Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

KWGDL KWGDLS Agdl

Caricato da

alin.butunoi865Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

KWGDL KWGDLS Agdl

Caricato da

alin.butunoi865Copyright:

Formati disponibili

KWGDLKWGDLS & AGDL

Duplex Worm Gears

Spur

Gears

Description of duplex worm gears

The usual method of adjusting the backlash of a worm gear assembly is to modify the center distance. Once assembled, such

adjustment requires a major rework of the gearbox housing. The

Helical

Gears

use of duplex worm gears allows the backlash adjustment to be

made by axially shifting the worm. This simplifies greatly the assembly and maintenance operations. Because of the unique characteristics of the product, please take time to study its construc-

CP Racks

& Pinions

Racks

Internal

Gears

tion and proper use.

Backlash adjustment mechanism and method of adjustment

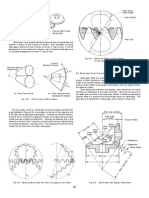

The dual-lead worm is formed to give a difference between the right tooth surface and

left tooth surface so that it provides a unique tooth profile in which the tooth thickness varies continuously, corresponding with the lead difference. (Fig.1)

The worm gear is also formed in its right and left tooth surface.

When such a worm and worm gear are set up at a constant assembly distance and

Miter

Gears

the worm is moved in the axial direction, the tooth thickness of the worm in mesh

with the worm gear changes making backlash adjustment possible.

An arrow marking on the outer circumference of the hub of the

KHK duplex worm indicates the direction of assembly as well

as acts as a guide for the backlash adjustment.

When the worm is held with arrow mark pointing right, the

tooth thickness is thinner on the right and thicker on the left.

Therefore, moving the worm to the right causes the thicker

teeth to come into actual engagement with the worm gear,

thereby reducing the backlash. (Fig.2)

Bevel

Gears

(a tooth surface pitch) (b tooth surface pitch)

a tooth surface

(Nominal surface)

Other

Bevel

Worm

Products Gearboxes Gear Pair

Screw

Gears

b tooth surface

Fig.1

CAUTIONThe amount of change in backlash ( j mm) in relation to the axial movement of

the duplex worm shaft (V mm) can be calculated from the formula below.

j 2V

mb ma

ma mb

Reference tooth

Moving the worm in the direction of the

arrow causes the backlash to decrease.

Fig. 2

Where

m a Nominal Axial Module 0.01 Nominal Axial Module

m b Nominal Axial Module 0.01 Nominal Axial Module

CAUTION The KHK duplex worm is designed so that, for all

modules, the backlash reduces by 0.02 mm when

the worm is shifted 1 mm.

Application Examples

Adjusting Screw

Adjustment by using Screws *

514

Adjusting Shim

Adjustment by using Shims *

* The illustration above is a design example, not a design for machinery or a device in actual use.

KWGDLKWGDLS & AGDL

Duplex Worm Gears

Point of caution during assembly

Spur

Gears

KHK duplex worm gears differs in module between the right and left

tooth surface and, therefore, you must orient the worm and worm

wheel properly. Please carefully verify the following two aspects be-

2. Verifying the reference position

A V-groove (60 , 0.3 mm deep line) on tip peripheral of the duplex worm tooth marks the reference tooth. The gear set is designated to have a backlash of nearly zero ( 0.045) when the reference tooth is positioned in alignment with the center of rota-

Reference tooth

Center distance

Reference tooth

Center distance

tion of the worm wheel with the center distance set at the value "a". (Fig.4)

Internal

Gears

Other

Bevel

Worm

Products Gearboxes Gear Pair

Arrow mark indicates the correct orientation of two gears when assembled. As shown, the two arrows must point in the same direction.

Fig. 3

Screw

Gears

Bevel

Gears

Miter

Gears

CP Racks

& Pinions

Racks

1. Verifying the orientation of assembly

An arrow indicating the orientation of assembly is stamped on both the duplex worm and worm wheel. When assembling

the worm and worm wheel, check the worm wheel of the arrow mark on the front such that the direction of arrow mark on

the worm coincides with that on the worm wheel. Should the assembly be incorrect, the center distanceawill become

larger than the normal distance, resulting in difficulty of assembly and improper gear engagement. (Fig.3)

Helical

Gears

fore proceeding with assembly.

Fig. 4

To find information on new products, see Page 6 and 7.

515

KWGDLKWGDLS

Module 1.52

Duplex Worms

Specifications

Spur

Gears

Axial

Gear teeth

Standard full depth

S

G

Reference

section of gear

Helical

Gears

W4

Catalog No.

KWGDLS1.5-R1

KWGDLS2-R1

[Caution on Product Characteristics]

Nominal axial Number of Nominal

Hand of tread

module

start

lead angle

m2

341'

Shape

1

1

326'

341'

Hub dia.

Pitch dia.

Outside dia.

Face width

Hub width

LH7

14

25

31

35

36

14

50

W4

Nominal axial Number of Nominal

Hand of tread

module

start

lead angle

m1.5

m2

Bore

Shape

R

R

Total length Shaft length (L) Neck length (L) Face width Neck length (R) Shaft length (R)

W6

W6

Total length

Pitch dia.

190

220

66

75

12

13

28

36

18

21

66

75

25

31

When the center distance is moved to reduce the backlash, the V max is the maximum amount of distance that you may shift

without causing problems with the gear mesh. The V max is not a recommended value to use for adjustment when assembling.

For W6 Shaped Gears, the tolerances of the shaft diameter are set to S +0.2 and +0.1 (+0.40 and +0.35 for the ground area).

These worms produce axial thrust forces. See page 512 for more details.

AGDL

Module 1.52

Duplex Worms Wheels

Specifications

Screw

Gears

Precision grade KHK W 002 grade 1

Reference

section of gear

Rotating plane

Gear teeth

Standard full depth

Normal

pressure angle 17 30'

Material

A

B

C

D

D

Internal

Gears

KWGDL2-R1

CP Racks

& Pinions

Racks

Tooth hardness 45 55HRC

Bevel

Gears

Miter

Gears

Vmax

SCM440

Material

Catalog No.

Other

Bevel

Worm

Products Gearboxes Gear Pair

Normal

pressure angle 17 30'

Heat treatment Thermal refined, tooth surface

induction hardened

CAC702formerly JIS ABC2)

Heat treatment

Tooth hardness

H1

Catalog No.

Reduction Nominal axial No. of

Helix angle Hand of tread Shape

ratio

module

teeth

AGDL1.5-20R1

AGDL1.5-30R1

AGDL1.5-36R1

AGDL1.5-40R1

AGDL1.5-50R1

AGDL1.5-60R1

20

30

36

40

50

60

AGDL2-20R1

AGDL2-30R1

AGDL2-36R1

AGDL2-40R1

AGDL2-50R1

AGDL2-60R1

20

30

36

40

50

60

[Caution on Product Characteristics]

516

Precision grade KHK W 001 grade 1

Bore

Hub dia.

Pitch dia.

Throat dia.

AH7

D'

34.5

49.5

58.5

64.5

79.5

94.5

14

14

14

14

14

14

10

10

10

10

10

10

18

18

18

18

18

18

15

15

15

15

15

15

m1.5

20

30

36

40

50

60

326'

326'

326'

326'

326'

326'

R

R

R

R

R

R

H1

H1

H1

H1

H1

H1

8

10

10

12

12

12

22

30

35

35

45

50

30

45

54

60

75

90

33

48

57

63

78

93

m2

20

30

36

40

50

60

341'

341'

341'

341'

341'

341'

R

R

R

R

R

R

H1

H1

H1

H1

H1

H1

12

15

15

15

15

15

33

40

45

45

50

60

40

60

72

80

100

120

44

64

76

84

104

124

Outside dia. Face width Hub width

46

66

78

86

106

126

The allowable torques shown in the table are the calculated values according to the assumed usage conditions.

Please see page 510 for more details.

Duplex worms and worm wheels must be mated in a predetermined orientation, which is indicated by the arrows.

Therefore, the arrow on the wheel does not indicate the mounting direction, but the rotating direction. Please refer to

the Application Hints on page 515.

KWGDLKWGDLS

Duplex Worms

J

M

N

G

P

Q

Spur

Gears

Helical

Gears

Vmax

W6

Position of

reference tooth

Max. allowable shift

Weight

Vmax

(kg)

22

0.21

Outside dia.

Neck dia.

Shaft dia.

Position of

reference tooth

Max. allowable shift

Weight

Vmax

(kg)

28

35

21

24

26

30

17

22

6

8

0.74

1.17

Internal

Gears

KWGDL2-R1

Catalog No.

Racks

KWGDLS1.5-R1

KWGDLS2-R1

CP Racks

& Pinions

Please readCaution on Performing Secondary Operations(Page 512) when

performing modifications and/or secondary operations for safety concerns.

Haguruma Kobo, the KHK's system for quick modification of KHK stock gears is

also available.

Due to the gear teeth being induction hardened, no secondary operations can

be performed on tooth areas including the bottom land (approx. 1 to 2 mm).

AGDL

Miter

Gears

[Caution on Secondary Operations]

Catalog No.

NOTE 1. Allowable torques for worm rotation (rpm)

Total length

Web thickness Web O.D. Mounting distance

Allowable torque (Nm)

NOTE 1

30 rpm

100 rpm 300 rpm 600 rpm 900 rpm 1200 rpm 1800 rpm

24

24

24

24

24

24

27.5

35

39.5

42.5

50

57.5

9.84

20.8

29.3

35.6

53.8

75.3

8.18

17.5

24.6

30.0

45.4

63.8

33

33

33

33

33

33

35.5

45.5

51.5

55.5

65.5

75.5

[Caution on Secondary Operations]

6.40

13.9

19.8

24.2

36.9

51.9

21.0 17.5 13.6

44.3 37.3 29.6

62.3 52.6 42.0

75.8 64.0 51.4

115

96.8 78.4

160 136 110

Backlash

Weight

(mm)

(kg)

Catalog No.

5.30

11.7

16.8

20.6

31.6

44.7

4.68

10.4

14.9

18.3

28.3

40.4

4.25

9.40

13.5

16.6

25.8

36.7

3.68

8.28

11.9

14.6

22.6

32.4

00.045

00.045

00.045

00.045

00.045

00.045

0.10

0.22

0.32

0.37

0.59

0.83

AGDL1.5-20R1

AGDL1.5-30R1

AGDL1.5-36R1

AGDL1.5-40R1

AGDL1.5-50R1

AGDL1.5-60R1

11.2

24.8

35.5

43.6

66.9

94.6

9.84

21.9

31.3

38.5

59.5

84.9

8.94

19.8

28.4

34.9

54.2

77.2

7.75

17.4

25.0

30.7

47.6

68.1

00.045

00.045

00.045

00.045

00.045

00.045

0.26

0.51

0.73

0.86

1.30

1.88

AGDL2-20R1

AGDL2-30R1

AGDL2-36R1

AGDL2-40R1

AGDL2-50R1

AGDL2-60R1

Other

Bevel

Worm

Products Gearboxes Gear Pair

Screw

Gears

Bevel

Gears

Duplex Worm Wheels

Please readCaution on Performing Secondary Operations(Page 512) when performing modifications and/or

secondary operations for safety concerns. Haguruma Kobo, the KHK's system for quick modification of KHK

stock gears is also available.

To find information on new products, see Page 6 and 7.

517

KWGDLKWGDLS

Module 2.53

Duplex Worms

Specifications

Spur

Gears

Axial

Gear teeth

Standard full depth

S

G

Reference

section of gear

Helical

Gears

W4

KWGDLS2.5-R1

KWGDLS3-R1

[Caution on Product Characteristics]

Nominal axial Number of Nominal

Hand of tread

module

start

lead angle

m2.5

m3

1

1

352'

354'

Shape

R

R

1

1

352'

354'

Hub dia.

Pitch dia.

Outside dia.

Face width

Hub width

LH7

18

20

30

35

37

44

42

50

48

54

17

20

65

74

W4

W4

Nominal axial Number of Nominal

Hand of tread

module

start

lead angle

m2.5

m3

Bore

Shape

R

R

Total length Shaft length (L) Neck length (L) Face width Neck length (R) Shaft length (R)

W6

W6

Total length

Pitch dia.

260

300

85

100

16

18

48

54

26

28

85

100

37

44

When the center distance is moved to reduce the backlash, the V max is the maximum amount of distance that you may shift

without causing problems with the gear mesh. The V max is not a recommended value to use for adjustment when assembling.

For W6 Shaped Gears, the tolerances of the shaft diameter are set to S +0.2 and +0.1 (+0.40 and +0.35 for the ground area).

These worms produce axial thrust forces. See page 512 for more details.

AGDL

Module 2.53

Bevel

Gears

Duplex Worms Wheels

Specifications

Screw

Gears

Precision grade KHK W 002 grade 1

Reference

section of gear

Rotating plane

Gear teeth

Standard full depth

Normal

pressure angle 17 30'

Material

A

B

C

D

D

Internal

Gears

KWGDL2.5-R1

KWGDL3-R1

CP Racks

& Pinions

Racks

Tooth hardness 45 55HRC

Catalog No.

Miter

Gears

Vmax

SCM440

Material

Catalog No.

Other

Bevel

Worm

Products Gearboxes Gear Pair

Normal

pressure angle 17 30'

Heat treatment Thermal refined, tooth surface

induction hardened

CAC702formerly JIS ABC2)

Heat treatment

Tooth hardness

H1

Catalog No.

Reduction Nominal axial No. of

Helix angle Hand of tread Shape

ratio

module

teeth

AGDL2.5-20R1

AGDL2.5-30R1

AGDL2.5-36R1

AGDL2.5-40R1

AGDL2.5-50R1

AGDL2.5-60R1

20

30

36

40

50

60

AGDL3-20R1

AGDL3-30R1

AGDL3-36R1

AGDL3-40R1

AGDL3-50R1

AGDL3-60R1

20

30

36

40

50

60

[Caution on Product Characteristics]

518

Precision grade KHK W 001 grade 1

Bore

Hub dia.

Pitch dia.

Throat dia.

AH7

Outside dia. Face width Hub width

D'

m2.5

20

30

36

40

50

60

352'

352'

352'

352'

352'

352'

R

R

R

R

R

R

H1

H1

H1

HB

HB

HB

15

15

15

15

15

15

40

40

45

45

60

80

50

75

90

100

125

150

55

80

95

105

130

155

57.5

82.5

97.5

107.5

132.5

157.5

22

22

22

22

22

22

15

15

15

15

15

15

m3

20

30

36

40

50

60

354'

354'

354'

354'

354'

354'

R

R

R

R

R

R

H1

H1

H1

HB

HB

HB

20

20

20

20

20

20

50

55

60

60

70

80

60

90

108

120

150

180

66

96

114

126

156

186

69

99

117

129

159

189

28

28

28

28

28

28

17

17

17

17

17

17

The allowable torques shown in the table are the calculated values according to the assumed usage conditions.

Please see page 510 for more details.

Duplex worms and worm wheels must be mated in a predetermined orientation, which is indicated by the arrows.

Therefore, the arrow on the wheel does not indicate the mounting direction, but the rotating direction. Please refer to

the Application Hints on page 515.

KWGDLKWGDLS

Duplex Worms

P

Q

J

M

Spur

Gears

Helical

Gears

Vmax

W6

Position of

reference tooth

Max. allowable shift

Weight

Vmax

(kg)

29

32

10

10

0.37

0.61

Outside dia.

Neck dia.

Shaft dia.

Position of

reference tooth

Max. allowable shift

Weight

Vmax

(kg)

42

50

30

34

36

40

29

32

10

10

2.00

2.95

Internal

Gears

KWGDL2.5-R1

KWGDL3-R1

Racks

Catalog No.

KWGDLS2.5-R1

KWGDLS3-R1

CP Racks

& Pinions

Please readCaution on Performing Secondary Operations(Page 512) when

performing modifications and/or secondary operations for safety concerns.

Haguruma Kobo, the KHK's system for quick modification of KHK stock gears is

also available.

Due to the gear teeth being induction hardened, no secondary operations can

be performed on tooth areas including the bottom land (approx. 1 to 2 mm).

AGDL

Miter

Gears

[Caution on Secondary Operations]

Catalog No.

Bevel

Gears

Duplex Worm Wheels

F

Screw

Gears

B

C

D

D

HB

CS has a sand mold casting finish.

NOTE 1. Allowable torques for worm rotation (rpm)

Total length Web thickness Web O.D. Mounting distance

37

37

37

37

37

37

(10)

(12)

(12)

(86)

(108)

(133)

45

45

45

45

45

45

(14)

(14)

(14)

(106)

(134)

(164)

[Caution on Secondary Operations]

43.5

56

63.5

68.5

81

93.5

52

67

76

82

97

112

Allowable torque (Nm)

NOTE 1

Backlash

Weight

(mm)

(kg)

38.1 31.4 24.5 20.1 17.6 16.0 13.8

80.5 67.1 53.1 44.5 39.1 35.5 30.9

113

94.5 75.5 63.8 56.0 51.0 44.3

138 115

92.4 78.3 68.8 62.7 54.4

208 174 141 120 106

97.3 84.3

291 245 198 170 152 139 121

00.045

00.045

00.045

00.045

00.045

00.045

0.45

0.88

1.25

1.14

1.93

2.90

AGDL2.5-20R1

AGDL2.5-30R1

AGDL2.5-36R1

AGDL2.5-40R1

AGDL2.5-50R1

AGDL2.5-60R1

65.0

137

193

235

355

497

00.045

00.045

00.045

00.045

00.045

00.045

0.81

1.65

2.32

2.19

3.26

4.48

AGDL3-20R1

AGDL3-30R1

AGDL3-36R1

AGDL3-40R1

AGDL3-50R1

AGDL3-60R1

30 rpm

100 rpm 300 rpm 600 rpm 900 rpm 1200 rpm 1800 rpm

53.3

114

160

195

295

415

41.5

90.0

128

157

239

336

33.8 29.5 26.9 22.8

74.7 65.5 59.5 51.2

107

93.8 85.6 73.4

131 115 105

90.1

202 178 163 140

285 254 233 200

Catalog No.

Other

Bevel

Worm

Products Gearboxes Gear Pair

CS

CS

(I)

(H)

Please readCaution on Performing Secondary Operations(Page 512) when performing modifications and/or

secondary operations for safety concerns. Haguruma Kobo, the KHK's system for quick modification of KHK

stock gears is also available.

To find information on new products, see Page 6 and 7.

519

KWGDLKWGDLS

Module 3.54

Duplex Worms

Specifications

Spur

Gears

Axial

Gear teeth

Standard full depth

S

G

Reference

section of gear

Helical

Gears

W4

KWGDLS3.5-R1

KWGDLS4-R1

[Caution on Product Characteristics]

Nominal axial Number of Nominal

Hand of tread

module

start

lead angle

m3.5

m4

1

1

347'

341'

Shape

R

R

1

1

347'

341'

Hub dia.

Pitch dia.

Outside dia.

Face width

Hub width

LH7

24

28

44

50

53

62

60

70

62

74

23

26

85

100

W4

W4

Nominal axial Number of Nominal

Hand of tread

module

start

lead angle

m3.5

m4

Bore

Shape

R

R

Total length Shaft length (L) Neck length (L) Face width Neck length (R) Shaft length (R)

W6

W6

Total length

Pitch dia.

330

360

110

120

18

16

62

74

30

30

110

120

53

62

When the center distance is moved to reduce the backlash, the V max is the maximum amount of distance that you may shift

without causing problems with the gear mesh. The V max is not a recommended value to use for adjustment when assembling.

For W6 Shaped Gears, the tolerances of the shaft diameter are set to S +0.2 and +0.1 (+0.40 and +0.35 for the ground area).

These worms produce axial thrust forces. See page 512 for more details.

AGDL

Module 3.54

Bevel

Gears

Duplex Worms Wheels

Specifications

Screw

Gears

Precision grade KHK W 002 grade 1

Reference

section of gear

Rotating plane

Gear teeth

Standard full depth

Normal

pressure angle 17 30'

Material

A

B

C

D

D

Internal

Gears

KWGDL3.5-R1

KWGDL4-R1

CP Racks

& Pinions

Racks

Tooth hardness 45 55HRC

Catalog No.

Miter

Gears

Vmax

SCM440

Material

Catalog No.

Other

Bevel

Worm

Products Gearboxes Gear Pair

Normal

pressure angle 17 30'

Heat treatment Thermal refined, tooth surface

induction hardened

CAC702formerly JIS ABC2)

Heat treatment

Tooth hardness

H1

H5 shape have a hub made from S45C cast iron.

Catalog No.

Reduction Nominal axial No. of

Helix angle Hand of tread Shape

ratio

module

teeth

AGDL3.5-20R1

AGDL3.5-30R1

AGDL3.5-36R1

AGDL3.5-40R1

AGDL3.5-50R1

AGDL3.5-60R1

20

30

36

40

50

60

AGDL4-20R1

AGDL4-30R1

AGDL4-36R1

AGDL4-40R1

AGDL4-50R1

AGDL4-60R1

20

30

36

40

50

60

[Caution on Product Characteristics]

520

Precision grade KHK W 001 grade 1

Bore

Hub dia.

Pitch dia.

Throat dia.

AH7

Outside dia. Face width Hub width

D'

m3.5

20

30

36

40

50

60

347'

347'

347'

347'

347'

347'

R

R

R

R

R

R

H1

H1

H1

HB

HB

HB

20

20

20

20

20

20

55

60

70

70

80

90

70

105

126

140

175

210

77

112

133

147

182

217

80.5

115.5

136.5

150.5

185.5

220.5

32

32

32

32

32

32

18

18

18

18

18

18

m4

20

30

36

40

50

60

341'

341'

341'

341'

341'

341'

R

R

R

R

R

R

H1

HB

HB

HB

HB

H5

20

20

20

20

20

30

60

65

75

75

90

120

80

120

144

160

200

240

88

128

152

168

208

248

92

132

156

172

212

252

35

35

35

35

35

35

20

20

20

20

20

20

The allowable torques shown in the table are the calculated values according to the assumed usage conditions.

Please see page 510 for more details.

Duplex worms and worm wheels must be mated in a predetermined orientation, which is indicated by the arrows.

Therefore, the arrow on the wheel does not indicate the mounting direction, but the rotating direction. Please refer to

the Application Hints on page 515.

KWGDLKWGDLS

Duplex Worms

P

Q

J

M

Spur

Gears

Helical

Gears

Vmax

W6

Position of

reference tooth

Max. allowable shift

Weight

Vmax

(kg)

37

44

12

14

1.05

1.67

Outside dia.

Neck dia.

Shaft dia.

Position of

reference tooth

Max. allowable shift

Weight

Vmax

(kg)

60

70

42

50

48

56

37

44

12

14

4.72

7.10

Internal

Gears

KWGDL3.5-R1

KWGDL4-R1

Racks

Catalog No.

KWGDLS3.5-R1

KWGDLS4-R1

CP Racks

& Pinions

Please readCaution on Performing Secondary Operations(Page 512) when performing modifications and/or secondary

operations for safety concerns. Haguruma Kobo, the KHK's system for quick modification of KHK stock gears is also available.

Due to the gear teeth being induction hardened, no secondary operations can be performed on tooth areas including the bottom land (approx. 1 to 2 mm).

AGDL

Miter

Gears

[Caution on Secondary Operations]

Catalog No.

G

E F

B

C

D

D

(I)

B

C

D

D

Screw

Gears

(H)

HB

H5

CS has a sand mold casting finish.

NOTE 1. Allowable torques for worm rotation (rpm)

Total length Web thickness Web O.D. Mounting distance

Allowable torque (Nm)

NOTE 1

Backlash

Weight

(mm)

(kg)

30 rpm

100 rpm 300 rpm 600 rpm 900 rpm 1200 rpm 1800 rpm

50

50

50

50

50

50

(15)

(16)

(16)

(124)

(155)

(189)

61.5

79

89.5

96.5

114

131.5

98.5

208

293

356

538

753

80.4

172

242

295

446

627

62.5

136

193

236

360

506

50.4

111

160

196

301

425

44.2

98.1

141

173

267

381

40.0

88.3

127

156

243

345

33.7

75.7

109

133

207

296

00.045

00.045

00.045

00.045

00.045

00.045

1.24

2.51

3.61

3.34

5.02

6.87

55

55

55

55

55

55

(17)

(17)

(17)

(17)

(17)

(99)

(121)

(137)

(177)

(200)

71

91

103

111

131

151

109

234

329

400

605

851

84.8

184

262

320

488

687

67.9

150

215

264

405

572

59.7

132

190

233

361

515

53.4

118

170

208

324

461

44.8

101

144

177

275

393

00.045

00.045

00.045

00.045

00.045

00.045

1.76

3.01

4.18

4.78

7.07

11.5

[Caution on Secondary Operations]

134

284

400

486

735

1030

Catalog No.

AGDL3.5-20R1

AGDL3.5-30R1

AGDL3.5-36R1

AGDL3.5-40R1

AGDL3.5-50R1

AGDL3.5-60R1

AGDL4-20R1

AGDL4-30R1

AGDL4-36R1

AGDL4-40R1

AGDL4-50R1

AGDL4-60R1

Other

Bevel

Worm

Products Gearboxes Gear Pair

CS

CS

(I)

(H)

Bevel

Gears

Duplex Worm Wheels

Please readCaution on Performing Secondary Operations(Page 512) when performing modifications and/or

secondary operations for safety concerns. Haguruma Kobo, the KHK's system for quick modification of KHK

stock gears is also available.

To find information on new products, see Page 6 and 7.

521

Potrebbero piacerti anche

- (MITSUBISHI) Manual de Taller Mitsubishi Outlander 2007Documento62 pagine(MITSUBISHI) Manual de Taller Mitsubishi Outlander 2007DERLIS RAMIREZ100% (2)

- Gear Guide1Documento57 pagineGear Guide1dedemuamariskandar88Nessuna valutazione finora

- Life and Death CodeDocumento5 pagineLife and Death Codealin.butunoi865Nessuna valutazione finora

- Gear Backlash - KHK GearsDocumento7 pagineGear Backlash - KHK Gearsadhytia farma arsalNessuna valutazione finora

- Bevel Gear CalcsDocumento11 pagineBevel Gear Calcsmanish_umdNessuna valutazione finora

- Gear Backlash: 6.1 Types of BacklashesDocumento13 pagineGear Backlash: 6.1 Types of BacklashesRamazan MERALNessuna valutazione finora

- Tech Sec 8Documento6 pagineTech Sec 8Nabende UmarNessuna valutazione finora

- Helical Gears: DefinitionDocumento29 pagineHelical Gears: DefinitionMuthuvel MNessuna valutazione finora

- ASSAG Cylkro (FACE) Gear Mounting InstructionsDocumento6 pagineASSAG Cylkro (FACE) Gear Mounting InstructionscjdengateNessuna valutazione finora

- Parametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical ApproachDocumento5 pagineParametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical ApproachseventhsensegroupNessuna valutazione finora

- Bevel GearDocumento13 pagineBevel GearADII 2701Nessuna valutazione finora

- Bevel GearDocumento13 pagineBevel GearADII 2701Nessuna valutazione finora

- BOOK73Documento8 pagineBOOK73Vaibhav GuptaNessuna valutazione finora

- Design of Transmission System Unit IIIDocumento57 pagineDesign of Transmission System Unit IIIRaj MohanNessuna valutazione finora

- Connecting Rod - Steel Crankshaft PDFDocumento6 pagineConnecting Rod - Steel Crankshaft PDFjoaobargasNessuna valutazione finora

- Section 8 Bevel GearingDocumento5 pagineSection 8 Bevel GearingLiniel de JesusNessuna valutazione finora

- Super Smart Ball Bushing Bearings BrenDocumento8 pagineSuper Smart Ball Bushing Bearings BrenAchim OvidiuNessuna valutazione finora

- GEARDocumento21 pagineGEARraidahNessuna valutazione finora

- Gearabc BDocumento40 pagineGearabc Bvadi100% (1)

- Rolling GearDocumento14 pagineRolling GearRamesh SalriaNessuna valutazione finora

- Profile Shift of Involute Gears - Tec-ScienceDocumento17 pagineProfile Shift of Involute Gears - Tec-ScienceManoj SinghNessuna valutazione finora

- Medidas para Mecanizar Alojamiento Anillo Sello EspejoDocumento11 pagineMedidas para Mecanizar Alojamiento Anillo Sello EspejoJhonatan Valencia MillanNessuna valutazione finora

- Roller Circle - Check and AdjustDocumento3 pagineRoller Circle - Check and AdjustGilney FreitasNessuna valutazione finora

- Gear Guide 060817Documento40 pagineGear Guide 060817Vivek AbrolNessuna valutazione finora

- One Way Clutch PDFDocumento19 pagineOne Way Clutch PDFahmednppNessuna valutazione finora

- Echnical Information: Oncept and Main ApplicationsDocumento14 pagineEchnical Information: Oncept and Main ApplicationspopokateNessuna valutazione finora

- Influence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationDocumento7 pagineInfluence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationsamanaveenNessuna valutazione finora

- Mod-3B-Helical GearDocumento2 pagineMod-3B-Helical GearSharthak GhoshNessuna valutazione finora

- Machine Design & CAD-II Lecture 01gears & Types of GearsDocumento44 pagineMachine Design & CAD-II Lecture 01gears & Types of GearsMuhammad Naveed 952-FET/BSME/F20Nessuna valutazione finora

- Harmonic DriveDocumento52 pagineHarmonic DriveRahul TanwarNessuna valutazione finora

- BacklashDocumento29 pagineBacklashAnurag SarkarNessuna valutazione finora

- Direct Gear DesignDocumento7 pagineDirect Gear DesignFranco Angelo RegenciaNessuna valutazione finora

- Universal JointDocumento17 pagineUniversal Jointakmalzuhri96Nessuna valutazione finora

- Bevel GearDocumento28 pagineBevel Gearmahesh kitturNessuna valutazione finora

- WinchDocumento4 pagineWinchAntal SrlNessuna valutazione finora

- Sturmey Archer S RF3 Hub InstructionsDocumento4 pagineSturmey Archer S RF3 Hub Instructionsdupazbita11Nessuna valutazione finora

- Main Shaft of Two Wheerls Modelling and AnalysisDocumento42 pagineMain Shaft of Two Wheerls Modelling and AnalysisAVINASHNessuna valutazione finora

- Cycloid Drive - Replaced by Planocentric Involute GearingDocumento6 pagineCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeNessuna valutazione finora

- ShavingDocumento8 pagineShavingkarthikNessuna valutazione finora

- Toothed GearingDocumento33 pagineToothed GearingpvkkrNessuna valutazione finora

- Timing Chain: Service and Repair InstallationDocumento3 pagineTiming Chain: Service and Repair InstallationDiego496Nessuna valutazione finora

- Timing Chain: Service and Repair InstallationDocumento3 pagineTiming Chain: Service and Repair InstallationDiego496Nessuna valutazione finora

- Timing Chain: Service and Repair InstallationDocumento3 pagineTiming Chain: Service and Repair InstallationDiego496Nessuna valutazione finora

- Gear Cutting Grinding and Measuring MethodsDocumento15 pagineGear Cutting Grinding and Measuring Methodshumayun121Nessuna valutazione finora

- Sae Sis03 NarDocumento6 pagineSae Sis03 Narsuraj dhulannavarNessuna valutazione finora

- Unit-3 Helical GearsDocumento38 pagineUnit-3 Helical GearsMarthande100% (1)

- Gear Box & Its MaintenanceDocumento28 pagineGear Box & Its MaintenanceJiten Kumar Biswal100% (1)

- Suspension AxleDocumento97 pagineSuspension AxleLoc TruongNessuna valutazione finora

- Calculation of The Tooth Root Load Carrying Capacity of Beveloid GearsDocumento10 pagineCalculation of The Tooth Root Load Carrying Capacity of Beveloid GearsdineshkshirsagarNessuna valutazione finora

- INA Conrod BearingsDocumento17 pagineINA Conrod Bearingsspeed844Nessuna valutazione finora

- Internal Gears: KHK Products Are Available From Maryland MetricsDocumento6 pagineInternal Gears: KHK Products Are Available From Maryland MetricsbtfreekNessuna valutazione finora

- IBC Ball Screw Support BearingsDocumento36 pagineIBC Ball Screw Support Bearingsfar23663Nessuna valutazione finora

- Involute Gear ProfileDocumento8 pagineInvolute Gear ProfiledressfeetNessuna valutazione finora

- Gear CuttingDocumento56 pagineGear Cuttingiyerrahul2679350% (2)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDa EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsValutazione: 5 su 5 stelle5/5 (1)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsDa EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsValutazione: 4 su 5 stelle4/5 (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDa EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheValutazione: 4.5 su 5 stelle4.5/5 (2)

- JESR201904V25S01A0002Documento7 pagineJESR201904V25S01A0002alin.butunoi865Nessuna valutazione finora

- Teorii OrganizationaleDocumento73 pagineTeorii Organizationaleliuduta1990Nessuna valutazione finora

- Surse Suplimentare BibliografieDocumento2 pagineSurse Suplimentare Bibliografiealin.butunoi865Nessuna valutazione finora

- Guidelines For Authors - IJMMTDocumento4 pagineGuidelines For Authors - IJMMTalin.butunoi865Nessuna valutazione finora

- SVAN 956 User ManualDocumento195 pagineSVAN 956 User Manualalin.butunoi865Nessuna valutazione finora

- About NanoLUBDocumento3 pagineAbout NanoLUBalin.butunoi865Nessuna valutazione finora

- ABB IRB 2400 SpecificatiiDocumento2 pagineABB IRB 2400 Specificatiialin.butunoi865Nessuna valutazione finora

- Linear Guideway (E)Documento198 pagineLinear Guideway (E)alin.butunoi865Nessuna valutazione finora

- Polynomial Curve Fitting in MatlabDocumento3 paginePolynomial Curve Fitting in MatlabKhan Arshid IqbalNessuna valutazione finora

- Variable Displacement Vane Pump Variable Displacement Vane PumpDocumento4 pagineVariable Displacement Vane Pump Variable Displacement Vane PumpRonaldNessuna valutazione finora

- Hierarchy Trouble Code For TSRDocumento10 pagineHierarchy Trouble Code For TSRAsri YanNessuna valutazione finora

- 980H Wheel Loader KZL00001-UP - General Information (Steering System)Documento4 pagine980H Wheel Loader KZL00001-UP - General Information (Steering System)Andri YuliantoNessuna valutazione finora

- Reciprocating PumpsDocumento16 pagineReciprocating PumpsMahmoud AfifyNessuna valutazione finora

- Pressure Build Up - SteeringDocumento3 paginePressure Build Up - Steeringwidanto0apriawanNessuna valutazione finora

- Automatic Transmission - PPT 1Documento23 pagineAutomatic Transmission - PPT 1Akshay29100% (1)

- Pressure ControlDocumento12 paginePressure ControlMohamed RashedNessuna valutazione finora

- Rajednra 2022 Price List PDFDocumento28 pagineRajednra 2022 Price List PDFMurali YNessuna valutazione finora

- 311B, 312B, and 312B L Excavators Boom Lowering Check (Attachment) Hydraulic SystemDocumento2 pagine311B, 312B, and 312B L Excavators Boom Lowering Check (Attachment) Hydraulic Systemcandido vargas gutierrezNessuna valutazione finora

- SR150C Rotary Drilling Rig Service Manual-Hydraulic System (Upper Carriage)Documento40 pagineSR150C Rotary Drilling Rig Service Manual-Hydraulic System (Upper Carriage)Rizal Abi100% (1)

- 6-24 Tandem Pump Assembly Front Drive Pump Housing, Valves and PlugsDocumento4 pagine6-24 Tandem Pump Assembly Front Drive Pump Housing, Valves and PlugsPaull SalasNessuna valutazione finora

- Hitachi EX120 5 130K 5Documento279 pagineHitachi EX120 5 130K 5Yew Lim100% (7)

- M07 Diagnosing Underchassis SystemDocumento114 pagineM07 Diagnosing Underchassis SystemBilal HussenNessuna valutazione finora

- Erreesse GlobevalveDocumento20 pagineErreesse Globevalvefaisal hajjNessuna valutazione finora

- Centrifugal Pump Types (API-610)Documento4 pagineCentrifugal Pump Types (API-610)Иван РадевNessuna valutazione finora

- GearsDocumento3 pagineGearsSridhar KanagarajNessuna valutazione finora

- Construction of TransaxleDocumento7 pagineConstruction of Transaxlemoba funnyNessuna valutazione finora

- Spares A4VG125Documento37 pagineSpares A4VG125Islam Actros100% (3)

- Av en Valves PDFDocumento246 pagineAv en Valves PDFWahyuNessuna valutazione finora

- Catalogue Maximator Valves Fittings and Tubings 05 2011Documento62 pagineCatalogue Maximator Valves Fittings and Tubings 05 2011willianNessuna valutazione finora

- New Product Catalog Dab 2022Documento2 pagineNew Product Catalog Dab 2022Nurdin FahimNessuna valutazione finora

- 2008 - 7 - 4 4L30E PumpDocumento4 pagine2008 - 7 - 4 4L30E PumpJon Rodriguez100% (1)

- Describe The Differences Between The Following. Include Diagrams. A. Open Center Hydraulic CircuitDocumento7 pagineDescribe The Differences Between The Following. Include Diagrams. A. Open Center Hydraulic CircuitMohammad UsmanNessuna valutazione finora

- Invoice AnnexureDocumento2 pagineInvoice Annexureauxiliar2cloNessuna valutazione finora

- Pioneer Cld-A100 SMDocumento84 paginePioneer Cld-A100 SMJorgeNessuna valutazione finora

- Price ListDocumento8 paginePrice ListGughhNessuna valutazione finora

- SangwonIntech CatalogueDocumento80 pagineSangwonIntech CatalogueNuryanti PratiwiNessuna valutazione finora

- 1 Bolter RE77Documento69 pagine1 Bolter RE77scarriongalindo100% (1)

- Pump A10VO DFR PrincipleDocumento25 paginePump A10VO DFR Principlemaintenance 2kpb100% (1)