Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LP Dosing Ts

Caricato da

axis meisterTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LP Dosing Ts

Caricato da

axis meisterCopyright:

Formati disponibili

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500 0034 B

NTPC Ref No. SIM / 1 / TS / 1 / 34 B

Sheet 1 of 11

Plant Area: BOILER

Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER

SL. NO.

CONTENTS

1.0

PLANT DETAILS

2.0

OBJECTIVE

3.0

PROPOSAL

4.0

SERVICES REQUIRED

5.0

SAFETY PRECAUTIONS

6.0

EMERGENCY PROCEDURE

7.0

STATE OF THE PLANT

8.0

METHOD

9.0

COMPLETION CRITERIA

10.

APPENDICES

a) DRAWINGS

b) LOG SHEET

Signatures

NTPC

BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500 0034B

NTPC Ref No. SIM / 1 / TS / 1 / 34B

Sheet 2 of 11

Plant Area: BOILER

Procedure for: COMMISSIONING OF LP DOSING SYSTEM OF BOILER

SL. NO.

1.0

STATUS

PLANT DETAILS

The LP Dosing System consists of the

following:

1.1

1 No. Mixing Tank with Agitator

1.2

1 No. Metering Tank

1.3

2 Nos. Pump with Motor (Positive Displacement

pump)

1.4

2 Nos. Suction Filters

1.5

2 Nos. Relief Valve

1.6

Inlet DM Water connection to Mixing and Metering

Tank

1.7

Level Gauges for Mixing and Metering

Tank

1.8

Local Instrumentation

Plant Item Completion List for

Mechanical, Electrical and C&I are to

be prepared at site.

1.9

The Schematic of LP Dosing System is enclosed in

Subsection 10.0

(Drawing No. 4: PS : TSX : 0066:00 Dt. 23.07.2001)

Signatures

NTPC

Station: NTPC - Simhadri

BHEL

BHEL Ref No. PS - DC - 186 - 500

0034B

Sheet 3 of 11

NTPC Ref No. SIM / 1 / TS / 1 / 34B

Plant Area: BOILER

Procedure for: COMMISSIONING OF LP DOSING SYSTEM FOR BOILER

SL. NO.

STATUS

2.0

OBJECTIVES

2.1

To commissionLP dosing system and make it

available for unit operation.

3.0

PROPOSAL

3.1

The Commissioning of LP Dosing System is carried

out as follows:

a) Flushing of Mixing, Metering Tanks and upto

Pump Station with DM Water.

b) Pump trial run, Relief Valve setting and C&I

System .

Signatures

NTPC

Station: NTPC Simhadri

BHEL

BHEL Ref No. PS - DC - 186 - 500

0034B

NTPC Ref No. SIM / 1 / TS / 1 / 34B

Sheet 4 of 11

Plant Area: BOILER

Procedure for: COMMISSIONING OFLP DOSING SYSTEM FOR BOILER

SL. NO.

STATUS

4.0

SERVICES REQUIRED

4.1

Availability of manpower with required tools for

attending to any leak, cleaning of filters.

4.2

Availability of operating personal to

co-ordinate the activities.

4.3

Availability of lighting arrangement in and around

the LP Dosing System.

4.4

Availability of portable fire fighting equipment near

the dosing system.

4.5

Availability of sufficient quantity of DM Water.

4.6

Availability of LT Power Supply.

4.7

Availability of Chemicals.

Signatures

NTPC

Station: NTPC - Simhadri

BHEL

BHEL Ref No. PS - DC - 186 - 500

0034B

NTPC Ref No. SIM / 1 / TS / 1 / 34B

Sheet 5 of 11

Plant Area: BOILER

Procedure for: COMMISSIONING OFLP DOSING SYSTEM FOR BOILER

SL. NO.

STATUS

5.0

SAFETY PRECAUTIONS

5.1

Goggles, Apron, Hand-gloves for handling

chemicals.

5.2

Bunding & draining arrangements are properly

done to take care of spillages.

5.3

First aid kid is available at test area.

6.0

EMERGENCY PROCEDURE

6.1

The operating staff should know about the normal

operating procedure to be adopted in case of

damage to machinery or injury to any person

connected in the activity.

6.2

The test team should be well aware of procedures to

be adopted in case of any abnormality in the

activity.

Signatures

NTPC

Station: NTPC - Simhadri

BHEL

BHEL Ref No. PS - DC - 186 - 500

0034B

NTPC Ref No. SIM / 1 / TS / 1 / 34B

Sheet 6 of 11

Plant Area: BOILER

Procedure for: COMMISSIONING OF LP DOSING SYSTEM FOR BOILER

SL. NO.

STATUS

7.0

STATE OF THE PLANT

7.1

LP Dosing Systems are erected as per

recommended drawing.

7.2

Mixing and Metering Tanks are cleaned with DM

Water and filled upto normal operating level.

7.3

LT power supply system for Pumps, are

commissioned and available for operation.

7.4

Required Local/Remote I&C Inputs are made

available.

7.5

DM Water connections to Mixing Tank, metering

tank and to lines (for flushing) are ready.

7.6

Lubricating oil is filled in the pump gear box up to

its normal level / Indication.

7.7

Suction filters are cleaned.

7.8

Tank Drains and Pump Relief Valves are

terminated as per scheme.

7.9

The test area is cleaned and proper approaches are

available.

7.10

LP dosing system are erected with proper bunding

and draining facility to contain any spillage.

Signatures

NTPC

BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500 34B

NTPC Ref No. SIM / 1 / TS / 1 / 34B

Sheet 7 of 11

Plant Area: BOILER

Procedure for: COMMISSIONING OF LP DOSING SYSTEM FOR BOILER

SL. NO.

8.0

STATUS

METHOD

8.1

FLUSHING OPERATION

The Mixing & Metering Tanks along with suction

pipe upto pump to be flushed with DM Water so

as to avoid the entry of dust into the pump.

8.2

PREPARATION:

Disconnect the pump suction connection flange

and connect the suction line with hose to nearby

drain. Remove the suction filters and make the

suction line through.

8.3

PROCESS

8.4

Fill the Mixing and Metering Tank with DM

Water.

8.5

Open the pump suction valve and flush the

system until clear water noticed in the temporary

hose.

Signatures

NTPC

BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500

0034B

NTPC Ref No. SIM / 1 / TS / 1 / 34B

Sheet 8 of 11

Plant Area: BOILER

Procedure for: COMMISSIONING OF LP DOSING SYSTEM FOR BOILER

SL. NO.

8.6

STATUS

Normalise the suction connection to pump.

8.7

Bump the motor (in decoupled condition) and check

the direction of rotation.

8.8

Trial run the motor for 2 hours and couple with the

pump.

8.9

Fill the Mixing and Metering Tank upto normal

level.

8.10

Open the Pumps Suction, Discharge and Recirculation valve.

8.11

Close the valve in the line going to boiler.

8.12

Ensure the suction & discharge gauges are installed

and the respective valve cocks are opened.

8.13

Keep pump stroke to minimum and start the pump

and observe discharge pressure.

8.14

Increase the pump stroke gradually to 100% and

observe pump performance.

8.15

Trial run the pump for 4 hours and maintain the

tank level keeping the pump stroke around 50%.

8.16

Commission the remote stroke adjustment system (if

provided) and operate and observe its performance.

Signatures

NTPC

BHEL

Station: NTPC - Simhadri

BHEL Ref No. PS - DC - 186 - 500

0034B

NTPC Ref No. SIM / 1 / TS / 1 / 34B

Sheet 9 of 11

Plant Area: BOILER

Procedure for: COMMISSIONING OF LP DOSING SYSTEM FOR BOILER

SL. NO.

8.17

STATUS

Set the relief valve by throttling the R/C Valve.

(The set pressure to be around 10 KSC more than

the working pressure of the system)

8.18

Stop the pump.

8.19

Ensure the Agitator is coupled with motor.

8.20

Bump the Agitator and check the direction of

rotation.

8.21

Trial run the Agitator for 2 Hours.

9.0

COMPLETION CRITERIA

Commissioning of LP dosing system completed

with

a) Flushing of the system from tanks to pump

suction.

b) Trial run of Pump and agitator for 4 Hours & 2

Hours respy.

c) Setting of Relief valve around 10.0 KSC above

working pressure of the system.

Signatures

NTPC

BHEL

SHEET 11 OF 11

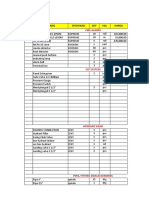

LOG SHEET

Date:

PROJECT :

UNIT

ACTIVITY:

Sl.

Date / Time

Pump in

Discharge

Mixing/Meterin

Gear

Remark

No.

service

Pressure

Kg/cm2

g Tank Level

in Mn.

Box Oil

Signatures

NTPC

BHEL

PROCEDURE FOR COMMISSIONING OF LP DOSING

SYSTEM FOR BOILER

(Testing schedule)

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Sinamics g120c BrochureDocumento12 pagineSinamics g120c Brochureaxis meisterNessuna valutazione finora

- ID FD PA Fans StructuresDocumento17 pagineID FD PA Fans StructuresMohan RajNessuna valutazione finora

- Sun Pharma AR FY19Documento264 pagineSun Pharma AR FY19Dhagash VoraNessuna valutazione finora

- Mech Check ListDocumento29 pagineMech Check Listaxis meisterNessuna valutazione finora

- 210MW PPS SimulationDocumento11 pagine210MW PPS Simulationkaruna346Nessuna valutazione finora

- References: Final Detail Sewer & WWTP Design ReportDocumento2 pagineReferences: Final Detail Sewer & WWTP Design ReportMesfinNessuna valutazione finora

- Waterpipe v1Documento25 pagineWaterpipe v1idigitiNessuna valutazione finora

- Water TreatmentDocumento8 pagineWater TreatmentMallela Sampath Kumar100% (1)

- Plumbing NC II Tools ListDocumento3 paginePlumbing NC II Tools ListIrvin Amor AndresNessuna valutazione finora

- Variable Displacement Axial Piston Pumps: Installation ManualDocumento20 pagineVariable Displacement Axial Piston Pumps: Installation ManualAPURV GOYALNessuna valutazione finora

- For This Is Unit of With: & Is Where Model Most Durable Fixtures RangeDocumento3 pagineFor This Is Unit of With: & Is Where Model Most Durable Fixtures RangeAdeNessuna valutazione finora

- Pipe Sizes According To Schedule Input Value Unit: Pipe Table - Extracted From Asme B36.1Documento6 paginePipe Sizes According To Schedule Input Value Unit: Pipe Table - Extracted From Asme B36.1Richard ObinnaNessuna valutazione finora

- I1. Objective Type Questions: Civl Engneering (Osjective Type)Documento18 pagineI1. Objective Type Questions: Civl Engneering (Osjective Type)ankush sharmaNessuna valutazione finora

- Normalizing NPSH: Calculating Suction Specific SpeedDocumento5 pagineNormalizing NPSH: Calculating Suction Specific Speedorchids28Nessuna valutazione finora

- Engineering Plumbing House Plumbing Document 7.guide To Toilet PlumbingDocumento8 pagineEngineering Plumbing House Plumbing Document 7.guide To Toilet Plumbingupavp cd14Nessuna valutazione finora

- Laboratory Experiment No. 5 Losses in Pipes, Pipe Bends and Pipe FittingsDocumento11 pagineLaboratory Experiment No. 5 Losses in Pipes, Pipe Bends and Pipe FittingsKhryz AbadNessuna valutazione finora

- MEP Progress TrackingDocumento18 pagineMEP Progress TrackingPaul KwongNessuna valutazione finora

- Baguio Sewage Treatment Plant: ESTIMATED PROJECT COST: Ranges From 1.576 Billion Yen-2.697 Billion YenDocumento7 pagineBaguio Sewage Treatment Plant: ESTIMATED PROJECT COST: Ranges From 1.576 Billion Yen-2.697 Billion YenRomulo CubidNessuna valutazione finora

- Fire Alarm, CO2, Hydrant Parts ListDocumento6 pagineFire Alarm, CO2, Hydrant Parts Listifdoit care solutionNessuna valutazione finora

- Gewater Corrosion Test CouponDocumento3 pagineGewater Corrosion Test CoupontuzlucayirNessuna valutazione finora

- Prihartanto, Heru Sri Naryanto Dan Deliyanti GaneshaDocumento8 paginePrihartanto, Heru Sri Naryanto Dan Deliyanti GaneshaGhoffar GiffariNessuna valutazione finora

- Why The Need For The Clean Water Act?Documento4 pagineWhy The Need For The Clean Water Act?Jerry Eduardo II BonaguaNessuna valutazione finora

- RR112 enDocumento8 pagineRR112 enqian heNessuna valutazione finora

- List of Industry in Odisha, Latest InformationDocumento7 pagineList of Industry in Odisha, Latest InformationAnonymous zy3rAYH0% (1)

- Medium Pressure and Low Pressure Steam Systems1Documento4 pagineMedium Pressure and Low Pressure Steam Systems1Lao ZhuNessuna valutazione finora

- Master Well Control TechniquesDocumento26 pagineMaster Well Control TechniquesJairo Cortes100% (1)

- An 910 An 911 An 914Documento1 paginaAn 910 An 911 An 914blackhawkNessuna valutazione finora

- Water and Wastewater Engineering: An Introduction to Treatment Processes and Design CriteriaDocumento105 pagineWater and Wastewater Engineering: An Introduction to Treatment Processes and Design Criteriapopup plounyNessuna valutazione finora

- Public Private Partnership Alandur SewerageDocumento12 paginePublic Private Partnership Alandur SewerageSubodh R Wasnick75% (4)

- Laguna Lake Development Authority Quarterly ReportDocumento8 pagineLaguna Lake Development Authority Quarterly ReportAnonymous 8HnV4CAo100% (1)

- CH 1 Quantity of Water M.M.PPT 2008Documento63 pagineCH 1 Quantity of Water M.M.PPT 2008Fetene Nigussie100% (2)

- Water Resources of PakistanDocumento2 pagineWater Resources of PakistanFarhan SajidNessuna valutazione finora

- 06 - AWWA Small Systems 1Documento22 pagine06 - AWWA Small Systems 1Paulo SantosNessuna valutazione finora

- Water Audit ChecklistDocumento2 pagineWater Audit ChecklistKogilahvaavi SritharanNessuna valutazione finora

- SPC Occ 221316 MeDocumento9 pagineSPC Occ 221316 Metarekhisham1234Nessuna valutazione finora