Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Training

Caricato da

Ashok RajanavarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Training

Caricato da

Ashok RajanavarCopyright:

Formati disponibili

HDM-4 Training Manual

PAVEMENT MAINTENANCE MANAGEMENT SYSTEM FOR

URBAN ROADS

Abstract

Transportation system plays an important role in the economic development of the country. In

this transportation system, road network has major contribution for economic growth of a

country. So in order to keep the road network in good condition, there is a need to provide more

attention towards the maintenance of the roads. Some of the developed countries concentrating

their attention towards maintaining the existing roads rather than planning and constructing new

roads. Maintenance activity is a continues ongoing process to keep the road network in good

condition.

Various maintenance treatments are being practiced in India for different categories of roads. The

maintenance activity is practiced to increase the serviceability of the road network .The decision

made for maintenance of road network is on the subjective basis. So decision on selecting the

section and type of treatment must be improve over subjective judgment and engineering

experience. The main aim of carrying out maintenance activities is to preserve the national asset.

The present study aims at developing the pavement management system for an identified urban

road network. And to determine the existing condition of the pavement in terms of level and type

of deterioration it has achieved. Also it includes suggesting optimum maintenance treatment

among the various alternatives recommended in Government of India specifications. This

maintenance activity and also economic strategy is decided by using a sophisticated and modern

scientific tool namely HDM - 4 developed by the World Bank.

This will helps to assist the highway engineers responsible for maintaining the highway network

as well as the authorities responsible for allocating funds, in making consistent and cost effective

decisions, related to maintenance and rehabilitation of pavements. This makes systematic

decision to predict the most economical maintenance strategy for a particular pavement section

and prioritization of such maintenance activities in the event of a constrained budget.

CHAPTER 1

Page 1

HDM-4 Training Manual

INTRODUCTION

1.1 Brief description about study stretch

Bangalore is the largest city in the state of Karnataka. It is also the capital city of Karnataka.

Bangalore boasts of being one of the highly developed countries in India. The city of Bangalore

is connected through more than 3000 km of road network.

Outer Ring Road is a road that runs around most of the perimeter of Bangalore. This road was

developed by Bangalore Development Authority and different sections were opened

progressively between 1996 to 2002. The 62 km long Outer Ring Road connects all the major

highways around the city of Bangalore. It includes Tumkur Road (NH 4), Bellary Road (NH 7),

Old Madras Road (NH 4), Hosur Road (NH 7), Bannerghatta Road, Kanakapura Road (NH 209),

Mysore Road (SH-17) and Magadi Road.

Also it passes through major neighborhoods and sub-urbans such as Hebbal(NH7), Banaswadi,

Krishnarajapuram(NH4), Marathahalli, Madiwala(NH7), BTM Layout, JP Nagar, Banashankari,

Kengeri, Bangalore University, Nagarbhavi, Nandini Layout and Gokula.

Tumkur Road to the West of Bangalore and Old Madras Road to the East connects the city to the

National Highway 4 & Bellary road to the North and Hosur Road to the South of the city

connects the city to the National Highway 7.

HosurRoad provides connectivity to Mysore from Bangalore. These are majorly used roads of

the city and are sights of traffic jams on various occasions.The Ring Road also gives access to

the city of Coimbatore which is the second largest city in the state of Tamil Nadu.

This project is intended to implement Pavement Management System for whole Bangalore city

roads. But because of time constraints we have selected Outer Ring Road of Bangalore city from

Goragunte playa to Hebbala.

The reason for selecting this Outer Ring Road is that it connects major roads like National

Highways, State Highways and also passes through citys major roads. This Outer Ring Road

also carries major traffic and the IT, BT companies were concentrated more besides this road.

Page 2

HDM-4 Training Manual

Also this road is connected to International Airport. So every time there is more traffic all along

this road which needs to be maintain properly to serve for long time.

1.2 Brief description about HDM-4

The Highway design model was developed by the World Bank in 1979. It has been updated to

Highway Development and Management Tool (HDM-4) in 1998, under the sponsorship of

Permanent International Association of Road Congress (PIARC). It is ideally suited for making

the total assessment of deterioration and economic returns so that optimum utilization of funds

may also be achieved for roads. Also it is recognized as a state-of-the-art system for the analysis

of road maintenance and investment alternatives because of the following advantages (HDM-4,

2001):

The incorporation of both agency costs and road user costs in a life-cycle cost analysis.

The use of calibration parameters for broad-based applicability in diverse climates and

conditions.

The use as an appropriate design tool for pavements, if properly calibrated, especially for

developing countries, while borrowing design standards directly from the design

specifications of industrialized countries.

The data required for the HDM-4 analysis are listed in the table1. HDM-4 supports flexible

options for data analysis and results. Users can make printed or electronic reports. They can also

export data and results to standard database for other users. HDM-4 can produce the following

three types of output, which can assist road managers to make informed decisions.

Strategic road maintenance and development plans, produced from long-term predictions

of road network performance.

Economic efficiency indicators, produced from analysis of individual road projects.

Multi-year work programs, produced from prioritization of several road projects.

Table 1.1 HDM-4 input files

Input File

Road network

Description

This file contains road network data such as basic road details,

geometrics, pavement history, pavement condition etc., This file

Page 3

HDM-4 Training Manual

Vehicle fleet

will be basis for the analysis.

It contains the vehicle fleet data such as basic characteristics of

vehicle fleet, economic and financial costs etc., that will be

Road Works

operating on the road network being analyzed.

It contains the specifications for maintenance and improvement

standards that will be applied to different road sections for

HDM configuration

analysis.

To reflect the actual traffic flow pattern, speed flow on the road

and climatic conditions of the study area, the actual data

obtained from field studies has to be used.

1.3 Need for present study

Most of the developed countries already moved their attention towards the maintenance of

existing roads. But in India construction and widening of existing road section is taking place. So

instead of construction of new roads maintenance of existing road must take importance.

Because now a days availability of funds is very less to carry out maintenance activities and also

major factors which affect the maintenance activity is the availability of resources like materials,

human resources, equipments etc., So this shows that there a is need to manage the pavements in

a systematic and planned way.

1.8 Objective of the present study

1. To assess the extent and severity of the pavement distresses such as cracking, patching,

ravelling etc.,

2. To suggest various pavement maintenance strategies based on the level and type of pavement

deterioration.

3. To carry out economic evaluation of various Pavement Maintenance Alternatives.

4. To find out the benefits due to application of various preventative maintenance treatments.

6. Selection of Optimal Pavement Maintenance Strategies based on economic analysis.

Page 4

HDM-4 Training Manual

CHAPTER 2

METHODOLOGY

The main objective of the study is to develop the PMMS by using HDM-4 for the network to

produce planning and programming the maintenance works for the existing Arterial ring road.

These data collection plan was made according to the requirements of input for HDM-4.

Page 5

HDM-4 Training Manual

Methodology adopted for the study

The methodology in this study involves following stages.

1.Selection of study stretch and define the area of study stretch.

2.Road inventory survey (visual observation)

3.Collection of secondary data i.e., type of the road, layer thickness, deflection values, key

map of the road, maintenance work carried out, overlay thickness etc.,

4. Field studies and data collection

5. Pavement Deterioration Condition analysis.

6. Economic analysis using HDM-4.

3.1Selection of study stretch and define the area of study stretch.

The main criteria used for the selection of study stretch is

i) Selected stretch must be within city limits (like arterial, sub-arterial, urban roads).

ii) Stretch should be constructed with flexible pavement.

iii)Selected road should connect major Highways and should passes through major

neighbourhoods and sub-urban roads.

iv)It should ensure uniformity in various characteristics for the database development.( like crust

composition, drainage condition, climate, rainfall )

Outer Ring Road is a road that runs around most of the perimeter of Bangalore. This road was

developed by Bangalore Development Authority and different sections were opened

progressively between 1996 to 2002.

This road connects all major highways around the city - Tumkur Road (NH 4), Bellary Road

(NH 7), Old Madras Road (NH 4), Hosur Road (NH 7), Bannerghatta Road, Kanakapura Road

(NH 209), Mysore Road (SH-17) and Magadi Road. It passes through major neighborhoods and

Page 6

HDM-4 Training Manual

suburbs

such

as

Hebbal(NH7),

Banaswadi,

Krishnarajapuram(NH4),

Marathahalli,

Madiwala(NH7), BTM Layout, JP Nagar, Banashankari, Kengeri, Bangalore University,

Nagarbhavi, Nandini Layout and Gokula.

For the study purpose we have selected Outer Ring Road from Goraguntepalya to CSB junction

via Hebbala(i.e., Ch 0.00 to 36.40km) and from Nayandanahalli Junction to Tumkur Junction

via Laggere( i.e., Ch 54.00 to 62.00km).

The reason for selecting this Outer Ring Road is that it connects major roads like National

Highways, State Highways and also passes through citys major roads. This Outer Ring Road

also carries major traffic and the IT, BT companies were concentrated more besides this road.

Also this road is connected to International Airport. So every time there is more traffic all along

this road which needs to be maintain properly to serve for long time.

Topographic survey was conducted at ORR-minor junctions and at grade separator locations

along ORR as a part of the study. Topographic survey was carried out to confirm the bearing,

levels and length/ distance of the existing road stretch. It was carried out with close traverse

system for horizontal control with GPS system and vertical traverse with GTS benchmarks. After

completion of traverse controls, additional detail topographic survey was carried out by the

consultants. Also existing road side features were mapped by them. Spot levels covering existing

road, shoulders and earthen embankment were taken by the consultants. This additional

topographic surveys were covered at following junctions- Hebbal, K.R.Puram, EMC square and

Ibblur.

From this study we can get the details of existing features of the Outer Ring Road study stretch.

Also the topographic map is shown in the Chapter 4.

3.2. Road inventory survey (visual observation)

It includes the field survey about the extent and severity of distress occurred in the selected study

stretch. And also the information about width of carriageway, drainage condition, number of

bridges, number of flyovers etc., is to be taken into account. The main aim of this step is to

collect as many as data required for the project. The inventory data includes the details like

Page 7

HDM-4 Training Manual

Name of road, category of road, carriageway and shoulder width, drainage conditions, surface

type and thickness, pavement layer details etc.

3.3. Collection of secondary data

From the BDA dept., which is the owner of this whole Outer Ring Road. we got some of the

details like thickness of each layer of the pavement, deflection value of the pavement,

maintenance work, overlay made details etc.,

a. Category of the road

The whole Outer Ring Road belongs to the Category of Arterial type, which connects various

National Highways, State Highways and other Urban roads.

b. Trench pit survey

Trench pit survey investigations was collected by the dept., to determine the depth of pavement

layers of main road and service road. Thickness of individual pavement layers i.e., surface

course, base course and sub base course layers were noted. This trench pit survey were carried

out at 0.5 to 1.0km staggered interval both on main road and service road. Soil samples were

collected to determine the laboratory CBR values and atterberg limits.

Based on trench pit survey following inferences can be made:

The thickness of the GSB layer provided for overall Outer Ring Road is 200mm.

The thickness of the WMM layer is 250mm for Main road of the ORR and it varies from

100 to 275 in case of service roads.

The thickness of DBM layer is 80mm and in some stretches overlay has been carried out

having the thickness 80mm.

The actual thickness of the BC layer is 40mm. But this layer is overlayed in all locations

of ORR by the thickness of 40mm.

Page 8

HDM-4 Training Manual

In most of the locations BC layer is overlaid for three times after the original construction

of this BC layer.

c. Benkelman Beam Deflection studies

Rebound Deflection survey was carried out by the consultants. We collected this survey data

from the Dept., in order to assess the residual strength of the existing pavement and also to

design the overlay thickness of pavement layers to be provided to withstand the future projected

traffic loading as per IRC 81:1997. Deflection measurements were taken on left and right wheel

path of left and right carriageways.

The studies were carried out by observing the initial, intermediate and final readings at each

deflection observation points. A standard truck with a rear axle load of 10500kg fitted with dual

tyres inflated to a pressure of 8kg/sq.cm was used for conducting rebound deflection studies on

the road pavement. The dual wheels of the truck wascentred above the selected points. In the

selected point, readings were taken at intervals of 0.00m, 2.70m, 9.00m.

Pavement temperature was measured at a depth of 40mm as per IRC. The subgrade soil samples

were collected from the wheel paths where deflection studies were conducted after digging and

removing the pavement materials upto the subgrade level, from a depth of 50cm. The subgrade

soil samples were subjected to test for the determination field moisture content and index

properties for soil classifications.

The procedure used for BBD studies as per IRC 81:1997 are as follows:

BBD of standard make complying with equipment specification as given in IRC 81:1997

was used for the study.

A standard truck with 10500kg fitted with dual tyre inflated to a pressure and load was

checked at-least twice in a days work.

Before starting the survey, BBD was calibrated to ensure proper working of dial gauges

as per procedure stated in cl 4.3.4 of IRC 81:1997.

Page 9

HDM-4 Training Manual

Deflection measurements was taken in accordance with CGRA procedure and relevant

data entered in accordance with format provided in IRC 81:1997.

The measurement points in the longitudinal direction (i.e., along traffic direction) was

taken at 50m interval on the wheel path for left wheel path (LWP), middle wheel

path(MWP) and right wheel path(RWP).

The measurement covered both carriageway left wheel path middle wheel path and right

wheel path for three lane road.

The measurement points was taken at 60cm from pavement edge excluding paved

shoulder.

Before commencement of survey, the points was marked on the road with paint for easy

identification. The dual wheels of the truck was centred, the BBD probe inserted

between the dual tyres on the test point. The dial gauge leg was adjusted so that the beam

was levelled using the spirit level.

The locking pin was removed from the beam and the legs adjusted so that the plunger of

the beam was in contact with the stem of dial gauge. The beam pivot arms was checked

for free movement and initial dial gauge reading noted.

The truck was moved slowly and stopped at a distance of 270cm and intermediate dial

gauge reading was recorded when the rate of recovery is less that 0.025mm per minute.

The truck moved further 9m away and the final gauge reading was recorded.

The pavement temperature was recorded at least once every hour inserting thermometer

in standard hole and filling with glycerol as per Cl4.4 of IRC 81:1997.

Plasticity Index, moisture content and soil type of subgrade was determined by preparing

a test pit at the shoulder and collecting subgrade soil sample and testing in accordance

with IS:2720

Based on BBD studies following inferences can be made:

Page 10

HDM-4 Training Manual

a. Deflection values are more at chainage 16 to17 (K.R.Puram to marathahalli),

chainage 31 to 32 (Sumanahalli to Tumkur) and chainage 57 to 58

(Nayandanahalli to Tumkur).

b. Chainages where the grade separator work going on in these places

deflection value is 98mm.

3.4. Traffic volume count survey

Traffic survey is to be carried out at the selected locations of the Outer Ring Road. This traffic

volume count survey is to be carried out only at the major junctions which requires

improvements. The selected study locations were Hebbal, Manyatha Tech park, EMC square,

Ibblur and Laggere Junctions.

a) Junction volume count

The junction volume count was conducted by the consultants for one day 24hr continuous

periods. From this survey we can get the information on turning movement characteristics (like

delay in traffic, infrastructure facilities, control of inflow traffic at the junction etc.,) in addition

to the variation in traffic and peak hour traffic. This junction volume count data can be used for

improving the signalization, land use, intersection design and traffic systems management. The

data were collected for every 15min interval throughout a day. The survey location selected for

the study are,

Ibblur Junction @ch 31.3km

EMC square @ch 22.0km

Motorised traffic

Two wheeler

Three wheeler

Tractor

Cars

Light commercial vehicles

Bus/ truck/ road rollers

Heavy trucks (3 to 6 axles)

Oversized vehicles (>7 axles)

Non motorised traffic

Bicycle

Cycle rikshaw

Animal drawn vehicle

Hand cart

Page 11

HDM-4 Training Manual

Based on Junction volume count survey, following inferences can be made.

1. At the Ibblur junction there is more traffic flow can be observed which shows that there is a

need for widening of the road.

2. At these junction points there is a need for special maintenance and improvement required.

b)Mid Block volume count

Mid Block volume count were conducted at various locations of the Outer Ring Road for one

day or three days continuous period. This type of volume count survey was carried out to get the

total number of vehicles moved and also to know the traffic volume on that road. The data

collected from theis type of volume count is useful in the design of pavement thickness.

The selected locations for the study were:

a.Manyatha Tech park

b.Marathahalli STP

c.Laggere

From these survey we can get the peak hour volume count. This value is to be used for the

determination of Annual Average Daily Traffic. This data is useful to know the present traffic and

number of vehicles moving along this ORR.

3.5. Pavement condition survey

Next step is to carry out the pavement condition survey which includes the physical

measurements of various performance indicators. They are cracking, patch work and pot hole

filling, ravelling, roughness, edge breaking, rutting etc.,

3.6 Roughness

Deviations of surface from true planar surface with characteristic dimensions that affect vehicle

dynamics, ride quality, dynamic of loads and drainage, expressed inthe International Roughness

Page 12

HDM-4 Training Manual

Index, IRI (m/km). Roughness can be measured either by using Fifth Wheel Bump Integrator or

by Roughometer 2 or 3.

IRI =0.0032 (UI)0.89Where,

IRI is in m/km or mm/km

For every 1 km we have to note down the Roughness values and to know the 1km stretch use

GPS to know the position where it will come in the field.

3.7 Pavement Deterioration Condition Analysis

Software HDM-4 includes relationship for modelling Road Deterioration (RD) and Road Works

Effects (WE). These are used for the purpose of predicting annual road condition and for

evaluating road work strategies.

Project analysis is to be carried out using HDM-4 software with various M&R strategies.

Procedure for project level pavement analysis are:i) Create the road project to be analyzed by giving a title and specifying the road to be analyzed.

ii) Define the project by specifying the following:

General information about the project

Road Network data, Pavement Condition data, Vehicle fleet data and Traffic Volume data.

Method of analysis.

Road sections to be analysed.

iii) Specify maintenance and improvement standards to be analyzed for each selected road

section. Set-up and run the analysis.

iv)Generate the reports and print the required outputs.

Page 13

HDM-4 Training Manual

Based on condition of the road, we have to select various Maintenance and Rehabilitation

(M&R) strategies. For the various alternative strategies, we have to refer Report of the

Committee on Norms for Maintenance of Roads in India [MoRT&H 2001].

3.8 Economic Analysis using HDM-4 software.

Highway Development and Management Tool (HDM-4) is also designed to make comparative

cost estimates and economic evaluations of different construction and maintenance options.

During project analysis, we have to compare various alternative strategies with the base

alternative. From the economic analysis we will get

NPV/cost ratio

Internal Rate of Return values.

The maximum value will shows the best alternative to keep the road in good condition. And also

it shows the economical option for maintenance of road about 10years period. Then the obtained

results are to be compared with actually required funds and Govt. Funding amount for M&R

works.

CHAPTER 3

FIELD STUDIES AND DATA COLLECTION

The data collected from the field studies are included in this chapter. Also various databases

needed to fulfil the requirement of inputs for HDM-4 are shown in the table format.

3.1 Key map of the study stretch

Page 14

HDM-4 Training Manual

Fig 4.1 CSB junction to Goraguntepalya Bus Stop(i.e., 36km)

3.2 Collection of secondary data

The main objective of the project is to study the condition of the pavement and to predict the

future condition of the pavement after considering the various alternative maintenance strategies.

So in order to predict the present condition we need some of the pavement evaluation details,

traffic growth rates, history of the pavement sections etc., These databases are collected from the

department., in order to develop the database for the Outer Ring Road. These databases are very

essential to carry out the life cycle cost analysis. Some of the databases we got from the

department is as shown in the table below.

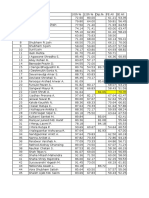

Table 4.2.a Material characteristics details-From Gorguntepalya to Hebal Junction

ID Chainag

1

2

3

4

5

6

7

e

0

1

2

3

4

5

6

Soil type

Field MC

OMC

MDD

CBR values

SW

SW

SW

CL

CL

SW

SW

10.52

12.31

14.26

16.12

16.95

10.46

6.09

9.7

8.8

8.9

11.8

11.0

9.8

10.9

1.81

1.83

1.79

1.6

1.52

1.69

1.68

6.8

9.7

5.3

4.0

3.8

4.9

5.0

Page 15

HDM-4 Training Manual

8

7

CL

11.42

(Source: STUP consultants Pvt. Ltd.)

12.9

1.51

4.7

Table 4.2.b Benkelman Beam Deflection details- From Goragunte playa to Hebbal Junction

I

Chainag

Deflectio

Pavemen

Temp

Moisture

Correc

t temp

correctio

correctio

t mean v

deflect

0.33

0.40

0.31

0.07

0.09

0.04

deflect

0.47

0.59

0.39

0.35

0.35

0.39

0.40

0.35

0.13

0.13

0.11

0.11

0.11

0.62

0.60

0.61

0.61

0.56

1

0

0.32

29

2

1

0.20

29

3

2

0.32

29

4

3

5

3.3

0.12

29

6

4

0.24

29

7

5

0.24

29

8

6

0.20

28

9

7

0.12

28

(Source: STUP consultants Pvt. Ltd.)

n

-0.06

-0.06

-0.06

-0.06

-0.06

-0.06

-0.07

-0.08

n factor

1.01

1.01

1.01

Under pass

1.08

1.06

1.01

1.08

1.03

Stdde

Correc

char

Based on the obtained deflection values we can design the overlay thickness to the section from

Goragunte playa to Hebbala junction.

Table 4.2.c Roughness value details- From Goragunte playa to Hebbala junction

ID

Chainag

Avg

Avg IRI

e

UI(mm)

1

0 to 1

2219

3.08

2

1 to 2

3405

4.51

3

2 to 3

2969

3.99

4

3 to 4

2910

3.92

5

4 to 5

2207

3.06

6

5 to 6

2428

3.33

7

6 to 7

1883

2.66

(Source: STUP consultants Pvt. Ltd.)

Landmark

Remark

Goragunte playa

Rail track, more value

BEL circle

Kuvempu circle

Hebbala junction

4.3 Details collected from the field survey

Page 16

HDM-4 Training Manual

In order to collect the present pavement condition in terms of severity and extent, we carried out

distress survey. In this distress survey we moved all along the pavement section and physically

measured the length and width of the distresses like cracks, potholes, ravels, rutting, edge breaks,

settlements, streaks etc., Also along with the measurements we have taken the GPS reading to

find out the position of distress. Then also collected the photographs of the distresses to present

those distresses in the maps. We are now thinking to attach those photographs to the google maps

based on their GPS readings.

Table 4.3.1 Details from Pavement condition survey- From Goragunte playa to Hebbal

SI

1

2

3

4

5

6

Chainage

Avg

0 to 1.1

1.1 to 2.3

2.3 to 3.6

3.6 to 4.2

4.2 to 5.4

5.4 to 6.7

(%)

0.57

0.07

1.91

0.47

0.47

1.67

crack Avgpatch(%) Pothole

5.50

0.00

0.33

0.42

0.42

0.00

0.10

0.12

0.12

0.02

0.02

0.00

Ravel

7.2

8.2

0

0

1.5

1.5

Rut

10

15

14

18

12

16

Landmar

k

GGPalya

MES stop

BEL stop

Hebbal

4.4Data needed to run HDM-4

Following are various tables showing the database necessary to carry out the life cycle cost

analysis. These details include road network data, vehicle fleet details, configuration details etc.,

Now we can see the details and their importance to include in the software.

Road network details

One of the major information required to run the HDM-4 includes road basic data, geometrics of

the road section, road condition details and history of the road section. These details are needed

to find out the actual surface of the pavement section. Following table shows the database

included in the software HDM-4. These details are collected from the various secondary sources

and primary sources.

Table 4.4.1.a Road basic and geometric details of selected sections

ID

Road sections basic details

Road sections geometric details

Page 17

Lanes

Width(m)

Length(km)

Drainage type

Speed limit(kmph)

Super elevation(%)

Hor curve(deg/km)

No. of rise+fall/km

Rise+fall(m/km)

AADT year

NMT traffic

MT traffic

Shoulder width(m)

Pavement type

Climatic zone

Road class

Traffic flow pattern

Speed flow type

HDM-4 Training Manual

AR

OR

Tr

1.0

3750

42

2014

10

15

40

Li

AR

OR

Tr

1.0

3426

45

2014

10

15

40

Li

AR

OR

Tr

1.5

3850

56

2014

10

15

40

Li

9.8

AR

OR

Tr

1.5

3950

55

2014

10

15

40

Li

9.8

AR

OR

Tr

1.5

5032

55

2014

10

15

40

Li

9.8

AR

OR

Tr

1.5

5151

49

2014

10

15

40

Li

9.8

AR

OR

Tr

1.5

6023

25

2014

10

15

40

Li

9.8

Table 4.4.1.b Road condition and inventory details of some typical sections

Last rehab year

Last surface year

Last prevent year

Base thickess(mm)

0.04

AC

40

80

2002

1996

2010

2012

150

15

4

201

3.06

0.46

15

15

AC

40

80

2002

1996

2010

2012

150

15

4

201

3.92

0.47

10

15

AC

40

80

2002

1996

2010

2012

150

15

4

201

3.99

1.91

15

0.5

10

AC

40

80

2002

1996

2010

2012

150

15

4

201

2.66

1.61

15

15

AC

40

80

2002

1996

2010

2012

150

15

Page 18

thickness(mm)

Material type

Resil. Mod(GPa)

Last const year

Prev surf thick(mm)

0.57

Currentsurface

3.08

Drainage condition

Texture depth(mm)

201

Rut depth(mm)

Edge break(m2/km)

Potholes(no./km)

Ravelled area(%)

Total crack area(%)

Road history

Roughness(m/km)

Road condition details

Condition year

HDM-4 Training Manual

6

201

3.33

0.47

15

15

AC

40

80

2002

1996

2010

2012

150

15

4

201

4.51

0.07

0.5

10

AC

40

80

2002

1996

2010

2012

150

15

Vehicle fleet details

It i0.5ncludes the collection of various motorised and non-motorised vehicles details. Some of

the ba1sic and economic details should be added to the HDM-4 software mainly to calculate the

road us1er cost(RUC), vehicle operation cost(VOC), maintenance costs etc., Following table

shows th0.5e various vehicles basic and economic details. These details are not accurate but still

valid information we have included in the software HDM-4. The details are collected from the

various secondary sources using internet and other sources.

Table 4.4.2.a Motorised vehicle fleet basic details

Name

Motor

Car

Car

LCV

BUS

Heavy

RTV

Tractor

Auto

Base type

cycle

Motor

NT

Small

OT

Large

Light

Medium

truck

Arti-

Light

Light

Motor

cycle

car

car

goods

bus

culated

bus

goods

cycle

PCSE

No. of wheels

No. of axles

Tyre type

0.5

2

2

Bias

1

4

2

Radial

1

4

2

Radial

1.5

4

2

Bias

1.5

4

2

Bias ply

trucks

1.5

8

5

Bias ply

2

4

2

Bias

1

8

4

Bias

1.5

3

2

Bias

Tyre base

ply

1.3

ply

1.3

ply

1.3

ply

1.3

1.3

1.3

ply

1.3

ply

1.3

ply

1.3

recaps

Tyre

15

15

15

12

20

25

15

15

15

retreadcost(%)

Annual km

Annual

work

10,787

300

32,077

1200

32,011

1200

41,831

1800

90,000

2250

99000

2200

60,000

2000

15,000

2000

45,000

2000

hours

Avg life(years)

Private use(%)

Passengers

10

100

1

10

100

2

10

100

3

9

0

0

8

0

40

10

0

0

9

0

20

8

0

0

6

0

3

Page 19

HDM-4 Training Manual

Work

related

75

75

75

75

100

75

75

trips(%)

ESALF

Oper. Weight in

0

0.2

0

1.35

0

1.59

0.02

7

0.78

9.2

6.77

32

0.02

7

0.02

7

0

0.6

tonnes

Table 4.4.2.b Non-motorised vehicle types

Name

Base type

Wheel

Wheels

Cycle

Bicycle

type

Pneumatic

Cart

Cart

Wooden

Rick

Rickshaw

Pneumatic

Dia

Oper. Wt

Play

Avg

Work

Annual

Passen

0.7

100

load(kg)

35

life

10

hours

150

km

2500

gers

1

1.0

1200

900

1300

4000

0.7

300

235

500

7200

Table 4.4.2.c Motorized vehicle fleet economic cost details

Base type

Motor

Car NT

Car

LCV

Bus

Heavy

RTV

Tract

Auto

cycle

Motor

Small

OT

Large

Light

Medium

truck

Articulate

Ligh

or

Light

Motor cycle

cycle

car

car

Goods

Bus

Truck

t Bus

good

s

New

25226

313582

2609

383386

623899

756460

3000

2000

78470

377

1315

95

1312

2332

5440

6632

00

2332

00

2332

377

tyre

Fuel

18

18

15

12

12

12

12

12

15

Lubr. Oil

60

60

60

60

60

60

60

60

60

Mainten.

15

30

30

30

30

30

30

30

25

labour

Crew

27

105

54

67

27

wages/hr

Annual

Interest

Passenger

19

39

30

24

24

24

10

vehicle

Replace

Work

Time/hr

Passenger

Non-work

time/hr

Page 20

HDM-4 Training Manual

Cargo

20

holding/hr

Table 4.4.2.d Non-Motorized vehicle fleet economic cost details

Cycle

Cart

Rickshaw

Base type

Purchase

Crew

Passenger

Cargo

Energy

Annual

Bicycle

Animal cart

Rickshaw

cost

1200

25000

4000

wages/hr

0

15

1

time/hr

0

0

15

holding

0

0

0

(per MJ)

0

0

0

Int(%)

9

9

9

Configuration details for HDM-4

This is one of the needed file to suite the factors for that particular area and location. It includes

the details like traffic flow pattern, climatic condition of the area and speed flow type. If we

accurately provide the details then the software matches according to the condition and

calibrates itself to match to that condition. Following are the values given to match the pavement

located area and its climatic details.

Table 4.4.3.a Traffic flow pattern on ring road

Period

Period 1

Period 2

Period 3

Period 4

Time

8.00 to 13.00

13.00 to 17.00

17.00 to 22.00

22.00 to 8.00

Hours per year

3750

2483

3457

2860

% of AADT

29.88

19.78

27.54

22.78

Table 4.4.3.b Climatic condition

Moisture classification

Moisture Index

Duration of Dry Season

Mean monthly precipitation

Temperature classification

Mean temperature

Average temperature range

Days T>24deg. C

semi arid

-40

0.33

90

Tropical

above 18deg C

5deg C

45

Page 21

HDM-4 Training Manual

Freeze Index

Percent of time Driven on snow covered roads

Percent of time Driven on water covered roads

0

0

30

Table 4.4.3.c Speed flow details

Capacity

Road type

Ultimate

capacity(PCSE/lane/h)

Free flow capacity

Normal capacity

Jam speed(km/hr)

Accident Rate(in number per 100 million veh Fatal

Injury

km)

Damage

annaxr

Speed related

Desired speed multification

factor

Calib factor

2L & 3L

2400

0.2

0.8

25

10

40

10

0.7m/s2

1

1

4.4.4 Type of maintenance activity applied to the present study

Various maintenance activities can be selected based on the present condition of the pavement.

For the present work we added maintenance work as the routine maintenance, preventive

maintenance, thin overlay, thick overlay and strengthening and overlay. In addition to this

maintenance activity we added the improvement work as lane addition. If there is an increase in

the traffic growth rate then this improvement programme can be recommend to the present

pavement condition.Following table shows the maintenance activity and intervention criteria

along with unit cost for the particular type of maintenance activity (ref. KPWD schedule of rates,

2013-14).

Page 22

HDM-4 Training Manual

4.4.5 Work standard details

Type of maintenance

Intervention criteria

Work item

Treatment

2

OR improvement

activity

Routine maintenance

Rs/m area

Potholes>=4 No.s

Crack area>= 3%

Every year

IRI>=6.0

Patch work

Crack repair

Drainage cleaning

Microsurfacing

Thin overlay

Thick overlay

Strengthening and

IRI>=6.0

IRI>=6.0

IRI>=6.0

12kg/m2

30mm BC

40mm BC

75mm BC

rehabilitation

Lane addition

Volume/capacity >=0.8

Lane addition by 3.0m 4000

Preventive maintenance

width

4.4.6 Maintenance alternatives

Alternative

Type of maintenance

Work item

OR improvement

Base Alternative

activity

Routine maintenance

Patch work

Crack repair

Alternative 1

Alternative 2

Alternative 3

Alternative 4

Alternative 5

Preventive maintenance

Drainage cleaning

Microsurfacing @

Thin overlay

Thick overlay

Strengthen & overlay

Lane Addition

12kg/m2

30mm BC

40mm BC

75mm BC

3.0m wide lane,

Volume/capacity >=0.8

CHAPTER 5

Page 23

125

110

140

80

140

150

250

cost

HDM-4 Training Manual

PAVEMENT DETERIORATION ANALYSIS

5.1 Development of Pavement Condition Index

The pavement condition is functionally evaluated by determining the Pavement Condition

Index(PCI) based on the deduct values. Deduct values are values that represent the condition of

theexisting pavement, i.e. the amount of distress that a present pavement has undergone. Serves

asa type of weighting factor that indicates the size of the effect that the particular distress type

hason the pavement condition.

Pavement condition index is one of the method of indicating the deterioration rate in terms of

severity and extent ratings. The present study also made PCI development in order to compare

with the software generated rating to the pavement sections. Following table shows the distress

survey details.

Following formula shows how to calculate the area of crack, patch work, ravelling in percentage.

Area of crack (%)= [Area of crack(L*W) / Total area of pavement (L*W)] * 100

Area of patch work (%)= [Area of crack(L*W) / Total area of pavement (L*W)] * 100

Area of ravelling (%)= [Area of crack(L*W) / Total area of pavement (L*W)] * 100

Table 5.1.a Pavement distress survey details- From GGPalya to Hebala Junction

SI

Segment

Avg crack % Avgpatch(%)

Pothole

(No./km)

1

0 to 1.1

0.57

5.50

0.10

2

1.1 to 2.3 0.07

0.00

0.12

3

2.3 to 3.6 1.91

0.33

0.12

4

3.6 to 4.2 0.47

0.42

0.02

5

4.2 to 5.4 0.47

0.42

0.02

6

5.4 to 6.7 1.67

0.00

0.00

The above table shows the various types of distresses on

Ravel %

Rut in Landmark

mm

7.2

10

8.2

15

0

14

0

18

1.5

12

1.5

16

the flexible pavement

GGPalya

MES stop

BEL stop

Hebbal

in terms of

percentage of cracks out of total area of the pavement section, rutting in terms of average mm per

km. And ravelling in terms of area of weared surface out of total area of the pavement section.

Page 24

HDM-4 Training Manual

Cracking

Severity

L=Light Cracking

Fine, longitudinal hairline cracks running parallel to each other with no, or only a few

interconnecting cracks.

M=Medium Cracking

Further development of light alligator cracks into a pattern or network of cracks that may be

lightly spalled

H=Heavy Cracking

Network or pattern cracking has progressed so that the pieces are well defined and spalled at the

edges, some of the pieces may rock under the traffic.

Density

L-

Low Density

M Medium Density

H-

High Density

Percentage of Area between 0-10%

Percentage of Area between 10-20%

Percentage of Area between >20%

Patching

Severity

L - Low Severity= Patch is in good condition and satisfactory. Ride quality is rated as low

severity or better

M Medium Severity= Patching is moderately deteriorated, or ride quality is rated as medium

severity, or both

H - High Severity= Patching is badly deteriorated, or ride quality is rated as high severity, or

both, needs replacement soon.

Rut Depth

SeverityL - Low Severity= Rut Depth between 6mm to 13mm

Severity= Rut Depth between 13mm to 25mm

between >25mm

Density

L - Low Density= Percentage of Area between 0-10%

M Medium Density= Percentage of Area between 10-20%

Page 25

H-

M - Medium

High Severity= Rut Depth

HDM-4 Training Manual

H - High Density= Percentage of Area between >20%

Table 5.1.b Severity and extent of distress- From Goraguntepalya to Hebbala

SI

1

2

3

4

5

6

Chainage

0 to 1.1

1.1 to 2.3

2.3 to 3.6

3.6 to 4.2

4.2 to 5.4

5.4 to 6.7

Avgcrack(%)

M

L

H

L

L

H

Avgpatch(%) Pothole

H

L

M

M

M

L

M

M

M

L

L

L

Page 26

Ravel

H

H

L

L

M

M

Rut(mm)

L

M

L

H

L

H

Landmar

k

GGPalya

MES stop

BEL stop

Hebbal

HDM-4 Training Manual

Table 5.1.c Calculated PCI From Goragunte playa to Hebbala

Id

1

2

3

4

5

6

Segment

0 to 1.1

1.1 to 2.3

2.3 to 3.6

3.6 to 4.2

4.2 to 5.4

5.4 to 6.7

Crack DV

16

6

38

6

6

33

Patch D V

38

4

7

7

8

3

Total D V

54

10

45

13

14

36

Page 27

Corrected D V

36

10

30

11

12

20

PCI

64

90

70

89

88

80

HDM-4 Training Manual

(Ref: Modern Pavement Management, Ralph Haas, pg no. 152)

5.3 Pavement condition analysis by using HDM-4

A Project is defined as several road works, or more than one road section, grouped together in

one contract. Project title, road network, or vehicle fleet information can create a project. Work

standards, general traffic composition and growth rate, extra benefits, and costs must be specified

to start a project analysis. Project analysis predicts pavement conditions and costs during a userspecified time period. The costs include capital investment, road maintenance works, and vehicle

operation costs. Accident costs and emission costs may also be included (Kerali, 2000). All road

Page 28

HDM-4 Training Manual

agency costs in this research are financial, which exclude the costs of overhead, taxes, project

engineering, and safety from the total road work economic costs.

5.3.1 Methods of analysis

Options for analyzing investment are provided by section or project. In analysis by section,

economic indicators (such as NPV and IRR) are calculated individually for each section

alternative; Thenanalysis by project will group alternatives to perform an economic analysis, and

a base alternative is compared for each project alternative to give annual total economic

indicators.

5.3.2 Reports generated

The goal of project level analysis is to identify the most cost-effective solutions by comparing

several project alternatives. HDM-4 project level analysis can generate thefollowing types of

reports:

traffic condition forecasting, which includes AADT, traffic volume, and volume/capacity ratio

road deterioration condition prediction, which includes roughness, pavement distress

conditions, and roadwork lists

road-user cost estimation, which includes an accident-rate summary, cargo holding hours, crew

hours, fuel consumption, labor hours, lubricant hours, overhead costs, parts consumption, vehicle

speed

environmental effects

comparison of the project alternatives

input data, which can be used for checking and review.

5.4 Traffic condition forecasting

Page 29

HDM-4 Training Manual

8000

AADT (vehicles/day)

7500

GGP TO RAIL

HEBLB TO HEBLJ

KVM TO HEBLB

MSR TO KVMP

NURS T JNCTN

NURS TO LAKE

RAIL TO MSR

7000

6500

6000

5500

5000

4500

4000

2023

2022

2021

2020

2019

2018

2017

2016

2015

3000

2014

3500

Year

From the above graphs we can observe that no effect on the motor vehicles growth rate. This is

because there is a normal growth rate of motor vehicles. And from the graph we can see that

there is a rapid growth rate of motor vehicles near the Hebbal Junction. This is due to the passing

of NH-7(Bellary-Hyderabad). And also the presence of various IT, BT companies and Airport

road will connect through this junction. So from these observations we can predict that there may

be rapid increase in traffic growth rate near the Hebbal junction. And the any alternative

maintenance activities will not affect the traffic growth rate from GGPalya to Hebala junction.

4600

AADT (v ehicles/day)

4500

Alternativ e 1

Alternativ e 2

Alternativ e 3

Alternativ e 4

Alternativ e 5

Base Alternativ e

4400

4300

4200

4100

4000

2023

2022

2021

2020

2019

2018

2017

2016

2015

3800

2014

3900

Year

From the AADT year by section we can say that there is no or very less effect on the traffic

growth for the any section considered for the matter of traffic growth is considered. Here from

Page 30

HDM-4 Training Manual

the graph we can say that there is constant increase in AADT(veh/day) value every year and this

growth will not affect any alternative maintenance as we observed above.

5.5 Road deterioration condition prediction

a) Average roughness

Average Roughness (IRIav) for each Project

(weighted by section length)

16

Altenative 2

Alternative 1

Alternative 2

Alternative 3

Alternative 4

Alternative 5

Base Alternative

14

IRIav (m /k m )

12

10

8

6

4

2023

2022

2021

2020

2019

2018

2016

2015

2014

2017

Year

From the above graph we can observe that alternative 4 is the best maintenance strategy which

will serve for long time without need of any other alternative maintenance treatment. Other than

that alternative maintenance treatment is that Base alternative which includes crack repairs, patch

works and drainage cleaning every year is the suitable alternative measure compared to

alternative 1,2,3 and 5.

Alternativ e-1

Alternativ e-2

Alternativ e-3

Alternativ e-4

Alternativ e-5

Base Alternativ ee

6

5

4

3

Year

Page 31

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

Av erage Roughness (m/km)

HDM-4 Training Manual

From the above average roughness value we can observe that there both base alternative and

alternative 4 can be the better option to carry out maintenance activity for the whole outer ring

roads section i.e., from Goraguntepalya to Hebbal junction.

b) Crack progression

Alternative 1, 2, 3 and 5

Progression of Cracking over time

(after works values)

100

90

@Total Area of

Cracking

(ACRA)

% Cracking

80

70

60

50

40

30

20

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

10

Year

The graph is plotted by taking year on X-axis and crack percentage on Y-axis. The above graphs

shows the progress of percentage of crack area. All the alternatives except 4 and base alternative

have the same effect on the progress of crack value over a period of time. So this should be

avoided by adding some other suitable alternatives.

Alternative 4

Page 32

HDM-4 Training Manual

Progression of Cracking over time

(after works values)

100

90

@Total Area of

Cracking

(ACRA)

80

% Cracking

70

60

50

40

30

20

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

10

Year

Above graph shows that alternative 4 will reduces all the percentage of cracks for a long period

of time. Actually there is a less percentage of crack is there in the pavement sections. But it will

increases over a period of time. In order to avoid this progress we have to apply some alternative

maintenance strategy that is strengthening and rehabilitation work.

Base alternative

Progression of Cracking over time

(after works values)

100

90

@Total Area of

Cracking

(ACRA)

80

% Cracking

70

60

50

40

30

20

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

10

Year

Here in the above graph alternative 4 is the best option to keep the crack projection at minimum

level. And also we can see that both alternative and base alternative are to be implemented as a

maintenance activity. So that we can manage the pavement for long period of time. Also we can

say that both base alternative and any one of the above alternative is to be considered for the

Page 33

HDM-4 Training Manual

maintenance activity. Crack progression is rapidly increases if we do not take care of the early

maintenance. This is applicable only to the section 1.

c) Progress of damaged surface area

Progression of Damaged Surface Area over time

(after works v alues)

100

Surface Damage (%)

90

@Total Area of

Cracking (ACRAaw)

@Area of Potholing

(APOTaw)

@Area of Edge Break

(AVEBaw)

@Area of Ravelling

(ARVaw)

@Total Damaged

Surface Area (ADA...

80

70

60

50

40

30

20

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

10

Year

The above graph represents the percentage of surface damage for a given period of time about 10

years. Even after the alternative work carried. From the above graph we can say that all the

alternative except alternative 4 and Base alternative have same surface damage percentages.

Alternative 4

Progression of Damaged Surface Area over time

(after works v alues)

100

Surface Damage (%)

90

@Total Area of

Cracking (ACRAaw)

@Area of Potholing

(APOTaw)

@Area of Edge Break

(AVEBaw)

@Area of Ravelling

(ARVaw)

@Total Damaged

Surface Area (ADA...

80

70

60

50

40

30

20

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

10

Year

This is one of the suitable alternative among all other alternative maintenance strategies. By

applying the alternative 4 that is strengthening and rehabilitation work. We can achieve better life

of the pavement section. This will reduces all the distresses rapidly and keeps minimum distress

over a period of time. This alternative is to be provided along with the base alternative. Then

Page 34

HDM-4 Training Manual

only the maintenance work can be effectively worked out otherwise alternative only 4 will not be

effective.

Base Alternative

Progression of Damaged Surface Area over time

(after works v alues)

100

Surface Damage (%)

90

@Total Area of

Cracking (ACRAaw)

@Area of Potholing

(APOTaw)

@Area of Edge Break

(AVEBaw)

@Area of Ravelling

(ARVaw)

@Total Damaged

Surface Area (ADA...

80

70

60

50

40

30

20

2023

2022

2021

2020

2019

2018

2017

2016

2015

2014

10

Year

This graph is also same as that of above showing the variation in the surface damage percentage

value. But the ravelling area is more for the various sections. It should be avoided by applying

only the alternative 4 along with the base alternative.

Page 35

HDM-4 Training Manual

Roughness (m /km )

4.5

LN_01

LN_02

LN_03

LN_04

LN_05

LN_06

LN_07

4

3.5

3

2.5

Year

2023

2022

2021

2020

2019

2018

2017

2016

2015

1.5

2014

he above graph shows the roughness value for the various sections of the pavement. The graph is

drawn by considering roughness value versus year for the various link Ids. But for the link 1

there is increase in roughness value. Because for this section we have not given the alternative

maintenance strategy. So the roughness value has increased from origin value to the maximum

extent.

Page 36

HDM-4 Training Manual

CHAPTER 6

ECONOMIC ANALYSIS

6.1 Program level analysis

The program level analysis selects a combination of treatments for sections by optimizing an

objective function under budget constraints. It generates the same type of reports as project level

analysis, such as traffic reports, pavement distress conditions, works effects, road-user effects,

and costs. Furthermore, it compares outputs by different categories under constrained budgets or

optimized conditions. The reports generated in program level analysis are (Kerali, 2000a):

optimum section alternatives for varying levels of budgets

a pavement surface condition summary by link ID (state route number) or road class (interstate,

major collector, minor arterial, or principal arterial)

average roughness (weighted by section length) by link ID, pavement surface, or road class

average speed by link ID, pavement surface, or road class

volume/capacity ratio by link ID, pavement surface, or road class

Page 37

HDM-4 Training Manual

work programs optimized or unconstrained by section or by year.

To demonstrate the functions, all I-5 flexible pavements, 141 sections and 872.73 lane miles

were analyzed in program level. Table 46 lists the traffic composition and growth rates.

6.2 Analysis by section

Analyses, individual, each of the road sections that makes up the project. Several alternatives can

be defined for each sections. All other alternatives will be compared with one alternate designed

as base case. Economic Indicator will be compared for each road section.(for example NPV, IRR,

BCR and FYB). The table 6.1 shows various pavement section and provided alternative

maintenance strategies along with the Net Present Value.

Table 6.2 Section alternative section details

Section Alternatives

Segment

Details

NPV

1

Section 1

ORR4,5,6

Section 2

RM

ORRRM

1, 3

Section 3

ORR-2

RM

Micro

Thin

surface

Overlay

Micro

Thin

Strengthen&

surface

overlay

rehabilitation

Micro

Thin

surface

overlay

6.3 Analysis by project

Page 38

5

1.34

Lane addition

Widening

2.65

S&R

1.2

HDM-4 Training Manual

Analyses road section together as a package by considering project alternatives as the basis unit

for performing economic analysis. First, the annual cost and benefits are summed over all the

section alternatives within each project alternative to give early totals. Economic indicators are

then calculated for each project alternative by comparison against a base year alternatives.

Table 6.2 Project alternative section details

Road

Project Alternatives

Section

Section 1

RM

Section 2

RM

Section 3

RM

Proj NPV

Micro

Thin

surface

overlay

Micro

Thin

Strengthen

surface

overlay

Rehabilitation

Micro

Thin

Strengthen

surface

overlay

Rehabilitation

2.85

3.08

4.72

&

&

Widening

Lane Addition

3.85

6.4 Optimum section alternatives

Section

Initial

Alternative

Avg IRI

Discounted Capital Costs

Net Present Value

AADT

0 to 1

4583

Base Alternative

3.32

0.00

0.00

6 to 7

5435

Alternative 4

1.80

5.68

1.47

3 to 4

4440

Alternative 4

1.98

5.68

2.13

2 to 3

4321

Alternative 4

2.00

5.68

1.20

5 to 6

7016

Alternative 4

1.71

5.68

1.33

Page 39

HDM-4 Training Manual

4 to 5

5786

Alternative 4

1.85

5.68

1.24

1 to 2

3751

Alternative 4

2.09

4.06

3.17

2.11

32.46

10.54

Optimum section alternative means for a particular section suitable maintenance activity is to be

selected based on economic analysis. Also NPV will shows which section will gives maximum

benefit among various pavement sections considered.

Page 40

HDM-4 Training Manual

CHAPTER 7

CONCLUSION

1) Maintenance strategy can be best judged based on economic analysis.

2) HDM-4 is used for developing the PMS.

3) The study demonstrated, that use of HDM-4 will provide required management information if

carefully adopted.

4) Use of HDM-4 showed better result than PCI rating scale.

5) For the present section, Strengthening and rehabilitation is better choice compared to other

alternatives.

Page 41

HDM-4 Training Manual

Scope for further studies

1) The present development of pavement management system can be used and continued for

further stretches.

2) The use of HDM-4 can be used as a supporting tool to make planning and programming of the

maintenance activities.

3) New technologies like use of GIS for mapping and programming of pavement condition can

be adopted.

Page 42

HDM-4 Training Manual

References

1) SanjivAgarwal, Prof.S.S.Jain and Dr.M.Parida(2004) Development of pavement management

system for Indian national highway network IRC publication, paper 502,pp 271-326.

2) R.Sudhakar(2009) Pavement maintenance management system for urban roads using HDM4 IGS Chennai Chapter, student paper competition 2009.

3) GeethuSaji, Sreelatha T and B.G Sreedevi(2013) A study on pavement performance and

overlay design using HDM-4 IJIRSET, Vol. 2, Issue 8, August 2013.

4) S.S.Naidu, Dr.P.K.Nanda et al.,(2003) Pavement maintenance management system for urban

roads using software HDM-4 a case study Indian Road Congress, Vol.66.3, pp 641-669.

5) Kunal Jain, Sukhvir Singh Jain et al.,(2013) Selection of optimum maintenance and

rehabilitation strategy for multilane highways IJTTE, 2013.

6) Maher Abdel Fatah Al-Hallaq (2004) Development of a Pavement Maintenance Management

System for Gaza City thesis report, Jan 2006.

7) Indian Road Congress(1993) Manual on economic evaluation of highway projects in India,

IRC:SP 30, New Delhi.

Page 43

HDM-4 Training Manual

Acknowledgement

Thanks to my Guide Prof.T.G.Sitharam, Dr.Venkat Chilukuri , and

Dr.Krishnamurthy.

Also I am grateful to Dr.Gururaja for providing video camera with GPS and

B.D.A. members for providing the data required for the project work

prepared by the STUP consultants.

Page 44

Potrebbero piacerti anche

- Irctcs E Ticketing Service Electronic Reservation Slip (Personal User)Documento2 pagineIrctcs E Ticketing Service Electronic Reservation Slip (Personal User)Ashok RajanavarNessuna valutazione finora

- Fatigue Analysis: Annexure 1Documento1 paginaFatigue Analysis: Annexure 1Ashok RajanavarNessuna valutazione finora

- Arun Vishwanath Unhale: Course/Degree Institution Board/University Year Average (%)Documento3 pagineArun Vishwanath Unhale: Course/Degree Institution Board/University Year Average (%)Ashok RajanavarNessuna valutazione finora

- Undertaking: AmieteDocumento5 pagineUndertaking: AmieteAshok RajanavarNessuna valutazione finora

- Equipment ListDocumento1 paginaEquipment ListAshok RajanavarNessuna valutazione finora

- Solar SystemDocumento1 paginaSolar SystemAshok RajanavarNessuna valutazione finora

- Minor Junctions-Package-I SL No - Existing Chainag e (KM) Design Chainag e (KM) Type of Intersectio N Categor y Other Features Junction LayoutDocumento2 pagineMinor Junctions-Package-I SL No - Existing Chainag e (KM) Design Chainag e (KM) Type of Intersectio N Categor y Other Features Junction LayoutAshok RajanavarNessuna valutazione finora

- Student Data For PlacementDocumento2 pagineStudent Data For PlacementAshok RajanavarNessuna valutazione finora

- ProfileDocumento5 pagineProfileAshok RajanavarNessuna valutazione finora

- QPR ReportDocumento76 pagineQPR ReportAshok RajanavarNessuna valutazione finora

- DP CVDocumento4 pagineDP CVAshok RajanavarNessuna valutazione finora

- Criteria 03Documento1 paginaCriteria 03Ashok RajanavarNessuna valutazione finora

- Number Key Answer Number Key Answer Number Key Answer Number Key AnswerDocumento1 paginaNumber Key Answer Number Key Answer Number Key Answer Number Key AnswerAshok RajanavarNessuna valutazione finora

- M45 Grade As Per Is 10262Documento4 pagineM45 Grade As Per Is 10262Ashok RajanavarNessuna valutazione finora

- Sl. No. Start Chainage End Chainage Length of RealignmnetDocumento6 pagineSl. No. Start Chainage End Chainage Length of RealignmnetAshok RajanavarNessuna valutazione finora

- Wachand Insitute of Technolgy, Solapur: Notice For Se, Te and Be StudentsDocumento1 paginaWachand Insitute of Technolgy, Solapur: Notice For Se, Te and Be StudentsAshok RajanavarNessuna valutazione finora

- Anmol MagdumDocumento3 pagineAnmol MagdumAshok RajanavarNessuna valutazione finora

- Project Summary Nagina-Kashipur NH74Documento35 pagineProject Summary Nagina-Kashipur NH74Ashok Rajanavar67% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 1.1 IntroductionDocumento17 pagine1.1 IntroductionRicka ValinoNessuna valutazione finora

- Advances in Energy Research, Vol. 1: Suneet Singh Venkatasailanathan Ramadesigan EditorsDocumento734 pagineAdvances in Energy Research, Vol. 1: Suneet Singh Venkatasailanathan Ramadesigan EditorsVishnuShantanNessuna valutazione finora

- Industrial Control Transformers (Machine Tool) - 9070T100D55Documento2 pagineIndustrial Control Transformers (Machine Tool) - 9070T100D55chardNessuna valutazione finora

- Presentation 5Documento18 paginePresentation 5Hazel Halili100% (1)

- Route Oct 2019Documento445 pagineRoute Oct 2019Alex AndruNessuna valutazione finora

- Co2 KiddeDocumento50 pagineCo2 KiddeNattapong Natt100% (2)

- Canada Autos (DSC) (Panel)Documento15 pagineCanada Autos (DSC) (Panel)Frontyardservices Uganda limitedNessuna valutazione finora

- Honeywell Question 1&2Documento6 pagineHoneywell Question 1&2anon_909027967Nessuna valutazione finora

- Film Script Writing GuideDocumento2 pagineFilm Script Writing GuideMrAlexSexton100% (3)

- The Harry Potter Movies (1-8) .Dvdrips - Engsub.swesub - Finsub - Read ThisDocumento3 pagineThe Harry Potter Movies (1-8) .Dvdrips - Engsub.swesub - Finsub - Read ThisEmil Borzasi0% (5)

- Post Building Techniques NX8Documento267 paginePost Building Techniques NX8Dolvando Ferreira Alves Filho100% (1)

- Simple Linear Programming Model: Joel S. CasibangDocumento49 pagineSimple Linear Programming Model: Joel S. CasibangMichelle Dela CruzNessuna valutazione finora

- How To Evaluate Credit Scorecards and Why Using The Gini Coefficient Has Cost You MoneyDocumento33 pagineHow To Evaluate Credit Scorecards and Why Using The Gini Coefficient Has Cost You Moneyhenrique_olivNessuna valutazione finora

- Reservoir Geology Lecture 02 - Master 2017-2018Documento24 pagineReservoir Geology Lecture 02 - Master 2017-2018juanseferrer15Nessuna valutazione finora

- Technical Data: Rotax Kart Type R1, Model 2002Documento2 pagineTechnical Data: Rotax Kart Type R1, Model 2002Gallego VilaNessuna valutazione finora

- Chapter6-Sedimentary RocksDocumento6 pagineChapter6-Sedimentary Rockssanaiikhan2020Nessuna valutazione finora

- Dragon Magazine #237Documento124 pagineDragon Magazine #237Anonymous OwiutM4l50% (2)

- Emilio Elizalde Et Al - Casimir Effect in de Sitter and Anti-De Sitter BraneworldsDocumento36 pagineEmilio Elizalde Et Al - Casimir Effect in de Sitter and Anti-De Sitter BraneworldsTurmav12345Nessuna valutazione finora

- Otorhinolaryngology NotesDocumento25 pagineOtorhinolaryngology NotesFako Filipinas100% (3)

- Economics NotesDocumento21 pagineEconomics NotesBARSHANessuna valutazione finora

- Clinical InterviewDocumento29 pagineClinical InterviewVasundhara RanaNessuna valutazione finora

- Problem Faced by EntrepreneurDocumento9 pagineProblem Faced by EntrepreneurRatnadeep PaulNessuna valutazione finora

- Ketogenic Diet PresentationDocumento64 pagineKetogenic Diet Presentationstefanie_561186832100% (2)

- Beauty Imagined Jones en 14985Documento5 pagineBeauty Imagined Jones en 14985Internetian XNessuna valutazione finora

- I Found The PathDocumento72 pagineI Found The PathmasterrkNessuna valutazione finora

- Certificate of Final Electrical Inspection - 0Documento3 pagineCertificate of Final Electrical Inspection - 0RM DulawanNessuna valutazione finora

- Algebra 2 and Trigonometry: English Bengali Problem SolvingDocumento13 pagineAlgebra 2 and Trigonometry: English Bengali Problem SolvingHasan AsifNessuna valutazione finora

- Cat and Dog Classification Using CNN: Project ObjectiveDocumento7 pagineCat and Dog Classification Using CNN: Project Objectivecoursera detailsNessuna valutazione finora

- English Course For Cyber Scientists - 1Documento44 pagineEnglish Course For Cyber Scientists - 11m0zvrtNessuna valutazione finora

- Glass Performance Days 2007Documento5 pagineGlass Performance Days 2007Daren Talana0% (1)