Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M11

Caricato da

Saurav KauraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M11

Caricato da

Saurav KauraCopyright:

Formati disponibili

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Module 11: Regenerative braking

Lecture 38: Fundamentals of Regenerative Braking

Fundamentals of Regenerative Braking

The topics covered in this chapter are as follows:

Introduction.

Energy Consumption in Braking

Braking Power and Energy on Front and Rear Wheels

Introduction

The electric motors in EVs and HEVs can be controlled to operate as generators to

convert the kinetic or potential energy of the vehicle mass into electric energy that can be

stored in the energy storage and reused. A successfully designed braking system for a

vehicle must always meet two distinct demands:

i. In emergency braking, the braking system must bring the vehicle to rest in the

shortest possible distance.

ii. The braking system must maintain control over the vehicles direction, which

requires braking force to be distributed equally on all the wheels.

Energy Consumption in Braking

A significant amount of energy is consumed by braking. Braking a 1500 kg vehicle from

100 km/h to zero speed consumes about 0.16 kWh of energy (0.5 Mv V2) in a few tens

of meters. If this amount of energy is consumed in coasting by only overcoming the drags

(rolling resistance and aerodynamic drag) without braking, the vehicle will travel about 2

km, as shown in Figure 1. When vehicles are driving with a stop-and-go pattern in urban

areas, a significant amount of energy is consumed by frequent braking, which results in

high fuel consumption.

The braking energy in typical urban areas may reach up to more than 25% of the total

traction energy. In large cities, such as New York, it may reach up to 70%. It is

concluded that effective regenerative braking can significantly improve the fuel economy

of EVs and HEVs.

Joint initiative of IITs and IISc Funded by MHRD

Page 1 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Braking Power and Energy on Front and Rear Wheels

Braking power and braking energy consumed by the front and rear wheels are closely

related to the braking forces on the front and rear wheels. A full understanding of the

braking force, braking power, and braking energy consumed by the front and rear wheels

in typical drive cycles is helpful in the design of regenerative braking systems.

Figure 1: Coasting time, Speed and Distance [1]

Joint initiative of IITs and IISc Funded by MHRD

Page 2 of 19

Energy (kWh)

Vehicle speed (km/h)

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Time (sec)

Figure 2: Total traction energy and energies consumed by drags and braking in an FTP 75 urban

drive cycle [2]

Initially, assuming that the braking distribution on the front and rear wheels follow the

curve I (refer to Chapter 2), ignoring vehicle drags, the braking forces on the front and

rear

Fbf

and

wheels

can

be

expressed

h

jM v

( Lb g j )

L

g

Fbr

Joint initiative of IITs and IISc Funded by MHRD

h

jM v

( La g j )

L

g

Page 3 of 19

as:

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

where j is the deceleration of the vehicle in m / s 2 , L is the wheel base of the vehicle,

La and Lb are the horizontal distances between the vehicle gravity center to the center of

the front and rear wheels, respectively, and hg is the height of the gravity center of the

vehicle to the ground. Figure 3 shows vehicle speed and acceleration/deceleration in an

FTP 75 urban drive cycle.

Figures 4 - 6 show the braking force, braking power, and braking energy of a 1500 kg

passenger car in an FTP 75 urban drive cycle. This example has parameters of L =2.7 m ,

La =0.4 L , Lb =0.6 L , and hg =0.55 m .

Figures 4 - 6 indicate that:

i. The front wheels consume about 65% of the total braking power and energy.

Thus, regenerative braking on front wheels, if available only on one axle, is more

effective than on rear wheels.

ii. The braking force is almost constant in the speed range of less than 50 km / h and

decreases when the speed is greater than 40 km / h . This characteristic naturally

matches that of an electric motor that has a constant torque at the low-speed

region and a constant power at the high-speed region. Further, Figure 6 indicates

that most braking energy is consumed in the speed range of 10 to 50 km / h .

Joint initiative of IITs and IISc Funded by MHRD

Page 4 of 19

Acceleration/deceleration (m/sec2)

Vehicle speed (km/h)

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Time (sec)

Figure 3: Vehicle speed and acceleration/deceleration in an FTP urban drive cycle [1]

Joint initiative of IITs and IISc Funded by MHRD

Page 5 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Brake force (front axle) (kN)

1.2

1

0.8

0.6

0.4

0.2

0

0

20

40

20

40

60

80

Vehicle Speed (km/h)

Braking force (rear axle) (kN)

1.2

1

0.8

0.6

0.4

0.2

0

0

60

Vehicle Speed (km/h)

(a)

80

(b)

Figure 4: Braking force vs. vehicle speed in an FTP 75 urban drive cycle: (a) on front wheels and (b)

on rear wheels.[1]

Joint initiative of IITs and IISc Funded by MHRD

Page 6 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Brake power (front axle)

(kW)

15

10

0

0

20

Vehicle40Speed 60

(km/h)80

20

Vehicle40Speed 60

(km/h) 80

Brake power (rear axle)

(kW)

15

10

(a)

(b)

Figure 5: Braking power vs. vehicle speed in an FTP 75 urban drive cycle: (a) on front wheels and (b)

on rear wheels. [1]

Joint initiative of IITs and IISc Funded by MHRD

Page 7 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Braking energy (front axle)

(kWh)

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0

0

20

Vehicle40Speed 60

(km/h)80

Brake energy (rear axle)

(kWh)

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0

0

20

40

Vehicle

Speed 60

(km/h)80

(a)

(b)

Figure 6: Braking energy vs. vehicle speed in an FTP 75 urban drive cycle: (a) on front wheels and

(b) on rear wheels. [1]

References:

[1]. M. Ehsani, Modern Electric, Hybrid Electric and Fuel Cell Vehicles: Fundamentals,

Theory and Design, CRC Press, 2005

[2] A. E. Fuhs, Hybrid Vehicles and the Future of Personal Transportation, CRC Press,

2009

Joint initiative of IITs and IISc Funded by MHRD

Page 8 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Lecture 39: Brake System of EVs and HEVs

Brake System of EVs and HEVs

The topics covered in this chapter are as follows:

Brake System of EVs and HEVs

Series Brake Optimal Feel

Series Brake Optimal Energy Recovery

Parallel Brake

Antilock Brake System (ABS)

Brake System of EVs and HEVs

Two basic questions arise while considering regenerative braking in EVs and HEVs:

i.

How to distribute the total braking forces required between the regenerative

brake and the mechanical friction brake so as to recover the kinetic energy of the

vehicle as much as possible.

ii.

The other is how to distribute the total braking forces on the front and rear axles

so as to achieve a steady-state braking.

Basically, there are three different brake control strategies: series braking with optimal

braking feel; series braking with optimal energy recovery; and parallel braking.

Series Brake -- Optimal Feel

The control objective is to minimize the stopping distance and optimize the drivers feel.

Figure 1 illustrates the principle of this braking control strategy. When the commanded

deceleration (represented by the braking pedal position) is less than 0.2 g , only the

regenerative braking on the front wheels is applied, which emulates the engine retarding

function in conventional vehicles. When the commanded deceleration is greater than 0.2

g , the braking forces on the front and rear wheels follow the ideal braking forces

distribution curve I, as shown in Figure 1 by the thick solid line.

The braking force on the front wheels (driven axle) is divided into two parts: regenerative

braking force and mechanically frictional braking force. When the braking force

demanded is less than the maximum braking force that the electric motor can produce,

only electrically regenerative braking will apply. When the commanded braking force is

greater than the available regenerative braking force, the electric motor will operate to

Joint initiative of IITs and IISc Funded by MHRD

Page 9 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

produce its maximum braking torque, and the remaining braking force is met by the

mechanical brake system.

It should be noted that the maximum regenerative braking force produced by an electric

motor is closely related to the electric motors speed. At low speed (lower than its base

speed), the maximum torque is constant. However, at high speed (higher than its base

speed), the maximum torque decreases hyperbolically with its speed. Therefore, the

mechanical brake torque at a given vehicle deceleration varies with vehicle speed.

Figure 1: Illustration of braking forces on the front and rear axle for series braking - optimal feel [1]

Joint initiative of IITs and IISc Funded by MHRD

Page 10 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Series Brake - Optimal Energy Recovery

The principle of the series braking system with optimal energy recovery is to recover the

braking energy as much as possible in the condition of meeting the total braking force

demanded for the given deceleration. This principle is illustrated in Figure 2.

When the vehicle is braked with an acceleration rate of j / g , the braking forces on

the front and rear wheels can be varied in a certain range, as long as the Fbf Fbr M v j is

satisfied. This variation range of the front and rear axles is shown in Figure 2 by the

thick solid line ab , where 0.9 and j / g 0.7 . In this case, regenerative braking

should be used in priority. If the available regenerative braking force (maximum braking

force produced by the electric motor) is in this range (point c in Figure 2, for example),

the braking force on the front wheels should be developed only by regenerative braking

without mechanical braking. The braking force on the rear wheels, represented by point e

, should be developed in order to meet the total braking force requirement. If, on the same

road, the available regenerative braking force is less than the value corresponding to point

a (e.g.

Joint initiative of IITs and IISc Funded by MHRD

Page 11 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Figure 2: Demonstration of series braking optimal energy recovery [1]

point i in Figure 2), the electric motor should be controlled to produce its maximum

regenerative braking force. The front and rear braking forces should be controlled at point

f so as to optimize the driver feel and reduce braking distance. In this case, additional

braking force on the front wheels must be developed by mechanical braking by the

amount represented by Fbf mech , and the braking force on the rear axle is represented by

point h .

Joint initiative of IITs and IISc Funded by MHRD

Page 12 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

When the commanded deceleration rate,

j / g , is much smaller than the road adhesive

coefficient ( j / g 0.3 in Figure 2 for example), and the regenerative braking force can

meet the total braking force demand, only regenerative braking is used without

mechanical braking on the front and rear wheels (point j in Figure 2).

When the commanded deceleration rate, j / g , is equal to the road adhesive coefficient

, the operating point of the front and rear braking forces must be on the curve I . On a

road with a high adhesive coefficient ( 0.7 , operating point f , in Figure 2, for

example), the maximum regenerative braking force is applied and the remaining is

supplied by the mechanical brake. On a road with a low adhesive coefficient ( 0.4 ,

operating point k , in Figure 2, for example), regenerative braking alone is used to

develop the front braking force.

When the commanded deceleration rate, j / g , is greater than the road adhesive

coefficient , this commanded deceleration rate will never be reached due to the

limitation of the road adhesion. The maximum deceleration that the vehicle can obtain is

(a / g )max . The operating point of the front and rear braking forces is on the curve I ,

corresponding to ( 0.4 and

j / g 0.4 in Figure 2, for example); the operating

point is point k and the maximum deceleration rate is j / g 0.4 .

It should be noted that the series brake with both optimal feel and energy recovery

needed active control of both electric regenerative braking and mechanical braking forces

on the front and rear wheels. At present, such a braking system is under research and

development.

Parallel Brake

The parallel brake system includes both an electrical (regenerative) brake and a

mechanical brake, which produce braking forces is parallel and simultaneously. The

operating principle is illustrated in Figure 3, in which regenerative braking is applied

only to the front wheels.

The parallel brake system has a conventional mechanical brake which has a fixed ratio of

braking force distribution on the front and rear wheels. Regenerative braking adds

additional braking force to the front wheels, resulting in the total braking force

distribution curve. The mechanical braking forces on the front and rear axles are

Joint initiative of IITs and IISc Funded by MHRD

Page 13 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

proportional to the hydraulic pressure in the master cylinder. The regenerative braking

force developed by the electric motor is a function of the hydraulic pressure of the master

cylinder, and therefore a function of vehicle deceleration. Because the regenerative

braking force available is a function of motor speed and because almost no kinetic energy

can be recovered at low motor speed, the regenerative braking force at high vehicle

deceleration (e.g., a / g 0.9 ) is designed to be zero so as to maintain braking balance.

When the demanded deceleration is less than this deceleration, regenerative braking is

effective. When the braking deceleration commanded is less than a given value, say

0.15g , only regenerative braking is applied. This emulates the engine retarding in a

conventional vehicle. In Figure 3, the regenerative braking force, Fbf regen , and

mechanical braking forces on the front and rear wheels, Fbf mech and Fbr , are illustrated.

Figure 4 shows the total braking force, regenerative braking force, and mechanical

braking force on the front wheels as well as the braking force on the rear wheels in the

parallel braking system of a passenger car.

The parallel braking system does not need an electronically controlled mechanical brake

system. A pressure sensor senses the hydraulic pressure in the master cylinder, which

represents the deceleration

Joint initiative of IITs and IISc Funded by MHRD

Page 14 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Figure 3: Illustration of parallel braking strategy [1]

Joint initiative of IITs and IISc Funded by MHRD

Page 15 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Braking force (kN)

0-a-b-c-d: total braking force on front wheels

0-a-e-f-g: regenerative braking forces on front wheels

0-h-i-c-d: mechanical braking on front wheels

0-h-j-k-m: braking force on rear wheels

Braking deceleration rate (g)

Figure 4: Braking forces varying with deceleration rate [1]

demand. The pressure signal is regulated and sent to the electric motor controller to

control the electric motor to produce the demanded braking torque. Compared with the

series braking of both optimal feel and energy recovery, the parallel braking system has a

much simpler construction and control system. However, the drivers feeling, and amount

of energy recovered are compromised.

Antilock Brake System (ABS)

Active control of the braking force (torque) of the electric motor is easier than the control

of the mechanical braking force. Thus, antilock in braking with an electric brake in EVs

and HEVs is another inherent advantage, especially for a vehicle with an electric motor

on four wheels. Figure 5 conceptually illustrates a scheme of regenerative braking, which

can potentially function as an ABS.

Joint initiative of IITs and IISc Funded by MHRD

Page 16 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

The main components of this braking system are the brake pedal, master cylinder,

electrically powered and electronically controlled brake actuators, electronically

controlled three-port switches (common mode: port 1 open, port 2 close, and port 3

open), fluid accumulator, pressure sensor, and an overall controller unit. The pressure

sensor measures the fluid pressure, which represents the drivers desirable braking

strength. The fluid is discharged into the fluid accumulator through the electronically

controlled three-port switches. This emulates the braking feeling of a conventional

braking system. After receiving a braking pressure signal, the overall controller unit

determines the braking torques of the front and rear wheels, regenerative braking torque,

and mechanical braking torque, according to the traction motor characteristics and control

rule. The motor controller (not shown in Figure 5) commands the motor to produce

correct braking torque, and the mechanical braking controller commands the electrically

powered braking actuator to produce correct braking torques for each wheel. The braking

actuators are also controlled to function as an antilock system to prevent the wheels from

being locked completely. If an electrically powered braking actuator is detected to be a

failure, the corresponding three-port switch closes port 3 and opens port 2, and then fluid

is directly discharged to the wheel cylinder to produce braking torque. The control

strategy is crucial for energy recovery and braking performance.

Figure 6 shows the simulation results of a passenger car, which is experiencing a sudden

strong braking on a road with varying road adhesive coefficients. When the commanded

braking force is less than the maximum braking force that the ground surface can support

without the wheel being locked, the actual braking force follows the commanded braking

force. However, when the commanded braking force is greater than the maximum

braking force that the ground can support, the actual braking force follows the maximum

ground braking force (in a period of 0.5 to 1.5 sec in Figure 6). Then, the wheel slip

ratios can be controlled in a proper range (usually 25% ). The vehicle will have

directional stability and short braking distance.

Joint initiative of IITs and IISc Funded by MHRD

Page 17 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Brake pedal Master cylinder

Controller

Pressure sensor

Speed sensor

Brake plate

Brake clipper

Electrically

Powered

Brake actuator

2

1

3

1

3

3

2

3

1

Three port

switch

Motor drive and

transmission

Regenerative

braking

torque

Fluid

accumulator

Figure 5: Electronically controlled regenerative braking system functioning as an ABS [1]

Joint initiative of IITs and IISc Funded by MHRD

Page 18 of 19

NPTEL Electrical Engineering Introduction to Hybrid and Electric Vehicles

Figure 6: Braking with ABS [1]

References:

[1]. M. Ehsani, Modern Electric, Hybrid Electric and Fuel Cell Vehicles: Fundamentals,

Theory and Design, CRC Press, 2005

Joint initiative of IITs and IISc Funded by MHRD

Page 19 of 19

Potrebbero piacerti anche

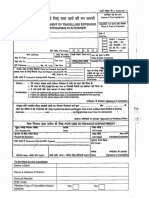

- Travelling ExpensesDocumento1 paginaTravelling ExpensesSaurav KauraNessuna valutazione finora

- Fee EWDocumento1 paginaFee EWSaurav KauraNessuna valutazione finora

- JEE Main Closing Ranks Category Wise For Spot RoundDocumento131 pagineJEE Main Closing Ranks Category Wise For Spot RoundAnweshaBoseNessuna valutazione finora

- Indian Institute of Technology Delhi: Application For Summer Research Fellowship Programme 2015 at Iit DelhiDocumento1 paginaIndian Institute of Technology Delhi: Application For Summer Research Fellowship Programme 2015 at Iit DelhiSaurav KauraNessuna valutazione finora

- User Guide IRCTCDocumento56 pagineUser Guide IRCTCShubhamGuptaNessuna valutazione finora

- Turowicz 1Documento62 pagineTurowicz 1Saurav KauraNessuna valutazione finora

- 2.1 Fiber Dispersion: Chapter 2: Optical Fiber Characteristics and System ConfigurationsDocumento23 pagine2.1 Fiber Dispersion: Chapter 2: Optical Fiber Characteristics and System ConfigurationsSaurav KauraNessuna valutazione finora

- Closing Ranks After Round IIIDocumento159 pagineClosing Ranks After Round IIIvidushi1121Nessuna valutazione finora

- Multi-Agent Systems: Which Research For Which ApplicationsDocumento16 pagineMulti-Agent Systems: Which Research For Which ApplicationsSaurav KauraNessuna valutazione finora

- 320 Lecture 15Documento10 pagine320 Lecture 15Murali MohanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Melt Viscometer For PET Testing Intrinsic Viscosity (IV) and Melt Viscosity (MV) MeasurementDocumento3 pagineMelt Viscometer For PET Testing Intrinsic Viscosity (IV) and Melt Viscosity (MV) MeasurementAnjum ParkarNessuna valutazione finora

- Xray Generation TroubleshootingDocumento50 pagineXray Generation TroubleshootingLuis BattaNessuna valutazione finora

- Object-Oriented Database Processing: Lecture Notes: CS/MIS 43 - 5/13/03Documento5 pagineObject-Oriented Database Processing: Lecture Notes: CS/MIS 43 - 5/13/03Ranju BhagatNessuna valutazione finora

- Important Note (S) :-To Participate in The Online Auction, There Is Need To Obtain Digital Signature Certificate (DSC) - Bidders Can Date andDocumento5 pagineImportant Note (S) :-To Participate in The Online Auction, There Is Need To Obtain Digital Signature Certificate (DSC) - Bidders Can Date andRunveer SurwadeNessuna valutazione finora

- Artificial Intelligence in 5GDocumento34 pagineArtificial Intelligence in 5GSakhawat Ali SahgalNessuna valutazione finora

- 14a03 tc358870 ProdbriefDocumento2 pagine14a03 tc358870 ProdbriefrahulNessuna valutazione finora

- (Delta Power) Esaa250-Haa Series r00 - VNPT NetDocumento5 pagine(Delta Power) Esaa250-Haa Series r00 - VNPT NetSangyup LeeNessuna valutazione finora

- Arun &associatesDocumento12 pagineArun &associatesSujaa SaravanakhumaarNessuna valutazione finora

- Steam - Receipt For Key SubscriptionDocumento1 paginaSteam - Receipt For Key SubscriptionLuis Felipe BuenoNessuna valutazione finora

- Prince2 ThemesDocumento3 paginePrince2 Themesshiva_1912-1Nessuna valutazione finora

- Dongleserver 20xusbDocumento8 pagineDongleserver 20xusbmasoodkamaliNessuna valutazione finora

- Ella Mae C. Acla Resume 2023 PDFDocumento2 pagineElla Mae C. Acla Resume 2023 PDFMark Wilber Diano GuzonNessuna valutazione finora

- CV-JM Van StraatenDocumento5 pagineCV-JM Van StraatenJovan Van StraatenNessuna valutazione finora

- COA - Chapter # 3Documento26 pagineCOA - Chapter # 3Set EmpNessuna valutazione finora

- CV Igor Chiriac enDocumento2 pagineCV Igor Chiriac enigorash17Nessuna valutazione finora

- ABB FactSheet SYMS - 112018Documento2 pagineABB FactSheet SYMS - 112018Muhammad Hassan BalochNessuna valutazione finora

- AVCCDocumento3 pagineAVCCTanya WilkersonNessuna valutazione finora

- PS 663x ENGDocumento10 paginePS 663x ENGtoseruNessuna valutazione finora

- Roads in MozambiqueDocumento17 pagineRoads in MozambiqueGladys Joyce FaustinoNessuna valutazione finora

- A9MEM3115 User ManualDocumento134 pagineA9MEM3115 User ManualispiracscribdNessuna valutazione finora

- Historia de Los AerogeneradoresDocumento8 pagineHistoria de Los AerogeneradoresHumberto MerizaldeNessuna valutazione finora

- Case Study II - RoffDocumento3 pagineCase Study II - RoffNikhil MaheshwariNessuna valutazione finora

- Wseries PDFDocumento4 pagineWseries PDFsongreNessuna valutazione finora

- Emerging Nokia Group Discusses Mobile Phone EvolutionDocumento11 pagineEmerging Nokia Group Discusses Mobile Phone EvolutionArunachalamNessuna valutazione finora

- Online CommunicationDocumento14 pagineOnline CommunicationClarin FleminNessuna valutazione finora

- Mechanical Engineering MSC Bulletin 2017Documento92 pagineMechanical Engineering MSC Bulletin 2017IrfanAhmadNessuna valutazione finora

- Commodore 64 Programmer's Reference GuideDocumento395 pagineCommodore 64 Programmer's Reference GuidemjmtNessuna valutazione finora

- Power Line Carrier CommunicationDocumento11 paginePower Line Carrier Communicationthe_ray004100% (1)

- Notifier FTM 1 Firephone Control ModuleDocumento2 pagineNotifier FTM 1 Firephone Control Modulejhon bayonaNessuna valutazione finora

- Advanced Python Lab GuideDocumento38 pagineAdvanced Python Lab GuideNetflix ChatbotNessuna valutazione finora