Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

EE3140 ElectronicManufacturing EAC May2013

Caricato da

Tanesh SegarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

EE3140 ElectronicManufacturing EAC May2013

Caricato da

Tanesh SegarCopyright:

Formati disponibili

1.

Name of Course/Module

INTRODUCTION TO ELECTRONIC MANUFACTURING

2.

Course Code

EE3140

3.

Name(s) of academic staf

Mr. Permesh Jethi

4.

Rationale for the inclusion of the course in the programme

The main objective of this course is to provide understanding on basic

physical properties of materials used in electronics. Manufacturing

techniques used in the making of electronic products are also covered in

this course apart from description on product development stages from an

original design to a complete and tested artefact. Student will learn how

PCBs are designed, developed and manufactured including CAD layout

generation. Impacts of manufacturing on the environment are also covered

in this course.

5.

Semester and Year ofered

Two / Year ONE

6.

7.

Total

Student

Learning

Time (SLT)

L = Lecture

T = Tutorial

P = Practical

O= Others

Credit Value

Face to Face

42

10

3 credit hours

8.

Prerequisite (if any)

None.

Total Guided and Independent

Learning

O

Guided: 56 hours

Independent Learning: 64 hours

Total: 120 hours

9.

Objective(s)

The main objective is to equip students with the understanding on

manufacturing techniques used in the making of electronic products.

Impacts of manufacturing on the environment are also covered in this

course.

10.

Learning Outcomes

LO1 Perform study on basic physical properties of materials used in

electronics (cognitive application, level 3);

LO2 Analyse PCB circuit design and fabrication (cognitive analysis, level

4);

LO3 Describe the manufacturing process for integrated circuits and its

effect on environment (cognitive comprehension, level 2).

11.

Transferable Skills

Transferable Skills developed through content-related lectures, tutorial and

practical work, continuous assessments as well as exam papers are as

follows:

12.

Transferable Skills

Taught

Practised

Self-Management

Learning

Communication

Teamwork

Problem Solving

Information Technology

Teaching-learning and assessment strategy

Assessed

Students will be given the opportunity to attend lectures, gain more

focused practice and understanding at tutorials, and hands-on experience

at the laboratory. Assessments would be conducted via test, lab, final

examination and assignment that would be evaluated based on a report

and presentation.

13.

Synopsis

This course covers every aspect of electronic packaging from development

and design to manufacturing, facilities, and testing. Students are taught

about materials, thermal management, mechanical and thermo mechanical

stress behaviour, wiring and cabling, soldering technology, integrated

circuit packaging, surface mount technologies, rigid and flexible printed

wiring boards. Students should be able to use tools and techniques to help

them in the design and analysis of analogue and digital circuits.

14.

Mode of Delivery:

Lectures, tutorials and laboratory.

15.

Assessment Methods and Type

Assessments of learning are based on a variety of information sources:

Assessment Methods

40 % Course work Assignment (20%)

Test (10%)

Lab (10%)

60% Final

Examination

16.

Exam (60%)

Assessment Type

Report writing

Written exam

Practical work & report

writing

Written exam

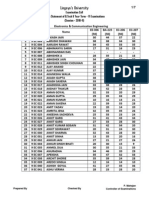

Mapping of the Course to the Learning Outcomes

LO1

LO2

LO3

Test

Assignme

nt

Lab

Exam

Learning Outcomes

LO1 Perform study on basic physical properties of materials used in

electronics;

LO2 Analyse PCB circuit design and fabrication;

LO3 Describe the manufacturing process for integrated circuits and its

effect on environment.

17.

Mapping of the Course to the Program Outcomes

LO1

LO2

LO3

PO

1

PO

2

PO

5

PO

7

Program Outcomes

PO1 Engineering Knowledge - Apply knowledge of

mathematics, science, engineering fundamentals and an engineering

specialization to the solution of complex engineering problems;

PO2 Problem Analysis - Identify, formulate, research

literature and analyse complex engineering problems reaching

substantiated conclusions using first principles of mathematics, natural

sciences and engineering sciences;

PO5 Modern Tool Usage - Create, select and apply

appropriate techniques, resources, and modern engineering and IT

tools, including prediction and modelling, to complex engineering

activities, with an understanding of the limitations;

PO7 Environment and Sustainability - Understand the

impact of professional engineering solutions in societal and

environmental contexts and demonstrate knowledge of and need for

sustainable development.

18.

Week

Content outline of the course/module and the SLT per topic

Topic

L

Materials for electronic packaging.

- Roles

of

engineering

materials,

relationship

between

products,

material

properties

and

their

processing.

Principles of Electronic Production

- Product life cycle, product and process

relationship, productivity.

SLT Hours

T

P/

IL

O

3

Tot

7

2- 3

4-5

6-7

8-9

10

11

12

13

14

Printed circuit boards

- Design, construction and manufacture

of rigid and flexible printed circuit

board versus multilayer boards. Use of

surface mount technologies

Lab 1

Passive

discrete

devicescapacitors, inductors

Physical

dimensions

and

manufacturing process.

Lab 2

resistors,

15

14

Active discrete devices- diodes, bipolar and

MOS transistors. Single chips PAL and Gate

Arrays technologies packaging in electronic

fabrications.

Integrated

circuits

construction

and

manufacture, semiconductor packaging. Chip

scale packaging and direct chip attach

technologies.

15

15

Reliability of electronic products. Connector

and interconnect technology and cabling.

Electronics

manufacturing

and

the

environment. Packaging of high speed and

microwave products. Packaging of high

voltage electronic products.

Production economics and comparative

studies on various packaging technologies.

Impact of manufacturing on the environment.

Product life cycle and process relationship.

Production reliability of electronic products.

Continuous Assessments (Test,

Assignment)

Examination

electronic

14

14

10

10

10

64

10

120

42

Total SLT

10

4

120

19.

Main references supporting the course

o

Harper C. A. (2008). Electronic Packaging and Interconnection

Handbook (4th ed.). New York: McGraw-Hill

Additional references supporting the course

o

o

Herniter, M. E. (2003).Schematic Capture with Electronics

Workbench Multisim. New Jersey: Prentice Hall

Callister W.D. (2007) Materials Science and Engineering: An

Introduction. (7th ed.). New York: John Willey

o

20.

Other additional information

Nil

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- College List-2015-16-As On 22-09-2015Documento30 pagineCollege List-2015-16-As On 22-09-2015api-303851396Nessuna valutazione finora

- Jenis-Jenis Profesi ITDocumento1 paginaJenis-Jenis Profesi ITAriSutaNessuna valutazione finora

- CS ProfessorsDocumento94 pagineCS ProfessorsiqraNessuna valutazione finora

- SPC For Non-Normal DataDocumento4 pagineSPC For Non-Normal DataEdNessuna valutazione finora

- Accelerate Special EditionDocumento132 pagineAccelerate Special EditionU.S. Army RDECOMNessuna valutazione finora

- Medc Autord Directory 2007Documento114 pagineMedc Autord Directory 2007Yogaditya ModukuriNessuna valutazione finora

- Spectrum 01Documento39 pagineSpectrum 01Chester Allan Miguel-EduriaNessuna valutazione finora

- C215 ListDocumento12 pagineC215 ListShivamNessuna valutazione finora

- IS222 Exam 2018Documento22 pagineIS222 Exam 2018TetzNessuna valutazione finora

- Automod Key FeaturesDocumento5 pagineAutomod Key Featuresfullkule0% (1)

- Articulo Semana 9 - 1Documento4 pagineArticulo Semana 9 - 1FatiiRicapaNessuna valutazione finora

- Sap Abap SQL Select Statements With ExamapleDocumento5 pagineSap Abap SQL Select Statements With ExamapleGurudath PVNessuna valutazione finora

- Internship Report HRDocumento6 pagineInternship Report HRUmer Khalid Behamni100% (1)

- 030 Ice 01 Result Dec10 InsDocumento41 pagine030 Ice 01 Result Dec10 InsDevanshu AnandNessuna valutazione finora

- The Role of Information and Communication Technology As A Tool For Effective Teaching and Learning of Mathematics 2168 9679 1000333Documento3 pagineThe Role of Information and Communication Technology As A Tool For Effective Teaching and Learning of Mathematics 2168 9679 1000333Rowly Pearl Iradiel NedicNessuna valutazione finora

- PHD Description-Marko MasicDocumento6 paginePHD Description-Marko MasicMohammad Hafiz OthmanNessuna valutazione finora

- List of Members Registered in NoidaDocumento4 pagineList of Members Registered in Noidatotan_suri8060100% (2)

- Sample Letter of Intent For Graduate Program Word FormatDocumento10 pagineSample Letter of Intent For Graduate Program Word Formatwondeful fordNessuna valutazione finora

- CGI Shortlist For Further ProcessDocumento4 pagineCGI Shortlist For Further Processhari sriNessuna valutazione finora

- Estimating Building CostDocumento10 pagineEstimating Building CostFREDIELABRADORNessuna valutazione finora

- BNMB KJHJK KJHK Ugillnlnj J LNMLKJNHKLDocumento6 pagineBNMB KJHJK KJHK Ugillnlnj J LNMLKJNHKLHumayun NawazNessuna valutazione finora

- Soviet CybernetikDocumento4 pagineSoviet CybernetikPaulo Henrique FloresNessuna valutazione finora

- Grade 11 Gas (Abm) : Time Allotment For Second Semester (3Rd Quarter)Documento13 pagineGrade 11 Gas (Abm) : Time Allotment For Second Semester (3Rd Quarter)Hart FranadaNessuna valutazione finora

- Quiz: A. Administration'S Roots in Management Quiz: A. Administration'S Roots in ManagementDocumento1 paginaQuiz: A. Administration'S Roots in Management Quiz: A. Administration'S Roots in ManagementDalayunan IloilocityNessuna valutazione finora

- Bachelor of Civil Engineering Date: ST NDDocumento3 pagineBachelor of Civil Engineering Date: ST NDRam NepaliNessuna valutazione finora

- Analysis and Design of (G+100) Storied Building by Using SoftwareDocumento3 pagineAnalysis and Design of (G+100) Storied Building by Using SoftwareInternational Journal of Innovations in Engineering and ScienceNessuna valutazione finora

- Conference ObjectivesDocumento2 pagineConference ObjectivesslametNessuna valutazione finora

- Medical Shop SynopsisDocumento12 pagineMedical Shop SynopsisSantosh Birajdar100% (1)

- Reverse Engineering: Presented By: Vishal Mahadule (ME17003)Documento15 pagineReverse Engineering: Presented By: Vishal Mahadule (ME17003)VishalNessuna valutazione finora

- EceDocumento7 pagineEceSachin BawejaNessuna valutazione finora