Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

X 904 Recommended Practice

Caricato da

user123Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

X 904 Recommended Practice

Caricato da

user123Copyright:

Formati disponibili

X -904 Recommended Practice

Recommended Practice for

Crane Suspended X -904 Offshore Personnel Transfers

Purpose

This recommended practice is intended to assist all

offshore employers in the development of safe work

practices relative to the task of transferring personnel

to-and-from offshore facilities utilizing a Billy Pugh Co.

X-904 personnel transfer device. This recommended

practice addresses the minimum requirements promulgated by both regulation, industry, and refined for the

use of this unit. Each offshore employer is encouraged

to follow these recommendations and to proactively

modify or supplement them with additional beneficial

practices or equipment, or environmental conditions.

Scope

This recommended practice is intended for application

by offshore employers working in a marine offshore

environment who transfer, move, or transport their

workforce by Billy Pugh X-904 personnel carrier. The elements of this recommended practice should be applied

as appropriate with due consideration made for any

additional special hazards identified by the employer as

a result of a thorough Job Hazard Analysis (JHA).

Responsibilities

It is the responsibility of the offshore employer to ensure this recommended practice is applied appropriately

within their organizations. Management of offshore

personnel transfer safety should be an integral component of the employers existing Safety and Environmental

Management Plan (SEMP).

A systematic management process used to identify and

control safety and environmental hazards in design,

construction, start-up, operation, inspection, and maintenance as promulgated in API RP-75

Definitions

*In Service Date: The date

the X-904 is unwrapped

is the In Service Date.

That date wil be noted on

the X-904 certificate and

the yellow sticker attached to the center pole.

The In Service Date is

used as the date for aging

the device for inspections and replacement. If during

inspection it is found that there is not an In Service

Date recorded, then the In Service Date will defer back

to the Manufacturing Datewhich is noted on tags and

paperwork.

Rigging

Load lines, master links, safety slings, and hardware that attach the personnel carrier to the

crane hook or block device.

Qualified Person

A person designated by the employer who has

the experience and formalized training to safely operate the crane, rigging, and associated

lifting devices assigned at the work location

Qualified Inspector

A person so designated by the employer who

by reason of appropriate experience and training, in addition to meeting the requirements of

a qualified person, has attended formal training in inspection, maintenance, and troubleshooting of cranes, rigging, and lifting devices.

www.billypugh.com

Excellence in offshore personnel safety

X -904 Recommended Practice

Case for Action

Analysis of available accident/injury data reveals that

offshore personnel transfers are not involved in high

rates of accidents relative to the number of transfers

carried out worldwide. But due to the sheer number of

personnel basket transfers, the potential does exist for

incidents to occur. Safe and consistent methods need

to be incorporated into the procedures of those utilizing crane assisted transfer devices. A safety system,

which addresses the specific areas of effective management relative to offshore personnel transfers, will be required so that industry can sustain and maximize overall

safety performance while showing a process of continuous improvement. The X-904 is the next step in this

continual improvement in boat to rig crane transfers.

Safety System Elements

The following are considered to be key elements of an

effective safety system for management of crane suspended offshore personnel transfers.

ELEMENT 1: Minimum Training Requirements

An on-site competency based orientation & JSA on the

safe use of personnel carrier devices should be administered by a qualified person before employees or visitors

unfamiliar with the device are loaded or lifted. At a

minimum the following elements should be included

in this orientation curriculum:

Safe loading & unloading procedures.

Crane actions, movements, and signals.

Body positions, pinch points, and personal

stability.

Personnel baggage loading procedures.

In addition to the training elements, the qualified person should ascertain whether any persons are feeling

ill, suffering from vertigo, or have any anxiety regarding

the transfer. These individuals should be discouraged

from suing this form of personnel transfer. The exception would be suing the X-904 stretcher capability as

described in the safety CD provided with the unit.

ELEMENT 2: Personnel Carrier Rigging

Configurations

The following rigging configurations are recommended

for all crane assisted personnel carrier devices:

Double load lines:

*Billy Pugh personnel nets as well as the X-904

have a backup fiber rope safety line contained

within the stabilizer unit.

Snag Resistant Tag Line

We recommend that the BPC semi-rigid, snag

resistant tag line should be affixed to all of our

personnel transfer devices. Tag lines should

have a minimum length of 10 (3.05m). Tag line

should be attached to either the center deck

lashing pint, or the outside bottom platform

ring in such a manner that minimizes tag line

damage when carrier is resting on a surface

and attach with a minimum 5/8 {190 mm)

bolt type anchor shackle. Personnel transfer

device tag lines should be identified by a high

visibility color. These tag lines can be obtained

by specifying Billy Pugh Tag Line followed by

the length. A normal length for these units is

15 ft. This recommendation is consistent with

API-RP 2D (Annex C). Our tag lines (PTL and STL

product codes) both conform to this API specification and work well with all slung loads as well

as personnel transfer devices.

Personnel protective equipment requirements.

Exceptions or anomalies to any of the above.

www.billypugh.com

ELEMENT 3: Inspection Procedures

All inspections should be performed by a qualified

person and should always incorporate an operators

pre-use inspection. The next two pages of the Best

Practices include both the daily and the semi-annual

inspection procedures for the X-904. Plastic laminated

versions have also been included with this booklet for

your convenience.

ELEMENT 4: Operational/Administrative

Practices

The following minimum lifting practices are recommended for all crane assisted personnel transfer net devices:

Any offshore facility making personnel transfers with a personnel carrier should have a

written procedure for this task.

A pre-use inspection should be conducted prior

to any personnel carrier transfer.

Cranes assigned to personnel lifting duties

should be suitable for this purpose per relevant

API spec.

Crane operators assigned to personnel lifting

duties should be certified and competent to

perform this task.

A snag resistant tag line should be affixed to all

personnel carriers.

Crane hooks used for personnel transfers must

have a positive locking latch.

Only approved personnel carriers should be

used for lifting personnel per API specifications.

Personnel carriers should not be used as a

workbasket or cargo net.

Personnel carriers should be legibly marked

with the maximum number of passengers.

The X-904 is equipped with areas designed for

light luggage. Luggage should be stowed before

the lift is made and easily accessible for debarkation. No large or heavy items (bigger than the

storage area) should be allowed on the X-904.

Large or heavy items should be sent up via

cargo basket.

Personnel carriers should not be utilized in

weather, wind, or sea conditions that the qualified person considers to be unsafe.

Excellence in offshore personnel safety

X -904 Recommended Practice

Before any attempt is made to lift personnel

with a carrier, clear instructions should be given to all persons involved.

No person suffering from acute seasickness

or vertigo shall be transported by personnel

carrier. If the transfer is necessary, the affected

person should be put inside stokes stretcher

and the stretcher shackled to the rigging in the

area provided inside the unit. (Someone should

ride up with this individual on the transfer as

well).

Any individual has the right to refuse transfer

by a personnel basket.

All personnel riding on a personnel carrier

should wear an approved life vest or life preserver. An approved Type I illuminated PFD

maybe required for all transfers conducted

at night (depending on operator/contractor

policy). Many contractors incorporate Type I as

well for rough sea/bad weather transfers.

lowered to the deck.

A loaded personnel carrier should not be raised

or lowered directly over a vessel.

The crane operator may refuse to lift any person who does not comply with the operators

instructions.

An experienced escort should be provided for

persons who are not confident performing a

personnel carrier transfer.

Injured, ill, or unconfident persons may ride in

a sitting position, on the inside of the personnel

carrier, with a qualified person as an escort.

NOTE: Depending on company policies, attaching the

man positioning lanyard to the riders PFDs may be optional during transfers on the X-904. Billy Pugh Company

encourages the use of this lanyard but is not a requirement to meet this recommended practice.

All personnel riding the X-904 carrier should

stand on the inside of the unit and grasp the

inner rigging. Passenger forearms should be

interlocked.

If crane operators view of the primary signalman is obstructed, the personnel carrier should

not be moved until alternative communication

or signal devices are placed in service.

A designated primary landing zone should be

marked in a safe area as determined by a Job

Hazard Analysis (JHA).

When transferring personnel, the personnel

carrier should be lifted only high enough to

clear obstructions. Is should then be gently

www.billypugh.com

References

American Petroleum Institute (API) API RP-2D Recommended Practice for Operation & Maintenance of

Offshore Cranes

International Association of Drilling Contractors (North

Sea Chapter)- IMCA SEL 08/01 Transfer of Personnel by

Basket on the UK Continental Shelf

Moxie Media Corporation Personnel Basket Safety

Video Training Series June 27, 2001 Issue 1 Rev 0 7

International Marine Contractors Association (IMCA)

Task Risk Assessment Study 8/2000

National Research Council, Assembly of Engineering

Marine Board Committee on Assessment of Safety of

OCS Activities

Billy Pugh company, Inc. Procedures for Maintenance

& Inspection of Personnel Baskets

Kennedy Wire Rope & Sling Company Procedures

for Inspection & Maintenance of Wire Rope Slings and

Rigging

Department of the Interior, Minerals Management

Service Safety Alert No. 190-1/22/00 & Safety Alert No.

193-2/28/01

Global Drilling Leadership Initiative Recommended

Practice #6

Excellence in offshore personnel safety

X -904 Recommended Practice

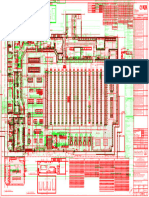

MODEL-900

MODEL-800

MASTER LINK

7

7"

/8" X 5" CROSBY RING / WORKING LOAD LIMIT: 5,600 LBS.

BOLT TYPE ANCHOR SAFETY SHACKLE

SAFETY SHACKLE " GALV.

5/8"

A

A

LOAD LINE

DIA. GALV. CABLE / TYPE 115-HT-HT / SWL 2.8 TON @ 90 DEGREES

6 X 37 - EIP IWRC RR

SYNTHETIC SAFETY LINE INCORPORATED IN STABILIZER UNIT

STABILIZER EXTENDED WITH SAFETY LOAD LINE

MODEL-800

MODEL-900 S

A

A

BB

C

C

D

ED

F

GE

HF

I

BOLT TYPE ANCHOR SAFETY SHACKLE

7/8" X 4" CROSBY RING / WORKING LOAD LIMIT: 7,200 LBS.

6"

9'

35'2"

84"

96"

11'

NYLON SAFETY STRAP

1' X 26 O.D. ALUM. RING / TYPE 6063T6

GALVANIZED CABLE (X-4)

4" FOAM PADDING WITH 10OZ. YELLOW VINYL COVER

B

C

4"

3'

5'

11'

NOTES: NET WT

530 L

X-871-6

SERIE

A THE 900 22'

ARE POWDER

SAFETY SHACKLE

" GALV.

MASTER

LINKS

X-871

X-904

22' X

20 FT.

2

67 INS.2'6" 7

62 INS.

7

9' 7

7 FT.

8 FT. 34'5"8

33 FT.

3

74 INS.60" 8

85INS. 72" 1

d. 11 FT. d

BOLT TYPE ANCHOR SAFETY SHACKLE (X-4)

FOAM

COVERED

WITH

YELLOW VINYLBLEND

MATERIAL

" DIA.

PREMIUM

POLYPROPYLENE

ROPE: 9,950LBS. MINIMUM STRENGTH

STAINLESS STEEL EYE BOLT

POWDER COATED ALUMINUM FRAME

EXPANDED ALUMINUM METAL TOP

STAINLESS STEEL CABLE INCORPORATED POLYESTER VERTICAL GRAB LINES

MAN POSITIONING LANYARD W/QUICK RELEASE S.S. SNAP HOOK

18OZ. ORANGE VINYL DECK COVER

NYLON

NETTING

6" FOAM

PADDING WITH 18OZ. ORANGE VINYL COVER

RUBBER FLOOR MATT

" DIA. ULTRABLU DECK NETTING

FOAM BUMPER COVERED WITH ORANGE VINYL MATERIAL

SHOCK ABSORBING RUBBER FEET

1" C/S PIPE - SCH - 40 BOTTOM RING

PAINTED WITH PROTAKTO PIPE COATING

4" X 3" RUBBER FEET

G

MASTER LINK

H

F

BOLT TYPE ANCHOR SAFETY SHACKLE

APRIL

2014

MAY 2014

MODEL-900

MODEL-800 SERIES SPECIFICATIONS

Figure 1.0

LOAD LINE

SYNTHETIC SAFETY LINE INCORPORATED IN STABILIZER UNIT

MODEL-900 SERIES SPECIFICATIONS

MODEL-900 SERIES DIMENSIONS

X-904

X-904-6

X-904-8

X-904-10 X-904-12

20 FT.

20 FT.

b.20 FT.

20 FT.

b.20 FT.

A

67 INS.

79.5 INS. 79.5 INS.

B

BILLY

BOX

802 CORPUS

CHRISTI

TX8378406

BILLY PUGH

PUGH CO.,

CO., INC.

INC. C P.O.

P.O.62

BOX

CORPUS

CHRISTI

78406

INS.80274.5

INS. 74.5

INS.

90 INS.

INS. TX

7 FT.

7 FT.

7 FT.

7 FT.

7 FT.

D

8 FT.

8 FT.

8 FT.

8 FT.

8 FT.

E

33 FT.

33 FT.

33 FT.

33 FT.

33 FT.

F

74 INS.

89 INS.

100 INS. 107 INS.

89 INS.

G

85INS.

100 INS.

100 INS.

111 INS. 118 INS.

H

d. 11 FT. d. 11 FT.

d. 11 FT.

d. 11 FT. d. 11 FT.

I

WWW.BILLYP

WWW.BILLYP

NOTES: NET WT 530 LBS.

THE 900 SERIES PERSONNEL TRANSFERS

ARE POWDER COATED

MASTER LINKS

www.billypugh.com

Excellence

BOLT TYPE ANCHOR SAFETY

SHACKLE

in offshore personnel safety

Potrebbero piacerti anche

- Safety of Life at SeaDocumento5 pagineSafety of Life at SeaAbdel Nasser Al-sheikh YousefNessuna valutazione finora

- Dynamic positioning The Ultimate Step-By-Step GuideDa EverandDynamic positioning The Ultimate Step-By-Step GuideNessuna valutazione finora

- ApaveMare Training 2013Documento41 pagineApaveMare Training 2013fbarakaNessuna valutazione finora

- Hazard And Risk Analysis A Complete Guide - 2020 EditionDa EverandHazard And Risk Analysis A Complete Guide - 2020 EditionNessuna valutazione finora

- Kikeh Marine TerminalDocumento8 pagineKikeh Marine TerminalBob TigerNessuna valutazione finora

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Da EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Nessuna valutazione finora

- OCIMF Books: Books Can Be Obtained From The Publishers Witherby Seamanship International atDocumento4 pagineOCIMF Books: Books Can Be Obtained From The Publishers Witherby Seamanship International atRobson PaixãoNessuna valutazione finora

- Life-Saving Appliances Including LSA Code 2017Documento8 pagineLife-Saving Appliances Including LSA Code 2017fajee_faridNessuna valutazione finora

- Tanker Disasters: IMO's Places of Refuge and the Special Compensation Clause; Erika, Prestige, Castor and 65 CasualtiesDa EverandTanker Disasters: IMO's Places of Refuge and the Special Compensation Clause; Erika, Prestige, Castor and 65 CasualtiesNessuna valutazione finora

- Part IV - 02 Marine OperationsDocumento5 paginePart IV - 02 Marine Operationssalah abddayemNessuna valutazione finora

- Guidance On Procedures For The Transfer of Personnel by BasketDocumento6 pagineGuidance On Procedures For The Transfer of Personnel by BasketciprianlightNessuna valutazione finora

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDa EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNessuna valutazione finora

- Maritime Envirinment Awarness SyllabusDocumento23 pagineMaritime Envirinment Awarness SyllabusdarrelsilvaNessuna valutazione finora

- Learning Outcome 2 Marine Law Lesson 10Documento26 pagineLearning Outcome 2 Marine Law Lesson 10ciprian predaNessuna valutazione finora

- Yokohama FENDER PRODUCT LITERATURE PDFDocumento8 pagineYokohama FENDER PRODUCT LITERATURE PDFitaaliyenNessuna valutazione finora

- Fire Wires or Emergency Towing-Off Pennants (ETOP's), MEG 4, ISGOTT Edn 6th RecommendationsDocumento6 pagineFire Wires or Emergency Towing-Off Pennants (ETOP's), MEG 4, ISGOTT Edn 6th RecommendationsGiorgi KandelakiNessuna valutazione finora

- HMP 10.13 EnocDocumento46 pagineHMP 10.13 EnocChander MehtaNessuna valutazione finora

- Solas Regulation IIDocumento3 pagineSolas Regulation IIhackey720Nessuna valutazione finora

- Guard VesselDocumento7 pagineGuard Vesselsjarvis5Nessuna valutazione finora

- Bollard Pull Standard JIP PDFDocumento2 pagineBollard Pull Standard JIP PDFRahmat AnpsNessuna valutazione finora

- IHM Part I Plan PreparationDocumento3 pagineIHM Part I Plan PreparationBoyan Balanov100% (1)

- 8 Point Mooring - Attachment XxxiiDocumento5 pagine8 Point Mooring - Attachment XxxiiFaiqah AzmirNessuna valutazione finora

- Strength in Depth: Single Point MooringDocumento20 pagineStrength in Depth: Single Point MooringVincinius Axel100% (1)

- Free-Fall Lifeboat Safety: Purpose Incident Analysis - AquarosaDocumento2 pagineFree-Fall Lifeboat Safety: Purpose Incident Analysis - AquarosavdevivNessuna valutazione finora

- PUBS Loss Prevention Gangways - 0719 1Documento23 paginePUBS Loss Prevention Gangways - 0719 1karaflass100% (1)

- IMO MSC.1-Circ.1255 Guideline On Emergency TowingDocumento6 pagineIMO MSC.1-Circ.1255 Guideline On Emergency TowingChristina OoiNessuna valutazione finora

- Iacs Rec 34Documento4 pagineIacs Rec 34Gobinda SinhaNessuna valutazione finora

- Amends To SDs 2011Documento214 pagineAmends To SDs 2011duaankushNessuna valutazione finora

- SPS Code General - 1Documento27 pagineSPS Code General - 1famwhaiyun100% (1)

- Marine Transfer of PersonnelDocumento74 pagineMarine Transfer of PersonnelSew Chi Zhong100% (1)

- DNV - Examination and Test of Launching Appliances and On-Load Release GearDocumento9 pagineDNV - Examination and Test of Launching Appliances and On-Load Release GearCleverson SchmidtNessuna valutazione finora

- Tmsa 2014Documento39 pagineTmsa 2014Alcides Hermoza MejiaNessuna valutazione finora

- LifeboatDocumento6 pagineLifeboatvanmaika9960Nessuna valutazione finora

- Modu Code 2009Documento128 pagineModu Code 2009RAZORMWNessuna valutazione finora

- Norsok - Marine OperationsDocumento27 pagineNorsok - Marine OperationsbeegmacNessuna valutazione finora

- 1000 Ways To Secure A Pilot LadderDocumento17 pagine1000 Ways To Secure A Pilot LadderROSAN FURIOUSNessuna valutazione finora

- MSC.1-Circ.1327-Guidelines For The Fitting and Use of Fall Prevention Devices (FPDS)Documento6 pagineMSC.1-Circ.1327-Guidelines For The Fitting and Use of Fall Prevention Devices (FPDS)CaptShivraj ManeNessuna valutazione finora

- OCIMF Pre Vetting Booklets 2009 Ed GMDSS OfficerDocumento6 pagineOCIMF Pre Vetting Booklets 2009 Ed GMDSS OfficerFreddy José CastroNessuna valutazione finora

- Safety Environmental Management System (Sems) Standards ManualDocumento26 pagineSafety Environmental Management System (Sems) Standards ManualrwerwerwNessuna valutazione finora

- OMHEC Lifting of Personnel OffshoreDocumento17 pagineOMHEC Lifting of Personnel OffshoreLasse WelleNessuna valutazione finora

- AlexandraDocumento52 pagineAlexandraÇevik AhmetNessuna valutazione finora

- Pilotladdersafety Ver 2 MRT 2021Documento48 paginePilotladdersafety Ver 2 MRT 2021P Carrero HurtadoNessuna valutazione finora

- Marine Transfer of Personnel GuidelinesDocumento74 pagineMarine Transfer of Personnel GuidelinesAhmed AddaNessuna valutazione finora

- BPcraneLifting North Sea Rules OffshoreDocumento56 pagineBPcraneLifting North Sea Rules Offshorebwadsager75% (4)

- Gangways EnglishDocumento12 pagineGangways EnglishNareshNessuna valutazione finora

- Survival in An Emergency MarEngDocumento6 pagineSurvival in An Emergency MarEngPelayo García-Pardo Martín-SerranoNessuna valutazione finora

- Linethrower 250 Pains WessexDocumento2 pagineLinethrower 250 Pains WessexAntonio Clas100% (2)

- Light and Smoke Signal: Warning DisposalDocumento1 paginaLight and Smoke Signal: Warning Disposalariesyiha100% (1)

- Recognised Security Organisation Instruction 1 2018 PDFDocumento21 pagineRecognised Security Organisation Instruction 1 2018 PDFHamzah HinduanNessuna valutazione finora

- NWEA GuidelinesDocumento160 pagineNWEA GuidelinesMorten Monika MosbergNessuna valutazione finora

- Strength of Pilot LadderDocumento12 pagineStrength of Pilot LadderMeyyappan aNessuna valutazione finora

- Hatch Cover Maintenance DNVDocumento2 pagineHatch Cover Maintenance DNVkurtmusNessuna valutazione finora

- GL Pers Transfer Basket Inspection PDFDocumento26 pagineGL Pers Transfer Basket Inspection PDFSteve Morrison100% (1)

- AIMPA - Marine Pilots' Journal - August 2020 Year 1 - Issue 1Documento16 pagineAIMPA - Marine Pilots' Journal - August 2020 Year 1 - Issue 1Capt Gajanan KaranjikarNessuna valutazione finora

- X904 Recommened Practice and MaintDocumento4 pagineX904 Recommened Practice and MaintSteve MorrisonNessuna valutazione finora

- X 904 Recommended PracticeDocumento4 pagineX 904 Recommended PracticemuralisunNessuna valutazione finora

- OMSA BasketTransfer BestPractice July2007Documento14 pagineOMSA BasketTransfer BestPractice July2007AlfredNessuna valutazione finora

- Manual MagneticDocumento12 pagineManual Magneticuser123Nessuna valutazione finora

- WKS3625 ManualDocumento6 pagineWKS3625 Manualuser123Nessuna valutazione finora

- RG3518 ManualDocumento6 pagineRG3518 Manualuser123Nessuna valutazione finora

- WKS3576 ManualDocumento6 pagineWKS3576 Manualuser123Nessuna valutazione finora

- MGN 279 (M) : Certificate of Competency As Compass AdjusterDocumento6 pagineMGN 279 (M) : Certificate of Competency As Compass Adjusteruser123Nessuna valutazione finora

- USB Upgrade Guide PDFDocumento1 paginaUSB Upgrade Guide PDFuser123Nessuna valutazione finora

- Magnetic Calibration Manual: Document MT0202P, Revision O, Nov 2019Documento37 pagineMagnetic Calibration Manual: Document MT0202P, Revision O, Nov 2019user123Nessuna valutazione finora

- Msa BarkhousenDocumento9 pagineMsa BarkhousenWagner Garcia FernandesNessuna valutazione finora

- Peesapati, Cotton-SupergenNanjing2009 - 2 PDFDocumento8 paginePeesapati, Cotton-SupergenNanjing2009 - 2 PDFuser123Nessuna valutazione finora

- Aircraft Lightning Protection Handbook DOT FAA CT 89 22Documento503 pagineAircraft Lightning Protection Handbook DOT FAA CT 89 22melfroNessuna valutazione finora

- Avionics Lightning Protection Design GUIDocumento14 pagineAvionics Lightning Protection Design GUIuser123Nessuna valutazione finora

- 10.1.1.381.8188 LightningDocumento10 pagine10.1.1.381.8188 Lightninguser123Nessuna valutazione finora

- How To Protect A Wind Turbine From Lightning: EnergyDocumento109 pagineHow To Protect A Wind Turbine From Lightning: Energyuser123Nessuna valutazione finora

- 398 Cold ClimateDocumento28 pagine398 Cold Climateuser123Nessuna valutazione finora

- AppendixA Lightning Protection PDFDocumento9 pagineAppendixA Lightning Protection PDFuser123Nessuna valutazione finora

- Envmag 4 5magneticDocumento28 pagineEnvmag 4 5magneticuser123Nessuna valutazione finora

- Diagnostic Examination Boiler Steel Plate Barkhausen MethodDocumento12 pagineDiagnostic Examination Boiler Steel Plate Barkhausen Methoduser123Nessuna valutazione finora

- MagneticDocumento14 pagineMagneticuser123Nessuna valutazione finora

- MagnetizationDocumento25 pagineMagnetizationuser123Nessuna valutazione finora

- Elmer TutorialsDocumento148 pagineElmer Tutorialsuser123Nessuna valutazione finora

- LPS Lightning ProtsDocumento6 pagineLPS Lightning Protsuser123Nessuna valutazione finora

- PIERS2006CambridgeProceedings PDFDocumento546 paginePIERS2006CambridgeProceedings PDFuser123Nessuna valutazione finora

- Protection From LightningDocumento3 pagineProtection From Lightninguser123Nessuna valutazione finora

- Handbook 2017 OnlineDocumento62 pagineHandbook 2017 Onlineuser123Nessuna valutazione finora

- ABB Marine Energy Efficiency Guide 04062013 PDFDocumento98 pagineABB Marine Energy Efficiency Guide 04062013 PDFuser123Nessuna valutazione finora

- T1080 eDocumento8 pagineT1080 euser123Nessuna valutazione finora

- 05 Ballast Water Record BookDocumento3 pagine05 Ballast Water Record Bookuser123100% (1)

- T1053 eDocumento4 pagineT1053 euser123Nessuna valutazione finora

- Lloyds Ballast Water Management Guide PDFDocumento28 pagineLloyds Ballast Water Management Guide PDFuser123Nessuna valutazione finora

- Ships OffshoreDocumento20 pagineShips Offshoreuser123Nessuna valutazione finora

- Blackbook 2Documento94 pagineBlackbook 2yogesh kumbharNessuna valutazione finora

- What Is The PCB Shelf Life Extending The Life of PCBsDocumento9 pagineWhat Is The PCB Shelf Life Extending The Life of PCBsjackNessuna valutazione finora

- Developpments in OTC MarketsDocumento80 pagineDeveloppments in OTC MarketsRexTradeNessuna valutazione finora

- Lab Science of Materis ReportDocumento22 pagineLab Science of Materis ReportKarl ToddNessuna valutazione finora

- Sage TutorialDocumento115 pagineSage TutorialChhakuli GiriNessuna valutazione finora

- Affidavit of Co OwnershipDocumento2 pagineAffidavit of Co OwnershipEmer MartinNessuna valutazione finora

- PRESENTACIÒN EN POWER POINT Futuro SimpleDocumento5 paginePRESENTACIÒN EN POWER POINT Futuro SimpleDiego BenítezNessuna valutazione finora

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocumento7 pagineSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0Nessuna valutazione finora

- Tata NanoDocumento25 pagineTata Nanop01p100% (1)

- Extraction of Mangiferin From Mangifera Indica L. LeavesDocumento7 pagineExtraction of Mangiferin From Mangifera Indica L. LeavesDaniel BartoloNessuna valutazione finora

- 5045.CHUYÊN ĐỀDocumento8 pagine5045.CHUYÊN ĐỀThanh HuyềnNessuna valutazione finora

- Pen Pal Lesson Plan 3Documento3 paginePen Pal Lesson Plan 3api-664582820Nessuna valutazione finora

- Joomag 2020 06 12 27485398153Documento2 pagineJoomag 2020 06 12 27485398153Vincent Deodath Bang'araNessuna valutazione finora

- OBOE GougerDocumento2 pagineOBOE GougerCarlos GaldámezNessuna valutazione finora

- Localization On ECG: Myocardial Ischemia / Injury / InfarctionDocumento56 pagineLocalization On ECG: Myocardial Ischemia / Injury / InfarctionduratulfahliaNessuna valutazione finora

- Makalah Bahasa Inggris TranslateDocumento14 pagineMakalah Bahasa Inggris TranslatevikaseptideyaniNessuna valutazione finora

- Overlay Control PlansDocumento1 paginaOverlay Control PlansSTS-SPARK GAMINGNessuna valutazione finora

- SHS G11 Reading and Writing Q3 Week 1 2 V1Documento15 pagineSHS G11 Reading and Writing Q3 Week 1 2 V1Romeo Espinosa Carmona JrNessuna valutazione finora

- Flipkart Labels 06 Jul 2022 09 52Documento37 pagineFlipkart Labels 06 Jul 2022 09 52Dharmesh ManiyaNessuna valutazione finora

- A. Computed Only For A 2x2 Table B. 0 Cells (,0%) Have Expected Count Less Than 5. The Minimum Expected Count Is 3,40Documento1 paginaA. Computed Only For A 2x2 Table B. 0 Cells (,0%) Have Expected Count Less Than 5. The Minimum Expected Count Is 3,40harvey777Nessuna valutazione finora

- Journal of Molecular LiquidsDocumento11 pagineJournal of Molecular LiquidsDennys MacasNessuna valutazione finora

- B-GL-385-009 Short Range Anti-Armour Weapon (Medium)Documento171 pagineB-GL-385-009 Short Range Anti-Armour Weapon (Medium)Jared A. Lang100% (1)

- Parrot Mk6100 Userguide Zone1Documento100 pagineParrot Mk6100 Userguide Zone1Maria MartinNessuna valutazione finora

- Acute Suppurative Otitis MediaDocumento41 pagineAcute Suppurative Otitis Mediarani suwadjiNessuna valutazione finora

- Zero Tolerance 2010Documento16 pagineZero Tolerance 2010Adrian KozelNessuna valutazione finora

- Financial Institutions Markets and ServicesDocumento2 pagineFinancial Institutions Markets and ServicesPavneet Kaur Bhatia100% (1)

- Eng Notes2Documento10 pagineEng Notes2Arti KapurNessuna valutazione finora

- Chapter 13 Current Liabilities Test Bank Versi 2Documento72 pagineChapter 13 Current Liabilities Test Bank Versi 2Slamet Tri PrastyoNessuna valutazione finora

- Fuentes v. Office of The Ombudsman - MindanaoDocumento6 pagineFuentes v. Office of The Ombudsman - MindanaoJ. JimenezNessuna valutazione finora

- Final - Anarchy One-Sheet Sell SheetDocumento2 pagineFinal - Anarchy One-Sheet Sell SheetMaddanie WijayaNessuna valutazione finora

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDa EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionValutazione: 4.5 su 5 stelle4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (242)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesDa EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNessuna valutazione finora

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDa EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseValutazione: 5 su 5 stelle5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyDa EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyValutazione: 4 su 5 stelle4/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDa Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideValutazione: 3.5 su 5 stelle3.5/5 (7)

- Civil Engineer's Handbook of Professional PracticeDa EverandCivil Engineer's Handbook of Professional PracticeValutazione: 4.5 su 5 stelle4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1Da EverandBuilding Construction Technology: A Useful Guide - Part 1Valutazione: 4 su 5 stelle4/5 (3)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDa EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishValutazione: 4 su 5 stelle4/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsDa EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsValutazione: 1 su 5 stelle1/5 (4)

- Estimating Construction Profitably: Developing a System for Residential EstimatingDa EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNessuna valutazione finora

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDa EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyValutazione: 4 su 5 stelle4/5 (1)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftDa EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftValutazione: 5 su 5 stelle5/5 (5)

- Real Life: Construction Management Guide from A-ZDa EverandReal Life: Construction Management Guide from A-ZValutazione: 4.5 su 5 stelle4.5/5 (4)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEDa EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEValutazione: 4 su 5 stelle4/5 (1)

- Field Guide for Construction Management: Management by Walking AroundDa EverandField Guide for Construction Management: Management by Walking AroundValutazione: 4.5 su 5 stelle4.5/5 (3)