Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Apoy

Caricato da

markalvinbon0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni2 pagineFire

Titolo originale

apoy

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFire

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni2 pagineApoy

Caricato da

markalvinbonFire

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

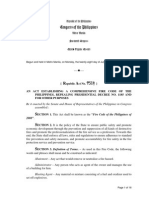

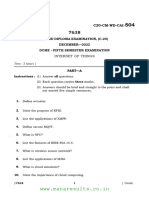

fire code of the philippines

phil. national drinking water standards

batas pambansa 344 (for Persons with Disabilities or PWD)

commercial sizes ng pipes (plastic, copper, cast iron, etc)

color coding ng piping

plumbing tools and uses

pH

sanitation code of the phlippines and its IRR

Sanitary eng'g law

master plumbing law

definition of uPVC, PE.HDPE, PE etc

plumbing design & estimate by Fajardo (lumabas yung hotwater tank sizes, p 259.)

1.PVC : Polyvinyl chloride.

2.uPVC : Unplasticized polyvinyl chloride .

3.HDPE:High Density Polyethylene.

4.RCC : Reinforced Cement Concrete.

5.DIP : Ductile Iron Pipe.

Materials used

ABS (acrylonitrile butadiene styrene)

UPVC (unplasticized polyvinyl chloride)

CPVC (post chlorinated polyvinyl chloride)

PB-1 (polybutylene)

PP (polypropylene)

PE (polyethylene) also known as LDPE and HDPE (low and high density)

PVDF (polyvinylidene fluoride)

PVC (polyvinyl chloride)

Material characteristics

ABS (acrylonitrile butadiene styrene)

ABS is used for the conveyance of potable water, slurries and chemicals. Most commonly used for

DWV (drain-waste-vent) applications. It has a wide temperature range, from -40C to +60C.

UPVC (unplasticized polyvinyl chloride) and CPVC (post chlorinated polyvinyl chloride)

UPVC has excellent chemical resistance across its operating temperature range, with a broad band of

operating pressures. Due to its long-term strength characteristics, high stiffness and cost effectiveness,

UPVC systems account for a large proportion of plastic piping installations.

CPVC is resistant to many acids, bases, salts, paraffinic hydrocarbons, halogens and alcohols. It is not

resistant to solvents, aromatics and some chlorinated hydrocarbons. It can carry higher temperature

liquids than pvc.

PB-1 (polybutylene)

PB-1 is used in pressure piping systems for hot and cold potable water, pre-insulated district heating

networks, and surface heating and cooling systems. Key properties are weldability, temperature

resistance, flexibility and high hydrostatic pressure resistance. One standard type, PB 125, has a

minimum required strength (MRS) of 12.5 MPa. It also has low noise transmission, low linear thermal

expansion, no corrosion and calcification.

PB-1 piping systems are no longer sold in North America. Market share in Europe and Asia is small

but steadily growing. In some markets, e.g. Kuwait, UK, Korea and Spain, PB-1 has a strong position.

PP (polypropylene)

Polypropylene is suitable for use with foodstuffs, potable and ultra pure waters, as well as within the

pharmaceutical and chemical industries.

PE (polyethylene)

Polyethylene has been successfully used for the safe conveyance of potable and waste water,

hazardous waste, and compressed gases for many years. Two variants are HDPE (high-density

polyethylene) and the more heat resistant PEX (cross-linked polyethylene).

PVDF (polyvinylidene fluoride)

PVDF has excellent chemical resistance which means that it is widely used in the chemical industry as

a piping system for aggressive liquids.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Personal Protective Equipment Policy - FinalDocumento6 paginePersonal Protective Equipment Policy - FinalmarkalvinbonNessuna valutazione finora

- Ethics and Accountability The Philippine Experrience by CSCDocumento5 pagineEthics and Accountability The Philippine Experrience by CSCLinda Himoldang Marcaida100% (2)

- PropertiesDocumento6 paginePropertiesmarkalvinbonNessuna valutazione finora

- Ethics and Accountability The Philippine Experrience by CSCDocumento5 pagineEthics and Accountability The Philippine Experrience by CSCLinda Himoldang Marcaida100% (2)

- Impacts of EthicsDocumento15 pagineImpacts of EthicsmarkalvinbonNessuna valutazione finora

- Reducing Avoidable ConflictDocumento16 pagineReducing Avoidable ConflictmarkalvinbonNessuna valutazione finora

- Boysen Paints Calculator-1550805650057Documento1 paginaBoysen Paints Calculator-1550805650057markalvinbonNessuna valutazione finora

- Questions and AnswersDocumento9 pagineQuestions and AnswersmarkalvinbonNessuna valutazione finora

- ThermodynamicsDocumento2 pagineThermodynamicsmarkalvinbonNessuna valutazione finora

- RA 1378 - Master Plumber LawDocumento5 pagineRA 1378 - Master Plumber LawFzoe YambaoNessuna valutazione finora

- ATOM Install Notes ReadmeDocumento2 pagineATOM Install Notes ReadmeNik Syukriah AminNessuna valutazione finora

- Thermodynamics 2Documento6 pagineThermodynamics 2markalvinbon0% (1)

- Refresher MathDocumento3 pagineRefresher Mathrmgc1003Nessuna valutazione finora

- Technical Specifications - PlumbingDocumento19 pagineTechnical Specifications - PlumbingVicVicNessuna valutazione finora

- PH Code On Sanitation ChapterVII IRRDocumento42 paginePH Code On Sanitation ChapterVII IRRmarkalvinbonNessuna valutazione finora

- Sanitary Eng'g LawDocumento5 pagineSanitary Eng'g LawBelle Micole EcleoNessuna valutazione finora

- R.A. 7920Documento21 pagineR.A. 7920Jezreel P. ImportanteNessuna valutazione finora

- HLURBDocumento16 pagineHLURBAlex SenajonNessuna valutazione finora

- SpesDocumento1 paginaSpesmarkalvinbonNessuna valutazione finora

- Plumbing LMDocumento131 paginePlumbing LMmarkalvinbon100% (1)

- Plumbing Tools and Equipment 1Documento62 paginePlumbing Tools and Equipment 1markalvinbonNessuna valutazione finora

- Right of PWD'sDocumento23 pagineRight of PWD'smarkalvinbonNessuna valutazione finora

- Pipe Labeling To Ansi Asme A13.1Documento1 paginaPipe Labeling To Ansi Asme A13.1Anindito NurprabowoNessuna valutazione finora

- Fire Code of The Philppines 2008 PDFDocumento16 pagineFire Code of The Philppines 2008 PDFjpkhepNessuna valutazione finora

- Fluid ReferenceDocumento19 pagineFluid ReferencemarkalvinbonNessuna valutazione finora

- Fluid ReferenceDocumento19 pagineFluid ReferencemarkalvinbonNessuna valutazione finora

- Hotel Water Supply PlanDocumento1 paginaHotel Water Supply PlanmarkalvinbonNessuna valutazione finora

- Hotel Structl FoundationDocumento1 paginaHotel Structl FoundationmarkalvinbonNessuna valutazione finora

- Fluid ReferenceDocumento19 pagineFluid ReferencemarkalvinbonNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Brother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDocumento123 pagineBrother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDuplessisNessuna valutazione finora

- PRELEC 1 Updates in Managerial Accounting Notes PDFDocumento6 paginePRELEC 1 Updates in Managerial Accounting Notes PDFRaichele FranciscoNessuna valutazione finora

- Faculty of Business and Law Assignment Brief Mode E and R RegulationsDocumento4 pagineFaculty of Business and Law Assignment Brief Mode E and R RegulationsSyeda Sana Batool RizviNessuna valutazione finora

- Chapter 11 Walter Nicholson Microcenomic TheoryDocumento15 pagineChapter 11 Walter Nicholson Microcenomic TheoryUmair QaziNessuna valutazione finora

- Risk and Uncertainty in Estimating and TenderingDocumento16 pagineRisk and Uncertainty in Estimating and TenderingHaneefa ChNessuna valutazione finora

- Musings On A Rodin CoilDocumento2 pagineMusings On A Rodin CoilWFSCAO100% (1)

- Integrated Building Managemnt SystemDocumento8 pagineIntegrated Building Managemnt SystemRitikaNessuna valutazione finora

- Sec2 8 PDFDocumento3 pagineSec2 8 PDFpolistaNessuna valutazione finora

- 7933-Article Text-35363-1-10-20230724Documento8 pagine7933-Article Text-35363-1-10-20230724Ridho HidayatNessuna valutazione finora

- Bondoc Vs PinedaDocumento3 pagineBondoc Vs PinedaMa Gabriellen Quijada-TabuñagNessuna valutazione finora

- Nguyen Dang Bao Tran - s3801633 - Assignment 1 Business Report - BAFI3184 Business FinanceDocumento14 pagineNguyen Dang Bao Tran - s3801633 - Assignment 1 Business Report - BAFI3184 Business FinanceNgọc MaiNessuna valutazione finora

- SEBI Circular Dated 22.08.2011 (Cirmirsd162011)Documento3 pagineSEBI Circular Dated 22.08.2011 (Cirmirsd162011)anantNessuna valutazione finora

- Rideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardDocumento45 pagineRideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardpaolaNessuna valutazione finora

- Electric Arc Furnace STEEL MAKINGDocumento28 pagineElectric Arc Furnace STEEL MAKINGAMMASI A SHARAN100% (3)

- WWW - Manaresults.co - In: Internet of ThingsDocumento3 pagineWWW - Manaresults.co - In: Internet of Thingsbabudurga700Nessuna valutazione finora

- Mix Cases UploadDocumento4 pagineMix Cases UploadLu CasNessuna valutazione finora

- A Study On Effective Training Programmes in Auto Mobile IndustryDocumento7 pagineA Study On Effective Training Programmes in Auto Mobile IndustrySAURABH SINGHNessuna valutazione finora

- Yamaha F200 Maintenance ScheduleDocumento2 pagineYamaha F200 Maintenance ScheduleGrady SandersNessuna valutazione finora

- CE5215-Theory and Applications of Cement CompositesDocumento10 pagineCE5215-Theory and Applications of Cement CompositesSivaramakrishnaNalluriNessuna valutazione finora

- Reading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1Documento27 pagineReading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1shehla khanNessuna valutazione finora

- How To Attain Success Through The Strength of The Vibration of NumbersDocumento95 pagineHow To Attain Success Through The Strength of The Vibration of NumberszahkulNessuna valutazione finora

- For Email Daily Thermetrics TSTC Product BrochureDocumento5 pagineFor Email Daily Thermetrics TSTC Product BrochureIlkuNessuna valutazione finora

- GSMDocumento11 pagineGSMLinduxNessuna valutazione finora

- Alphacenter Utilities: Installation GuideDocumento24 pagineAlphacenter Utilities: Installation GuideJeffersoOnn JulcamanyanNessuna valutazione finora

- BS en 118-2013-11Documento22 pagineBS en 118-2013-11Abey VettoorNessuna valutazione finora

- Fcode 54 en El SytucDocumento2 pagineFcode 54 en El SytucAga MenonNessuna valutazione finora

- CORDLESS PLUNGE SAW PTS 20-Li A1 PDFDocumento68 pagineCORDLESS PLUNGE SAW PTS 20-Li A1 PDFΑλεξης ΝεοφυτουNessuna valutazione finora

- WPGPipingIndex Form 167 PDFDocumento201 pagineWPGPipingIndex Form 167 PDFRaj AryanNessuna valutazione finora

- The Fundamentals of Investing PPT 2.4.4.G1Documento36 pagineThe Fundamentals of Investing PPT 2.4.4.G1Lùh HùñçhòNessuna valutazione finora

- MSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)Documento10 pagineMSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)ANNaNessuna valutazione finora