Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gabions

Caricato da

Francois-Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gabions

Caricato da

Francois-Copyright:

Formati disponibili

African Gabions (Pty) Ltd reserves the right to amend product specifications

without notice and specifiers are requested to check as to the validity of the

specifications they are using.

PRODUCT TECHNICAL DATA SHEET

Rev: 00, Issue Data 01.10.2003

GABIONS

Gabions

Gabions are baskets made of hexagonal woven wire Mesh Type

80, commonly referred to as double twist wire mesh as per SANS

1580:2001 (Figures 1 and 2). Gabions are filled with rock at the

project site to form flexible, permeable, monolithic structures such

as retaining walls, channel linings and weirs for erosion control

projects.

The steel wire used in the manufacture of the gabion is heavily zinc

coated (275g/m) as per SANS 675:1997. If required, a PVC

coating is extruded over the galvanised wire to provide added

protection for use in aggressive environments such as acidic soils

and water, in salt water, in water carrying a high abrasive sediment

load or wherever the risk of corrosion is present. The PVC coating

has a nominal thickness of 0.5 mm. The tolerances of mesh and

wire are shown in Figures 2 and 3.

In order to reinforce the structure, all mesh panel edges are

selvedged with a wire having a greater diameter than the mesh

wire. The gabion is divided into cells by means of diaphragms

positioned at approximately 1m centres (Figure 1). Dimensions

and sizes of galvanised and PVC coated gabions are shown in

Figure 5. When specifying Gabions in the tender documents or bill

of quantities, please refer to Figure 8.

Filling and Lacing

The Gabions must be filled with rock ranging between 100 mm and

250 mm. The range in sizes may allow for a variation of 5%

oversize and / or 5% undersize rock, provided it is not placed at the

exposed surface. In all cases, oversize rock shall not be larger than

300 mm and the undersize rock shall not be smaller than 100 mm.

Rocks shall be hard, angular to round, durable and of such quality

that they shall not disintegrate on exposure to water or weathering

during the life of the structure. Care should be taken when placing

the stone to assure that the PVC coating on gabions will not be

damaged. All visible faces should be carefully hand-placed for

appearance purposes. For further information on the installation of

gabions please refer to the Product Installation Guide for Gabions.

In place of lacing wire, lacing operations can be made by using

Spenax tools (Figure 7) available from our offices together with

stainless steel rings (Figure 6A) having the following specifications:

- diameter: 3mm

- tensile strength: 156-178 kg/mm2

Spacing of the rings or loops must not exceed that shown in

Figure 6B.

Wire

All tests on wire must be performed prior to manufacturing the mesh.

1. Tensile strength: The wire used for the manufacture of the

gabions has a tensile strength between 350-575 N/mm2

according to SANS 675:1997.

2. Elongation: Elongation shall not be less than 10% in accordance

with EN 10223-3. Tests are carried out on a sample at least 30

cm long.

3. Adhesion of zinc: The adhesion of the zinc coating to the wire is

such that, when the wire is wrapped six turns around a mandrel

having four times the diameter of the wire, it does not flake or

crack when rubbed with the bare fingers, in accordance with

SANS 675:1997.

4. Ductility: The ductility of the zinc-coated wire is such that when

the wire is wrapped at least eight times around a wire having the

same diameter of the test specimen at a rate not exceeding

15 turns per minute and then unwrapped at the same rate, it does

not show any sign of fracture of the underlying steel wire in

accordance with SANS 675:1997.

Lid

Diaphragm

Height

Length

Width

Figure 1

STANDARD MESH-WIRE

Mesh Type 80

Tolerance

OD Wire (mm)

Galvanised

80

-2 +5

2.7

Galvanised + PVC

80

-2 +5

3.7

MESH TOLERANCE

The tolerance on the opening of mesh b

being the distance between the axis of two

consecutive twists according to SANS

1580:2001

Figure 2

PROPERTIES OF WIRE

Use

Wire**

Galvanised

Galvanised + PVC

Wire

Tolerance*

Quantity of zinc*

Units

Lacing

Mesh

Selvedge

mm

2.2

3.2

2.7

3.7

3.4

4.4

mm

0.08

0.08

0.1

245

275

275

g/m

Tensile strength*

N/mm2

350-575

** According to SANS 675:1997

** According to SANS 1580:2001 and SANS 675:1997

Figure 3

Figure 4

PVC Coating Characteristics

The properties of the PVC material should adhere to the

following:

Width W(m)

1.0

1.0

1.0

Height H(m)

1.0

1.0

1.0

3.0

1.0

1.0

4.0

1.0

2.0

0.5

2.0

1.0

3.0

1.0

4.0

1.0

Tolerances : Height, Width : 5%; Length : 10%

All sizes and dimensions are nominal.

B

Open

Closed

Single Twist

Max. 6 in

100mm

100mm

Double Twist

100mm

45 mm

Single Twist

Figure 6

The properties after aging tests shall be as follows:

Appearance of coated mesh: no cracking, stripping or air

bubbles, and no appreciable variation in color;

Specific Gravity: variations shall not exceed 6%;

Hardness: variations shall not exceed 10%;

Tensile strength: variations shall not exceed 25%;

Modulus of elasticity: variations shall not exceed 25%;

Abrasion resistance: variations shall not exceed 10%;

Brittleness temperature: shall not exceed +18C.

1.0

0.5

0.5

0.5

0.5

Figure 5

20 mm

Specific gravity: 1.30-1.35 kg/dm in accordance with

ASTM D792 Table 1;

Hardness: between 50 and 60 Shore D, according to

ASTM D2240;

Tensile strength: not less than 20.6 MPa, according to

ASTM D412-92;

Modulus of elasticity: not less than 18.6 MPa, in accordance

with ASTM D412-92;

Abrasion resistance: the percentage of the weight loss shall be

less than 12%, according to ASTM D1242-92.

Creeping corrosion: max. penetration of corrosion of the wire

from a square cut end is 25 mm when the specimen has been

immersed for 2,000 hrs in a 5% solution HCl (hydrochloric

acid 12 Be).

The accelerated aging tests are:

Salt spray test: test period 3,000 hours, test method

ASTM B117-94

Exposure to UV rays: test period 3,000 hours at 63C, test

method ASTM D1499-92a and ASTM G23-93 apparatus

Type E

Brittleness temperature: no higher than -9C, or lower

temperature when specified by the purchaser, when tested in

accordance with ASTM D746.

STANDARD GABION SIZES

Length L(m)

1.0

1.5

2.0

1. Pliers

2. Pliers with nipper

3. Nipper

Pneumatic

Spenax tool

Manual tool

Figure 7

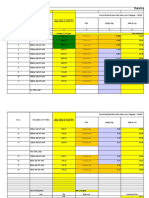

BILL OF QUANTITIES

Item

No

Description

Unit

Quantity

Rate

GABIONS SANS 1200DK:1995 (Double twist hexagonal wire mesh to SANS 1580:2001)

1

GABIONS (Including material and delivery).

1.1

Mesh Type 80 with 2,7mm Class A Galvanised wire

Length x Width x Height

Mesh Type 80 with 2,7/3,7mm Class A Galvanised and PVC coated wire

Length x Width x Height

Surface preparation for bedding the Gabions

Installation of Gabion units (including unfolding, placing, filling, lacing and bracing).

Rockfill.

Packing selected stone for exposed face

AG Geotextile (Including material, delivery, unrolling, cutting and placing)

Continuous Polyester Filament Double Needle-Punched

AG150 - Minimum Energy Absorption of 4,0 kN/m

AG200 - Minimum Energy Absorption of 6,5 kN/m

AG300 - Minimum Energy Absorption of 10 kN/m

AG400 - Minimum Energy Absorption of 12 kN/m

m

m

m

m

1.2

6.1

6.2

6.3

6.4

Figure 8

Quality System Guarantees

production, certified internal management and

technical assistance in compliance with ISO 9001:2000

HEAD OFFICE - DURBAN, SOUTH AFRICA

P O Box 15777, Westmead, 3608 Tel: +27-31-700 8456 Fax: +27-31-700 8469 E-mail: sales@africangabions.co.za

JOHANNESBURG, SOUTH AFRICA

P O Box 133, Kya Sands, 2163 Tel: +27-11-704 0160 Fax: +27-11-704 0159 E-mail: jhb@africangabions.co.za

CAPE TOWN, SOUTH AFRICA

P O Box 22150, Fish Hoek, 7974 Tel: +27-21-702 1416 Fax: +27-21-702 2977 E-mail: cptsales@africangabions.co.za

MALAWI

P O Box 40494, Kanengo, Lilongwe 4, Malawi Tel/Fax: +265-1-756 109 E-mail: maccaferri@malawi.net

MADAGASCAR

BP 168 Antananarivo 101, Madagascar Tel: +261-20-22-231 02 Fax: +261-20-22-553 90 E-mail: africangabions@wanadoo.mg

Website: www.africangabions.co.za

African Gabions (Pty) Ltd, Durban, South Africa.

Amount

(R)

Potrebbero piacerti anche

- Concrete Block Paving Specification Guide for South AfricaDocumento3 pagineConcrete Block Paving Specification Guide for South AfricaShadrach Fiamenyor Dapaah100% (1)

- tackCoat&Emulsion PDFDocumento5 paginetackCoat&Emulsion PDFe110807Nessuna valutazione finora

- 02525Documento3 pagine02525uddinnadeem0% (1)

- BS 1881-103Documento13 pagineBS 1881-103tipe123456789Nessuna valutazione finora

- BS 812-123Documento19 pagineBS 812-123aliscooter65Nessuna valutazione finora

- Sans 1350 - 2005Documento1 paginaSans 1350 - 2005LungisaniNessuna valutazione finora

- Concrete Specifications and Quality StandardsDocumento30 pagineConcrete Specifications and Quality StandardsForbes KambaNessuna valutazione finora

- Sub BaseDocumento4 pagineSub BaseAnonymous Dk3ItoC8MFNessuna valutazione finora

- SikaProof membrane PDSDocumento2 pagineSikaProof membrane PDSKennethNessuna valutazione finora

- City of Durban Standard Engineering Specification Part C - Concrete WorkDocumento33 pagineCity of Durban Standard Engineering Specification Part C - Concrete WorkLuke Jabulani ReidNessuna valutazione finora

- Sans10100 2Documento71 pagineSans10100 2Rynardt VogelNessuna valutazione finora

- MasterSeal 726 - TDSDocumento2 pagineMasterSeal 726 - TDSKhin Sandi KoNessuna valutazione finora

- Mastertop 290: Iron Aggregate Hardener For Concrete FloorsDocumento3 pagineMastertop 290: Iron Aggregate Hardener For Concrete FloorsFrancois-Nessuna valutazione finora

- List of EStandardsDocumento10 pagineList of EStandardsRetselisitsoeNessuna valutazione finora

- SANS 3001-AG10 2012 Part AG10 ACV (Aggregate Crushing Value) and 10 % FACT (Fines Aggregate CrushingDocumento19 pagineSANS 3001-AG10 2012 Part AG10 ACV (Aggregate Crushing Value) and 10 % FACT (Fines Aggregate Crushingqinmingchang19841020Nessuna valutazione finora

- Astm C305-99 STDDocumento3 pagineAstm C305-99 STDBarak Hussain100% (1)

- COLTO SPECIFICATIONS - MARCH 1998 REVIEWDocumento2 pagineCOLTO SPECIFICATIONS - MARCH 1998 REVIEWMaria Fernanda MurilloNessuna valutazione finora

- Din en 12390 - 8Documento7 pagineDin en 12390 - 8Tarek KhallafNessuna valutazione finora

- SATCC Chapter 8Documento20 pagineSATCC Chapter 8Rui Lourenco50% (2)

- MPVC UPVC CatalogueDocumento31 pagineMPVC UPVC CataloguealviralurvebeenoNessuna valutazione finora

- Cast Iron Heavy Duty Manhole Cover & Frame: COMPLY WITH BSEN 124:1994 (230KN) SS30:1999Documento1 paginaCast Iron Heavy Duty Manhole Cover & Frame: COMPLY WITH BSEN 124:1994 (230KN) SS30:1999parathasiNessuna valutazione finora

- TRRL-Research Report 87-Thick Design of Concrete RoadsDocumento17 pagineTRRL-Research Report 87-Thick Design of Concrete RoadsJack 'oj' Ojuka100% (1)

- Sabs 864Documento6 pagineSabs 864RetselisitsoeNessuna valutazione finora

- BS For Highways TestsDocumento12 pagineBS For Highways Testsdbg2012Nessuna valutazione finora

- Concrete Formwork and FinishesDocumento15 pagineConcrete Formwork and FinishesIm Chinith100% (1)

- Series 4000 - Bituminous Layers and SealsDocumento52 pagineSeries 4000 - Bituminous Layers and SealsBatenda Felix0% (1)

- Sans 51008Documento21 pagineSans 51008Kyle MoolmanNessuna valutazione finora

- Sans 3001-Ag4Documento11 pagineSans 3001-Ag4Sergio VianaNessuna valutazione finora

- ConRepair 04 JurcemNonshirk GP Ed01Documento2 pagineConRepair 04 JurcemNonshirk GP Ed01Tuntun Tat0% (1)

- SANS5861-3 - Making and Curing of Test SpecimensDocumento5 pagineSANS5861-3 - Making and Curing of Test SpecimensBrendon GovaNessuna valutazione finora

- Multifix All Mechanical Anchor - Design GuideDocumento28 pagineMultifix All Mechanical Anchor - Design GuideConstantino Ramirez (Cons)Nessuna valutazione finora

- Technical Datasheet for MoyaProof CWP Cementitious WaterproofingDocumento4 pagineTechnical Datasheet for MoyaProof CWP Cementitious Waterproofingcmtheboss100% (1)

- Technical ManualDocumento48 pagineTechnical ManualStewart BenNessuna valutazione finora

- A975-11 (Reapproved 2016)Documento8 pagineA975-11 (Reapproved 2016)duongNessuna valutazione finora

- Making Precast Prestressed Concrete LintelsDocumento2 pagineMaking Precast Prestressed Concrete LintelsRm126260% (5)

- Specifications Concrete Products Aug 08Documento9 pagineSpecifications Concrete Products Aug 08vijvel100% (1)

- Runway and airfield pavement designDocumento18 pagineRunway and airfield pavement designspruhatechNessuna valutazione finora

- Sikagard EPSDocumento18 pagineSikagard EPSTheOne Yasir0% (1)

- M 82-75 (2004) Cutback Asphalt (MC Type)Documento2 pagineM 82-75 (2004) Cutback Asphalt (MC Type)WalticoZegarraHerrera100% (1)

- Basf Masteremaco Application GuideDocumento15 pagineBasf Masteremaco Application GuideSolomon AhimbisibweNessuna valutazione finora

- Australian Manufactured Sand GuidelineDocumento2 pagineAustralian Manufactured Sand GuidelineahmadiahreadymixlabNessuna valutazione finora

- Testing Aggregates: BS 812: Part 120: 1989Documento10 pagineTesting Aggregates: BS 812: Part 120: 1989AmanNessuna valutazione finora

- BS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesDocumento19 pagineBS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesRaviranjan kumarNessuna valutazione finora

- Reinforced Concrete Class A3Documento33 pagineReinforced Concrete Class A3jimdabrond100% (2)

- Inspection Manual For Precast Concrete Pipe and StructuresDocumento63 pagineInspection Manual For Precast Concrete Pipe and StructuresMukeshNessuna valutazione finora

- Aggregates and Their Properties in Concrete Presentation - Mark Alexander PDFDocumento75 pagineAggregates and Their Properties in Concrete Presentation - Mark Alexander PDFharold romuald Lele FotsoNessuna valutazione finora

- Infraset Product Catalogue (2014)Documento55 pagineInfraset Product Catalogue (2014)Christian JordaanNessuna valutazione finora

- MS 628-3 2014 - PrepdfDocumento7 pagineMS 628-3 2014 - PrepdfMay OngNessuna valutazione finora

- Cyclone-Brochure PubDocumento2 pagineCyclone-Brochure Pubsk lukoNessuna valutazione finora

- Ccanz tm35 PDFDocumento246 pagineCcanz tm35 PDFcristiano68071Nessuna valutazione finora

- Kenya RDM Volume 6 Part 2 - Traffic Signs - 2nd Draft - Rev 3-26-07-23Documento246 pagineKenya RDM Volume 6 Part 2 - Traffic Signs - 2nd Draft - Rev 3-26-07-23mauncheetah_01Nessuna valutazione finora

- 187 NanoGrout EGDocumento2 pagine187 NanoGrout EGTristan Irvin Asi100% (3)

- Timber connector load dataDocumento8 pagineTimber connector load dataDinh Nam NguyenNessuna valutazione finora

- Vista CatalogueDocumento10 pagineVista CataloguelaukuneNessuna valutazione finora

- BS 1722-14-1992 Specification For Open Mesh Steel Panel FencesDocumento24 pagineBS 1722-14-1992 Specification For Open Mesh Steel Panel FencesAnoyNessuna valutazione finora

- BSI - CubesDocumento18 pagineBSI - CubesJay Musa0% (1)

- SANS5863 - Compressive Strength of Hardened ConcreteDocumento8 pagineSANS5863 - Compressive Strength of Hardened ConcreteBrendon GovaNessuna valutazione finora

- Sans50934 2Documento27 pagineSans50934 2Kyle MoolmanNessuna valutazione finora

- New Steelgrid HR Rockfall NettingDocumento2 pagineNew Steelgrid HR Rockfall NettingMario CordovaNessuna valutazione finora

- TDS - Galmac PVC Coated Gabions June 10Documento2 pagineTDS - Galmac PVC Coated Gabions June 10Chana PalominoNessuna valutazione finora

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocumento3 pagineSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-Nessuna valutazione finora

- MEYCO MP 364 Flex PDFDocumento2 pagineMEYCO MP 364 Flex PDFFrancois-Nessuna valutazione finora

- Ferroflow 939: Iron Fortified Shrinkage Compensated GroutDocumento2 pagineFerroflow 939: Iron Fortified Shrinkage Compensated GroutFrancois-Nessuna valutazione finora

- Standard Grout PDFDocumento3 pagineStandard Grout PDFFrancois-Nessuna valutazione finora

- Meyco MP 301 PDFDocumento2 pagineMeyco MP 301 PDFFrancois-Nessuna valutazione finora

- Meyco MP308 PDFDocumento3 pagineMeyco MP308 PDFFrancois-Nessuna valutazione finora

- Masterflow 410 PCDocumento3 pagineMasterflow 410 PCFrancois-Nessuna valutazione finora

- Masterflow 524: High Strength, Non Shrink Cementitious Construction GroutDocumento3 pagineMasterflow 524: High Strength, Non Shrink Cementitious Construction GroutFrancois-Nessuna valutazione finora

- FlowcableDocumento4 pagineFlowcableFrancois-Nessuna valutazione finora

- MEYCO MP 367 Foam PDFDocumento2 pagineMEYCO MP 367 Foam PDFFrancois-Nessuna valutazione finora

- Ferromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationDocumento2 pagineFerromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationFrancois-Nessuna valutazione finora

- Method Statement - Masterseal 345 REV D PDFDocumento17 pagineMethod Statement - Masterseal 345 REV D PDFFrancois-Nessuna valutazione finora

- Masterflow 400: High Strength, Free Flowing Epoxy GroutDocumento2 pagineMasterflow 400: High Strength, Free Flowing Epoxy GroutFrancois-Nessuna valutazione finora

- MEYCO MP320 Questions & Answers PDFDocumento12 pagineMEYCO MP320 Questions & Answers PDFFrancois-Nessuna valutazione finora

- Meyco MP302 PDFDocumento3 pagineMeyco MP302 PDFFrancois-Nessuna valutazione finora

- Meyco MP 357 GS PDFDocumento2 pagineMeyco MP 357 GS PDFFrancois-Nessuna valutazione finora

- Primer SC PDFDocumento3 paginePrimer SC PDFFrancois-Nessuna valutazione finora

- Meyco Fix Lube 1 PDFDocumento2 pagineMeyco Fix Lube 1 PDFFrancois-Nessuna valutazione finora

- RheoFIT 761 PDFDocumento2 pagineRheoFIT 761 PDFFrancois-Nessuna valutazione finora

- Meyco FIB 600 PDFDocumento2 pagineMeyco FIB 600 PDFFrancois-Nessuna valutazione finora

- Rheocrete 222+: Organic Corrosion Inhibiting AdmixtureDocumento3 pagineRheocrete 222+: Organic Corrosion Inhibiting AdmixtureFrancois-Nessuna valutazione finora

- Meyco FIB 500 PDFDocumento2 pagineMeyco FIB 500 PDFFrancois-Nessuna valutazione finora

- MBrace RESIN SYSTEMS PDFDocumento6 pagineMBrace RESIN SYSTEMS PDFFrancois-Nessuna valutazione finora

- Pozzolith 555: Non-Chloride Accelerating AdmixtureDocumento3 paginePozzolith 555: Non-Chloride Accelerating AdmixtureFrancois-Nessuna valutazione finora

- Rheoface 405: (Formerly Known As Surface Retarder)Documento1 paginaRheoface 405: (Formerly Known As Surface Retarder)Francois-Nessuna valutazione finora

- Meyco MP355 1K - TDS - 07 - PDFDocumento2 pagineMeyco MP355 1K - TDS - 07 - PDFFrancois-Nessuna valutazione finora

- Micro Air 120 PDFDocumento2 pagineMicro Air 120 PDFFrancois-Nessuna valutazione finora

- Protectosil CIT PDFDocumento3 pagineProtectosil CIT PDFFrancois-Nessuna valutazione finora

- Pozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteDocumento2 paginePozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteFrancois-Nessuna valutazione finora

- Rheobuild 1030: High Range Water ReducerDocumento2 pagineRheobuild 1030: High Range Water ReducerFrancois-Nessuna valutazione finora

- Series: Question BookletDocumento32 pagineSeries: Question BookletRishant ThakurNessuna valutazione finora

- Asme Sa-265 Specification For Nickel and Nickel-Base Alloy-Clad Steel PlateDocumento7 pagineAsme Sa-265 Specification For Nickel and Nickel-Base Alloy-Clad Steel Platelucecita1902100% (1)

- Technical Requirements For SS 2015 210915Documento132 pagineTechnical Requirements For SS 2015 210915L YO PinNessuna valutazione finora

- Foundry: Ex. Mo.1. Preparation of Mould of A Stepped PulleyDocumento4 pagineFoundry: Ex. Mo.1. Preparation of Mould of A Stepped PulleyAtshayaNessuna valutazione finora

- ENGINEERING REVIEW CENTER DOCUMENT SUMMARYDocumento71 pagineENGINEERING REVIEW CENTER DOCUMENT SUMMARYFernan MacusiNessuna valutazione finora

- Iso 9226 2012-02 PDFDocumento12 pagineIso 9226 2012-02 PDFIsrael Orta Sánchez100% (1)

- TCDPDocumento88 pagineTCDPPrakash KumarNessuna valutazione finora

- Structural Steel Load and Resistance Factor Design Short VersionDocumento8 pagineStructural Steel Load and Resistance Factor Design Short Versionjack.simpson.changNessuna valutazione finora

- Item 311Documento64 pagineItem 311Jansen WongNessuna valutazione finora

- Work Method Statement of RCP Works Pipe LayingDocumento6 pagineWork Method Statement of RCP Works Pipe LayingLod.N.S100% (3)

- ETICS BrochureDocumento8 pagineETICS Brochureterec_mariusNessuna valutazione finora

- Dartar Berat BesiDocumento12 pagineDartar Berat BesiIskak UnoNessuna valutazione finora

- Concrete Pipe vs HDPE Drainage Pipe: A Performance ComparisonDocumento15 pagineConcrete Pipe vs HDPE Drainage Pipe: A Performance Comparisonyyanan1118Nessuna valutazione finora

- WeLding Record & Report Track Piping WorkDocumento533 pagineWeLding Record & Report Track Piping WorkUjang SonjayaNessuna valutazione finora

- Duplex Stainless SteelDocumento231 pagineDuplex Stainless Steelponnivalavans_994423Nessuna valutazione finora

- Dismantling & Reinstatement Qty. For Working DprsDocumento28 pagineDismantling & Reinstatement Qty. For Working DprsDeepak ChandolaNessuna valutazione finora

- Especificacion Tuberias R08Documento226 pagineEspecificacion Tuberias R08Lenin Casanova CNessuna valutazione finora

- Material Issue (Jan) 2024Documento123 pagineMaterial Issue (Jan) 2024Laras SafitriNessuna valutazione finora

- CI pipe joint cost dataDocumento56 pagineCI pipe joint cost dataVenkataLakshmiKorrapatiNessuna valutazione finora

- Turkish-Aluminium IndustryDocumento19 pagineTurkish-Aluminium Industrygalaxy2002Nessuna valutazione finora

- Bolted Bamboo Joints Reinforced With Fibers: SciencedirectDocumento7 pagineBolted Bamboo Joints Reinforced With Fibers: SciencedirectMario Cruz BaNessuna valutazione finora

- Berat BajaDocumento25 pagineBerat BajaAchmad Zaki ZulkarnainNessuna valutazione finora

- 3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Documento22 pagine3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Gaurav BedseNessuna valutazione finora

- Hammer GuideDocumento5 pagineHammer GuideMuhammad Rizqi NugrohoNessuna valutazione finora

- Material and Construction CA1Documento20 pagineMaterial and Construction CA1Amit DharaNessuna valutazione finora

- Ch06 NonferrousDocumento13 pagineCh06 NonferroushasbyNessuna valutazione finora

- 70Documento41 pagine70masoud132Nessuna valutazione finora

- Estimate 29 - 11Documento19 pagineEstimate 29 - 11Ositha WarunaNessuna valutazione finora

- BCDA Construction Estimate for New Clark City Connecting RoadDocumento7 pagineBCDA Construction Estimate for New Clark City Connecting RoadNicky BalabboNessuna valutazione finora

- Name of Project: Expansion of Balasig Barangay Health Station W/ Birthing Location: Cabagan IsabelaDocumento30 pagineName of Project: Expansion of Balasig Barangay Health Station W/ Birthing Location: Cabagan IsabelaGel MagaddonNessuna valutazione finora