Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bfviom

Caricato da

AHMEDMALAHYTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bfviom

Caricato da

AHMEDMALAHYCopyright:

Formati disponibili

TITAN

TITAN FLOW

CONTROL, INC.

INSTALLATION, OPERATION,

AND MAINTENANCE

PREFACE:

Figure 1: Butterfly Valve - Lug Style

BUTTERFLY VALVE

This manual contains information concerning the installation,

operation, and maintenance of Titan Flow Control (Titan FCI)

Butterfly Valves. To ensure efficient and safe operation of Titan FCI

Butterfly Valves, the instructions in this manual should be thoroughly

read and understood. This manual is general in nature and is not

meant to take the place of an on-site, process engineer or pipe

fitter. As such,Titan FCI recommends that only experienced, skilled

personnel be allowed to install and maintain Titan FCI Butterfly

Valves. Please retain this manual in a location where it is readily

available for reference.

GENERAL INFORMATION:

Butterfly Valves are quarter-turn valves that are installed between

flanges to regulate flow in a pipeline. The disc, positioned in the

center of the pipe, rotates so that the valve can be opened, closed,

or partially opened.

Material construction requirements of the Butterfly Valve.

Design and working pressure/temperature requirements.

Operating conditions (throttling, pressure drop, condensation,

flow reversal, operation frequency, etc.).

Service media type (liquid, gas, abrasive, corrosive, dirty, etc).

Pipeline Media Flow-rate and Viscosity.

Clean Start-up Pressure of the Pipeline.

Space availability for installation.

Please contact a Titan Design Engineer to assist in the determination

of these requirements prior to selection and purchase.

CAUTION:

For large or heavy Butterfly Valves, the appropriate material

handling equipment must be used to prevent injury and

possible damage to the Butterfly Valve.

All Titan FCI Butterfly Valves are shipped in specialized

shipping containers designed to prevent damage during

transportation. If external damage to the shipping

container is evident upon receipt of product, please

request that a representative of the shipping carrier be

present before unpacking the product.

Carefully open the shipping container, following any

instructions that may be marked on the container.

Remove all packing material surrounding the Butterfly

Valve and carefully lift it from the container. It

is recommend to keep the shipping container and all

packing material for reuse in storage or reshipment.

Visually inspect the Butterfly Valve for any signs of

damage including scratches, loose parts, broken

parts or any other physical damage that may have

occurred during shipment. If damage is observed,

immediately file a claim with the shipping carrier.

Butterfly Valves that are damaged during

transportation are the responsibility of the customer.

For information regarding Titan FCIs warranty policy,

please refer to the last page of this document.

YOUR PIPELINE TO THE FUTURE!

Tel: 910-735-0000 s Fax: 910-738-3848 s titan@titanfci.com s www.titanfci.com

290 Corporate Drive s PO Box 7408 s Lumberton, NC 28358

BFVIOM1009

Prior to selection of a Titan FCI Butterfly Valve the following factors

must be determined:

Upon receipt of product, it is important to follow these

unpacking and inspection procedures.

Specific engineering design data, not contained in this manual, may

be located within the BFV Specification Sheets or on certified

Engineering drawings available upon request.

UNPACKING AND INSPECTION:

TITAN

TITAN FLOW

CONTROL, INC.

INSTALLATION, OPERATION,

AND MAINTENANCE

UNPACKING AND INSPECTION: Continued...

If the Butterfly Valve is not required to be installed

immediately, it should be stored indoors in a clean, dry,

consistent temperature environment. It is also recommended

to utilize the original shipping container and packing materials

to properly store the Butterfly Valve and keep it out of direct

light. If long term storage is required, a desiccant may be

necessary. This would be based upon the local, environmental

storage conditions. Please consult a Titan FCI Design Engineer

to assist in this determination.

When ready to install, remove any preservatives with solvent

dampened cloths. Remove any loose material and protective

packing material.

Figure 2: Wafer Butterfly Valve with Actuator

Pre-Installation Checklist continued...

The distance between pipe flanges should be checked

to assure sufficient clearance for valve installation.

Installation Procedure

Ensure Working conditions (pressure and temperature) are

within the specified capacity of the product being installed.

Please refer to the certified Engineering drawings to assist in

determining these values.

Step 1:

Titans Butterfly Valves are bi-directional and can be

installed in a vertical or horizontal position. Check that

the existing pipe sizes match the inlet and outlet sizes of

the unit being installed. If pipeline strain is a concern with

larger Butterfly Valves and accessories, additional support

may be necessary.

Inspect the Butterfly Valves flange ends and the pipelines

mating flanges to ensure the surfaces are clean and free

of defects. The pipeline should also be checked for proper

alignment. Titan FCI Butterfly Valves should never be utilized

to realign an existing piping system.

CAUTION:

Titan Flow Control, Incs Butterfly Valves are designed only for

installation between ASME/ANSI 125 Cast Iron or 150 Ductile

Iron Flanges. Although the pressure ratings are different, the

bolting patterns are identical.

Step 2:

Special flange gaskets are not required because the

extruded portion of the seat functions as a gasket.

Step 3:

Make sure the Butterfly Valve is in a closed position.

Step 4:

Place the Butterfly Valve into position. For wafer valves,

the alien holes should be aligned to the flange bolt holes

ensuring that the valve is centered; the bolt holes on the

lug valves should be aligned with the flange bolting.

YOUR PIPELINE TO THE FUTURE!

Tel: 910-735-0000 s Fax: 910-738-3848 s titan@titanfci.com s www.titanfci.com

290 Corporate Drive s PO Box 7408 s Lumberton, NC 28358

BFVIOM1009

Pre-Installation Checklist

INSTALLATION:

The appropriate material handling equipment (joist

and slings) should be available to lift larger units into

position.

Make sure that the construction material of the Butterfly Valve

is chemically compatible with the media flowing in the pipeline.

BUTTERFLY VALVE

Carefully remove packing material around Butterfly Valve.

Inspect to make sure there are no pieces of the packaging left

on the valve that could interfere with its operation.

TITAN

TITAN FLOW

CONTROL, INC.

Installation Procedure continued...

Step 5:

Wafer valves are placed between flanges and installed with fully

threaded studs. Tapped lug valves are installed between the flanges

with small cap screws on the inlet and the outlet of the valve. (See

Figure 3.)

Cap Screws

Studs & Nuts

CAUTION:

Excessive bolt torque may damage flanges. Please refer

to established flange bolt torques for guidelines.

OPERATION:

Once proper installation has been successfully completed,

start the system gradually, at start up as well as after shut

down.This eliminates sudden shock to the butterfly valve

and other equipment in the line.

Start-up Procedure:

Step 1:

Gradually increase system pressure until working pressure

is reached.

Cap Screw

Threaded Studs

Step 7:

Open valve slowly to make sure that the disc does not make contact

with the piping or the flanges. Close the valve.

Step 8:

Flange bolts should then be tightened, using a star or crisscross

pattern to evenly load the bolts, in accordance with established

piping standards. This is illustrated in Figure 4.

1

7

6

Step 3:

Adjusting flow from 0 (closed) to 90 (full flow) can

be done manually or automatically depending on the

type of butterfly valve installed. Manual operators are

available in a 10 position handle, an infinite handle, and

a gear operator. Automatic operation can be achieved

with a pneumatic or electric operator.

CAUTION:

To assist in opening and closing Butterfly Valves, gear

operators are typically recommended for valves 8

and larger.

MAINTENANCE:

Titan Flow Control Butterfly Valves require minimal

regular maintenance. Below is a preventive checklist with

recommended monthly practices:

Figure 4: Bolting Sequence Pattern

Adjust the valve from closed to full flow periodically

YOUR PIPELINE TO THE FUTURE!

Tel: 910-735-0000 s Fax: 910-738-3848 s titan@titanfci.com s www.titanfci.com

290 Corporate Drive s PO Box 7408 s Lumberton, NC 28358

BFVIOM1009

Step 6:

Install lubricated flange bolts and hand tighten.

Figure 3: Installation of Wafer and Lug Butterfly Valves

Step 2:

Inspect flange connections for leaks. If leaking occurs,

check for piping misalignment, that the flange bolts

are properly tightened, and that the cover is properly

seated.

BUTTERFLY VALVE

Lug Body

Wafer Body

INSTALLATION, OPERATION,

AND MAINTENANCE

TITAN

TITAN FLOW

CONTROL, INC.

MAINTENANCE: Continued...

Visually inspect fasteners, piping, wiring, and any related

equipment for problems that could hinder operation such as

loosening or corrosion.

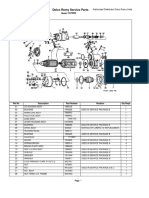

PARTS LIST:

For the bill of materials and parts listing of each Butterfly Valve

model, please refer to the corresponding Engineering Specification

Sheet. For special or fabricated units, please refer to the certified

engineering drawing for that unit.

Side View

Front View

Figure 4: Illustrations of Butterfly Valve

PARTS LIST

No.

Butterfly Valve

Stem

Bushing

Body

O-Ring

Seat

Pin

Disc

End Cap

Bolt

10

Key

11

Set Screw

THIS WARRANTY IS IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

ANY IMPLIED WARRANTY OF FITNESS OR

MERCHANTABILITY. SELLER SHALL NOT BE LIABLE FOR

ANY SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES. NO REPRESENTATIVE OR SELLER HAS

AUTHORITY TO MAKE ANY REPRESENTATIONS OR

WARRANTIES, EXCEPT AS STATED HEREIN.

YOUR PIPELINE TO THE FUTURE!

Tel: 910-735-0000 s Fax: 910-738-3848 s titan@titanfci.com s www.titanfci.com

290 Corporate Drive s PO Box 7408 s Lumberton, NC 28358

BFVIOM1009

Seller warrants each of the products and parts sold

hereunder, under normal use of service, and subject to

users compliance with any operating instructions and

other directions given by seller, to be free from defects

in materials or workmanship for a period of one year

from date of shipment from sellers plant. Sellers liability,

under this warranty, shall be limited to, at the sellers

option, to repairing or replacing any such defective product

FOB sellers plant in Lumberton, NC, and reimbursing

purchaser for shipping costs, subject to the following:

(1) Timely receipt of purchasers written notice that such

products are defective. (2) Sellers written authorization

to purchaser for the return of such products, (3) the return

of such products to seller with shipping charges prepaid

and (4) sellers inspection of and confirmation that such

products are defective in materials or workmanship. If

sellers inspection shows that the products returned are

defective due to dirt, rust or any foreign material not

attributable to seller: improper usage, over tightening

on threads, abuse or incorrect assembly in the field, or

other cause not due to sellers improper manufacture,

seller will, subject to purchasers written authorization,

repair or replace such products at cost. Sellers factory

inspection and testing reports will be made available to

purchaser upon request.

WARRANTY:

BUTTERFLY VALVE

Check the valve and around the valve for any signs of

leakage.

INSTALLATION, OPERATION,

AND MAINTENANCE

Potrebbero piacerti anche

- Titan Flow Control, Inc.: Installation, Operation, and MaintenanceDocumento5 pagineTitan Flow Control, Inc.: Installation, Operation, and MaintenanceAHMEDMALAHYNessuna valutazione finora

- 390 InstructionsDocumento48 pagine390 InstructionsemaanazeemNessuna valutazione finora

- CVS EZ Instruction ManualDocumento28 pagineCVS EZ Instruction ManualJohn Harry RamirezNessuna valutazione finora

- Rotary Valve Operating InstructionsDocumento11 pagineRotary Valve Operating InstructionsAdem AltanNessuna valutazione finora

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocumento47 pagineInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasNessuna valutazione finora

- Lt Valves Trunnion Mounted Ball ValvesDocumento48 pagineLt Valves Trunnion Mounted Ball ValvesXioamiWangWertNessuna valutazione finora

- Maintenance Instruction Manual: Severe Service Control ValvesDocumento9 pagineMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقNessuna valutazione finora

- PED - Operating Safety Instructions for Direct Spring Safety ValvesDocumento2 paginePED - Operating Safety Instructions for Direct Spring Safety ValvesndngnngdngngNessuna valutazione finora

- VAAS Fig 740 and 730 Series IOMDocumento9 pagineVAAS Fig 740 and 730 Series IOMCarlos GutierrezNessuna valutazione finora

- Iom WKM 310FDocumento4 pagineIom WKM 310FNasir NaqviNessuna valutazione finora

- O&S Instructions - Reducing ValvesDocumento1 paginaO&S Instructions - Reducing ValvesTifano KhristiyantoNessuna valutazione finora

- Gate Valve Installation Operation & Maintenance ManualDocumento5 pagineGate Valve Installation Operation & Maintenance ManualViba Fluid ControlNessuna valutazione finora

- Vaas Automation C47 cryogenic valve manualDocumento8 pagineVaas Automation C47 cryogenic valve manualKannan KrisNessuna valutazione finora

- Butterfly Valve User ManualDocumento10 pagineButterfly Valve User ManualEduardoAscencioNessuna valutazione finora

- Iom MVT ValvesDocumento5 pagineIom MVT ValvesNaser JahangiriNessuna valutazione finora

- Series 808Y Installation InstructionsDocumento4 pagineSeries 808Y Installation InstructionsFEBCONessuna valutazione finora

- Weflo Nrs Gate Op and MaintDocumento5 pagineWeflo Nrs Gate Op and MaintyusufNessuna valutazione finora

- N-583 Foot ValveDocumento1 paginaN-583 Foot ValveSầu ĐờiNessuna valutazione finora

- Forged Floating & Trunnion-Mounted Ball Valves: Installation, Operation & Maintenance ManualDocumento66 pagineForged Floating & Trunnion-Mounted Ball Valves: Installation, Operation & Maintenance ManualKYAWNessuna valutazione finora

- Digital Set Stop Valves: Features, Benefits and OperationDocumento6 pagineDigital Set Stop Valves: Features, Benefits and Operationvishnunair27Nessuna valutazione finora

- Series 39 Inline Check Valve: Installation, Operation, and Maintenance ManualDocumento4 pagineSeries 39 Inline Check Valve: Installation, Operation, and Maintenance ManualLalo SepulvedaNessuna valutazione finora

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocumento12 pagineFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalNessuna valutazione finora

- Hopkinson Valves IOM Manual PDFDocumento7 pagineHopkinson Valves IOM Manual PDFGiorgiana RosuNessuna valutazione finora

- INSTALLATION OPERATION AND MAINTENANCE MANUAL-MilwakeeDocumento10 pagineINSTALLATION OPERATION AND MAINTENANCE MANUAL-MilwakeeMASOUDNessuna valutazione finora

- Handling Precautions: Butterfly Valves (Common To All Models)Documento9 pagineHandling Precautions: Butterfly Valves (Common To All Models)xaaabbb_550464353Nessuna valutazione finora

- Corsbysek PDFDocumento16 pagineCorsbysek PDFMargaret DaughertyNessuna valutazione finora

- 2000 Iom SeriesDocumento6 pagine2000 Iom SeriesLakshmi NarayananNessuna valutazione finora

- TBV Series 21 20 Cryogenic Flanged Ball ValveDocumento5 pagineTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranNessuna valutazione finora

- Hattersley+A5+IOM+Fig.370+&+Fig.371+Colour 0119 WEBDocumento4 pagineHattersley+A5+IOM+Fig.370+&+Fig.371+Colour 0119 WEBFareethAbdullahNessuna valutazione finora

- valveIT Storage and Maintainance Generic PDFDocumento5 paginevalveIT Storage and Maintainance Generic PDFsami maNessuna valutazione finora

- Tom Wheatley Piston CK IOM PDFDocumento12 pagineTom Wheatley Piston CK IOM PDFsitaNessuna valutazione finora

- Vciom 06208 enDocumento18 pagineVciom 06208 enElver AmesquitaNessuna valutazione finora

- EQ VA20 Volumetric Valve: Operating ManualDocumento17 pagineEQ VA20 Volumetric Valve: Operating ManualChristian RobertoNessuna valutazione finora

- Condensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsDocumento4 pagineCondensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsMarcial NuñezNessuna valutazione finora

- Manual 1956 PN 09-1013 VF-61Documento3 pagineManual 1956 PN 09-1013 VF-61fabiosparkNessuna valutazione finora

- 727 PosrvDocumento7 pagine727 Posrvtxlucky80Nessuna valutazione finora

- Rofi Operation and Maintenance ManualDocumento3 pagineRofi Operation and Maintenance ManualSteve NewmanNessuna valutazione finora

- Checks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlDocumento4 pagineChecks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlSyko GuyNessuna valutazione finora

- V800 - Ball - Installation & Maintenance ManualDocumento15 pagineV800 - Ball - Installation & Maintenance ManualHayderr HassNessuna valutazione finora

- Install, operate and maintain Hopkinsons swing check valveDocumento7 pagineInstall, operate and maintain Hopkinsons swing check valveGiorgiana RosuNessuna valutazione finora

- Es Acv M115F M1115FDocumento4 pagineEs Acv M115F M1115FWattsNessuna valutazione finora

- Installation Manual - Eaton Model 53BTX SizesDocumento6 pagineInstallation Manual - Eaton Model 53BTX SizesGrafton MontgomeryNessuna valutazione finora

- Prevent MaintenanceDocumento15 paginePrevent Maintenancemecanico_ipnNessuna valutazione finora

- Ideal Installation: I & M Mark 68G SeriesDocumento4 pagineIdeal Installation: I & M Mark 68G SeriesByron PanchiNessuna valutazione finora

- Installation and Maintenance Instructions Ball Valves, Fully WeldedDocumento6 pagineInstallation and Maintenance Instructions Ball Valves, Fully WeldedvictorbirlanNessuna valutazione finora

- Standard Gate Valves ManualDocumento8 pagineStandard Gate Valves ManualmechanikyNessuna valutazione finora

- Iom Cam Ball t31Documento20 pagineIom Cam Ball t31Albino Felix HernandezNessuna valutazione finora

- Install and operate food waste disposer unitDocumento9 pagineInstall and operate food waste disposer unitLeonardo AlvarezNessuna valutazione finora

- Installation, Operation & Maintenance ManualDocumento4 pagineInstallation, Operation & Maintenance ManualgshdavidNessuna valutazione finora

- Apollo Ball Valve Installation & Maintenance ManualDocumento9 pagineApollo Ball Valve Installation & Maintenance ManualErcan YilmazNessuna valutazione finora

- Tank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDocumento4 pagineTank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDanielle JohnsonNessuna valutazione finora

- KF Ball Iom Series WBDocumento10 pagineKF Ball Iom Series WBXing ChenNessuna valutazione finora

- Williams-Manual de Instalacion y MantenimientoDocumento12 pagineWilliams-Manual de Instalacion y MantenimientoespanolasaNessuna valutazione finora

- Globe Valve General Installation Operation & Maintenance ManualDocumento5 pagineGlobe Valve General Installation Operation & Maintenance ManualViba Fluid ControlNessuna valutazione finora

- Titan Environmental Domestic Oil Tank Installation GuideDocumento24 pagineTitan Environmental Domestic Oil Tank Installation GuideTitanEnvNessuna valutazione finora

- Sempell: Before Installation These Instructions Must Be Fully Read and UnderstoodDocumento1 paginaSempell: Before Installation These Instructions Must Be Fully Read and UnderstoodDGWNessuna valutazione finora

- IOM Manual For CAMAROON Ball ValvesDocumento20 pagineIOM Manual For CAMAROON Ball ValvesSathish Kumar Pt100% (2)

- Vaas 90 Series Installation ManualDocumento5 pagineVaas 90 Series Installation ManualDanielle JohnsonNessuna valutazione finora

- Cam-Tite Ball Valve Operating Instructions: WarningDocumento3 pagineCam-Tite Ball Valve Operating Instructions: WarningSubbarayan SaravanakumarNessuna valutazione finora

- Iso DWG Sample.04Documento1 paginaIso DWG Sample.04AHMEDMALAHYNessuna valutazione finora

- Pipe Rack 3d Snapshot SampleDocumento1 paginaPipe Rack 3d Snapshot SampleAHMEDMALAHYNessuna valutazione finora

- Metering Skid 3d Model 01Documento1 paginaMetering Skid 3d Model 01AHMEDMALAHYNessuna valutazione finora

- Nozzle Loads Piping Stresses and The Effect of Piping On EquipmentDocumento40 pagineNozzle Loads Piping Stresses and The Effect of Piping On Equipmentcaesar00100% (6)

- Iso DWG Sample.02Documento1 paginaIso DWG Sample.02AHMEDMALAHYNessuna valutazione finora

- Iso DWG Sample.03Documento1 paginaIso DWG Sample.03AHMEDMALAHYNessuna valutazione finora

- Iso DWG Sample.03 PDFDocumento1 paginaIso DWG Sample.03 PDFAHMEDMALAHYNessuna valutazione finora

- Iso DWG Sample.01Documento1 paginaIso DWG Sample.01AHMEDMALAHYNessuna valutazione finora

- Design Criteria For Suspended Pipeline PDFDocumento11 pagineDesign Criteria For Suspended Pipeline PDFAHMEDMALAHYNessuna valutazione finora

- pressureProcedTest PDFDocumento7 paginepressureProcedTest PDFfaizal azizNessuna valutazione finora

- Ml11346a637 PDFDocumento86 pagineMl11346a637 PDFAHMEDMALAHYNessuna valutazione finora

- Globe Valve BrochureDocumento5 pagineGlobe Valve Brochurevk1234Nessuna valutazione finora

- M CR 601r1Documento14 pagineM CR 601r1nazari123Nessuna valutazione finora

- Fluid Flow Pump System - Technical - 6Documento25 pagineFluid Flow Pump System - Technical - 6kasandra01Nessuna valutazione finora

- BLEED/TEST RINGS AND RING TYPE JOINT SPECSDocumento1 paginaBLEED/TEST RINGS AND RING TYPE JOINT SPECSLuis Eduardo CaicedoNessuna valutazione finora

- Gate Valves Material RequisitionDocumento43 pagineGate Valves Material RequisitionAHMEDMALAHYNessuna valutazione finora

- B-Line Pipe Supports, Guides, Shields & SaddlesDocumento44 pagineB-Line Pipe Supports, Guides, Shields & SaddlesMfon UdoitaNessuna valutazione finora

- Wheatley Dual Plate Wafer Check ValveDocumento8 pagineWheatley Dual Plate Wafer Check ValveAHMEDMALAHYNessuna valutazione finora

- Expansion Joint Cyclic Deflections and Cycle LifeDocumento4 pagineExpansion Joint Cyclic Deflections and Cycle LifeAHMEDMALAHYNessuna valutazione finora

- Combined Deflections For Metallic Expansion JointsDocumento1 paginaCombined Deflections For Metallic Expansion JointsAHMEDMALAHYNessuna valutazione finora

- CvwiomDocumento5 pagineCvwiomAHMEDMALAHYNessuna valutazione finora

- Metallic Expansion Joint CatalogDocumento1 paginaMetallic Expansion Joint CatalogAHMEDMALAHYNessuna valutazione finora

- Angular Expansion Joint Deflection - U.SDocumento2 pagineAngular Expansion Joint Deflection - U.SAHMEDMALAHYNessuna valutazione finora

- Expansion Joint Examples Using Hinged or Gimbal Expansion JointsDocumento2 pagineExpansion Joint Examples Using Hinged or Gimbal Expansion JointsAHMEDMALAHYNessuna valutazione finora

- Axial Expansion Joint Movement ExamplesDocumento2 pagineAxial Expansion Joint Movement ExamplesAHMEDMALAHYNessuna valutazione finora

- Flange Insulating Flange KitDocumento8 pagineFlange Insulating Flange Kitim4uim4uim4uim4uNessuna valutazione finora

- SUSIOMDocumento5 pagineSUSIOMAHMEDMALAHYNessuna valutazione finora

- GRE-guide To Iso 14692Documento12 pagineGRE-guide To Iso 14692AHMEDMALAHY100% (2)

- Equipment Specifications and RequirementsDocumento62 pagineEquipment Specifications and Requirementsjkhgvdj mnhsnjkhgNessuna valutazione finora

- Smaw 8 Module 1 - V5Documento23 pagineSmaw 8 Module 1 - V5Jhoanna Lovely OntulanNessuna valutazione finora

- Bs 7916 Osb BoardDocumento30 pagineBs 7916 Osb Boardrealdaross100% (1)

- TAS Flange CouplingDocumento30 pagineTAS Flange CouplingJaime Casas-corderoNessuna valutazione finora

- Rollix Slewing Ring Installation Maintenance EnglishDocumento7 pagineRollix Slewing Ring Installation Maintenance EnglishAngela MarkovskaNessuna valutazione finora

- Combating Enemy SurveillanceDocumento18 pagineCombating Enemy SurveillanceFora GoodaNessuna valutazione finora

- Machine Design and Shop Practice ProblemsDocumento19 pagineMachine Design and Shop Practice Problemsdarius james del mar75% (8)

- Flyer Round Tube System D28 enDocumento12 pagineFlyer Round Tube System D28 enS JNessuna valutazione finora

- Vetrolux Din 28120 28121Documento4 pagineVetrolux Din 28120 28121Brian RobertsNessuna valutazione finora

- Sunjoy A102008100 Assembly Instruction enDocumento35 pagineSunjoy A102008100 Assembly Instruction enTerrence JonesNessuna valutazione finora

- Victaulic Grooved Piping Method StatementDocumento3 pagineVictaulic Grooved Piping Method Statementka lok LiNessuna valutazione finora

- Delco RemyDocumento3 pagineDelco Remyboobalan_shriNessuna valutazione finora

- Manual de PartesDocumento171 pagineManual de PartesthonnyNessuna valutazione finora

- RocMaster Roc en PDFDocumento24 pagineRocMaster Roc en PDFKKien VuNessuna valutazione finora

- Technical Manual Fulcrum ENG Op004 Rev03!09!2016Documento8 pagineTechnical Manual Fulcrum ENG Op004 Rev03!09!2016Robert ClevelandNessuna valutazione finora

- Hilti 3.1 Anchor Principles and DesignDocumento10 pagineHilti 3.1 Anchor Principles and DesignTony KrolikowskiNessuna valutazione finora

- RePacking HT 400 PDFDocumento113 pagineRePacking HT 400 PDFridwansaungnage_5580Nessuna valutazione finora

- CIVIL ENGINEERING BOARD EXAMDocumento7 pagineCIVIL ENGINEERING BOARD EXAMConan EdogawaNessuna valutazione finora

- User Manual TFP SeriesDocumento24 pagineUser Manual TFP SeriesJaekeun Sung0% (1)

- Gener. Inverter. KGE3000ti Manual de Servicio PDFDocumento35 pagineGener. Inverter. KGE3000ti Manual de Servicio PDFManuel Sierra100% (1)

- Ring Mill Manual Rock Labs PDFDocumento48 pagineRing Mill Manual Rock Labs PDFCuchito Miraval100% (2)

- Coolaire Installation InstructionsDocumento15 pagineCoolaire Installation Instructionsgeorgemesfin@gmailNessuna valutazione finora

- Ford Figo Body Repair Manual B517 PDFDocumento718 pagineFord Figo Body Repair Manual B517 PDFjgarfield420Nessuna valutazione finora

- P.C. MS14-MS16 (C852) - EngDocumento114 pagineP.C. MS14-MS16 (C852) - EngRicardo Bilbao100% (7)

- Underpinning Systems For Settled FoundationsDocumento3 pagineUnderpinning Systems For Settled FoundationsNazirul FariqNessuna valutazione finora

- Service Manual: 2-Spring Nozzle & Nozzle HolderDocumento53 pagineService Manual: 2-Spring Nozzle & Nozzle HolderUserfabian215100% (1)

- BVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety ClampsDocumento8 pagineBVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety ClampsRakefsNessuna valutazione finora

- BS 5400 Part 6 1999 PDFDocumento36 pagineBS 5400 Part 6 1999 PDFDang Thanh TuanNessuna valutazione finora

- Machinery's Handbook 28 EditionDocumento7 pagineMachinery's Handbook 28 EditionRoland Salvador Salvador9% (68)

- Fabory Screw Threads PDFDocumento2 pagineFabory Screw Threads PDFalifuat duyguNessuna valutazione finora