Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

400KV GT Tech Data

Caricato da

srigirisetty208Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

400KV GT Tech Data

Caricato da

srigirisetty208Copyright:

Formati disponibili

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

DOCUMENT REVIEW STATUS

REJ

ROC

RWC

CFC

By

Date..

Comment Note No

D

C

B

-

2004-08-24

Rev. :

2004-04-20

THIRD ISSUE

SECOND ISSUE

FIRST ISSUE

PRELIMMINARY ISSUE

TANVI

TANVI

MKK

MKK

MVK

MVK

MVK

MVK

Date :

Description :

Prepared :

Reviewed:

2004-08-11

2004-06-11

Released :

Project Doc.No.

GVK INDUSTRIES LIMITED

JEGURUPADU PHASE II 228 MW CCPP (KA13E2 1)

Responsible Department :

abcd

Take over Department:

Project

ALSTOM Projects India Ltd

PS

Language:

KKS

en

No. of Sheets

GVJ

21

28BAT10

Document No.

GVJ 02 E ---- P13 DS 202

Sheet

1

abcd

ALL DIMENSIONS ARE IN

MILLIMETERS UNLESS

OTHERWISE SPECIFIED

NAME

SIGN.

TANVI

MVK

MVK

TRQF : 04505.C

ALSTOM Limited , NAINI ALLAHABAD

SCALE : NTS

INDENT No.

TITLE

Technical Particulars

STEAM TURBINE GENERATOR TRANSFORMER

CUSTOMER

ALSTOM Projects India Limited for GVK

T-6591

DRAWING No.

A421447

ISSUE-D

(1)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

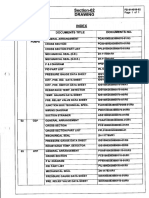

SL No.

Particulars

Units

A.

GENERATOR

TRANSFORMER

1.0

General

1.1

Make

ALSTOM

1.2

Type

OUTDOOR

1.3

Number of Windings per

phase

TWO

1.4

Number of Phases

1.5

Service

1.6

Reference Standard

2.0

Rating

2.1

Type of Cooling

2.2

Rated Power

Generator Transformer

:

IS 2026 and CBIP

Manual on Transformer

OFAF

MVA

120

:

2.2.1

Transformer

outputs

(continuous kVA ratings at

different

ambient

temperature to limit the hot

spot temperature to 98C

5 C

10 C

15 C

20 C

25 C

30 C

35 C

40 C

45 C

50 C

28BAT10

MVA

MVA

MVA

MVA

MVA

MVA

MVA

MVA

MVA

MVA

Page 2 of 21

141

137

132

128

123

119

113

108

103

97

A421447/D

(2)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No.

Particulars

2.3

Rated Voltage (No-Load)

2.4

Units

kV

H.V.

400

L.V.

11.5

H.V.

173.4

L.V.

6031.6

Rated Current

2.5

Rated Frequency

2.6

Connection

Hz :

50

H.V.

STAR

L.V.

DELTA

2.7

Vector Group designation

YNd1

2.8

Voltage withstand Time

a. 110% of rated voltage

Continuos

b. 125% of rated voltage

1 minutes

c. 140% of rated voltage

5 Seconds

d. 150% of rated voltage

1 Seconds

1.1 :

Continuos

b.

1.25 :

1 minutes

c.

1.4 :

5 Seconds

2.9

Overfluxing Capability

a. For Overfluxing Factor

2.10

28BAT10

HV Neutral Earthing

Solid

Page 3 of 21

A421447/D

(3)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No.

Particulars

3.0

Temperature

3.1

Reference ambient temperature

3.2

Temperature rise over reference

ambient Deg. C :

a. Of Top oil by thermometer

C :

50

b.

Of winding by resistance

measurement

C :

55

Maximum continuous over loading

capacity of the transformer without

exceeding the specified winding

temperature

3.3

3.4

Thermal time constant

4.0

Tappings

4.1

Units

49

As per IS 6600

h :

3 (Approx)

Type

Reversing

4.2

Capacity

FULL

4.3

Range Steps x % variation

+10% to 10% x 1.25%

4.4

Taps provided on HV/LV Winding

On HV

5.0

Insulation Level

5.1

Separate

source

power

frequency voltage withstand

28BAT10

kV

RMS

Winding

Bushing

Winding

Bushing

H.V

38*

38*

L.V.

50

70

H.V. Neutral

38

Page 4 of 21

105

A421447/D

(4)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

5.2

5.3

5.4

Unit

s

kVrms

Induced overvoltage withstand

Winding

H.V

L.V.

570*

630

(Test as per method II)

50

70

H.V. Neutral

38

Full wave lightning

withstand voltage

impulse

Winding

kVpeak

38

Bushing

H.V

1300

1425

L.V.

125

170

H.V. Neutral

Switching surge withstand voltage

Phase to earth

H.V

kV

250

Winding

Peak

1050

L.V.

6.0

Bushing

N.A.

Bushing

1050

N.A.

6.1

Impedance at Rated Frequency

and 75 C winding temperature

with 100% rating :

Impedance at principal tap

% :

12.5 (+ IS Tol)

6.2

Impedance at maximum voltage tap

% :

13.0 (Approx.)

6.3

Impedance at minimum voltage tap

13.0 (Approx.)

6.4

Reactance at

principal tap

% :

12.49 (Approx.)

6.5

Resistance at 75 C.

0.28 (Approx.)

6.6

Zero Sequence Impedance at 75 C

at principal tap

% :

10.3 (Calculated)

6.7

Capacitance of Windings

a. H.V. Earth

pF/ph. :

4000 (Calculated)

rated

current

for

b. L.V. - Earth

7800 (Calculated)

c. H.V - L.V

1700 (Calculated)

28BAT10

Page 5 of 21

A421447/D

(5)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL

No.

7.0

Particulars

Units

7.1

No load losses at rated voltage and

at rated frequency and without any

+ve tolerances

kW :

80 Max

7.2

Load Losses at rated current without

any +ve tolerances

kW :

335 Max @75C and

Principal Tap

7.3

Cooler losses

tolerances

+ve

kW :

25 Max

8.0

8.1

Efficiency at 75 C and 0.8

Power Factor Lag and at unity

power factor

At full load

% :

8.2

At 3/4 full load

% :

8.3

At 1/2 full load

% :

8.4

Maximum efficiency

% :

8.4.1

9.0

Load and Power Factor at which it

occurs

Regulation at Full Load at 75 C

9.1

At unity power factor

% :

1.06

9.2

At 0.85 power factor lagging

% :

7.37

9.3

At 0.8 power factor lagging

% :

8.2

10.0

No Load Current referred to HV at

rated frequency

10.1

At 90% rated voltage

A :

0.5 Approx.

10.2

At 100% rated voltage

A :

1.0 Approx.

10.3

At 110% rated voltage

A :

2.0 Approx.

Guaranteed Losses at Principal

Tap, Full Load and 75 C.

28BAT10

without

any

Page 6 of 21

0.8 p.f.

0.85 p.f. 1.0 p.f.

99.570

99.595

99.655

99.629

99.650

99.703

99.660

99.680

99.728

99.728

48.868 , Unity p.f.

A421447/D

(6)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL

No.

11.0

Particulars

Units

11.1

Approximate Maximum Flux

Density at rated frequency in the

core

At 90% rated voltage

11.2

At 100% rated voltage

11.3

At 110% rated voltage

12.0

Maximum Current Density at

rated load

12.1

H.V. Winding

12.2

L.V. Winding

12.3

Maximum Current Density under

short circuit

12.3.1

H.V. Winding

L.V. Winding

13.0

Withstand Time without injury

for

Three phase dead short circuit at

terminal

with

rated

voltage

maintained on the other side.

Single phase short-circuit at

terminal

with

rated

voltage

maintained on other side

Cooling System

13.2

14.0

14.1 (a) Number of unit coolers and rating as

% of transformer cooling equipment

14.1 (b) Temperature range over which

cooler control is adjustable

14.2

Mounting

28BAT10

1.53 Approx.

A/ :

cm2

A/ :

cm2

:

3.15

A/ :

cm2

A/ :

cm2

12.3.2

13.1

Wb/ :

m2

Wb/ :

m2

Wb/ :

m2

:

Page 7 of 21

1.70 Approx.

1.87 Approx.

At rated Tap

3.48

8 times of above

Approx

s :

3 Sec

s :

3 Sec

5 x 25 %

:

50C to 110 C

Vertical

A421447/D

(7)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No.

Particulars

14.3

Fan motor data

Units

I) Number per cooler and rating

as % of cooler requirement

ii) Type

iii) Rating

Axial flow type

kW : 1.6 kW (Approx)

iv) Locked rotor current

14.4

: 2 x 50 %

Oil pump motor data

I) Number per cooler and rating

as % of cooler requirement

: 1 x 100 %

ii) Type

Centrifugal radial flow

iii) Rating

kW : 3.2 kW (Approx)

iv) Locked rotor current

vi) Insulation class

14.6

28BAT10

25 Amps

F

vii) Motor speed at rated voltage

14.5

15 A approx.

rpm

1400

Duration

for

generator

transformer withstand capability

after failure of forced cooling

under the following conditions:

I)

Full load

min

10

ii)

Partial load(50%)

min

20

iii)

No load

min

60

Whether generator transformer is

capable of withstanding for 1

hour without load current after

failure of forced cooling?

Page 8 of 21

Yes

A421447/D

(8)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No.

Particulars

15.0

Details of Tank

15.1

Material

15.2

Thickness of sides

mm : 10 approx.

15.3

Thickness of bottom

mm : 20 approx.

15.4

Thickness of cover

mm : 20 approx.

15.5

Tank Designed for :

15.5.1

Vacuum withstand capability for

main tank and accessories

15.5.2

Vacuum leak rate of transformer

15.5.3

Pressure

15.6

Tank cover - Conventional or bell

type?

16.0

Core

16.1

Type of construction- Core or shell

: Core

16.2

Core material used

: CRGO

16.3

Thickness of lamination

16.4

Insulation of lamination

16.5

Equivalent cross-sectional area of

core

16.6

Type of joint between core and yoke

Fully Mitred

16.7

Percentage silicon content

0.2 % Approx.

28BAT10

Units

Steel

mm : Full Vacuum

of Hg

N/A

kN/ m2 : 96

Bell

mm : 0.27 Approx.

: Inorganic Coating

Page 9 of 21

cm : 5378 (Approx)

A421447/D

(9)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

17.0

17.1

Units

Coils

Type of Coil :

a. H.V

: Interleaved Disc

b. L.V.

: Helical

17.2

Conductor Material

: Electrolytic copper

17.3

Insulating Material :

a. H.V Turn

: Paper + Oil Duct

b. L.V - Earth

c. L.V. Earth

d. H.V. - L.V.

17.4

Magnetising inrush current

17.5

Magnetising

current

at

frequency and at rated voltage

17.6

Conductor area approx

rated

Pressboard Wrap +Oil

Duct

: Pressboard Wrap +Oil

Duct

: Pressboard Wrap +Oil

Duct

A

Approx. 10 times of Rated

Current

A

Pl refer Cl. No. 10

HV

mm2

55

LV

mm2

1000

18.0

On-load Tap Changer details

18.1

Make

18.2

Type

18.3

Rated Voltage class of tap changer

18.4

Rated Current

: High Transition

Resistance Type

kV : Suitable for 420 kV

Neutral Winding

A : 350

18.5

Auxiliary Power

kW : 1.0 kW approx.

18.6

Step voltage

28BAT10

: BHEL

Page 10 of 21

2886

A421447/D

(10)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No.

Particulars

Units

18.7

Number of steps

16

18.8

Control

Auto/Manual

18.9

Voltage Control :

Automatic/Non-automatic

: Automatic

Auxiliary supply details

: 415 V, 3F

18.10

18.11

Maximum Short Circuit

Current withstand capability :

a. Current

A : 6 kA

b. Time

s : 3 sec

Local indicator furnished for :

a. Tap position

b. Operation counter

: Yes

18.12

Number of revolutions to complete

one step

: 33 approx

18.13

Time to complete one step on Auto /

Manual operation

s : 6 Sec (Approx)

18.14

Rated voltage of drive motor

V : 415, 3 F

18.15

Power required

18.16

Approximate overall weight

18.17

Approximate overall dimensions

kW : 1.0 approx.

kg

Length

(MM)

Dia

(MM)

Ltr.

18.18

Approximate overall quantity of oil

18.19

Is vacuum filling required? If so, mm of

state absolute pressure.

Hg.

28BAT10

Yes

Page 11 of 21

310 Approx.

2700 (Approx.)

740 (Approx.)

170 Approx.

Yes, 1 Torr

A421447/D

(11)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

Units

19.0

Insulating Oil

19.1

Approximate volume required for first

filling

19.2

10% excess oil furnished ?

: Yes

19.3.1

Oil conforms to :

: IS:335

Ltr. : 56 Kl

IS:1866

Before commission

19.3.2

19.4

Details of oil furnished

I)

Moisture content

ppm

ii)

Max tan delta value at 90C

iii)

Resistivity at 90C

iv)

Interfacial tension at 27C

50

O-cm

v)

Breakdown strength

a. Oil preservation system provided ?

N/m

kVrms

b. Type of oil preservation system

10

0.002

0.01

35 x 1012

6 x 1012

0.04

0.035

30

: Yes

60

20.0

Bushings (for HV / LV / HVN)

: Flexible Seperator +

Silicagel

: HV

HVN

LV

20.1

Make

: BHEL

20.2

Type

20.3

Reference Standard

20.4

Voltage Class

20.5

Creepage Distance

20.6

Free space required for bushing mm

removal

Whether test tap for tan delta

measurements for H.V bushing are

provided ?

One minute power frequency

kVrms

withstand voltage

Impulse withstand voltage

kVPeak

20.7

20.8

20.9

28BAT10

---------- OIP------

-----------IS:2099--------

kV : 420

mm : 10500

Page 12 of 21

ALSTOM TELK

: 10250

: Yes

52

36

1300

900

7100

6600

Yes

No

: 630

105

70

: 1425

250

170

A421447/D

(12)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL

No.

Particulars

Units

20.10 Rated current

20.11 Rated short circuit current and duration

20.12 Cantilever strength of the bushing

20.13 Weight of the assembled bushings

kA/

s

kg

kg

21.2

1250

1250

1250

LV

12500

49

155

-----------Outdoor-------

20.15 Whether CTs are included as per

specific requirements?

21.0 Minimum Clearances

Between Phases :

a. In air

I.

HV

II.

LV

b. In oil

I. HV

ii. LV

Between Phase & Earth :

HVN

31.25kA 31.25kA 100 kA

--------------2 sec----------

2.5 kN

1.25kN 3.15kN

20.14 Mounting arrangement of the bushing

21.1

HV

Yes

mm :

mm :

4000

330

mm : As per Alstom Practices

mm :

a. In air

I. HV

ii. LV

mm : 3500

mm : 230

b. In oil

21.3

I. HV

ii. LV

Clearance between core and coil

mm : As per Alstom Practices

mm :

mm

As per Alstom Practices

21.4

Clearance between coils

mm

21.5

Clearance between neutral to ground

in air

mm

230 (As per CBIP)

22.0

Terminal Connections

22.1

H.V.

: Outdoor Bushings

22.2

L.V

: Suitable for Bus Duct

22.3

H.V. Neutral

: Outdoor Bushing

28BAT10

Page 13 of 21

A421447/D

(13)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

Units

23.0

Marshaling Box

23.1

23.2

Weatherproof, suitable for outdoor

duty

Degree of protection

23.3

Painting shade

24.0

Terminal Blocks

24.1

Make

: Phoenix

24.2

Type

24.3

20% spare terminals furnished?

: Clip-on (disconnecting type

for CT only)

: Yes

25.0

Wiring

25.1

Cable type

25.2

Voltage grade

25.3

Conductor Size

Instrumentation

Stranded

Trip and Alarm Contacts Ratings

26.1

Voltage

26.2

Rated

Power

: PVC shielded

PVC

V : Nominal Uo/U

300/500

2

mm : 2.5 / 4.0

:

: Copper

1100

Yes /

No.

26.0

Yes

2.5

Copper

Yes

V : 220 V DC

:

Making current

A :

Breaking Current

A :

As per

GVJ 02 E ----- P13 TC 216

Accessories

Each transformer furnished with

fittings and accessories as per

specification ?

28BAT10

: IP:55

631 AS PER IS 5

Material

27.0

: Yes

Page 14 of 21

Yes/ : Yes

No.

A421447/D

(14)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

Units

28.0

Detail of Conservator

28.1

Volume of Conservator

Ltr. : 7.5 % of Total Oil (Approx.)

28.2

Volume of oil between the highest and

lowest levels

Pressure Release devices

Ltr. :

2500 Ltr. approx.

a. Minimum pressure the device is set

to operate / rupture

kg /

m2

0.49 kg/cm2

29.0

b.Alarm and trip contacts provided?

Yes

30.0

Approximate Overall Dimension

30.1

Length

mm :

10500

30.2

Breadth

mm :

9450

30.3

Height

mm :

8700

30.4

Crane lift (a) for untanking core and coil

assembly (including sling)

mm

31.0

Approximate Weights

31.1

Core with clamps

kg :

63000 kg Approx.

Windings with insulation

kg

20000 kg Approx.

31.2

Tanks, fittings and accessories

kg :

37000 kg Approx.

31.3

Oil

kg :

50000 kg Approx.

31.4

Total Weight

kg :

170000 kg Approx.

32.0

Shipping Data

32.1

Weight of the heaviest package

Core / coil

Bell tank

Dimension of the largest

package (LxBxH)

32.2

28BAT10

Page 15 of 21

kg :

kg

kg

mm :

Not applicable

for Bell Tank

110000 kg Approx.

83000 kg Approx.

22000 kg Approx.

8500 x 3450 x 4240

A421447/D

(15)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

Units

32.3

Height for untanking the bell tank

32.4

List parts detached for transport

33

Proposed method of transportation

for the transformer

33.1

Impact recorder / shock recorder

during transportation provided?

28BAT10

Page 16 of 21

mm

9700

Refer document no.

GVJ 02 E-----P13 LE 203

Nitrogen Filled

Yes

A421447/D

(16)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

Units

34.0

Tests to be

Transformer

conducted

on

34.1

Routine tests as per specification /

relevant standards will be provided?

34.2

Tank pressure test

As per CBIP Manual

a. Test Pressure at Tank Base

b. Duration

c.

34.3

34.4

Permanent deflection

kN/m2 : 96

(35 +Normal pressure)

h : 1

mm : 19

Tank vacuum test

a.

Vacuum

b.

Duration

c.

Permanent deflection

: Vacuum at Test Place

25 mm of Hg.

h : 1

mm : 19

Oil leakage test on each transformer

a.

Test pressure at Tank Base

b.

Duration

:

kN/ : 96

m2

(35 +Normal pressure)

hours : 8 (As per CBIP)

34.5

Core bolt withstand voltage for 1

minute on each transformer

35

GENERAL

Minimum draw bar pull required to

move the transformer on level track?

28BAT10

: Yes

Page 17 of 21

kV : Bolt less Design as Per

Alstom Technology

4 T/Winch,4 Winches

(1000 mm between

winches minimum)

A421447/D

(17)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

Units

36

ACCESSORIES

A.

CURRENT TRANSFORMER

1.0

General

1.1

Make

: Mahindra

1.2

Type

Ring Type, Bar Primary

1.3

Reference Standard

IS 2705

1.4

Use

: Inside Oil

2.0

Rating

2.1

C.T.Ratio

2.2

Class

2.3

Insulation level

2.4

Burden

3.0

Insulation Class

3.1

Temperature rise at rated burden

over top oil temperature

4.0

Characteristics

4.1

Secondary resistance RCT at 75 C

O :

4.2

Knee point voltage Vk

V : -

4.3

Excitation current at V k/2

5.0

Rating

5.1

C.T.Ratio

5.2

Class

28BAT10

Line CT (CT 9 & CT 11)

A :

250/1

5 P20

V :

VA :

600

30

:

C :

55

mA : Line CT (CT 8)

A :

:

Page 18 of 21

250/1

PS

A421447/D

(18)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

5.3

Insulation level

5.4

Burden

6.0

Insulation Class

6.1

Temperature rise at rated burden

over top oil temperature

7.0

Characteristics

7.1

Secondary resistance RCT at 75 C

O : <3V

7.2

Knee point voltage Vk

V : > 500

7.3

Excitation current at V k/2

8.0

Rating

8.1

C.T.Ratio

8.2

Class

8.3

Insulation level

8.4

Burden

9.0

Insulation Class

9.1

Temperature rise at rated burden

over top oil temperature

10.0

Characteristics

10.1

Secondary resistance RCT at 75 C

O :

10.2

Knee point voltage Vk

V : > 150

10.3

Excitation current at V k/2

11.0

Rating

11.1

C.T.Ratio

11.2

Class

28BAT10

V : 600

VA : :

C :

55

mA : 125

Line CT ( CT 31)

A :

:

250/1

PS

V : 600

VA :

:

C :

55

<3V

mA : 125

Neutral CT ( NCT 32)

A :

:

Page 19 of 21

250/1

PS

A421447/D

(19)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

11.3

Insulation level

11.4

Burden

12.0

Insulation Class

12.1

Temperature rise at rated burden

over top oil temperature

13.0

Characteristics

13.1

Secondary resistance RCT at 75 C

O :

13.2

Knee point voltage Vk

V : > 150

13.3

Excitation current at V k/2

14.0

Rating

14.1

C.T.Ratio

14.2

Class

14.3

Insulation level

14.4

Burden

15.0

Insulation Class

15.1

Temperature rise at rated burden

over top oil temperature

16.0

Characteristics

16.1

Secondary resistance RCT at 75 C

O :

16.2

Knee point voltage Vk

V : -

16.3

Excitation current at V k/2

17.0

Tests

28BAT10

V :

VA :

600

-

:

C :

55

<3V

mA : 125

NEUTRAL CT ( NCT 12)

A :

250/1

5 P20

V :

VA :

600

30

:

C :

55

mA : : As per IS 2705

Page 20 of 21

A421447/D

(20)

TECHNICAL PARTICULAR FOR GENERATOR TRANSFORMER

SL No. Particulars

Units

TEMPERATURE INDICATORS

(OTI / WTI / RWTI )

Manufacturer

Perfect Control

Range

0-150C

Accuracy

Remote Indicator with 4-20 mA Yes/No

Provided

28BAT10

Page 21 of 21

+/- 1.5% of FSD

Yes (Perfect Control Make)

220 V DC Aux. Supply.

A421447/D

(21)

Potrebbero piacerti anche

- Rev. Status: Customer Drawing ListDocumento12 pagineRev. Status: Customer Drawing ListAbdus SalamNessuna valutazione finora

- 110V Battery SizingDocumento13 pagine110V Battery SizingsofianeNessuna valutazione finora

- 33kv SLDDocumento1 pagina33kv SLDKhajaBurhan100% (1)

- 4CP7Documento79 pagine4CP7Rajesh MauryaNessuna valutazione finora

- Test Report For: CT Primary Injection TestDocumento4 pagineTest Report For: CT Primary Injection TestAhmed FathyNessuna valutazione finora

- 11KV SubstationDocumento70 pagine11KV SubstationElsayed Abdelmagid MohamedNessuna valutazione finora

- MV Panel Earth Switch Contact Resistance Test ReportDocumento1 paginaMV Panel Earth Switch Contact Resistance Test ReportGajendran SriramNessuna valutazione finora

- BUSHING CT SIZINGDocumento9 pagineBUSHING CT SIZINGNageswar MakalaNessuna valutazione finora

- Generator Transformer - Technical Parameters Rev. GDocumento19 pagineGenerator Transformer - Technical Parameters Rev. GMinh Tien DangNessuna valutazione finora

- AS-BUILT DRG. - 33KV VCB Panel PDFDocumento54 pagineAS-BUILT DRG. - 33KV VCB Panel PDFrana abrar100% (1)

- RSC SLDDocumento1 paginaRSC SLDMichael Parohinog Gregas0% (1)

- Ltbe1 With Blk222Documento12 pagineLtbe1 With Blk222rpshvjuNessuna valutazione finora

- Odhisha Power Generation Corporation LTD Page 1 of 2 BGR Energy Systems LTD - Power Project Division Date: 31.5.17Documento2 pagineOdhisha Power Generation Corporation LTD Page 1 of 2 BGR Energy Systems LTD - Power Project Division Date: 31.5.17alagurajNessuna valutazione finora

- PDF Created With Pdffactory Pro Trial VersionDocumento7 paginePDF Created With Pdffactory Pro Trial Versionwaveengg.coNessuna valutazione finora

- Technical Data 33kV GIS GV3Documento5 pagineTechnical Data 33kV GIS GV3muthusamyeeeNessuna valutazione finora

- Control and Protection Philosophy for 400kV Kalawad GIS Sub StationDocumento4 pagineControl and Protection Philosophy for 400kV Kalawad GIS Sub Stationsauravkafle1Nessuna valutazione finora

- Protection Relay Inspection ReportDocumento37 pagineProtection Relay Inspection ReportteferayirgaNessuna valutazione finora

- H01 PanelDocumento84 pagineH01 PanelNAGARAJNessuna valutazione finora

- GTP Inverter Transformer Rev 02Documento5 pagineGTP Inverter Transformer Rev 02Jaks JaksNessuna valutazione finora

- Ipcl VCB From LRVDocumento17 pagineIpcl VCB From LRVSudeep DuttaNessuna valutazione finora

- 6.6kv MV Switch Board-1 (Single Bus) Part - 02 of 02Documento46 pagine6.6kv MV Switch Board-1 (Single Bus) Part - 02 of 02unimarineNessuna valutazione finora

- Relay Setting ChartDocumento10 pagineRelay Setting ChartnadalllabeedNessuna valutazione finora

- Design Basis For 850kVAR 440V 7% CSC APFC PanelDocumento10 pagineDesign Basis For 850kVAR 440V 7% CSC APFC Panelchitra rameshNessuna valutazione finora

- GT Relay PanelDocumento53 pagineGT Relay PanelPamela Bradley100% (1)

- GTP 63 Mva - R0 FinalDocumento10 pagineGTP 63 Mva - R0 FinalmidhunvarNessuna valutazione finora

- Cable Termination DetailsDocumento14 pagineCable Termination DetailsmanishNessuna valutazione finora

- 33 KV Control Relay Spec PDFDocumento75 pagine33 KV Control Relay Spec PDFMohanta Amrit100% (2)

- GTP-R1 TR 60mvaDocumento6 pagineGTP-R1 TR 60mvaEzechukwu UkiweNessuna valutazione finora

- Earthing Cal - Rev-01 - As Per Mecon Comnt.Documento9 pagineEarthing Cal - Rev-01 - As Per Mecon Comnt.Prateek SinghNessuna valutazione finora

- Technical Specification Compliance HT - 1 Panel - 24072020 - Smart Electric (ABB)Documento48 pagineTechnical Specification Compliance HT - 1 Panel - 24072020 - Smart Electric (ABB)Muthu KumaranNessuna valutazione finora

- Calculatin For Voltage Drop ¤t MV CircuitDocumento9 pagineCalculatin For Voltage Drop ¤t MV CircuitSatyaNessuna valutazione finora

- YN1M354105-CAA - 132kV Line CRP - REV01-2015-08-20-cst-en PDFDocumento107 pagineYN1M354105-CAA - 132kV Line CRP - REV01-2015-08-20-cst-en PDFKarthikeyan SNessuna valutazione finora

- Ge P643 TF PanelDocumento93 pagineGe P643 TF PanelRAJESH BODDUNA100% (1)

- Data Logger SystemDocumento18 pagineData Logger SystemTarun AggarwalNessuna valutazione finora

- 400KV & 220KV DR PanelDocumento53 pagine400KV & 220KV DR PanelBijaya Kumar MohantyNessuna valutazione finora

- 11 KV Power Cable Site Test Report: (NMGR105 To NMGR106)Documento3 pagine11 KV Power Cable Site Test Report: (NMGR105 To NMGR106)Gajendran Sriram100% (1)

- Visio-C System Overview JEC PAS V2-0Documento5 pagineVisio-C System Overview JEC PAS V2-0باسم العوفيNessuna valutazione finora

- NTPC CW - 3006600303 - Sec - C - Rev - BDocumento93 pagineNTPC CW - 3006600303 - Sec - C - Rev - BGautamupadhyay100% (1)

- 8.relay Incomer 1Documento5 pagine8.relay Incomer 1alagurajNessuna valutazione finora

- Huzurnagar 220kV line-BOQDocumento22 pagineHuzurnagar 220kV line-BOQzakir242Nessuna valutazione finora

- DBAD118077 A REND CT - Sizing CalculationDocumento10 pagineDBAD118077 A REND CT - Sizing CalculationBravery DamanikNessuna valutazione finora

- 33KV Switchboard Panel DetailsDocumento3 pagine33KV Switchboard Panel DetailsArunava Basak100% (1)

- Ict-1 Test ReportDocumento41 pagineIct-1 Test ReportSuresh Chandra PadhyNessuna valutazione finora

- SLD of 6.6kv Switch Board-1 (r5) 1 of 5 (Jsw-hsm2Documento1 paginaSLD of 6.6kv Switch Board-1 (r5) 1 of 5 (Jsw-hsm2vipinrajNessuna valutazione finora

- Switchboard Schematic and BOM TitleDocumento45 pagineSwitchboard Schematic and BOM Titlewaveengg.coNessuna valutazione finora

- 132kV New Anuradapura LineDocumento25 pagine132kV New Anuradapura LineKrishna ThangarajNessuna valutazione finora

- 44ac2700-00-E.05-0005-A4 - DC Ups SizingDocumento14 pagine44ac2700-00-E.05-0005-A4 - DC Ups SizingSatrajit BanerjeeNessuna valutazione finora

- CT & PT Sizing Calculation for Bandreah 115/13.8kV SubstationDocumento110 pagineCT & PT Sizing Calculation for Bandreah 115/13.8kV SubstationJay WinNessuna valutazione finora

- 220 KV CBDocumento12 pagine220 KV CBGurudatt SHNessuna valutazione finora

- 220KV Line - 2 P444Documento5 pagine220KV Line - 2 P444JayamkondanNessuna valutazione finora

- CBIP - Earthing of AC Power Systems - Pub. No. 339 - 2018Documento46 pagineCBIP - Earthing of AC Power Systems - Pub. No. 339 - 2018Ayan BanerjeeNessuna valutazione finora

- SLD of 6.6kV Unit Board 7UADocumento10 pagineSLD of 6.6kV Unit Board 7UAVenkatesh RaoNessuna valutazione finora

- 380KV Gis Expansion of Al Dhahiyah BSP - CT & PT Sizing CalculationDocumento24 pagine380KV Gis Expansion of Al Dhahiyah BSP - CT & PT Sizing CalculationJay WinNessuna valutazione finora

- LV Relay SettingDocumento12 pagineLV Relay SettingRatheesh KumarNessuna valutazione finora

- Areva 765kV Training PDFDocumento38 pagineAreva 765kV Training PDF1382aceNessuna valutazione finora

- 33kV-11.5kV transformer drawingDocumento7 pagine33kV-11.5kV transformer drawingIrshad Khan100% (1)

- Vaa33 InfoDocumento24 pagineVaa33 InfoSujoy PaulNessuna valutazione finora

- 1.6 Mva Dry Type TransformerDocumento10 pagine1.6 Mva Dry Type TransformerRamesh CuppuNessuna valutazione finora

- 850 KVAR 400v.doc - 400V Capacitor Bank - SpecDocumento10 pagine850 KVAR 400v.doc - 400V Capacitor Bank - Specdeepthik27Nessuna valutazione finora

- SEO-Optimized Lighting Transformer TitleDocumento8 pagineSEO-Optimized Lighting Transformer TitleShrikant KajaleNessuna valutazione finora

- Arar 33kV Cable Sizing ReportDocumento9 pagineArar 33kV Cable Sizing Reportsrigirisetty208Nessuna valutazione finora

- 4.17 - Powerhouse - Powerhouse CraneDocumento3 pagine4.17 - Powerhouse - Powerhouse Cranesrigirisetty208Nessuna valutazione finora

- NB O&M Brochure 01sept2020Documento10 pagineNB O&M Brochure 01sept2020srigirisetty208Nessuna valutazione finora

- 5C1. Coal Ash Generation Process and Application FieldsDocumento2 pagine5C1. Coal Ash Generation Process and Application Fieldssrigirisetty208Nessuna valutazione finora

- 4.5 - Dam and Spillway - ElevatorDocumento2 pagine4.5 - Dam and Spillway - Elevatorsrigirisetty208Nessuna valutazione finora

- 330MW Shrinagar Project Technical Data SheetDocumento4 pagine330MW Shrinagar Project Technical Data Sheetsrigirisetty208Nessuna valutazione finora

- Care and Maintenance of CFB Boilers Refractory FailureDocumento6 pagineCare and Maintenance of CFB Boilers Refractory FailureAnonymous a19X9GHZNessuna valutazione finora

- Fire Detection and Alarm System Design Basis DocumentDocumento12 pagineFire Detection and Alarm System Design Basis Documentsrigirisetty208Nessuna valutazione finora

- Boiler Tube Failures Due To Improper CommissioningDocumento21 pagineBoiler Tube Failures Due To Improper CommissioningDhandapani ManoharanNessuna valutazione finora

- 4.11 - Bypass Channel - Automatic GateDocumento1 pagina4.11 - Bypass Channel - Automatic Gatesrigirisetty208Nessuna valutazione finora

- 330MW Shrinagar Project Technical Data SheetDocumento4 pagine330MW Shrinagar Project Technical Data Sheetsrigirisetty208Nessuna valutazione finora

- HZL Ahs EssentialsparesDocumento8 pagineHZL Ahs Essentialsparessrigirisetty208Nessuna valutazione finora

- 4.19 - Instrumentation and ControlDocumento2 pagine4.19 - Instrumentation and Controlsrigirisetty208Nessuna valutazione finora

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDocumento3 pagine4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Nessuna valutazione finora

- 4.13 - Penstock Intake - Trashrack and Cleaning MachineDocumento2 pagine4.13 - Penstock Intake - Trashrack and Cleaning Machinesrigirisetty208Nessuna valutazione finora

- 330MW Shrinagar Hydroelectric Project Penstock Intake DataDocumento2 pagine330MW Shrinagar Hydroelectric Project Penstock Intake Datasrigirisetty208Nessuna valutazione finora

- 150 MW Coal Fired Power Plant Construction Equipment ListDocumento2 pagine150 MW Coal Fired Power Plant Construction Equipment Listsrigirisetty208Nessuna valutazione finora

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDocumento3 pagine4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Nessuna valutazione finora

- SCH 3A.11 SparesDocumento3 pagineSCH 3A.11 Sparessrigirisetty208Nessuna valutazione finora

- SCH 3A.9 Places of Mfg.Documento1 paginaSCH 3A.9 Places of Mfg.srigirisetty208Nessuna valutazione finora

- HZL Crane EssentialsparesDocumento2 pagineHZL Crane Essentialsparessrigirisetty208Nessuna valutazione finora

- HZL Chs EssentialsparesDocumento6 pagineHZL Chs Essentialsparessrigirisetty208Nessuna valutazione finora

- SCH 3A.17 Q.a.assessmentDocumento1 paginaSCH 3A.17 Q.a.assessmentsrigirisetty208Nessuna valutazione finora

- Quality Assurance Plan for 2x150 MW Coal Power PlantDocumento1 paginaQuality Assurance Plan for 2x150 MW Coal Power Plantsrigirisetty208Nessuna valutazione finora

- Sch-3A 14-Perfor GuartDocumento5 pagineSch-3A 14-Perfor Guartsrigirisetty208Nessuna valutazione finora

- BFP Drawings PDFDocumento42 pagineBFP Drawings PDFsrigirisetty208Nessuna valutazione finora

- SCH 3A.12 Special Tools &tacklesDocumento3 pagineSCH 3A.12 Special Tools &tacklessrigirisetty208Nessuna valutazione finora

- Equipment Supply by BidderDocumento6 pagineEquipment Supply by Biddersrigirisetty208100% (2)

- BFP DrawingsDocumento42 pagineBFP Drawingssrigirisetty208Nessuna valutazione finora

- Guaranteed DataDocumento2 pagineGuaranteed Datasrigirisetty208Nessuna valutazione finora

- Emex PDFDocumento4 pagineEmex PDFWolf LillyNessuna valutazione finora

- ProTrack I ManualDocumento203 pagineProTrack I ManualhishamuddinohariNessuna valutazione finora

- Nitroglycerine, C3H5N3O9, Is An Explosive Which, On Detonation, Decomposes RapidlyDocumento14 pagineNitroglycerine, C3H5N3O9, Is An Explosive Which, On Detonation, Decomposes Rapidlyapi-25909541Nessuna valutazione finora

- Cod.1828 - r4 Nema InputDocumento306 pagineCod.1828 - r4 Nema InputidontlikeebooksNessuna valutazione finora

- Reinforcing steel procurement guidelinesDocumento3 pagineReinforcing steel procurement guidelinesSasanka SekharNessuna valutazione finora

- Pe Plastics The Facts v7 Tue 19-10-1Documento81 paginePe Plastics The Facts v7 Tue 19-10-1Ajeya SaxenaNessuna valutazione finora

- Cameron Compressor OperationDocumento13 pagineCameron Compressor Operationfructora0% (1)

- Da-Lite IDEA Screen InstallationDocumento13 pagineDa-Lite IDEA Screen InstallationNurevaNessuna valutazione finora

- Mark 300 ManualDocumento8 pagineMark 300 ManualcjfgksNessuna valutazione finora

- Application of NanotubesDocumento28 pagineApplication of Nanotubesarian2arian2Nessuna valutazione finora

- DALI ManualDocumento93 pagineDALI ManualtichvraNessuna valutazione finora

- EPSON AcuLaser C1100Documento565 pagineEPSON AcuLaser C1100Lukáš KadeřábekNessuna valutazione finora

- Sym Euro MX 125 (EN)Documento193 pagineSym Euro MX 125 (EN)manualsym0% (1)

- Circular Pelletizing Technology General Presentation: We Just Made It BetterDocumento46 pagineCircular Pelletizing Technology General Presentation: We Just Made It BetterkalaiNessuna valutazione finora

- Dic Pps Weld StrengthDocumento1 paginaDic Pps Weld StrengthWoong KimNessuna valutazione finora

- Sitework: 1.02 Definitions, Standard Tests 1.02 Definitions, Standard TestsDocumento49 pagineSitework: 1.02 Definitions, Standard Tests 1.02 Definitions, Standard TestsJr FranciscoNessuna valutazione finora

- Specification for glass fiber yarn, cordage, sleeving, cloth, and tapeDocumento37 pagineSpecification for glass fiber yarn, cordage, sleeving, cloth, and tapeMichael SkrableNessuna valutazione finora

- Bahria Town Karachi E&P Department: Oil Topup ReportDocumento1 paginaBahria Town Karachi E&P Department: Oil Topup ReportAmjad HussainNessuna valutazione finora

- MS5002EDocumento8 pagineMS5002EMatt AgonyaNessuna valutazione finora

- EST120 Basiccivil&mechanical PDFDocumento12 pagineEST120 Basiccivil&mechanical PDFlecim12450Nessuna valutazione finora

- Inspection Test Plan (Itp) of PVC Conduits: Project: DateDocumento6 pagineInspection Test Plan (Itp) of PVC Conduits: Project: Dateshinto_thekkekkaraNessuna valutazione finora

- Các loại đầu nối cho ống- fittings for high pressure PDFDocumento45 pagineCác loại đầu nối cho ống- fittings for high pressure PDFKiên MaiNessuna valutazione finora

- Vacuum Pump Systems BrochureDocumento10 pagineVacuum Pump Systems BrochureMelissa WilliamsNessuna valutazione finora

- Culasi Phase 1 (BOX CULVERT) - Recover-ModelDocumento1 paginaCulasi Phase 1 (BOX CULVERT) - Recover-ModelEmman De los ReyesNessuna valutazione finora

- Tech Paper - Pipes Wagga 2007Documento43 pagineTech Paper - Pipes Wagga 2007Lauren BowenNessuna valutazione finora

- Seals Amp Bearings PDFDocumento16 pagineSeals Amp Bearings PDFLingu LsNessuna valutazione finora

- Thumb Rules For Steel&Concrete DesignDocumento11 pagineThumb Rules For Steel&Concrete DesigngvgbabuNessuna valutazione finora

- Housing & CouplingDocumento12 pagineHousing & Couplingmajid fardniaNessuna valutazione finora

- Peikko Catalogue 2016Documento68 paginePeikko Catalogue 2016strakdesme100% (1)

- UBCHYST Model Implementation in FLACDocumento8 pagineUBCHYST Model Implementation in FLACFrank Perez CollantesNessuna valutazione finora