Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HMT Ltd. In-Plant Training Report 2015-16

Caricato da

Safalsha BabuDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HMT Ltd. In-Plant Training Report 2015-16

Caricato da

Safalsha BabuCopyright:

Formati disponibili

In-Plant Training Report 2015-16

1. HINDUSTANMACHINETOOLSLIMITED

BytheendoftheSecondWorldWarthegovernmentofIndiawasconfrontedbyabig

problem ofdisposing the colossal warwaste. Ultimately acommittee was constituted to

inquireintothepossibilities.Thecommitteereportof1948proposedtheestablishmentofa

Govt.ownedmachinetoolindustry.Thiswasexpectedtofulfilltwoaspects.Thefirstwas

being utilization of Rs. 4000 Million worth of metallic waste. The second was the

incorporation of a state owned manufacturing facility. The result was the birth of the

HINDUSTANMACHINETOOLSLIMITED,whichdiversifiedinduecourseoftimetothe

presentstatureofthemultiproductindustrialgiantHMYLtd.TheHMTLtd.Wasstartedas

a single factory to produce Tool Room Lathes at Bangalore in collaboration with M/S

OerlikonofSwitzerlandin1953,withacapacitytomanufacturearound400machinesper

year.Sincethendifferentcollaboration,continuedinhouseR&Dandtremendousmarketing

effortsbroughtHMT,topresentstatus.

ThegrowthofHMTLtd.wascharacterizedbytheforwardandbackwardintegration

oftechnologyandproductdiversification.Thusthecompanythatstartedwithmanufacturing

andsellinglathesexpandeditsmachinetoolsproductrangetoevolveastheultimatesolution

inmetal cutting.Theproductdiversificationeffortstookthecompanytothebusinessof

watchesin1976,FoodprocessingMachineryin1980,CNCSystemin1986,BallScrewin

1986andreconditioningin1990.

ThemultiproductactivitiesmadeHMTLtd.ChangesitsidentityasHINDUSTAN

MACHINETOOLSLTD.

Today, HMT Ltd. Has 16 manufacturing units with 22 product divisions, spread

throughthelengthandbreadthofINDIA.ASUBSIDIARYVise,HMT(international)Ltd.

undertakestheexportsofthecompany.TheyarealsoexportagentsforseveralotherIndian

Companies.

HMT Ltd. Was restructured in 1992 to facilities better administration of the

multiproductbusinessgroupswasestablished.

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

MachineToolsBusinessGroup,toconcentrateonthemetalcuttingmachines.

IndustrialMachineryBusinessGroup,todealwithprintingMachines,Diecastingand

plasticsinjectionmoldingmachines,Foodprocessingmachinesandmetalforming

machines.

AgriculturalBusinessGrouptoconcentrateonTractors Engineeringcomponents

BusinessGrouptodealwithcastingandBallScrewsConsumerproductsBusiness

Grouptodealwithwatchesandlamps.Inadditiontothisbusinessgroupthecompany

ownsthreesubsidiariesasfollows:

2. ORGANIZATIONCHART

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

TOPEXECUTIVES

3.HMTMACHINETOOLSLIMITED:

TheHMTMACHINETOOLSLIMITEDisengagedinthemanufacture

and marketing of General Purpose Machine Tools, Special Purpose Machine Tools,

Computer Machines, Metal Forming Presses, Die Casting and Plastic injection Molding

Machines,FerrousCasting.

1.1.1HMTMACHINESTOOLSUNITS:

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

1.HMTmachinetoolsltdBangalore

2.HMTmachinetoolsltdHyderabad

3.HMTmachinetoolsltdkalamassery

4.HMTmachinetoolsltdpinjore

5.HMTmachinetoolsltdAjmer

6.PragamachinetoolsltdHyderabad

KALAMASSERY:

CNCTurningCenters

TurnMillCentre

FlexibleturningCell

CentreLathe

OffsetPrintingMachines

PaperCuttingMachine.

4. PRODUCTIONPLANNING

4.1INTRODUCTION

Theproductionplanningdepartmentisthemostvitallinkbetweenproductdesignand

productiondepartment.Theproductionplanningdepartmentprovidesthenecessaryfacilities

andtechnicalnowhowforthemanufactureoftheproduct.Productionrequirestheorganized

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

utilizationofnaturalresourcesmenmoneymaterialandmachine.Theroleofproduction

planningdepartmentMTKisasshownbelow.Productionplanningdepartmentcomparesthe

followingsections.

ProductionpreplanningandplanningestimationPPPandPPE

ProductionplanningorderingandPPSPPOandFPC

4.2OBJECTIVEOFPRODUCTIONPLANNING

Inanybusinessorganizationproductionactivitiesmustberelatedtomarketdemands

as indicated by continuous stream of customer orders. Objective of production planning

departmentensurethatannualproductionplanningisachievedisaneconomicmanner.

4.3FUNCTIONSANDRESPONSIBILITYOFPLANNINGPERSONNEL

1.Processingofdesigndocumentreceivedforcorrespondingproducts

2.Implementationofdesignalternation

3.Coordinatingactivityrelatedtoalterationrequestsreceivedfromotherdepartments

4.CoordinatingallactivitiesrelatedtocomputerizationPPPfunction

5.Coordinationwithfoundryforthemanufactureoralterationofpatterns

4.4FUNCTIONSANDRESPONSIBILITYOFPPCPERSONNEL

1.Estimationofstandardtimeforallmanufacturingorassemblyoperation

2.Identifiedinoperationlayoutsassemblylistofoperations

3.Attendingshopcomplaintsregardingstandardtime

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

4.Authorizationforspecialtimeinjobcards.

5.QUALITYCONTROL

INTRODUCTION

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

Qualitycontrolinit'ssimplesttermrefertocontrolofqualityduringmanufacturing

bothquality.Controlandinspectorareenvisagedtoassurethequalityisentireareaofany

productionprocessinspectionisdeterminefunction.Whenthecontrolbecauseeffectivethe

needofinspectiondecreases.Hencequalitycontroldeterminesthecausesofvariationinthe

characteristicsofproductionandgivessolutionbywhichtherevariationscanbecontrolled.It

iseconomicalinit'spurposeobjectiveinit'sproceduredynamicinit'soperationandhelpful

needtreatment

OBJECTIVE

Thetotalqualitymanagementdepartmentseriesmeasurablequalityobjectiveforevery

year.Theseobjectivesensurethattherequirementofproductsnotonlyidentifiedandmetbut

alsoconsulterwideandimproved.Themeasurableobjectivesaretakingit'stoconsidering

the followings *To reduce internal losses due to scrap rejection and reworks To reduce

externallossesduetosciencecostTomaximizethecustomersatisfaction3.3PURPOSE

To ensure in coming items or raw material being used directly indirectly are not

supplied for manufacturing and product without inspection or verification for it's

conformancetospecifiedstandard

Toensurethecastingproductsinthefoundryneedspecifiedstandards

Toensurethecomponentsandassembledunitsduringvariousstagesofit'sprogress

areinspectedortestedandthedetailsdocumented

To ensure major components at various manufacturing process are inspected and

designrecordedinthereagentdocuments.

INTERACTIVEGRAPHICSYSTEMINCOMPUTERAIDEDPART

PROGRAMMING

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

6.HIGHTECHNOLOGYCENTRE

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

INTRODUCTION

ThemostimportantsectioninthemanufacturingdepartmentistheHighTechnology

Centre(HTC).ThisistheprestigiousmanufacturingsectionofHMT.inthissection,thereare

fiveCNCmachines

1.VMC(VerticalMachiningCentre)

2.HMC(HorizontalMachiningCentre)

3.HM.4(HorizontalMachiningCentrewith4axis)

4.VTC.1(VerticalMachiningCentrewithautomatictoolchanger)

5.VTC.2(VerticalMachiningCentrewithautomatictoolcentre)

AllthesemachinesareworkingwiththehelpofCNCcontrol.Controllingamachine

toolbymeansofapreparedprogramwhichconsistsofblocksorseriesofnumbersisknown

numericalcontrolorNC.AnNCmachinetoolsystemcontainsamachinetoolitself.

DEFINITION

Computer Numerical Control(CNC) is one which the functions and motions of a

machinetoolarecontrolledbymeansofapreparedprogramcontainingcodedalphanumeric

data.

APPLICATIONS

TheapplicationsofCNCincludebothformachinetoolaswellasnonmachinetool

areas.InthemachinetoolcategoryCNCiswidelyusedforthe,drillpress,millingmachine,

grindingunit,laser,sheetmetalpressworkingmachine,tubebendingmachineetc.Highly

automated machine tools such as turning centre and machining centre which change the

cuttingtoolsautomaticallyunderCNCcontrolhavebeendeveloped.

Dept.of Mechanical Engg

AWH PTC

In-Plant Training Report 2015-16

PATTERNSHOP

A pattern is defined as anything used for an important is called mould in the sand

mould when filled with molten material on solidifying forms a reproduction of pattern and is

known as mould. Its slightly longer in size then casting. as the first stage in preparing the

casting the pattern of casting prepared at pattern shop with either of the material as its given

below.

WOOD;-Wood is most commonly used pattern material as its cheap, easily available can also

easy to joint and fabricate

METALS;-Metals have advantage of that they do not wrap, very accurate and have high

strength. But shaping is slightly difficult and it's also subjected to rusting and the cost is high

PLASTICS;-The most common example is gypsum cement prepare cannot easily done and it

does not need skilled labors

THERMOCOAL;-Single use pattern are made using thermo coal in the process of casting a

pattern of casting of pattern is repair of the object to be cast used to prepare the cavity into

which molten material will poured during the casting process. the pattern made to incorporate

suitable shrinkage allowance depending or material followed heat transfer considerate.

Pattern making is skilled technique that was highly indulgent.

In sand casting pattern is usually of wood where as it may be metal or other material in

pressure of centrifugal casting. The pattern making also decide where the space respect to the

pattern parts object which have holes or depression. Material will not flow sometime pattern

may also accommodate chills, solid piece of final material to make rapid cooling resisting in

mastinsticness during in high neighborhood of chill

SAND MAKING PROCEDURE

The procedure of making a typical sand molding start by placing a button board, first

either the molding plate form on the floor making the surface when the drag molding flask is

kept upside down on the bottom board acting with the drag part of pattern at the centre of the

board. These should be enough clearance between the pattern and the walls of the flask. Rest

of the drug flask is completely filled with backup sand and uniformly rammed to compact the

sand and after the ramming out the excess sand in flask is completely suspend using a flat bar

to lead of flask edge. The finished drag flask is near rolled out to the bottom board expose the

pattern using stick. The edge of sand around is replaced and cope with the help of pattern is

replaced. Out the drag pattern changing with the help of the pins dry parting sand sprinkled

all over on the drag on the pattern.

Dept.of Mechanical Engg

10

AWH PTC

In-Plant Training Report 2015-16

The space pin for making the replaced passage is located at the small distance to form

the pattern also a riser pin of required is kept at an appropriate place and freshly prepared

molding sand similar to that of the drag along with backing sand is sprinkled. The sand

thoroughly removed excess sand shaped and holes are made all over in the copy as in the

drag. Now the cope and the drag pattern holes are withdrawn by using the draw spikes and

rapping the pattern all around to slightly enlarge the mould cavity that the mould wall are not

spilled by withdrawing pattern.

MOULDINGPROCEDURE

Thepigiron,msscrap,carbon,andotherconstitutematerialsaremeltedinelectricarc

furnace.Themoltenmetalisdrawnintoaladderandtransportedcasingalloverhead.The

moltenmetalispouredintothemouldcavitywhichdesigned

FORGING

It's the operation of where the metal is heated and then the force is applied to

manipulate themetal insuchawaythattherequired final shapeis obtained. Forgingis

generallyahotworkingoperationthoughcoldforgingisusedsometimes

FETLING

Thecompleteprocessofcleaningofcastingcalledfetling.itinvolvestheremovalof

cores gate,riscus cleaning of the casting surface and chipping of any of unnecessary

Dept.of Mechanical Engg

11

AWH PTC

In-Plant Training Report 2015-16

projectionsonthesurfacethedrysandcoverscanberemovedsimplybyremakingofwith

ironbarBymeansofcorevibratororbymeansofhydroblasting.Themethoddependupon

the size completely and core material used in gates and raisers can be removed by

hammering,chipping,obsessivecutofforbigflamesorcuttingremovalofgatesandresults

can be simplified by providing a reduced by metal sultan at the casting joint for brittle

materialsuchasgraycastironinthegates.Labeasilybebrokenbyhittingwithhammerfor

steelandothersimilarmaterialssavingwithanymetalcuttingsawlikehacksaworbandbe

more

FOUNDRYPATTERN

Dept.of Mechanical Engg

12

AWH PTC

In-Plant Training Report 2015-16

7. M T K SMALL PARTS

Dept.of Mechanical Engg

13

AWH PTC

In-Plant Training Report 2015-16

INTRODUCTION

MTKSmallpartsisaseparatedivisionofHMTKalamasserywhichmanufactureand

producessmallpartsrelatedwithlatheandCNC'sMTKSmallpartscanbedecidedinto

followingalldepartmentsonthebasisofeffectivecostcalculationmanufacturingprocessetc.

1.NonRoundSection5.Leadscrew2.CNCTurning6.Accessories3.RoundSection7.

Spindles4.Gears8.Turrets10.2NONROUNDSECTION

Thissectionmainlyconsistsofmillingoperationofthenonroundpartsoflathe.Inthe

millingmachinekeylegclampingisusedtoholdthewhichistheworkpiecc.Thereare2

typesofmillingmachines.Verticalmillingmachine2.Horizontalmillingmachine

GEARS

Dept.of Mechanical Engg

14

AWH PTC

In-Plant Training Report 2015-16

Gearsareusuallyusedtotransmittingpowerfromoneshafttoanotlier.Gearsnecessary

belathetoproperadding,turning,facingandholdingshapingarevariousspacesusually

involvedingearmanufacture.Shapingismoreaccurateandusuallyusedforproduction

ofgearsitsmoveeconomic.Afterholdingprocessthegearshouldundergogrindingfor

squarefinishgearsareproducedbygearshapingmach

ACCESSORIES

1. Accessoriesasthetoolandequipmentusedinlathetheoperation.Theyhavethetools

whicharegeneraloperation.Theyhavethetoolswhichareprovidedwithlitheand

intrudetoolsforlatheandCNC'Sandalsochecks4gearsand3gears.Checkisa

devicewhichisusedtoholdsworkpiece.

2. TURRETS:Itproducedbyusingdies.Turretreferstoasetofarrangement.Itsusedto

severalbuoyancywhichcanbeinspectandlowspeedinnecessaryforthreadingthe

turret. The proper preparation of turret is necessary. The coolant usually used in

satisfied.

3. Features : Rotary and reciprocating motion Shearing actions used Honing

operationislimitedtoveryfewnumberofindustries

Dept.of Mechanical Engg

15

AWH PTC

In-Plant Training Report 2015-16

BORINGMACHINE

Theyareusedtomilldrillboreandcutthreadscuringrotatingtool,usuallyacutter,

drillerormillinghead.Boringmachineisusedfordrillclosedandopenopeningissolid

materials boring, reaming, threading. Boring machine include vertical boring mill and

horizontalboringmachinemill.Boringoperationistoenlargeandfinishhole.

FEATURES

WorkpieceonecommonlyH04molesindiameter

Controlsystemcanliecomputercased

Bottomcoolingoftheboresaredonethroughahollowpassagewayt

Horizontalandverticalmovement

Handoperationknurledsocketattachedtohandstockdrivemotor

Highsurfacefinish

GRINDINGMACHINE

Dept.of Mechanical Engg

16

AWH PTC

In-Plant Training Report 2015-16

Grinding machine is used to fresh work piece that must shows. Accuracy of shape and

dimension.Itconsistsof

abedwithafracturetoguideandholdtheworkpiece

Powerdivinegrindingwheelspinningatrequiredspeed

Surface grinding work piece moved back and forth under the grinding wheel 1E4

DRILLINGMACHINEThismachineisusedtodrill,mainlyrotationandmovementofthe

rail.Drillbitisdampedmanuallyorautomaticallyandspeedofmovementandrotationare

varied. Features : o Electromagnetic damping provide for drill head and arm sleeve o

Machinedrillingcapacityis80mm/100mmoMassiveandrigidconstructionoPreciousdepth

releaseoElectricmotorAC/400V

Dept.of Mechanical Engg

17

AWH PTC

In-Plant Training Report 2015-16

8.HEAVYPARTS

HeavypartssectioninHMTincludesmillingplanning,drilling,boringetc.operations.

Pantsoflathesliketide,headstock,tailstocketc.aremachinedhere.

PLANE MILLING Plane milling is the process of production of plane, flat, horizontal

surfaceparalleltothecrisisoftherotationofaplanecutterFeatures:DCmotorRack&

pinionarrangementsusedLengthupto13metersused.

Dept.of Mechanical Engg

18

AWH PTC

In-Plant Training Report 2015-16

PLANOMILLINGMACHINEPlanomillingmachineiswidelyusedinpreciseshapingof

methods of various processes such as slot cutting, routing, welding & turning in many

industry.

Features:

Precisedimension

Easytoinstall

Highoperationefficiency

Hydraulicpressisused

Variouslengthsof1.5m,lm&3mareused.

9.CNCASSEMBLY

Dept.of Mechanical Engg

19

AWH PTC

In-Plant Training Report 2015-16

Ever increasing demands the need for accuracy, scrub reduction have pushed for

developmentinthefieldofmachiningandmanufacture.Allthishaveledtotheinventionand

improvementofCNCmachineswhichcanundoubtedlybelearnedasoneofthemilestones

ofthecentury.ApartfromrocketingtheproductionsskyhighCNCmachineshavemadeit

possibletomachineuptoanaccuracyofmicrontoamodestoneofthegrowingpopularityof

CNCmachinescanalsobeattaintedtorepeatabilityofCNCpartprogramsandreachedskill

demandsoflabors.

HMTmachinetoolsKalamasseryisfamousforitsworldclassCNCturningcentre.It

wasinthelate80'sthatHMTmachinetoolsLtd.Kalamasserystaredtheproductionofthe

CNC turning centers. The earlier models of machines and liniment and numeric control

systemandMCU(machinecontrolunit)whereasthenewgenerationCNCmachineofthe

unitwas(fame/sins)controlsystem.

TheassemblyofCNCturningcenterscanbedividedinto:

1.Groupassembly

2.Prefinalassembly

3.Finalassembly

ELEMENTSOFACNC

Dept.of Mechanical Engg

20

AWH PTC

In-Plant Training Report 2015-16

ACNCsystemconsistofthreebasiccomponents

1.Partprogram

2.Machinecontrolunit(MCU)

3.Machinetool(lathe,drillpress,millingmachineetc...)

Part program:Part program is a detailed set of commands to be followed by the

machine tool. Each command specifies a position in the car tension coordinate

system(x, y, z) or motion (work place travel or cutting tool travel),machining

parametersandon/offfunction.

Machinecontrolunit (MCU):Itis amicro computerthat storestheprogramand

executesthecommandsintoactionsbythemachinetool.TheMCUconsistoftwo

mainunitsthedataprocessingunit(DPU)andcontrolloopsunit(CLU).

Machine tool:It could be one of the following: Lathe, milling machine,

laser,plasma,coordinatemeasuringmachineetc.

POINTTOPOINTSYSTEM

PointToPointSystemisthosethatmovethetoolortheworkplacefromonepointto

anotherandthenthetoolperformstherequiredtask

Dept.of Mechanical Engg

21

AWH PTC

In-Plant Training Report 2015-16

CONTINOUSPATHSYSTEM(Straightcut&contouringsystem)

These systems provide continuous path such that tool can perform while they are

moving, enabling the system to generate angular surfaces, two dimensional cut or three

dimensionalcontours.Exampleisamillingmachine.

GROUPASSEMBLY

This is the place where Assembly of the headstock, tailstock, turret, indexingunit,

powerstockturretfixing,etc.isdone.Thepartsrequiredfortheassemblyareproducedby

variousunitsandkeptinstore.Asperrequirementbytheassemblyunit,thestoresissuesthe

requiredcomponentsfortheassemblyoftheproducts.Afterassemblyofeachparttheyare

settoanextensivetestandarepassedontoprefinalassemblyonlyaftertheinspection

departmentcertifyonit.Themostcommonlyusedmethodistheuseofcurviercoupling.It

hastwogearslikeparts.Oneofthemhasaconvexsurfaceandotheraconcavesurfacefor

firmcontact.Anothermethodistousehydraulicpressureabout4Mpaforclamping.When

thepressureisreleasedtheturretisunclampedandreadyforindexing.

PREFINALASSEMBLYTheprefinalassemblyisthesectionwheretheassemblies

ofvariouscomponentsoftheCNClikeheadstocktakesplacetothelathebed.The

head is moved from the heavy parts store to the preassembly directly upon the

request.

FINALASSEMBLY Thelathe isbroughtfromtheprefinal assembly thevarious

electricalcomponentsrequiredforthefunctioningareinstalled.Theelectricaldrives,

systems andspecial accessories like tools,studyrests,etc. are imported Themain

suppliers are Siemens and Franc. The stabilizer unit and coverer belt are also

assembledduringthisstage.Thevariousfunctionalgroupsareexplainedbrieflyas

follows:

BED MostofCNCturningcenters ofHMTisofslantbedtype.Therearemany

reasonsbehindsuchadesign.Afewcanbelistedas:reducedthermalgrowth:The

thermalgrowthduringmachiningcanbeconsiderablyreducedbyusingslantbeds.

Chip removal becomes easier when it comes to slant beds. Loading/Unloading

becomemuchlesstediousinslantbedmachines.

HEADSTOCK:Unliketheheadstockofconventionallathes,theCNCdonothave

speedshiftgearsincorporated.Twotypesofpulleysareusedtotransferpowerfrom

Dept.of Mechanical Engg

22

AWH PTC

In-Plant Training Report 2015-16

themainmotortospindle.Taperedpulleysandkeyedpulleys.Moreovertwotypesof

beltsareused:Vbeltsandparallelbelts.Themainspindlehasalsoanencoderwhich

actsastothefeebackservomotorsothattherequiredspeedisattained.Allspindles

arestabilized(Startingfromlowspeedthespeedofthespindleisgraduallyincreased

toitsmaximumratedspeed)andthenputonthetestrunbeforemountingonthe

machine.Manufacturingthespindlesfreeofvibrationsiscriticaltomaintainaccuracy

inmachiningandforlifeoftheentireunit.

DRIVES:The machinecontainsthreeservomotors.Oneformainspindles,onefor

saddleTraversoverthebedandthethirdoneforcrossslide/turretmovementacross

thesaddle.Thedrivingunitandaredirectlycontrolledbythecomputerwhileonrun.

SADDLE:Saddleisthatportionwhichcarriestheturretandslidesoverthebed.The

saddleactuallyisfixedtotheballnut.Theballscrewmountedonbearingispowered

byaservomotor.Asthescrewrotates,thenutmovescausingtheturretandhencethe

cuttingtooltomoveintheaxialdirection(Z).

TURRET:TurretisthatpartofaCNCmachinethatholdsvarioustoolsandpositions

therequiredformtoperformthecutting.Thesequenceofoperationsthattakesplace

duringindexingisgivenbelow:

i.Unclamping:Theturretmalepartunclampsfromthecurvy coupling.Thisactuatedbya

pistoncylinderarrangementenclosedwithintheturrethousing.ii.Rotation:Thehydraulic

motorisactuatedbymeansofadirectioncontrolvalvesolenoidvalves(DCV).Thisrotation

isfedbacktothecontrollerbyanotherencoder.Thisrotationistakesplaceinthedirectionof

shortestpossibleangle.iii.Creep:Astheturretreachesthedesiredangleanoppositeflowis

giventomotorsoastoreducethespeedofrotation.iv.Clamping:oncethedesiredposition

isattainedtheturretclampsbacktothecouplingandreadyformachining.

TAILSTOCKThe tailstockofaCNCmachineishighlyadvanced.Insteadofrotatinga

rotatingcentreisusedtoreduceheatgeneration.Thetailstockbodyisusedtoreduceheat

generation. The tail stock Body is moved by means of a special hooklike mechanism

providedattheendofthesaddle.Thetailstockisclampedtotheguidewaybytheplungerin

andplungeroutoperationsandmovementareonlypossibleiftheplungerisexecuted.

HYDRAULLIC SYSTEMS Many of the critical operations of the CNC machines,

includingfoolproofsetuparehydraulicsystemsowingtheirflexibilityandcontrollability.

Themajorhydraulicsystemsaredescribedbelow:i.Headstock:Asexplainedabovethe

Dept.of Mechanical Engg

23

AWH PTC

In-Plant Training Report 2015-16

workpieceisclampedbymeansofapistoncylinderarrangement.ii.Tailstock:thetailstock

cylinderisalsocontrolledvalves.TheplungertooishydraulicallyControlled.iii.Turret:As

abovementionedtheturretclamping/unclamping,indexing,creepingandallarecontrolled

hydraulically. iv. Gearbox: The gear shifts in CNC machines are actuated by hydraulic

systems.Theleversareshiftedwhenthepistoninsidethecylinderpushesthem.

LUBRICATIONSYSTEM

Ensuringsufficientlubricationfortherotatingaswellasslidingpartsareessentialto

maintainsmoothrunningforthemachineaswellastoreducevibrationsheatgenerationsand

errors.Thelubricationpipesaremadeofcopperpipesandflowiscontrolledbymetering

cartridges.

LUBRICATIONSYSTEM

Ensuringsufficientlubricationfortherotatingaswellasslidingpartsareessentialto

maintainsmoothrunningforthemachineaswellastoreducevibrationsheatgenerationsand

errors.Thelubricationpipesaremadeofcopperpipesandflowiscontrolledbymetering

cartridges.

OTHERSYSTEMS

Chipconveyorforremovalchipsinsidethemachine.

Cabinetcoolingsetuptokeeptheelectroniccircuitsandoptimumtemperature

Oilrefrigerationunitforcoolingandcontroltemperatureofoilinsidethepowerpack.

Powersupplysystemtoprovideconstantvoltagetothepumpandservomotors.

TheMCVCsuppliedbythecontrolsystemmanufacture.

AXISALIGNMENT

AxisalignmentisdoneoneverymachineproducedatHMT.ButforCNCmachineit

is of slightly higher importance, because the accuracy of machine is determined by this

process.This is different fromthosedoneonconventional lathes producedinthatslight

errorsbeyondallowablevaluesarecompensatedforthecontrolsystem.

Dept.of Mechanical Engg

24

AWH PTC

In-Plant Training Report 2015-16

10. NH/NL ASSEMBLY

Assemblyistheprocessofcollaborationofallcomponentpartofalathetoforma

lathe. It involves three step of assembly: 1)pre assembly 2)group assembly 3)final

assembly

SCRAPING

Removalofhighpointstogetqualitycontactorbearingforgettingasmoothsurface

forgoodbattling.Itisamanualprocess.Thefollowingpartsarescrapedbyscrapes.

1.Saddle2.keepers3.crossslide5.apronsplitnut

4.Legs

6.Tailstockbase

7.Componentslide8.accessories

SADDLEASSEMBLY

a)Oilgrooving:forlubricationpurposes,somegroovesareprovidedonthesaddle

b)DistributionassemblyOilpiping:forreducingfrictiontheoildistributionProperly

c)Crossfeedassembly.

FEEDBOXASSEMBLY&INSPECTION

Itconsistofsizeshaftpreassembledwithgears.Itconsistoffeedrode,controlshaft,lead

screw.It'sstepsarefrictionconeassembly

APRONEASSEMBLY

Dept.of Mechanical Engg

25

AWH PTC

In-Plant Training Report 2015-16

a)preassembly

b)groupassembly

Csplitnutleadscrewengagement

d)reciprocatingpumpandlubrication

e)feeddrivetransmissiontocrossslideandlongitudinalmovementonbed

HYDRAULICS

Lapping:Itistheprocessdonebyscribingthemetalpartwithmixtureofsiliconcarbide

and kerosene Pump assembly and inspection Pipe bending Valve body assembly

DistributeassemblyPipingontomachine

TAILSTOCKASSEMBLY

SleeveclampingRollerassembly=Topandclampingassembly

SWIVELASSEMBLY

HEADSTOCKASSMBLY

Headstock pre assembly Saddle balancing and pulley balancing Break assembly

Clutch assembly Lubrication distributes Dial assembly Head stock control

assemblyHeadstockgroupassembly

HEADSTOCKINSPECTION

CheckingnoiselevelCheckingmainspindleHeadstocklubrication

FINALASSEMBLY

Frontworkontobed

SpindleapronassemblyFeedboxassemblyLeadscrew,frictioncone,controlrod

andbearingassemblySupportassemblyRackassembly

TOPWORKONHEAD:

HeadstockpermeatingTailstockassemblyCrossslideassemblyswivelassembly

andit'sreading

QUADRENTBOXASSEMBLY

PickofgearswithdifferentgearratioscanbefittedatquadrantForfeedsasperthe

requirementandatkeyisusedtoshearithighloadoccur

MAJORMOUTING

Dept.of Mechanical Engg

26

AWH PTC

In-Plant Training Report 2015-16

Pulleymotored.

MACHINES

SurfacegrindingTapergrindingTurninglatheMillingmachine

VARIENTSOFNH/NLASSEMBLY

Bed length wise1,1.5,2,3....etc Gap bed straight bed Hardness Centre height(nh

22,nh26,nh32)Headstock(A26,A28)Motorspeed(high/low)

PROTECTINGASSEMBLY

FrontcoverNameplateChiptrayWiperSplashguardsHydraulictankassembly

11.CONCLUSION

The machine tool industry is experiencing both evolutionary and revolutionary

change.Keycomponentssuchasspindlesandmotorsareimprovingincrementallywhile

researchesproposeradicalnewdesignsforbearingandmachinetoolconfiguration.HMTis

theleadingmachinetoolmanufacturingcompanyinIndia.Thecompanyhastofacetough

competitionfromvariouscompanies.Eveninthemidstoftoughcompetitionfromgiantsit

stillhasauniquereputationofbeingtheproducerofaqualityproduct.Eventhoughthe

producthasgoodwillandgooddemand,therecordshowsthatthecompanyisrunningon

loss.Therearemanyfactors,whichcontributestothelossofthecompany.

1itwasawonderfulexperienceforallofushavingourfirstindustrialHMTMachinetools

Ltd.

2.Realizedtheexperienceofteamwork.

3.Gettheknowledgeofaproductioncompany.

4.Gettheknowledgeofworkingofmachineryinthecompany.

5.GetthelittleknowledgeofCNCmachineworking.6Goodexperienceoftheproductionof

machinetools.

Dept.of Mechanical Engg

27

AWH PTC

Potrebbero piacerti anche

- Engineering Applications: A Project Resource BookDa EverandEngineering Applications: A Project Resource BookValutazione: 2.5 su 5 stelle2.5/5 (1)

- SH Bearings A 1 August 2017Documento8 pagineSH Bearings A 1 August 2017rohanNessuna valutazione finora

- Top Global Contractors SourcebookDocumento59 pagineTop Global Contractors SourcebookThomas ReubenNessuna valutazione finora

- Need For Strengthening Automobile Industry in EthiopiaDocumento5 pagineNeed For Strengthening Automobile Industry in EthiopiaIJMERNessuna valutazione finora

- Automobile & Auto Components Policy 2015-20 of Andhra PradeshDocumento19 pagineAutomobile & Auto Components Policy 2015-20 of Andhra PradeshHarshith TammuNessuna valutazione finora

- Meditaciones Diarias THOMAS PRINTZDocumento100 pagineMeditaciones Diarias THOMAS PRINTZCristian Andres Araya CisternasNessuna valutazione finora

- Seven Ocean - EquipmentDocumento9 pagineSeven Ocean - EquipmentsdanishrizviNessuna valutazione finora

- Global ProjectDocumento36 pagineGlobal ProjectSrinivasan KasthuriNessuna valutazione finora

- Furniture Pearl State of The Sector Report 2005 - SmallDocumento147 pagineFurniture Pearl State of The Sector Report 2005 - SmallKatya TarigaNessuna valutazione finora

- As 4024.3101-2008 Safety of Machinery Materials Cutting - Milling Machines (Including Boring Machines) - SafeDocumento7 pagineAs 4024.3101-2008 Safety of Machinery Materials Cutting - Milling Machines (Including Boring Machines) - SafeSAI Global - APACNessuna valutazione finora

- Project Work On Textile IndustryDocumento36 pagineProject Work On Textile Industrybabu_910% (1)

- Retail Food Sector Growth in IndonesiaDocumento28 pagineRetail Food Sector Growth in IndonesiaSiPoedjangga TjintaNessuna valutazione finora

- 2017-05-11 - Moneysaver - Lewis-Clark EditionDocumento16 pagine2017-05-11 - Moneysaver - Lewis-Clark EditionDavid ArndtNessuna valutazione finora

- Letterhead - Singbuild - Sengkang Notice-For BLK 433A R1Documento1 paginaLetterhead - Singbuild - Sengkang Notice-For BLK 433A R1Jeff JiaNessuna valutazione finora

- AS 4921-2003 (Reference Use Only) General Conditions of Contract For The Provision of Asset Maintenance and S PDFDocumento7 pagineAS 4921-2003 (Reference Use Only) General Conditions of Contract For The Provision of Asset Maintenance and S PDFSAI Global - APACNessuna valutazione finora

- Institution (Date From - Date To) Degree(s) or Diploma(s) ObtainedDocumento8 pagineInstitution (Date From - Date To) Degree(s) or Diploma(s) ObtainedBraidi georgesNessuna valutazione finora

- WTO Agrees Global Trade Deal Worth $1tnDocumento37 pagineWTO Agrees Global Trade Deal Worth $1tnMelwyn CardozaNessuna valutazione finora

- Manufacturing Quality Investigation of EPS Block With Homogeous TestDocumento10 pagineManufacturing Quality Investigation of EPS Block With Homogeous Testderim_Nessuna valutazione finora

- Organic Composts, Plant Raising Media and MulchesDocumento16 pagineOrganic Composts, Plant Raising Media and MulchesreadalotbutnowisdomyetNessuna valutazione finora

- Swiss Textile Machinery Export StrengthDocumento20 pagineSwiss Textile Machinery Export StrengthKomol KabirNessuna valutazione finora

- United States District Court For The District of Puerto RicoDocumento59 pagineUnited States District Court For The District of Puerto Ricohappiness ElemNessuna valutazione finora

- Furn Best ManufacturingDocumento11 pagineFurn Best ManufacturingAbdullah BawzeerNessuna valutazione finora

- The Use of Post Consumer Wood Waste For The Production of Wood Plastic Composites: A ReviewDocumento15 pagineThe Use of Post Consumer Wood Waste For The Production of Wood Plastic Composites: A ReviewShahid MehmoodNessuna valutazione finora

- International Well Control Forum LocationsDocumento15 pagineInternational Well Control Forum LocationsEbuka Nkem OzughaNessuna valutazione finora

- Qualitas Insurance USA Enews - 2014 - 03Documento7 pagineQualitas Insurance USA Enews - 2014 - 03Jim LargeNessuna valutazione finora

- GCSR Projrct ImpDocumento176 pagineGCSR Projrct ImpParmar Nirav A.100% (1)

- Autopipe Spring Hanger Manufacturer ListDocumento2 pagineAutopipe Spring Hanger Manufacturer ListBabyface888Nessuna valutazione finora

- 08-30-2016 ECF 1158 USA V A BUNDY Et Al - Amended Exhibit List by USADocumento31 pagine08-30-2016 ECF 1158 USA V A BUNDY Et Al - Amended Exhibit List by USAJack RyanNessuna valutazione finora

- Sample Project of The Month 01Documento46 pagineSample Project of The Month 01Nana Melani Astari PutriNessuna valutazione finora

- Biotechnology in Korea 2013Documento30 pagineBiotechnology in Korea 2013decker_bptcNessuna valutazione finora

- Small and Medium Business in USADocumento18 pagineSmall and Medium Business in USABhargav ChaitanyaNessuna valutazione finora

- 2nd International Congress Seafood Technology PDFDocumento250 pagine2nd International Congress Seafood Technology PDFRaul UlfeNessuna valutazione finora

- App D SuppliersDocumento4 pagineApp D SuppliersJoe ClarkeNessuna valutazione finora

- 2nd International Congress Seafood Technology PDFDocumento250 pagine2nd International Congress Seafood Technology PDFsheriefmuhammedNessuna valutazione finora

- Mechanical Trades Preferred Manufacturers List August 2012Documento17 pagineMechanical Trades Preferred Manufacturers List August 2012Nabil RamehNessuna valutazione finora

- EU-Korea FTA - Key BenefitsDocumento4 pagineEU-Korea FTA - Key BenefitsHyeji Giselle LeeNessuna valutazione finora

- IVCO Defence Contractor Guidance Oct 2012U PDFDocumento26 pagineIVCO Defence Contractor Guidance Oct 2012U PDFmkivNessuna valutazione finora

- Ethical Issues in Vietnam's Seafood IndustryDocumento5 pagineEthical Issues in Vietnam's Seafood IndustrytoanvmpetrologxNessuna valutazione finora

- As 2514-1999 Drying Cabinets For Medical EquipmentDocumento8 pagineAs 2514-1999 Drying Cabinets For Medical EquipmentSAI Global - APACNessuna valutazione finora

- Usfts SPDDocumento355 pagineUsfts SPDford7451Nessuna valutazione finora

- Address Operating Hours Store Format Telephone Number (S)Documento10 pagineAddress Operating Hours Store Format Telephone Number (S)CleoNessuna valutazione finora

- Universal Industrial Plants Manufacturing Co PLTD Delhi IndiaDocumento10 pagineUniversal Industrial Plants Manufacturing Co PLTD Delhi IndiaUniversal Industrial Plants Manufacturing Co. (P) LtdNessuna valutazione finora

- Automobile IndustryDocumento22 pagineAutomobile IndustryKoshy Abraham KaithackalNessuna valutazione finora

- Wool 2Documento72 pagineWool 2Geetanajli GirdharNessuna valutazione finora

- De-Coding Seafood Eco-Labels: How The European Commission Can Help Consumers Access Sustainable SeafoodDocumento24 pagineDe-Coding Seafood Eco-Labels: How The European Commission Can Help Consumers Access Sustainable SeafoodFood and Water WatchNessuna valutazione finora

- Sol 001 031Documento106 pagineSol 001 031Joanna GohNessuna valutazione finora

- Atlas Product ManualDocumento165 pagineAtlas Product ManualAndrew WallworkNessuna valutazione finora

- Construction Equipment: September 2009Documento34 pagineConstruction Equipment: September 2009Dhruv DaveNessuna valutazione finora

- Vietnam Textile and Garment Comprehensive ReportDocumento6 pagineVietnam Textile and Garment Comprehensive ReportAnonymous hXUhpe7SNessuna valutazione finora

- 3rd Annual MEA Insurance 2013Documento6 pagine3rd Annual MEA Insurance 2013rameem_mohammedNessuna valutazione finora

- 7-Eleven Singapore Store Address List As at 1 January 2009: Store No. Area Tel/Fax Address P.CodeDocumento18 pagine7-Eleven Singapore Store Address List As at 1 January 2009: Store No. Area Tel/Fax Address P.CodeKaushik DeNessuna valutazione finora

- QWRDocumento4 pagineQWRkonainglincho001Nessuna valutazione finora

- Welding Consumables-Stainless SteelDocumento27 pagineWelding Consumables-Stainless SteelibicengNessuna valutazione finora

- Pharmaceutical Sector in PakistanDocumento15 paginePharmaceutical Sector in PakistanAamir Shehzad100% (1)

- As 4242-1994 Earth-Moving Machinery and Ancillary Equipment For Use in Mines - Electrical Wiring Systems at eDocumento7 pagineAs 4242-1994 Earth-Moving Machinery and Ancillary Equipment For Use in Mines - Electrical Wiring Systems at eSAI Global - APACNessuna valutazione finora

- Types of Heavy EquipmentDocumento2 pagineTypes of Heavy EquipmentAngel MangoNessuna valutazione finora

- Food Report CGI Hong KongDocumento84 pagineFood Report CGI Hong Kongmehmetredd100% (1)

- HMTDocumento26 pagineHMTGanesh B NairNessuna valutazione finora

- HMT Training Report PDFDocumento40 pagineHMT Training Report PDFMohammedNessuna valutazione finora

- Industriall Training Report HMT PinjoreDocumento49 pagineIndustriall Training Report HMT PinjoreJaskiratSingh100% (1)

- 3Documento19 pagine3Safalsha BabuNessuna valutazione finora

- Super ReportDocumento21 pagineSuper ReportSafalsha BabuNessuna valutazione finora

- SuperDocumento21 pagineSuperSafalsha BabuNessuna valutazione finora

- Transport Airplane, Which Is Purposely Deemed To Exploit Ground-Effect (8) - Some GroundDocumento14 pagineTransport Airplane, Which Is Purposely Deemed To Exploit Ground-Effect (8) - Some GroundSafalsha BabuNessuna valutazione finora

- Wing-In-ground-effect Craft A Case Study in AerodyDocumento5 pagineWing-In-ground-effect Craft A Case Study in AerodySafalsha BabuNessuna valutazione finora

- Awh Polytechnic College: Seminar ReportDocumento6 pagineAwh Polytechnic College: Seminar ReportSafalsha BabuNessuna valutazione finora

- ThedDocumento15 pagineThedSafalsha BabuNessuna valutazione finora

- CRDocumento17 pagineCRSafalsha BabuNessuna valutazione finora

- Axial Field Electrical MachinesDocumento20 pagineAxial Field Electrical Machinesవారణాసిరవిసత్యలక్ష్మీనరసింహ. శాస్త్రి100% (1)

- S A Niknamandv songmeneINLACO2013Documento11 pagineS A Niknamandv songmeneINLACO2013Safalsha BabuNessuna valutazione finora

- Sanu 39Documento5 pagineSanu 39Safalsha BabuNessuna valutazione finora

- DynaDocumento19 pagineDynaSafalsha BabuNessuna valutazione finora

- Gyrobus Seminar Report Details Early Electric BusDocumento24 pagineGyrobus Seminar Report Details Early Electric BusVara Lakshmi100% (1)

- NBCDocumento27 pagineNBCSafalsha BabuNessuna valutazione finora

- Cryogenic Materials and Circuit Integration For Quantum ComputersDocumento15 pagineCryogenic Materials and Circuit Integration For Quantum ComputersSafalsha BabuNessuna valutazione finora

- Chapter 1Documento17 pagineChapter 1Safalsha BabuNessuna valutazione finora

- Ece Free Space Optics Report PDFDocumento24 pagineEce Free Space Optics Report PDFBhavya PatelNessuna valutazione finora

- NafihDocumento6 pagineNafihSafalsha BabuNessuna valutazione finora

- SuperadobeDocumento27 pagineSuperadobeSafalsha BabuNessuna valutazione finora

- Fig 1.1 Axial-Field Electrical MachineDocumento26 pagineFig 1.1 Axial-Field Electrical MachineSafalsha BabuNessuna valutazione finora

- The Design and Fabrication of An Improved Diesel Powered Hydraulic Red Brick Molding MachineDocumento8 pagineThe Design and Fabrication of An Improved Diesel Powered Hydraulic Red Brick Molding MachineSafalsha BabuNessuna valutazione finora

- SreenathDocumento6 pagineSreenathSafalsha BabuNessuna valutazione finora

- Business Process Reengineering: A Recent Review: December 2014Documento29 pagineBusiness Process Reengineering: A Recent Review: December 2014muhsin alamNessuna valutazione finora

- Ece Free Space OpticsDocumento14 pagineEce Free Space OpticsSafalsha BabuNessuna valutazione finora

- Engine Heat Sink Thermal Energy Recovery SystemDocumento10 pagineEngine Heat Sink Thermal Energy Recovery SystemSafalsha BabuNessuna valutazione finora

- Axial Field Electrical MachinesDocumento20 pagineAxial Field Electrical Machinesవారణాసిరవిసత్యలక్ష్మీనరసింహ. శాస్త్రి100% (1)

- MUHAMMED - ASHIQ PT - Resume - 02-02-2023-13-23-28Documento1 paginaMUHAMMED - ASHIQ PT - Resume - 02-02-2023-13-23-28Safalsha BabuNessuna valutazione finora

- Heat SinkDocumento14 pagineHeat SinkSafalsha BabuNessuna valutazione finora

- 2Documento18 pagine2Safalsha BabuNessuna valutazione finora

- Ece Free Space Optics Report PDFDocumento24 pagineEce Free Space Optics Report PDFBhavya PatelNessuna valutazione finora

- Reverse Engineering Project - Carleton University - 2009Documento8 pagineReverse Engineering Project - Carleton University - 2009Noshin NugawelaNessuna valutazione finora

- CRA Glossery of TermsDocumento11 pagineCRA Glossery of TermsDC1234Nessuna valutazione finora

- Effect of Tempering On The Microstructure and Mechanical Properties of Resistance of Spot Welded DP 980 SteelDocumento6 pagineEffect of Tempering On The Microstructure and Mechanical Properties of Resistance of Spot Welded DP 980 SteelShameekaNessuna valutazione finora

- Honeywell Purge Timer S427B, CDocumento2 pagineHoneywell Purge Timer S427B, CRyan TrialsNessuna valutazione finora

- Presentation - John LangleyDocumento30 paginePresentation - John LangleyReza GholamiNessuna valutazione finora

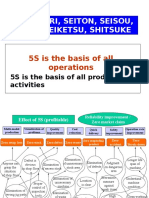

- 5 S Seiri, Seiton, Seisou, Seiketsu, Shitsuke: 5S Is The Basis of All OperationsDocumento21 pagine5 S Seiri, Seiton, Seisou, Seiketsu, Shitsuke: 5S Is The Basis of All OperationsAtul SharmaNessuna valutazione finora

- General Electric y EmdDocumento6 pagineGeneral Electric y EmdJimenez Valencia100% (1)

- To What Extent Is Hosting The Olympic Games Socio Economically Beneficial To The Host Country, Comparing The London 2012 and Rio 2016 GamesDocumento60 pagineTo What Extent Is Hosting The Olympic Games Socio Economically Beneficial To The Host Country, Comparing The London 2012 and Rio 2016 GamesOmar KabirNessuna valutazione finora

- Bangladesh & Global Studies Class NotesDocumento3 pagineBangladesh & Global Studies Class NotesanonymousNessuna valutazione finora

- Thermal Analysis of Cutting Tools Using Different Cutting FluidsDocumento45 pagineThermal Analysis of Cutting Tools Using Different Cutting FluidspothanNessuna valutazione finora

- AAL-Meritor Operations Case Study For Naissance 2012Documento11 pagineAAL-Meritor Operations Case Study For Naissance 2012Gaurav GuptaNessuna valutazione finora

- Chapter Two Traditional Material Removal Processes MachiningDocumento21 pagineChapter Two Traditional Material Removal Processes MachiningkidusNessuna valutazione finora

- Director Facilities Management in Boston MA Resume Jana DenglerDocumento2 pagineDirector Facilities Management in Boston MA Resume Jana DenglerJanaDengler100% (1)

- BT2 ConcreteDocumento7 pagineBT2 ConcreteMicah Dianne DizonNessuna valutazione finora

- WI 190 004 Cosmetics Acceptability Rev A PDFDocumento18 pagineWI 190 004 Cosmetics Acceptability Rev A PDFUlysses CarrascoNessuna valutazione finora

- An Introduction To International Economics: Dominick Salvatore John Wiley & Sons, IncDocumento51 pagineAn Introduction To International Economics: Dominick Salvatore John Wiley & Sons, IncTuyết TrinhNessuna valutazione finora

- Fuel From Plastic WasteDocumento32 pagineFuel From Plastic WasteMANN BATTISE100% (1)

- Welcome: Refinery Overview & ConfigurationDocumento51 pagineWelcome: Refinery Overview & ConfigurationHarish GojiyaNessuna valutazione finora

- Expert-Reconditioning Reduces CostsDocumento97 pagineExpert-Reconditioning Reduces CostsBryanNevadoNessuna valutazione finora

- Graham v. John Deere, 735Documento1 paginaGraham v. John Deere, 735kprasannanNessuna valutazione finora

- A32Documento2 pagineA32Ivan GarzonNessuna valutazione finora

- 4 Process Layout-Ch 6 (Stevenson)Documento51 pagine4 Process Layout-Ch 6 (Stevenson)tahmid quayumNessuna valutazione finora

- Reforming Labour Bro KingDocumento4 pagineReforming Labour Bro KingThepatternsNessuna valutazione finora

- Polysafe Standard PUR PS PDFDocumento1 paginaPolysafe Standard PUR PS PDFFloorkitNessuna valutazione finora

- Cir 041 - Information of Member MillsDocumento6 pagineCir 041 - Information of Member MillsAzhar RanaNessuna valutazione finora

- FSSC Document KitDocumento11 pagineFSSC Document KitDarja SubotičkiNessuna valutazione finora

- Ryder Consolidates WhirlpoolDocumento2 pagineRyder Consolidates WhirlpoolMayank VermaNessuna valutazione finora

- Taig Lathe ManualDocumento12 pagineTaig Lathe Manualpeter smithNessuna valutazione finora

- PFR Koyali-Ahmednagar PipelineDocumento4 paginePFR Koyali-Ahmednagar PipelineKalai SelvanNessuna valutazione finora

- Nilkamal Presentation 2011 FinalDocumento33 pagineNilkamal Presentation 2011 Finalbhushii_jagsNessuna valutazione finora

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityDa EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityValutazione: 5 su 5 stelle5/5 (1)

- Algorithms to Live By: The Computer Science of Human DecisionsDa EverandAlgorithms to Live By: The Computer Science of Human DecisionsValutazione: 4.5 su 5 stelle4.5/5 (722)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyDa EverandChip War: The Quest to Dominate the World's Most Critical TechnologyValutazione: 4.5 su 5 stelle4.5/5 (227)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessDa EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNessuna valutazione finora

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveDa EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNessuna valutazione finora

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldDa EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldValutazione: 4.5 su 5 stelle4.5/5 (54)

- Generative AI: The Insights You Need from Harvard Business ReviewDa EverandGenerative AI: The Insights You Need from Harvard Business ReviewValutazione: 4.5 su 5 stelle4.5/5 (2)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideDa EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideValutazione: 5 su 5 stelle5/5 (2)

- 8-Bit Apocalypse: The Untold Story of Atari's Missile CommandDa Everand8-Bit Apocalypse: The Untold Story of Atari's Missile CommandValutazione: 3.5 su 5 stelle3.5/5 (10)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseDa EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseValutazione: 3.5 su 5 stelle3.5/5 (12)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldDa EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldValutazione: 4.5 su 5 stelle4.5/5 (107)

- Everybody Lies: Big Data, New Data, and What the Internet Can Tell Us About Who We Really AreDa EverandEverybody Lies: Big Data, New Data, and What the Internet Can Tell Us About Who We Really AreValutazione: 4.5 su 5 stelle4.5/5 (911)

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesDa EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesValutazione: 4.5 su 5 stelle4.5/5 (12)

- Dark Data: Why What You Don’t Know MattersDa EverandDark Data: Why What You Don’t Know MattersValutazione: 4.5 su 5 stelle4.5/5 (3)

- So You Want to Start a Podcast: Finding Your Voice, Telling Your Story, and Building a Community that Will ListenDa EverandSo You Want to Start a Podcast: Finding Your Voice, Telling Your Story, and Building a Community that Will ListenValutazione: 4.5 su 5 stelle4.5/5 (35)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewDa EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewValutazione: 4.5 su 5 stelle4.5/5 (104)

- Mastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)Da EverandMastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)Nessuna valutazione finora

- 97 Principles for Software Architects: Axioms for software architecture and development written by industry practitionersDa Everand97 Principles for Software Architects: Axioms for software architecture and development written by industry practitionersValutazione: 5 su 5 stelle5/5 (21)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- AI Money Machine: Unlock the Secrets to Making Money Online with AIDa EverandAI Money Machine: Unlock the Secrets to Making Money Online with AINessuna valutazione finora

- AI and Machine Learning for Coders: A Programmer's Guide to Artificial IntelligenceDa EverandAI and Machine Learning for Coders: A Programmer's Guide to Artificial IntelligenceValutazione: 4 su 5 stelle4/5 (2)

- Make Money with ChatGPT: Your Guide to Making Passive Income Online with Ease using AI: AI Wealth MasteryDa EverandMake Money with ChatGPT: Your Guide to Making Passive Income Online with Ease using AI: AI Wealth MasteryNessuna valutazione finora