Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dynaflo HS Series

Caricato da

ZeshanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dynaflo HS Series

Caricato da

ZeshanCopyright:

Formati disponibili

2.

Fill pump body and suction

line through priming plug hole

located above suction inlet and

replace plug.

WARNING: When servicing or attending pump, always ensure power

is switched off and lead unplugged. Electrical connections should be

serviced only by qualified persons.

Care should also be taken when servicing or disassembling pump to

avoid possible injury from hot pressurised water. Unplug pump, relieve

pressure by opening a tap on the discharge side of the pump and allow

any hot water in the pump to cool before attempting to dismantle.

4. Prime should establish almost

immediately with a strong flow

of water, however, in some

installations it may be

necessary to repeat

the above operation

to remove all air from

the system.

WARNING:

DO NOT RUN DRY.

DO NOT RUN WITH LOSS OF PRIME.

DO NOT PUMP WATER CONTAINING ABRASIVE MATERIALS.

IMPORTANT:

DO NOT USE petroleum based fluids or solvents (e.g. Oils, Kerosene,

Turpentine, Thinners, etc) on the plastic pump components or seal

components.

After Sales Service

For professional after sales service or repair contact your Davey Dealer.

For assistance in locating your nearest dealer contact the Davey Support

Centre on 1300 2 DAVEY.

Davey Support Centre

7 Rockridge Avenue,

Penrose, Auckland 1061

Ph:

0800 654 333

Fax:

09 527 7654

Website: daveynz.co.nz

Davey Support Centre

6 Lakeview Drive,

Scoresby, Australia 3179

Ph:

1300 367 866

Fax:

1300 369 119

Website: davey.com.au

P/N 402105

Warning: Automatic reset thermal overloads will allow the pump to

restart without warning. Always disconnect the pump motor from the

electrical supply before maintenance or repairs.

Please pass these instructions on to the operator of this equipment.

MODELS: HS50-06, HS60-08

Trouble Shooting Check List

* Installation and operating instructions are included with the product when purchased new.

They may also be found on our website.

Davey is a registered trade mark of Davey Water Products Pty Ltd.

Davey Water Products Pty Ltd 2012.

Davey Water Products Pty Ltd

Member of the GUD Group

ABN 18 066 327 517

NEW ZEALAND

AUSTRALIA

For a complete list of Davey Dealers visit our website (davey.com.au) or call:

Should your Davey product require repair or service after the guarantee period; contact your nearest Davey Dealer or phone the Davey Customer Service

Centre on the number listed below.

In Australia, you are entitled to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You

are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

*NOTE MOTOR PROTECTION DEVICE :

For protection, the Davey pump motor is fitted with an automatic

reset thermal overload, constant tripping of this overload indicates a

problem e.g. low voltage at pump, excessive temperature (above 50C)

in pump enclosure.

Installation and

Operating Instructions

for Dynaflo

HS Series Electric Pumps

MOTOR RUNS FOR SOME TIME THEN STOPS - RESTARTS

AUTOMATICALLY AFTER SHORT TIME

Overload tripping in motor - low voltage at motor terminals

- motor in direct sunshine or in hot box

- motor not free to turn (eg: blocked)

Davey shall not be liable for any loss of profits or any consequential, indirect or special loss, damage or injury of any kind whatsoever arising directly

or indirectly from Davey products. This limitation does not apply to any liability of Davey for failure to comply with a consumer guarantee applicable to

your Davey product under the Australian or New Zealand legislation and does not affect any rights or remedies that may be available to you under the

Australian or New Zealand Consumer Legislation.

3. Switch on.

MOTOR NOT RUNNING

1. Power not connected.

2. Supply voltage too low.

3. Overload tripped.

4. Motor not free to turn e.g. a blocked impeller.

5. Internal motor fault.

Your Davey Two Year Guarantee does not cover freight or any other costs incurred in making a claim. Please retain your receipt as proof of purchase; you

MUST provide evidence of the date of original purchase when claiming under the Davey Two Year Guarantee.

1. Ensure outlet nearest to pump is

open.

MOTOR OPERATING BUT NOT PUMPING

1. Suction line and pump body not filled with water.

2. Leaking foot valve.

3. Air leaks in suction lines or suction pipe not under water.

4. Air trapped in suction lines (also possible with flooded suction) due to

uneven rise in piping (eliminate humps and hollows).

5. No water at source or water level too low.

6. Valve on suction or delivery lines closed.

Your Davey Two Year Guarantee naturally does not cover normal wear or tear, replacement of product consumables (i.e. mechanical seals, bearings or

capacitors), loss or damage resulting from misuse or negligent handling, improper use for which the product was not designed or advertised, failure to

properly follow the provided installation and operating instructions, failure to carry out maintenance, corrosive or abrasive water or other liquid, lightning

or high voltage spikes, or unauthorized persons attempting repairs. Where applicable, your Davey product must only be connected to the voltage shown

on the nameplate.

Priming and Operation

Should you experience any difficulties with your Davey product, we suggest in the first instance that you contact the Davey Dealer from which you

purchased the Davey product. Alternatively you can phone our Customer Service line on 1300 367 866 in Australia, or 0800 654 333 in New Zealand, or

send a written letter to Davey at the address listed below. On receipt of your claim, Davey will seek to resolve your difficulties or, if the product is faulty or

defective, advise you on how to have your Davey product repaired, obtain a replacement or a refund.

Davey Water Products Pty Ltd can not accept responsibility for loss or

damage resulting from incorrect or unauthorised installations.

In the unlikely event in Australia or New Zealand that this Davey product develops any malfunction within two years of the date of original purchase due to

faulty materials or manufacture, Davey will at our option repair or replace it for you free of charge, subject to the conditions below.

Most Water Supply Authorities have strict regulations regarding direct

connection of pumps to mains water supplies. In most cases an isolating tank

is required between mains supply and pump. Davey also recommend this

method. Directly applied mains pressure can exceed pump operating pressure

and damage pump.

Davey Repair or Replacement Guarantee

Connection of Mains Scheme or Town Water Supply

to either Suction or Discharge of Pumps

Prior to using this pump you must ensure that:

The pump is installed in a safe and dry environment

The pump enclosure has adequate drainage in the event of leakage

Any transport plugs are removed

The pipe-work is correctly sealed and supported

The pump is primed correctly

The power supply is correctly connected

All steps have been taken for safe operation

IP55 Compliant Connection

For some installations, such as wet areas in dairies, the pump is required to be

IPX5 compliant. The Dynaflo HS pump is IP55 compliant.

Pipe Connections

For best performance use P.V.C. or

polythene pipe at least the same

diameter as the pumps inlet. Larger

diameter pipe may be used to minimise

resistance to flow when pumping longer

distances.

Appropriate details for all of these items are contained in the following Installation and

Operating Instructions. Read these in their entirety before switching on this pump. If you

are uncertain as to any of these Installation and Operating Instructions please contact

your Davey dealer or the appropriate Davey office as listed on the back of this document.

Before installing your new pump, please read all instructions carefully as failures

caused by incorrect installation or operation are not covered by the guarantee.

Your Dynaflo HS Electric Pump is designed to handle clean water. The pump

should not be used for any other purpose without specific referral to Davey.

The use of the pump to pump flammable, corrosive and other materials of a

hazardous nature is specifically excluded.

NOTE: Prior to installation remove the red transport plugs & associated seals from

the suction and/or discharge ports.

Choosing a Site

Choose a site with a firm base as close to the water

source as possible with correct power supply. Make

sure your pump is always connected to an adequate,

reliable source of clean water.

Housing your Davey Pump

To protect your pump from the weather, make

sure the pump house is both water proof, frost

free and has adequate ventilation.

The pump should be mounted on a firm base

allowing for drainage, to avoid damage to

flooring etc., that over time may occur from

leaking pipe joints or pump seals.

Do not mount the pump vertically.

Power Connection

Connect lead to power supply designated on pump label, do not

use long extension leads as they cause substantial voltage drop,

poor pump performance and may cause motor overload.

Whenever the installation position of the pump is higher than the lowest water

level, a foot valve fitted to the end of the suction pipe as illustrated in (A) below

is required. Ensure that the foot valve is at least 1/2 metre below minimum

water level.

Use unions at pipe connections to enable easy

removal and servicing. Use sufficient tape to

ensure airtight seal and hand tighten only, do

not screw connections all the way into suction

port. To prevent strain on pump thread always

support heavy inlet and outlet pipes.

Lay suction pipe at a constant gradient to avoid

air pockets which may reduce pump efficiency.

NOTE: Suction leaks are the largest

cause of poor pump performance

and are difficult to detect. Ensure

all connections are completely

sealed using thread tape only.

Do not use sealing Compounds or pipe dope.

Connection to your Water Source

SPEAR POINT INSTALLATIONS

When a Dynaflo HS is installed on a spear or well point, the in-built check

valve MUST be removed and a check valve fitted immediately on top of the

spear point itself, as shown in (B) above.

NOTE: DO NOT install the check valve at the pump or at the top of

the well. DO NOT run the pump without water.

NOTE: Be certain to select the spear point to suit the well conditions

and regulate the flow rate from the pump accordingly.

Spear Size

11/4 (32mm)

11/2 (38mm)

2

(50mm)

Mesh

60

60

60

Approx. Max. Capacity of Spear Point

15 - 23 l/min or 200 - 300 gal/hr

23 - 38 l/min or 300 - 500 gal/hr

38 - 75 l/min or 500 - 1000 gal/hr

ABOVE GROUND WATER SOURCES

Installations with flooded suction require a gate valve so water supply can be

turned off for pump removal and servicing.

Removal of in-built check valve

Leave the in-built one-way check

valve installed to avoid water draining

back past the pump while not in

operation and causing possible pump

damage.

If your installation requires the removal of the in-built check valve or the inbuilt check valve requires removal for servicing, this can be achieved without

difficulty.

The in-built check valve is a cassette design, which is screwed in through the

suction inlet.

The electrical connections and checks must be made by a

qualified electrician and comply with applicable local standards.

In accordance with AS/NZS 60335.2.41 we are obliged to inform you that this

pump is not to be used by children or infirm persons and must not be used as a

toy by children.

DO NOT USE THREAD SEALING COMPOUNDS, HEMP OR PIPE

DOPE!

Connection to your Water Source

BELOW GROUND WATER SOURCES

NOTE: HS models are fitted with an in-built suction check valve

which should be removed on all suction lift applications and a

foot valve or check valve installed in the suction pipework as

appropriate.

Removal of the check valve cassette is achieved by inserting any suitable tool

(eg: a pair of pliers or the handle from an adjusting spanner) into the inlet.

The check valve cassette has various ribs and recesses to allow a variety of

nonspecific tools to be used in the removal or insertion process.

Potrebbero piacerti anche

- Ultimate Guide: Plumbing, Updated 5th EditionDa EverandUltimate Guide: Plumbing, Updated 5th EditionValutazione: 4 su 5 stelle4/5 (3)

- Hague WaterMax Owners ManualDocumento36 pagineHague WaterMax Owners ManualGreg ReynekeNessuna valutazione finora

- Sample Appellant BriefDocumento6 pagineSample Appellant BriefKaye Pascual89% (9)

- Labstrong User Manual Cyclon 4lt 2010Documento36 pagineLabstrong User Manual Cyclon 4lt 2010Jason Rodriguez RomaniNessuna valutazione finora

- Pipe Span ChartDocumento6 paginePipe Span ChartZeshanNessuna valutazione finora

- AIR Conditioner: Owner'S ManualDocumento52 pagineAIR Conditioner: Owner'S Manualashley diazNessuna valutazione finora

- Davey Water PumpDocumento8 pagineDavey Water PumpMohamedAbdel-Rahman0% (1)

- Davey Manual (XS Unheated) Spa PumpDocumento2 pagineDavey Manual (XS Unheated) Spa Pumpthemrnutz100% (2)

- Series OF1465-75H Hot Water Systems OneFlow Anti-Scale System Installation InstructionsDocumento12 pagineSeries OF1465-75H Hot Water Systems OneFlow Anti-Scale System Installation InstructionsWattsNessuna valutazione finora

- Pressure CompositeSupercell IOIDocumento4 paginePressure CompositeSupercell IOIstanleybhoopathyNessuna valutazione finora

- HTTP WWW - FluidmasterukDocumento1 paginaHTTP WWW - FluidmasterukAnup MahanthyNessuna valutazione finora

- Manual Bomba Electrosumergible Little Giant - 20e-3phDocumento8 pagineManual Bomba Electrosumergible Little Giant - 20e-3phArturo VillenaNessuna valutazione finora

- Iron Hunter HD ManualDocumento22 pagineIron Hunter HD ManualGreg ReynekeNessuna valutazione finora

- WWW - Wallacepumps.co - NZ - PDF - Instructions VSD Operated DHF 440,460 Series Horizontal Multistage PumpsDocumento14 pagineWWW - Wallacepumps.co - NZ - PDF - Instructions VSD Operated DHF 440,460 Series Horizontal Multistage PumpsJabbalSinghNessuna valutazione finora

- Bomas Centrifugas Sta-Rite Owner ManualsDocumento12 pagineBomas Centrifugas Sta-Rite Owner ManualsGuatemalan1979Nessuna valutazione finora

- Booster PumpDocumento28 pagineBooster PumpCollin PhelpsNessuna valutazione finora

- Eco 16 Thru Eco 27 Owners ManualDocumento12 pagineEco 16 Thru Eco 27 Owners ManualntportilloNessuna valutazione finora

- Installation, Operation and Maintenance Manual: Date: October 2005 SupersedesDocumento20 pagineInstallation, Operation and Maintenance Manual: Date: October 2005 SupersedesYoyokaeNessuna valutazione finora

- Lavaojos PortatilDocumento16 pagineLavaojos PortatilFosting SolanoNessuna valutazione finora

- Durojet SW Jet Pumps 51451 EnglishDocumento12 pagineDurojet SW Jet Pumps 51451 EnglishJhun Michael JaminalNessuna valutazione finora

- Manual Bomba BestwayDocumento16 pagineManual Bomba BestwayRuy Alberti50% (2)

- Owner Manual: Foot-SpaDocumento17 pagineOwner Manual: Foot-Spatim3269Nessuna valutazione finora

- Hotpoint BFV620 Dishwasher Owners ManualDocumento20 pagineHotpoint BFV620 Dishwasher Owners Manualmylitter5391Nessuna valutazione finora

- CV Mini InstallDocumento12 pagineCV Mini InstallYu MatsuNessuna valutazione finora

- Manual de Usuario de Calentador EléctricoDocumento12 pagineManual de Usuario de Calentador Eléctricohxzg7d7w8dNessuna valutazione finora

- Speedyblue Pool PumpDocumento36 pagineSpeedyblue Pool PumpLucian LeonteNessuna valutazione finora

- Polaris Booster Pump Installation InstructionsDocumento4 paginePolaris Booster Pump Installation InstructionsChristopher BrownNessuna valutazione finora

- Tanque Presurizado de Acero Pro-Source Plus - Manual Del Propietario - 1000000173 - 2010 - PENTAIR WATER PDFDocumento24 pagineTanque Presurizado de Acero Pro-Source Plus - Manual Del Propietario - 1000000173 - 2010 - PENTAIR WATER PDFpevareNessuna valutazione finora

- Philips Flat TV 15PF9936 - User ManualDocumento64 paginePhilips Flat TV 15PF9936 - User ManualVlad Florescu100% (1)

- Rconl 15V764 1094Documento7 pagineRconl 15V764 1094ndrocker3Nessuna valutazione finora

- RedLion RL30E - 2005 PDFDocumento12 pagineRedLion RL30E - 2005 PDFEd FalckNessuna valutazione finora

- Phtowner ManualDocumento33 paginePhtowner ManualBob MichaelsNessuna valutazione finora

- Tidal Filter InstructionsDocumento104 pagineTidal Filter InstructionsDani.ZNessuna valutazione finora

- Fistreem CycloneDocumento44 pagineFistreem CyclonedavidadyNessuna valutazione finora

- Installation, Operation and Maintenance Manual: Date: October 2006 Supersedes: 806 C - 05/10 CDocumento28 pagineInstallation, Operation and Maintenance Manual: Date: October 2006 Supersedes: 806 C - 05/10 Cmohamed ibrahimNessuna valutazione finora

- Cla FiltersDocumento22 pagineCla FiltersAce Dynamics IndiaNessuna valutazione finora

- Distilator Fistream - enDocumento36 pagineDistilator Fistream - enErdin FeizulaNessuna valutazione finora

- Sealweld Catalogue CADDocumento68 pagineSealweld Catalogue CADmaheshv79Nessuna valutazione finora

- Series 1156F, T156B and N256 Installation InstructionsDocumento2 pagineSeries 1156F, T156B and N256 Installation InstructionsWattsNessuna valutazione finora

- American Standard - IN BATH-ENDocumento27 pagineAmerican Standard - IN BATH-ENVicNessuna valutazione finora

- Dishwasher: Owner'S ManualDocumento24 pagineDishwasher: Owner'S ManualRui Filipe PinheiroNessuna valutazione finora

- What To Expect From Your Water Softener: Salt/Brine TankDocumento7 pagineWhat To Expect From Your Water Softener: Salt/Brine Tanknermeen ahmedNessuna valutazione finora

- 5606 - 2 - Zoeller 400 Series Owners Manual PDFDocumento8 pagine5606 - 2 - Zoeller 400 Series Owners Manual PDFbugmenot_testNessuna valutazione finora

- Operating and Maintenance Manual For Power Burner Series Forced Draft Commercial Water HeaterDocumento27 pagineOperating and Maintenance Manual For Power Burner Series Forced Draft Commercial Water HeaterAmir EbrahimNessuna valutazione finora

- IM107Documento36 pagineIM107Stefano Di LuccaNessuna valutazione finora

- Sea Clone 100Documento8 pagineSea Clone 100chris77779Nessuna valutazione finora

- High Performance Pool & Spa Pumps: Installation and Operation ManualDocumento8 pagineHigh Performance Pool & Spa Pumps: Installation and Operation ManualAdam CleggNessuna valutazione finora

- w2 C Mira Atom Erd Bar ValveDocumento2 paginew2 C Mira Atom Erd Bar ValvejayteNessuna valutazione finora

- Owner Manual Petite Footspa: La Petite Fleur La Petite ChiDocumento13 pagineOwner Manual Petite Footspa: La Petite Fleur La Petite Chitim3269Nessuna valutazione finora

- Series WDS-E220 and LFWDS-E220 Installation InstructionsDocumento12 pagineSeries WDS-E220 and LFWDS-E220 Installation InstructionsWattsNessuna valutazione finora

- Manual de WhisperFloODocumento28 pagineManual de WhisperFloOTirso R BonanoNessuna valutazione finora

- Owner Manual: Foot-SpaDocumento18 pagineOwner Manual: Foot-Spatim3269Nessuna valutazione finora

- Hotpoint Dishwasher - Model BFV62 ManualDocumento20 pagineHotpoint Dishwasher - Model BFV62 ManualMartin Lee SmithNessuna valutazione finora

- Hopkinson Valves IOM ManualDocumento7 pagineHopkinson Valves IOM ManualGiorgiana RosuNessuna valutazione finora

- DurajetDocumento20 pagineDurajetRick StarksNessuna valutazione finora

- Liquid Ring Pump ManualDocumento25 pagineLiquid Ring Pump ManualCornelius Toni KuswandiNessuna valutazione finora

- AP-WATERPUMP PlumbDocumento8 pagineAP-WATERPUMP PlumbWilson wayerNessuna valutazione finora

- Sealweld Catalogue CAD PDFDocumento79 pagineSealweld Catalogue CAD PDFTom Henry Bernabe CastroNessuna valutazione finora

- Sta-Rite Jet PumpDocumento40 pagineSta-Rite Jet Pumpaaronsmokes1100% (1)

- Proflow Water Heater ManualDocumento20 pagineProflow Water Heater ManualPedro BurkaNessuna valutazione finora

- Diesel Engine Care and Repair: A Captain's Quick GuideDa EverandDiesel Engine Care and Repair: A Captain's Quick GuideValutazione: 5 su 5 stelle5/5 (1)

- Advanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3Da EverandAdvanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3Nessuna valutazione finora

- Automatic Priming of PumpDocumento4 pagineAutomatic Priming of PumpZeshanNessuna valutazione finora

- Astm A 563-2000Documento8 pagineAstm A 563-2000ZeshanNessuna valutazione finora

- Astm A 563-2000Documento8 pagineAstm A 563-2000ZeshanNessuna valutazione finora

- Astm A 563-2000Documento8 pagineAstm A 563-2000ZeshanNessuna valutazione finora

- Automatic Priming of PumpDocumento4 pagineAutomatic Priming of PumpZeshanNessuna valutazione finora

- Calculating Slope - ArchtoolboxDocumento1 paginaCalculating Slope - ArchtoolboxZeshanNessuna valutazione finora

- Astm F 104-2002Documento12 pagineAstm F 104-2002ZeshanNessuna valutazione finora

- Pipe Stress Analysis Using CAESAR IIDocumento42 paginePipe Stress Analysis Using CAESAR IIpca97100% (1)

- Amipox at Asl PDFDocumento8 pagineAmipox at Asl PDFZeshanNessuna valutazione finora

- MassflwskidDocumento1 paginaMassflwskidZeshanNessuna valutazione finora

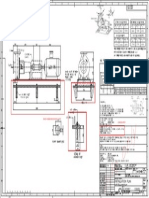

- Sample Pump GADocumento1 paginaSample Pump GAZeshanNessuna valutazione finora

- Ch1 Z10 AttG R0Documento11 pagineCh1 Z10 AttG R0ZeshanNessuna valutazione finora

- Amipox at Asl PDFDocumento8 pagineAmipox at Asl PDFZeshanNessuna valutazione finora

- Revised SOR Excel Large Diameter Type ContractDocumento57 pagineRevised SOR Excel Large Diameter Type ContractZeshanNessuna valutazione finora

- Ansi b16.9 TeeDocumento1 paginaAnsi b16.9 TeebarukomkssNessuna valutazione finora

- Class IndexDocumento8 pagineClass IndexZeshanNessuna valutazione finora

- Steps To Completing Sprinkler Layout 2012Documento24 pagineSteps To Completing Sprinkler Layout 2012Anonymous qrSsYuxyoYNessuna valutazione finora

- 13.date Sheet For Gate Valve PDFDocumento2 pagine13.date Sheet For Gate Valve PDFSIVANessuna valutazione finora

- DesignDeliverables DetailsDocumento11 pagineDesignDeliverables DetailsZeshanNessuna valutazione finora

- Fittings Symbols PDFDocumento1 paginaFittings Symbols PDFRainbow CreaterNessuna valutazione finora

- Leg CalculationDocumento10 pagineLeg Calculationmashudi_fikriNessuna valutazione finora

- Reducing TeeDocumento4 pagineReducing TeeJevi SeptiawanNessuna valutazione finora

- Analysis of Plot Plan - 05.03.15Documento1 paginaAnalysis of Plot Plan - 05.03.15ZeshanNessuna valutazione finora

- Dimensions and Dimensional Tolerances of Concentric and Eccentric Reducers, NPS 1 - 2 - NPS 48, ASME B16Documento8 pagineDimensions and Dimensional Tolerances of Concentric and Eccentric Reducers, NPS 1 - 2 - NPS 48, ASME B16ZeshanNessuna valutazione finora

- Dimensions and Dimensional Tolerances of Concentric and Eccentric Reducers, NPS 1 - 2 - NPS 48, ASME B16Documento8 pagineDimensions and Dimensional Tolerances of Concentric and Eccentric Reducers, NPS 1 - 2 - NPS 48, ASME B16ZeshanNessuna valutazione finora

- OPP Design Phase Deliverables - 8-12-11Documento11 pagineOPP Design Phase Deliverables - 8-12-11ZeshanNessuna valutazione finora

- Mandrel Chrome Plant LayoutDocumento1 paginaMandrel Chrome Plant LayoutZeshanNessuna valutazione finora

- Self Priming Pumps: 761 Ahua Honolulu, HI 96819 Phone 808.536.7699 Fax 808.536.8761Documento1 paginaSelf Priming Pumps: 761 Ahua Honolulu, HI 96819 Phone 808.536.7699 Fax 808.536.8761sheik145Nessuna valutazione finora

- Orbitol Motor TMTHWDocumento20 pagineOrbitol Motor TMTHWRodolfo ErenoNessuna valutazione finora

- F24 60manual (New)Documento14 pagineF24 60manual (New)Robert CumpaNessuna valutazione finora

- Line Differential Protection Red670Documento8 pagineLine Differential Protection Red670igorsfaceNessuna valutazione finora

- Automatic Train OperationDocumento6 pagineAutomatic Train OperationAnupam KhandelwalNessuna valutazione finora

- 3397 - Ciat LDC 300VDocumento71 pagine3397 - Ciat LDC 300VPeradNessuna valutazione finora

- Matters Signified by The Sublord of 11th Cusp in KP SystemDocumento2 pagineMatters Signified by The Sublord of 11th Cusp in KP SystemHarry HartNessuna valutazione finora

- AppearancesDocumento4 pagineAppearancesReme TrujilloNessuna valutazione finora

- Adriano Costa Sampaio: Electrical EngineerDocumento3 pagineAdriano Costa Sampaio: Electrical EngineeradrianorexNessuna valutazione finora

- Maritime Management SystemsDocumento105 pagineMaritime Management SystemsAndika AntakaNessuna valutazione finora

- 500 TransDocumento5 pagine500 TransRodney WellsNessuna valutazione finora

- Flusser-The FactoryDocumento2 pagineFlusser-The FactoryAlberto SerranoNessuna valutazione finora

- ECE199R-C12 Final Document OJTDocumento48 pagineECE199R-C12 Final Document OJTRigel ZabateNessuna valutazione finora

- W0L0XCF0866101640 (2006 Opel Corsa) PDFDocumento7 pagineW0L0XCF0866101640 (2006 Opel Corsa) PDFgianyNessuna valutazione finora

- Liftchain (LC2A) Catalog AirHoistDocumento10 pagineLiftchain (LC2A) Catalog AirHoisteduardshark100% (1)

- MA 106: Linear Algebra Tutorial 1: Prof. B.V. Limaye IIT DharwadDocumento4 pagineMA 106: Linear Algebra Tutorial 1: Prof. B.V. Limaye IIT Dharwadamar BaroniaNessuna valutazione finora

- Synthesis Essay Coming To Grips With GenesisDocumento11 pagineSynthesis Essay Coming To Grips With Genesisapi-259381516Nessuna valutazione finora

- Multi Pressure Refrigeration CyclesDocumento41 pagineMulti Pressure Refrigeration CyclesSyed Wajih Ul Hassan80% (10)

- Armadio Presentation-2019Documento45 pagineArmadio Presentation-2019Subhash Singh TomarNessuna valutazione finora

- FebvreDocumento449 pagineFebvreIan Pereira AlvesNessuna valutazione finora

- Kimi No Na Wa LibropdfDocumento150 pagineKimi No Na Wa LibropdfSarangapani BorahNessuna valutazione finora

- Diagnosis of TrypanosomiasisDocumento82 pagineDiagnosis of TrypanosomiasisDrVijayata Choudhary100% (1)

- Multi Organ Dysfunction SyndromeDocumento40 pagineMulti Organ Dysfunction SyndromeDr. Jayesh PatidarNessuna valutazione finora

- Atomic St. Package PDFDocumento28 pagineAtomic St. Package PDFSatvik RaoNessuna valutazione finora

- The Process: by Andy ZoppeltDocumento4 pagineThe Process: by Andy ZoppeltMark Stephen HuBertNessuna valutazione finora

- Stopping by Woods On A Snowy EveningDocumento9 pagineStopping by Woods On A Snowy EveningJulia Garces100% (2)

- Carrefour-SA Shopping Center TurkeyDocumento2 pagineCarrefour-SA Shopping Center TurkeyVineet JogalekarNessuna valutazione finora

- EXAMPLE 8.6 Veneer Grades and RepairsDocumento2 pagineEXAMPLE 8.6 Veneer Grades and RepairsnickNessuna valutazione finora

- Hypothesis Testing - IDocumento36 pagineHypothesis Testing - Isai revanthNessuna valutazione finora