Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cheklist

Caricato da

Andre Cloop'sTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cheklist

Caricato da

Andre Cloop'sCopyright:

Formati disponibili

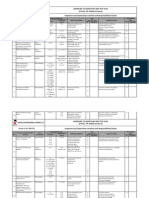

PT.

MARKA INSPEKTINDO TECHNICAL

(MARINDOTECH)

DAFTAR PERIKSA SERTIFIKASI TANGKI TIMBUN

(CHECK LIST OF STORAGE TANK CERTIFICATION)

No Item :T-H

Kegunaan : HSD Storage Tank

(Tag. No.)

(Service)

I.

Digunakan untuk Tangki Timbun

II.

Pemeriksaan sebelum fabrikasi

(Inspection before fabrication)

Telah dilakukan review terhadap :

(Have Been reviewed for)

Baru

(New)

Ya

(Yes)

1. Sistem Kendali Mutu

(Quality Control System)

2. Desain dan Gambar Kontruksi

(Design and Drawing)

3. Spesifikasi Material

(Material Specification)

4. WPS, PQR, Welder dan Welding Operator

(WPS, PQR, Welder and Welding Operator)

5. Prosedur NDT, Personil NDT dan Alat NDT

(NDT Procedure, Personnel and Equipment)

Catatan

(Note)

Tidak

(No)

6. Prosedur Reparasi

(Reparation Procedure)

7. Prosedur Perlakuan Panas

(PWHT Procedure)

8. Prosedur Uji Tekan

(Hydrostatic Test Procedure)

:

2.

3.

4.

5.

9.

Hal. 1/3

Design & drawing as per owner data sheet and approved by owner

Specification material

WPS, PQR and Welder certificate approved by Migas

NDT Procedure approved by ASNT Level III

Hydrostatic Procedure

Keterangan

(Remark)

PT. MARKA INSPEKTINDO TECHNICAL

(MARINDOTECH)

DAFTAR PERIKSA SERTIFIKASI TANGKI TIMBUN

(CHECK LIST OF STORAGE TANK CERTIFICATION)

No Item : T-H

Kegunaan :HSD Storage Tank

(Tag. No.)

(Service)

III.

Hal. 2/3

Pemeriksaan selama fabrikasi

(Inspection during fabrication)

Telah dilakukan pemeriksaan terhadap :

(Have Been Inspected for)

Ya

(Yes)

1. Material meliputi identifikasi, kondisi, dimensi &

pemindahan heat number

(Material included identification, condition,

dimention & heat number transfer)

Tidak

(No)

2. Pembentukan shell, roof, bottom dan bagian lain

(Forming of shell, roof, bottom & other part)

3. Pengukuran ketebalan

(Thickness check)

4. Persiapan pengelasan

(Welding preparation)

5. Hasil pengelasan

(Result of welding)

6. Hasil NDT

(Result of NDT)

7. Hasil PWHT

(Result of PWHT)

8. Pengukuran dimensi

(Dimensional check)

9. Pengukuran settlement

(Settlement check)

10. Peralatan pengaman tangki

(Safety device)

11. Bagian luar dan dalam secara visual

(Visual check for external & internal parts)

Keterangan

(Remark)

PT. MARKA INSPEKTINDO TECHNICAL

(MARINDOTECH)

DAFTAR PERIKSA SERTIFIKASI TANGKI TIMBUN

(CHECK LIST OF STORAGE TANK CERTIFICATION)

No Item :

Kegunaan :

(Tag. No.)

(Service)

12. Hydrostatic tes, meliputi :

(Hydrostatic included)

- Peralatan hydrostatic test

(Hydrostatic tets equipment)

- Pelaksanaan hydrostatic test

(Hydrostatic tets)

- Kondisi setelah hydrostatic test

(Condition after hydrostatic tets)

13. Penandatanganan data fabrikasi

(Manufacturer's data report sign)

14. Kelengkapan dokumen

(Documentation)

Catatan

(Note)

Hal. 3/3

:

1. Material identification as per mill certificate

2. Roundness

4, 5. Welding as per WPS & PQR, welder qualified, result of visual inspection not find

surface defect (Crack), high of reinforcement

6, 7. NDT & PWHT as per NDT procedure and PWHT procedure

8, 9. Result of final dimensional check still on the range of dimensional tolerance

settlement

11. Final inspection internal & external accepted, part of storage tank as per drawing

range of equipment hydrostatic test

12. pressure as per hydrostatic procedure, result of hydrostatic test acceptable

13. Manufacturer data report already sign by manufacturer & 3rd party (Marindotech)

14. Review of document manufacturer is completed (MDR, Drawing, Design Calculation,

WPS, Welder Certificate, NDT Report, Dimensional Report & Hydrostatic Report)

Potrebbero piacerti anche

- 1.1 Signing Off The ProductDocumento3 pagine1.1 Signing Off The ProductJSG GroupNessuna valutazione finora

- Above Ground Storage Tank (New) - MDRDocumento2 pagineAbove Ground Storage Tank (New) - MDRAris Munandar0% (1)

- 2.5 QK-CL-08-00002-2-Installation of Ductile Iron Pipes For Water Tank Main Pump Room PipingDocumento1 pagina2.5 QK-CL-08-00002-2-Installation of Ductile Iron Pipes For Water Tank Main Pump Room PipingMoh'd SameerNessuna valutazione finora

- Itp For Field Erected Tank Rev A PDF FreeDocumento9 pagineItp For Field Erected Tank Rev A PDF FreeMahmoud GaberNessuna valutazione finora

- ITP Pressure Vessel InspectionDocumento8 pagineITP Pressure Vessel InspectionerniNessuna valutazione finora

- Petroserve PDFDocumento3 paginePetroserve PDFSenthil KumarNessuna valutazione finora

- Data Book Vendor RequirementsDocumento4 pagineData Book Vendor RequirementsTim HardingNessuna valutazione finora

- Hydrostatic Test ProcedureDocumento7 pagineHydrostatic Test ProcedurequalityNessuna valutazione finora

- Saudi Aramco Pressure Testing ProcedureDocumento21 pagineSaudi Aramco Pressure Testing ProcedureDilshad AhemadNessuna valutazione finora

- Itp For SSDP Project Rev CDocumento9 pagineItp For SSDP Project Rev CRachel FloresNessuna valutazione finora

- Welding Inspection Ass 1Documento7 pagineWelding Inspection Ass 1mohd as shahiddin jafriNessuna valutazione finora

- A. Position: Welding Inspector (QA/QC Inspector) ResponbilityDocumento8 pagineA. Position: Welding Inspector (QA/QC Inspector) Responbilitydidi sudiNessuna valutazione finora

- Sationary Equipment InstallationDocumento7 pagineSationary Equipment Installationsaif aliNessuna valutazione finora

- SAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWDocumento27 pagineSAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWNaushad AlamNessuna valutazione finora

- Saic-A-2001 Rev 62Documento21 pagineSaic-A-2001 Rev 62pradeepthalava97Nessuna valutazione finora

- Engineering ProceduresDocumento23 pagineEngineering ProceduresadammzjinNessuna valutazione finora

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Documento15 pagineSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- ITP For Field Erected Tank Rev ADocumento9 pagineITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 1-Dec-06 MechDocumento30 pagineSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 1-Dec-06 Mechரமேஷ் பாலக்காடு86% (7)

- Itp - Rev eDocumento36 pagineItp - Rev ezaki_saddarNessuna valutazione finora

- Audit Agenda and Scope (Draft)Documento3 pagineAudit Agenda and Scope (Draft)Niraj PandyaNessuna valutazione finora

- Cover Page Load Test.Documento6 pagineCover Page Load Test.RktBatam100% (1)

- Fat ProcedureDocumento50 pagineFat ProcedureDin AizuNessuna valutazione finora

- Inspection and Test Procedure of SwitchgearDocumento4 pagineInspection and Test Procedure of SwitchgearShahadat HossainNessuna valutazione finora

- Table of Content: Sample For: Pressure VesselDocumento7 pagineTable of Content: Sample For: Pressure Vesseliwan100% (1)

- SAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)Documento13 pagineSAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)walidNessuna valutazione finora

- Inspection and Test Plan For Storage TankDocumento8 pagineInspection and Test Plan For Storage TankAndreas AlexanderNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento3 pagineSaudi Aramco Inspection ChecklistDilshad AhemadNessuna valutazione finora

- Saic A 2001Documento21 pagineSaic A 2001GanesanNessuna valutazione finora

- SAIC-A-2001 Rev 7Documento23 pagineSAIC-A-2001 Rev 7shemeemtkmNessuna valutazione finora

- ITP Pressure VesselDocumento21 pagineITP Pressure VesselSds Mani SNessuna valutazione finora

- LOG-563-03 Receiving Inspection Checklist Rev.1Documento1 paginaLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNessuna valutazione finora

- 2.4 QK-CL-08-00002-1-Installation of Ductile Iron Pipes For Underground Water SupplyDocumento3 pagine2.4 QK-CL-08-00002-1-Installation of Ductile Iron Pipes For Underground Water SupplyMoh'd SameerNessuna valutazione finora

- Hydro Test Procedure for Berri Development Onshore PipelinesDocumento14 pagineHydro Test Procedure for Berri Development Onshore PipelinesARJUN100% (4)

- SS Piping Method StatementDocumento10 pagineSS Piping Method StatementNishar BalkavadeNessuna valutazione finora

- Fabrication Process Inspection PlanDocumento48 pagineFabrication Process Inspection Planmohd as shahiddin jafriNessuna valutazione finora

- Method Statement DuctingDocumento29 pagineMethod Statement DuctingAnish Kumar100% (8)

- Testing Procedures Inspection TestsDocumento45 pagineTesting Procedures Inspection TestspaolaNessuna valutazione finora

- Khulud Gas Development Project FabricationDocumento5 pagineKhulud Gas Development Project FabricationRana AsifNessuna valutazione finora

- 6.E Installation Qualification (IQ) : Here You Will Find Answers To The Following QuestionsDocumento10 pagine6.E Installation Qualification (IQ) : Here You Will Find Answers To The Following QuestionsFilipNessuna valutazione finora

- QA/QC documentation summariesDocumento24 pagineQA/QC documentation summariesAnoop Chandran50% (2)

- Engineers To Healthcare Industry®: Quality Assurance Protocol (QAP)Documento9 pagineEngineers To Healthcare Industry®: Quality Assurance Protocol (QAP)Suleman KhanNessuna valutazione finora

- ITP TableDocumento3 pagineITP Tablearunrad100% (1)

- Inspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselDocumento1 paginaInspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselNikki RobertsNessuna valutazione finora

- STFFD-P1-004003-P05-0001 Rev C FAT Procedure For Complete SkidDocumento50 pagineSTFFD-P1-004003-P05-0001 Rev C FAT Procedure For Complete SkidTuyen Pham100% (2)

- Pressure Vessel Fabrication DocumentationDocumento2 paginePressure Vessel Fabrication DocumentationSonNguyenNessuna valutazione finora

- Akhtar Ansari - TPI - FRT PDFDocumento5 pagineAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNessuna valutazione finora

- Documentation: 1 GeneralDocumento13 pagineDocumentation: 1 GeneralPaolita Auza BalderramaNessuna valutazione finora

- ITP Format For New PVDocumento8 pagineITP Format For New PVDavid LambertNessuna valutazione finora

- TANK 06 Test PackDocumento12 pagineTANK 06 Test PackGomathyselvi100% (2)

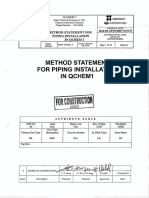

- MS For Piping Installation in QChem 1 Site Rev0Documento18 pagineMS For Piping Installation in QChem 1 Site Rev0Manzar KhanNessuna valutazione finora

- General QuestionnaireDocumento9 pagineGeneral Questionnairehemant1284Nessuna valutazione finora

- CSCS Rods & BracketsDocumento66 pagineCSCS Rods & BracketsshuklahouseNessuna valutazione finora

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocumento10 pagineInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNessuna valutazione finora

- Inspection Test Procedure TemplateDocumento8 pagineInspection Test Procedure TemplateMahesh SuthaNessuna valutazione finora

- 2.7 QK-CL-08-00004-Installation and Water Tightness Test of UPVC Pipes and Fittings For Irrigation SystemDocumento1 pagina2.7 QK-CL-08-00004-Installation and Water Tightness Test of UPVC Pipes and Fittings For Irrigation SystemMoh'd SameerNessuna valutazione finora

- Inspection and Test Plan: S. H. Joo D. H. YounDocumento2 pagineInspection and Test Plan: S. H. Joo D. H. YounfitriatitisariNessuna valutazione finora

- 1.MS HVAC Ducts and Accessories (26 11 2011)Documento12 pagine1.MS HVAC Ducts and Accessories (26 11 2011)721917114 47Nessuna valutazione finora

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionDa EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionValutazione: 4.5 su 5 stelle4.5/5 (16)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- ASTM D4752 MEK Test (Zinc Test)Documento8 pagineASTM D4752 MEK Test (Zinc Test)vlong300389% (9)

- NDT Methods for Non-Destructive TestingDocumento2 pagineNDT Methods for Non-Destructive TestingAekJayNessuna valutazione finora

- Non-Destructive Testing of Precast Concrete JointsDocumento10 pagineNon-Destructive Testing of Precast Concrete JointsshakeebNessuna valutazione finora

- Rope Access Technician ResumeDocumento3 pagineRope Access Technician ResumeKevin McGrathNessuna valutazione finora

- Phased Array CiorauDocumento9 paginePhased Array Ciorausolrac4371Nessuna valutazione finora

- AviaciónDocumento27 pagineAviaciónRogelio CastroNessuna valutazione finora

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocumento13 pagineJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNessuna valutazione finora

- CV Esteban Cordero DelgadoDocumento1 paginaCV Esteban Cordero DelgadoEsteban CorderoNessuna valutazione finora

- Is 10724 1990 PDFDocumento11 pagineIs 10724 1990 PDFpramod kumar100% (1)

- ASTM E747 (2010) IQI SpecificationDocumento15 pagineASTM E747 (2010) IQI Specificationndt_inspectorNessuna valutazione finora

- A Review of Residual Stresses and TensioningDocumento14 pagineA Review of Residual Stresses and TensioningFernando Spanholi TelesNessuna valutazione finora

- 1892 1Documento148 pagine1892 1Mohan KumarNessuna valutazione finora

- Dacon BrochureDocumento28 pagineDacon BrochureMohammed Ilyas MohiuddinNessuna valutazione finora

- 101 Mechanical Engineering Interview QuestionsDocumento16 pagine101 Mechanical Engineering Interview Questionsamr yosry100% (2)

- ASTM D 5641-94 Standard Practice For Geomembrane Seam Evaluation by Vacuum ChamberDocumento3 pagineASTM D 5641-94 Standard Practice For Geomembrane Seam Evaluation by Vacuum ChamberPablo Antonio Valcárcel VargasNessuna valutazione finora

- Aws Publications Catalog: Summer 2010Documento20 pagineAws Publications Catalog: Summer 2010saeedahmad901Nessuna valutazione finora

- Destructive Testing of WeldsDocumento4 pagineDestructive Testing of Weldsvikram5211Nessuna valutazione finora

- Ectane Surface Array Tube Inspection System December 2012Documento5 pagineEctane Surface Array Tube Inspection System December 2012Anonymous SKXvtEWAUNessuna valutazione finora

- 3index PDFDocumento22 pagine3index PDFdada jamdarNessuna valutazione finora

- Tendernotice 12Documento1.500 pagineTendernotice 12pankajmay100% (1)

- Safety Hazards: Section IVDocumento17 pagineSafety Hazards: Section IVSooraj RajanNessuna valutazione finora

- Hot TappingDocumento21 pagineHot TappingnayakyaNessuna valutazione finora

- API570 Training Book PDFDocumento312 pagineAPI570 Training Book PDFRamziAhmed100% (4)

- ASNT GLASSpring2022Documento8 pagineASNT GLASSpring2022hayder ahmedNessuna valutazione finora

- Drilled Shaft Foundation DefectsDocumento137 pagineDrilled Shaft Foundation DefectsUlissipo1955Nessuna valutazione finora

- Sample Procedure For The Ultrasonic Testing of Steel Castings To ASTM A609/ASME B16.34Documento5 pagineSample Procedure For The Ultrasonic Testing of Steel Castings To ASTM A609/ASME B16.34Mark Brailsford100% (2)

- Radiography - Film Quality ChecklistDocumento4 pagineRadiography - Film Quality ChecklistNatraji100% (1)

- DNV-Structural Design of TLPS (LRFD Method)Documento29 pagineDNV-Structural Design of TLPS (LRFD Method)gelo_17Nessuna valutazione finora

- Rack InspectionDocumento17 pagineRack InspectionSuprayitno Supra100% (1)

- Magnetic Particle Inspection PrinciplesDocumento5 pagineMagnetic Particle Inspection PrinciplesdonciriusNessuna valutazione finora