Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

0004-P180 PTG Sec 4

Caricato da

dwsimsDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

0004-P180 PTG Sec 4

Caricato da

dwsimsCopyright:

Formati disponibili

Electrical System Piaggio Avanti SimsAir

ELECTRICAL SYSTEM

Electrical power is supplied by a 28-volt direct current negative ground electrical system. Two 28

volt 400 ampere D.C. starter/generators in parallel provide torque for engine starting and generate

D.C. electrical power. One 25.2 volt, 38 ampere hour nickel-Cadnium battery located in the front

section of the rear baggage compartment, provides power for starting and also serves as reserve

source of emergency electrical power in the event of dual generator failure. The electrical system

is automatically protected from over-voltage and reverse current.

Nickel-Cadnium Battery

An external power receptacle located on the left side of the fuselage just above the main gear well

allows the use of an external auxiliary power source either to start the engines or to allow an

extended-ground check of electrical equipment.

External Power Receptacle

Rev 1 For Training Purposes Only 4-1

Copyright © 2006, Donald W. Sims, All rights reserved

SimsAir Piaggio Avanti Electrical System

The switches for controlling the electrical system are located in the MASTER SWITCHES panel

on the left section of the instrument panel and in the ENGINES panel on the control pedestal:

• The two-three-position switches placarded GENERATOR L-OFF-RESET (left) and

R-OFF-RESET (right) allow controlling the corresponding generator through individual

control units.

• The two-position battery switch placarded BAT-OFF, controls the power delivery from the

battery to the bus system through the battery relay.

• The three-position bus switch placarded EMER-NORM-BUS DISC provides control of the

busses interconnection system.

• The AVIONICS ON-COM1 ONLY-OFF master switch controls the power delivery to the

entire avionics equipment or to the primary VHF communication system only.

• The two INVERTERS switches placarded PRI-OFF and SEC-OFF, control the power

delivery to the primary and to the secondary inverter respectively.

• The L START-OFF and the R START-OFF start switches control the starter-operating

mode of the generators.

MASTER SWTCHES panel

The starting power is delivered to each starter/ generator from the battery bus through individual

start-relays. Momentary depressing to the START position each spring loaded start switch, the

corresponding starter/generator control unit initiates the starting cycle converting the generator to

the starter mode and actuating the engine ignition unit. As the engine reaches the 40% Ng speed,

the start switch automatically resets and the starting power is disconnected. At this point the

starter/generator is driven by the engine. After the 54% Ng speed has been reached, the

generator can be used provided the corresponding switch is moved from the OFF to the L (or R)

position.

4-2 For Training Purposes Only Rev 1

Copyright © 2006, Donald W. Sims, All rights reserved

Electrical System Piaggio Avanti SimsAir

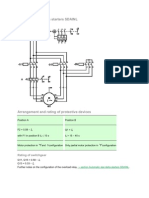

D.C. ELECTRICAL DIAGRAM

Rev 1 For Training Purposes Only 4-3

Copyright © 2006, Donald W. Sims, All rights reserved

SimsAir Piaggio Avanti Electrical System

BUS LOAD DISTRIBUTION

L SINGLE FEED BUS R SINGLE FEED BUS L DUAL FEED BUS R DUAL FEED BUS

PRI WSHLD CONT READING LIGHTS A.O.A. HEATER AVIONICS FAN NOSE

LIGHTS DIMMER FLOOR LIGHTS LTS DOOR ACTR BOOTS DE-ICER

L MAIN FUEL PUMP PAS ADVSY LIGHTS L FUEL QUANTITY R WING HEATER

POS LIGHTS TRIM L OIL COOLER L FUEL FIREWALL SOV R FUEL SOV

YAW TRIM R FWD WING HEATER L ENG ICE VANE R ENG ICE VANE

L FWD WING HEATER SEC WHSLD CONT TAXI LIGHT R OIL COOLER

CKPT BLOWER FIRE DETECTOR TEST L BLEED AIR R BLEED AIR

SOV FLOOR DIFF AIR CONDITIONING L WING HEATER R PITOT STATIC HTR

L LDG LT TRIM POSITION IND L TORQUE R TORQUE

STBY HORIZON ANTICOLLISION LTS L TURB RPM R TURB RPM

GROUND BEACON L PROPELLER RPM R OIL PRESS

R LDG LT L OIL PRESS R OIL TEMP

CLOCK L OIL TEMP R FUEL PRESS

WING INSPECT LIGHT L FUEL PRESS FILTER

R MAIN FUEL PIMP FILTER CABIN PRESS

SEC INVERTER PRI PITCH TRIM R FUEL QTY

REC LIGHT L TURB TEMP AUTOFEATHER

R TURB TEMP

PROP SYNCH

CHIP DETECTOR

L AVIONICS BUS BATTERY BUS L GENERATOR BUS R GENERATOR BUS

PRI VSI PRI PITCH TRIM POWER PILOT WSHLD ZONE 2 R GEN CONTROL

HSI 1 R ENG START ANTI-ICE L WSHLD ZONE 6

MPU L L ENG START UTILITY DEFOG

MFD R STBY FUEL PUMP L FWD WING, ANTI-ICE R FWD WING ANTI-ICE

RMI 1 L STBY FUEL PUMP L WSHLD ZONE 3 HYD PUMP MOTOR

DME 1 DEFOG L WSHLD ZONE 1

FLAPS ANTI-ICE

L GEN CONTROL

4-4 For Training Purposes Only Rev 1

Copyright © 2006, Donald W. Sims, All rights reserved

Electrical System Piaggio Avanti SimsAir

ESSENTIAL BUS ESSENTIAL AVIONICS BUS R AVIONICS BUS HOT BATTERY BUS

MASTER AVIONICS DPU 1 ADF 2 R FUEL SOV

COMM 1 ADI 1 DME 2 BATTERY RELAY

AUDIO 1 (PIL) DSP 1 SENSOR (LRN) L FUEL SOV

R OVERLOAD SENSOR CDU (LRN) HYD LEVEL / FILTER

L OVERLOAD SENSOR ADC/ALI PWR (LRN) ENG OIL

R ENG START MSI/ADC DSP GRND TEST PANEL

L ENG START NAV 1 PWR DPU REFUEL

IGNITION SYSTEM XPNDR 1 HSI ENTRY/BAGG LIGHT

BUS DISCONNECT COMPASS 1 PWR ADI R FIRE EXT

R DC GEN RESET L FIRE EXT

L DC GEN RESET COMM 2

HYDR WARNING/PRESS NAV 2 PWR

FLOOD LIGHT XPNDR 2

FUEL CROSSFEED ADF 1

MFDI RMl 2

WING OVHT RADIO ALTM

L PITOT STATIC HEATER AUDIO 2(COPIL)

OXY VALVE ALTM

LDG GEAR CONTROL

NOSE STEERING MPU R

STALL WARNING AUTOPILOT

PRI INVERTER AIR DATA SENSOR

WARNING SYS LIGHTS AP SERVOS

SEC PITCH TRIM HSI

BAT TEMP (MFDI) COMPASS 2 PWR

AURAL WRN RDR METEO

ICE DETECTOR

LDG GEAR POS LTS

TURN/SLIP IND

Rev 1 For Training Purposes Only 4-5

Copyright © 2006, Donald W. Sims, All rights reserved

SimsAir Piaggio Avanti Electrical System

MAIN JUNCTION BOX CIRCUIT BREAKER PANEL

NOTE

This circuit breaker panel is located in the baggage compartment and cannot be reached during

flight.

The cross-start system provides generator power to assist the battery in starting the second

engine. A generator assisted start is accomplished by engaging the operative engine generator.

The inoperative engine will receive power from both the battery and the running generator when

the start switch of the engine to be started is moved to the START position.

Resetting a generator after it has been de-energized by its own control unit requires that the

corresponding GENERATOR switch is pushed to the momentary RESET position and then

raised to the L (or R) position. The resetting circuit of each generator is protected by the

corresponding L or R GEN RESET 3-ampere circuit breaker on the pilot circuit breaker panel.

The L GEN and R GEN amber caution lights on the annunciator display come on when the

corresponding generator is either disengaged or failed.

The L and R GEN/START INTLK remote control circuit breakers located on the copilot circuit

breaker panel protect the output line from each generator and the corresponding control unit.

Each starter/generator control unit performs the following operating functions:

4-6 For Training Purposes Only Rev 1

Copyright © 2006, Donald W. Sims, All rights reserved

Electrical System Piaggio Avanti SimsAir

• Output voltage regulation

• Generators paralleling (load division control)

• Over voltage protection

• Over excitation protection

• Reverse current protection

• Automatic start cycle control

The battery is permanently connected to the hot battery bus and it can be connected on the bus

system only by setting to the BAT position the battery switch. A temperature probe installed on

the battery allows monitoring the battery temperature that will be displayed on the multi function

display indicator after selecting the BAT TEMP position. In addition a BAT TEMP amber caution

light and BAT OVHT red warning light are provided on the annunciator display to alert the pilot

the BAT TEMP light will come on when the battery temperature reaches 120 °F (battery warm),

while the BAT 0VHT light will come on when the battery temperature reaches 150 °F (battery

overheat).

Engine battery starts must be avoided if the battery is warm. (Above 120 °F) in order to prevent

possible battery destruction. In this condition secure ground power unit assist. When a battery

start or heavy charging is in progress the battery temperature will increase. The BAT TEMP light

may come on but this is not a warning, just a caution. If the BAT OVHT light (150 °F) comes on,

isolate the battery as soon as possible and allow to cool but continue to monitor the temperature.

NOTE

If the battery temperature reaches 150 °F. either during start or in flight, the battery must be

turned off and removed for bench test inspection prior to the next flight.

After engines are started and generators are running, note the battery temperature. If the

temperature has risen to 140 °F or above do not take off until the temperature has decreased to

120 °F and descending. After the takeoff, observe that the temperature continues to drop, the

BAT TEMP and the BAT OVHT lights should be off.

Subsequent to the takeoff and the flight if the BAT TEMP comes back on and the temperature is

in the caution range, the crew should monitor the trend. If the temperature continues to rise,

disconnect the battery at 140 °F and run on the generators.

If the temperature continues to rise after disconnection land the airplane as soon as practical. If

running on generators only when approaching terminal area if the battery has cooled below 120

°F, place it on the bus to land in order to prevent total power loss during engine idling. If the BAT

TEMP light comes back can turn the battery off exercise caution and notify tower of the problem

before landing. The battery temperature monitoring system is fed by the essential bus through

the 3-ampere BAT TEMP circuit breaker located on the pilot circuit breaker panel. The external

power socket connects on the bus system through a relay that actuates the connection only if the

external power source is properly plugged in (correct polarity) and the battery is on (battery

switch in BAT position). The specially shaped external power socket prevents the connection

Rev 1 For Training Purposes Only 4-7

Copyright © 2006, Donald W. Sims, All rights reserved

SimsAir Piaggio Avanti Electrical System

with inverted polarity. While the external power source is connected the EXT PWR green

advisory light in the center display panel is turned on.

NOTE

The external power source used for starting engines should have a peak capacity of at least

1200 Amps at 28 Volts D.C. and a maximum continuous capacity of 400 Amps.

D.C. electrical power supply is divided into separate busses in order to provide for safety and

redundancy in the electrical distribution system. Nine primary feed busses are provided:

• One essential triple feed bus

• Two dual feed busses (left and right)

• Two single feed busses (left anti right)

• Two generator busses (left and right)

• One battery bus

• One hot battery bus

The essential bus is fed from the battery and both generators. The left and right feeding lines are

individually protected by a reverse current diode and a circuit breaker. While the center feeding

line (from the battery bus) is protected by a reverse current diode and the 35-ampere ESNTL

BUS FEEDER circuit breaker located in the main junction box circuit breaker panel. The ESNTL

BUS 23 Amp circuit breakers from the generators are located on the pilot and the copilot circuit

breaker panels. The system ensures the essential bus operation also in the event of independent

failures on two of the three feeding lines.

The dual feed buses are fed from the battery and from the corresponding side generator. Each

feeding line is protected by a reverse current diode and the 35-ampere LH and RH DUAL BUS

FEEDER circuit breaker located in the main junction box circuit breaker panel. The L and R

DUAL FEED BUS 35 Amp circuit breakers froth the generators are located on the pilot and the

copilot circuit breaker panel respectively. The dual feed busses fail to supply the related loads

when failures occur on both feeding sources.

The single feed busses are fed from the corresponding side generator through individual 90

Amp. circuit breakers located in the main junction box.

The generator busses, the battery bus and the hot battery bus have no special protection due to

the reduced size and the very close position of the feeding source.

To ensure safe flight operations the electrical loads are assigned to the various busses according

to their functions.

4-8 For Training Purposes Only Rev 1

Copyright © 2006, Donald W. Sims, All rights reserved

Electrical System Piaggio Avanti SimsAir

D.C. electrical power to the avionics equipment is supplied through three auxiliary busses:

• The essential avionics bus, fed from the essential bus

• The left avionics bus, fed from the left dual feed bus

• The right avionics bus, fed from the right dual feed bus

During normal operations all the busses are interconnected acting as a single bus system with

power being supplied from the battery and both the generators. When a failure occurs, the

affected bus disconnects from the related feeding sources and from the other busses in order to

prevent more serious damages.

When either one or both generators are properly operating and the bus switch is in the NORM

position all the busses are interconnected. In the event of both generators failure the three bus

interconnecting relays automatically open disconnecting the busses while the BUS DISC amber

caution light on the center display panel comes on. The essential bus only remains powered by

the battery (as well as the battery bus and the hot battery bus), feeding all the loads essential for

the flight in emergency condition. The pilot can re-connect the dual feed busses to the battery if

necessary by setting the bus switch to the EMER position.

WARNING

In this condition in order to avoid a too rapid discharge of the battery, disengage all equipment

not strictly required by acting on the respective control switch or circuit breaker.

When the bus switch is set to the BUS DISC position the three-bus-interconnecting relays open

separating the busses and allowing the pilot to investigate for localizing failures.

Two thermal overload sensing controls are provided at the generators busses connections on the

battery bus. If an over-current occurs, the overload sensing controls actuate the three-

bus-interconnecting relays that open separating the busses. The BUS DISC caution light comes

on and the BUS DISC 3-ampere circuit breaker on the pilot circuit breaker panel trips out.

The electrical system is monitored through the Multi Function Display Indicator (MFDI) located on

the pilot instrument panel. The display selector allows displaying the desired function when

rotated to the related position.

• The output current of each generator (L and R GEN positions)

• The system voltage at the essential bus (BUS VOLTS position)

• The battery temperature (BAT TEMP position).

In the event the measured currents are above the maximum allowed value of 420 amps the

WARN reading will appear on the display alternatively to the displayed function and

independently from the display selector position.

Rev 1 For Training Purposes Only 4-9

Copyright © 2006, Donald W. Sims, All rights reserved

SimsAir Piaggio Avanti Electrical System

A.C. ELECTRICAL POWER

The A.C. electrical power required for avionics equipment is provided by two 250 volt-ampere

static inverters located in the nose compartment. The power output from both the inverters is

controlled by a unique control unit that connects each inverter to a proper 26 VAC bus and a

proper 115 VAC bus. The power is delivered from the buses to the using systems through fuses

located inside the inverter control unit. The loads are divided between the two inverters as per

their function. The primary inverter feeds the most important loads, while the secondary feeds the

remaining loads. The two-position INVERTERS control switches, marked PRI-OFF and

SEC-OFF respectively are located in the MASTER SWITCHES panel on the pilot instrument

panel. The primary inverter is feed from the essential bus through the PRI INV 15-ampere circuit

breaker on the pilot circuit breaker panel. The secondary inverter is fed from the right single feed

bus through the SEC INV 15 ampere circuit breaker on the copilot circuit breaker panel.

In the event of the primary inverter failure the control unit automatically connects the primary

inverters loads on the secondary inverter while the secondary inverter loads remain

disconnected. In the event of the secondary inverter failure the related loads are lost.

The inverters control unit drives, the PRI INV and the SEC INV amber caution lights on the

annunciator display. Each caution light comes on if the corresponding inverter is either failed or

disconnected.

4-10 For Training Purposes Only Rev 1

Copyright © 2006, Donald W. Sims, All rights reserved

Electrical System Piaggio Avanti SimsAir

A.C. ELECTRICAL DIAGRAM

Rev 1 For Training Purposes Only 4-11

Copyright © 2006, Donald W. Sims, All rights reserved

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 0020-P180 PTG Sec 20Documento16 pagine0020-P180 PTG Sec 20dwsims100% (1)

- N249C - Maintenance Tracking ReportDocumento1 paginaN249C - Maintenance Tracking ReportdwsimsNessuna valutazione finora

- 0022-P180 PTG Sec 22Documento10 pagine0022-P180 PTG Sec 22dwsims100% (1)

- 0019-P180 PTG Sec 19Documento40 pagine0019-P180 PTG Sec 19dwsims100% (1)

- 0016-P180 PTG Sec 16Documento6 pagine0016-P180 PTG Sec 16dwsims100% (2)

- 0018-P180 PTG Sec 18Documento13 pagine0018-P180 PTG Sec 18dwsims100% (1)

- 0015-P180 PTG Sec 15Documento8 pagine0015-P180 PTG Sec 15dwsims100% (1)

- 0010P180 PTG Sec 10Documento4 pagine0010P180 PTG Sec 10dwsimsNessuna valutazione finora

- 0006-P180 PTG Sec 6Documento11 pagine0006-P180 PTG Sec 6dwsimsNessuna valutazione finora

- 0014-P180 PTG Sec 14Documento8 pagine0014-P180 PTG Sec 14dwsims100% (2)

- 0012-P180 PTG Sec 12Documento9 pagine0012-P180 PTG Sec 12dwsims100% (1)

- 0011-P180 PTG Sec 11Documento11 pagine0011-P180 PTG Sec 11dwsims100% (1)

- 0013-P180 PTG Sec 13Documento6 pagine0013-P180 PTG Sec 13dwsims100% (1)

- 0008-P180 PTG Sec 8Documento13 pagine0008-P180 PTG Sec 8dwsimsNessuna valutazione finora

- 0009-P180 PTG Sec 9Documento6 pagine0009-P180 PTG Sec 9dwsimsNessuna valutazione finora

- 0007-P180 PTG Sec 7Documento3 pagine0007-P180 PTG Sec 7dwsims100% (1)

- 0005-P180 PTG Sec 5Documento7 pagine0005-P180 PTG Sec 5dwsimsNessuna valutazione finora

- 0002-P180 PTG Sec 2Documento39 pagine0002-P180 PTG Sec 2dwsims100% (1)

- 0003-P180 PTG Sec 3Documento5 pagine0003-P180 PTG Sec 3dwsimsNessuna valutazione finora

- 0001-P180 PTG Sec 1Documento13 pagine0001-P180 PTG Sec 1dwsims100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Green House Monitoring and Controlling Using Arduino: Submitted By-Abhishek Kumar JhaDocumento32 pagineGreen House Monitoring and Controlling Using Arduino: Submitted By-Abhishek Kumar JhaVito cocNessuna valutazione finora

- Technical SpecificationDocumento22 pagineTechnical SpecificationWilliam RuizNessuna valutazione finora

- Finder Relays Series 65Documento5 pagineFinder Relays Series 65PT. Tunas Ruang MesinNessuna valutazione finora

- Catalogue Installation TesterDocumento8 pagineCatalogue Installation TesterThanh Tam NguyenNessuna valutazione finora

- Automatic Star DeltaDocumento3 pagineAutomatic Star DeltaJitendra JainNessuna valutazione finora

- Datasheet - TR22AxxKNX - ENG - ITADocumento2 pagineDatasheet - TR22AxxKNX - ENG - ITAVishal SuryawaniNessuna valutazione finora

- Manual On Protection of GEN and GEN Transformer and 220 KV and 400 KV Network CBIPDocumento56 pagineManual On Protection of GEN and GEN Transformer and 220 KV and 400 KV Network CBIPMallikarjun Reddy92% (12)

- Elmeasure Automatic Power Factor Controller CatalogDocumento1 paginaElmeasure Automatic Power Factor Controller CatalogSEO BDMNessuna valutazione finora

- Unit-III: (Electromagnetic and Static Relays)Documento81 pagineUnit-III: (Electromagnetic and Static Relays)Shashikant MauryaNessuna valutazione finora

- 2016 SB03 Troubleshooting 12 V14 TAGECDcircuitDocumento10 pagine2016 SB03 Troubleshooting 12 V14 TAGECDcircuitAadarsh ReddyNessuna valutazione finora

- Fanuc PLC Syllabus - NewDocumento5 pagineFanuc PLC Syllabus - NewAbraham GutierrezNessuna valutazione finora

- ND4000A Technical-Instruction Chg1 01jul04Documento247 pagineND4000A Technical-Instruction Chg1 01jul04Syifa QolbiNessuna valutazione finora

- TH360B Plano Sistema ElectricoDocumento4 pagineTH360B Plano Sistema ElectricoCarlos Irabedra100% (1)

- Pressure Sensor With Relay Output PC250-Gi1/4A1M-ARX-B1151: Outp Ut1Documento2 paginePressure Sensor With Relay Output PC250-Gi1/4A1M-ARX-B1151: Outp Ut1CesarNessuna valutazione finora

- Motor Controller CenterDocumento17 pagineMotor Controller CenterSimbu ArasanNessuna valutazione finora

- Over CurrentDocumento30 pagineOver CurrentbaluNessuna valutazione finora

- S4000TH General Monitor Gas Detector Data SheetDocumento2 pagineS4000TH General Monitor Gas Detector Data SheetmuthuNessuna valutazione finora

- ISMA-B-MINI and MIX Series IO Manual ModbusDocumento75 pagineISMA-B-MINI and MIX Series IO Manual ModbusAndrea De PaolisNessuna valutazione finora

- High Speed Tripping Relay: Description FeaturesDocumento4 pagineHigh Speed Tripping Relay: Description FeaturestoogooodNessuna valutazione finora

- Tyco Rele EC V23078-c1002-A303 DatasheetDocumento5 pagineTyco Rele EC V23078-c1002-A303 DatasheetLuis Gustavo Coqueiro LeiteNessuna valutazione finora

- Omnicron Substation High Voltage CommissioningDocumento16 pagineOmnicron Substation High Voltage CommissioningZahidul zahidNessuna valutazione finora

- Manual All MultizetDocumento9 pagineManual All MultizetalbundNessuna valutazione finora

- Manual Softstarter 3RW52 en-USDocumento178 pagineManual Softstarter 3RW52 en-USCatarina ContenteNessuna valutazione finora

- Cherokee 2.5 TD PCMDocumento4 pagineCherokee 2.5 TD PCMNazael DiazNessuna valutazione finora

- 15ppm Alarm - BILGMON 488: Info@brannstrom - SeDocumento2 pagine15ppm Alarm - BILGMON 488: Info@brannstrom - SeAicky IkrackNessuna valutazione finora

- Dhesive Onitor Ystem: Copar CorporationDocumento2 pagineDhesive Onitor Ystem: Copar CorporationFernando MurrietaNessuna valutazione finora

- fh235 InstallationDocumento11 paginefh235 InstallationYudi setiawanNessuna valutazione finora

- GCP 32 - 37239 PDFDocumento45 pagineGCP 32 - 37239 PDFwagner_guimarães_1Nessuna valutazione finora

- Data Sheet 6ES7215-1HG40-0XB0: General InformationDocumento9 pagineData Sheet 6ES7215-1HG40-0XB0: General InformationDiego MontanezNessuna valutazione finora

- B43ib20c e Cobrix3 ServicebookDocumento90 pagineB43ib20c e Cobrix3 Servicebookfrank02130% (1)