapter 45 Operating Segments ProblemsDocumento5 pagineChapter 45 Operating Segments ProblemsHohohoNessuna valutazione finora

- 16Documento6 pagine16Trân LêNessuna valutazione finora

- Engineering Economics: Rate of Return AnalysisDocumento29 pagineEngineering Economics: Rate of Return AnalysisEkoNessuna valutazione finora

- ConAgra Processes Beef Cattle ProductsDocumento13 pagineConAgra Processes Beef Cattle ProductsMawaz Khan MirzaNessuna valutazione finora

- Af201 Final Exam Revision Package - S2, 2020 Face-to-Face & Blended Modes Suggested Partial SolutionsDocumento9 pagineAf201 Final Exam Revision Package - S2, 2020 Face-to-Face & Blended Modes Suggested Partial SolutionsChand DivneshNessuna valutazione finora

- 2.2 Location Breakeven AnalysisDocumento3 pagine2.2 Location Breakeven Analysisorenchladee100% (1)

- BEP Sums QuestionsDocumento7 pagineBEP Sums QuestionsPavan AcharyaNessuna valutazione finora

- Bafahawdaauf Daid AdsjaDocumento2 pagineBafahawdaauf Daid AdsjaSteve GdogNessuna valutazione finora

- Module 4 Technical WritingDocumento4 pagineModule 4 Technical WritingSJ AjineNessuna valutazione finora

- Paper 2 Quantitative Techniques PDFDocumento12 paginePaper 2 Quantitative Techniques PDFTuryamureeba JuliusNessuna valutazione finora

- Productivity and Reliability-Based Maintenance Management, Second EditionDa EverandProductivity and Reliability-Based Maintenance Management, Second EditionNessuna valutazione finora

- MGMT 405 Operations and Production Management Answer Set 5 (Reference Chapters 12 - William J. Stevenson-2007, Ninth Edition) ProblemsDocumento13 pagineMGMT 405 Operations and Production Management Answer Set 5 (Reference Chapters 12 - William J. Stevenson-2007, Ninth Edition) ProblemsÖzlem YurtseverNessuna valutazione finora

- Magnetic Pick UpsDocumento4 pagineMagnetic Pick UpslunikmirNessuna valutazione finora

- Usjr Temfacil Balance of Work Schedule Aug 25, 2022Documento5 pagineUsjr Temfacil Balance of Work Schedule Aug 25, 2022Maribeth PalumarNessuna valutazione finora

- IEEE T&D Insulators 101 Design CriteriaDocumento84 pagineIEEE T&D Insulators 101 Design Criteriasachin HUNessuna valutazione finora

- Effect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanDocumento7 pagineEffect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanJuniper PublishersNessuna valutazione finora

- SB Z Audio2Documento2 pagineSB Z Audio2api-151773256Nessuna valutazione finora

- Caterpillar Ep15krtDocumento37 pagineCaterpillar Ep15krtIvan MajikNessuna valutazione finora

- CIRC 314-AN 178 INP EN EDENPROD 195309 v1Documento34 pagineCIRC 314-AN 178 INP EN EDENPROD 195309 v1xloriki_100% (1)

- Panasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Documento39 paginePanasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Gordon Elder100% (5)

- ROMUS 2012 Flooring CatalogueDocumento20 pagineROMUS 2012 Flooring CatalogueDan George IIINessuna valutazione finora

- Diia Specification: Dali Part 252 - Energy ReportingDocumento15 pagineDiia Specification: Dali Part 252 - Energy Reportingtufta tuftaNessuna valutazione finora

- Gas Natural Aplicacion Industria y OtrosDocumento319 pagineGas Natural Aplicacion Industria y OtrosLuis Eduardo LuceroNessuna valutazione finora

- WL 318 PDFDocumento199 pagineWL 318 PDFBeckty Ahmad100% (1)

- NDE Procedure - Radiographic TestingDocumento43 pagineNDE Procedure - Radiographic TestingJeganeswaranNessuna valutazione finora

- Who will buy electric vehicles Segmenting the young Indian buyers using cluster analysisDocumento12 pagineWho will buy electric vehicles Segmenting the young Indian buyers using cluster analysisbhasker sharmaNessuna valutazione finora

- CAT Ground Engaging ToolsDocumento35 pagineCAT Ground Engaging ToolsJimmy Nuñez VarasNessuna valutazione finora

- An Online ECG QRS Detection TechniqueDocumento6 pagineAn Online ECG QRS Detection TechniqueIDESNessuna valutazione finora

- STS Chapter 1 ReviewerDocumento4 pagineSTS Chapter 1 ReviewerEunice AdagioNessuna valutazione finora

- VivsayamDocumento87 pagineVivsayamvalarumsakthi100% (2)

- Datasheet PDFDocumento6 pagineDatasheet PDFAhmed ElShoraNessuna valutazione finora

- VA TearDownDocumento5 pagineVA TearDownfaj_larcfave5149Nessuna valutazione finora

- Taking Back SundayDocumento9 pagineTaking Back SundayBlack CrowNessuna valutazione finora

- Swatchh Bharat AbhiyanDocumento13 pagineSwatchh Bharat AbhiyanHRISHI SHARMANessuna valutazione finora

- Draft Initial Study - San Joaquin Apartments and Precinct Improvements ProjectDocumento190 pagineDraft Initial Study - San Joaquin Apartments and Precinct Improvements Projectapi-249457935Nessuna valutazione finora

- Proposal Anguria Pasta NewDocumento24 pagineProposal Anguria Pasta NewNOOR IRDINA HAFIZAH BT TAUPISNessuna valutazione finora

- LKC CS Assignment2Documento18 pagineLKC CS Assignment2Jackie LeongNessuna valutazione finora

- FST Handbook 2014-Final Copy 1 PDFDocumento382 pagineFST Handbook 2014-Final Copy 1 PDFDelvon DownerNessuna valutazione finora

- 24.postpartum Period-Physiological Changes in The MotherDocumento16 pagine24.postpartum Period-Physiological Changes in The MotherHem KumariNessuna valutazione finora

- Basic First AidDocumento31 pagineBasic First AidMark Anthony MaquilingNessuna valutazione finora

- Nickel-Metal Hydride Battery Safety Data SheetDocumento8 pagineNickel-Metal Hydride Battery Safety Data SheetYeong WheeNessuna valutazione finora

- Tetracyclines: Dr. Md. Rageeb Md. Usman Associate Professor Department of PharmacognosyDocumento21 pagineTetracyclines: Dr. Md. Rageeb Md. Usman Associate Professor Department of PharmacognosyAnonymous TCbZigVqNessuna valutazione finora