Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vicking - Calculating Friction Loss

Caricato da

Sérgio GnipperCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vicking - Calculating Friction Loss

Caricato da

Sérgio GnipperCopyright:

Formati disponibili

Technical Article

Calculating Friction Loss

Darcy-Weisbach Formula vs. Hazen-Williams: Why Darcy is the Appropriate

Selection in Large Volume Sprinkler Systems That Use Propylene Glycol

Scott Martorano, CFPS, Senior Manager Technical Service

March 2006

Viking Technical Article

Calculating Friction Loss

Introduction

Propylene glycol has been widely accepted and utilized in fire sprinkler systems for many years. Until recently it has been restricted

to antifreeze loops on wet pipe sprinkler systems. Innovative advances in the design of sprinklers systems and full-scale fire testing of

class 2 commodities in rack storage configurations have demonstrated that sprinkler systems pre-primed with a water and propylene

glycol solution utilizing K 25.2 sprinklers are a viable option for the protection of cold storage occupancies under certain conditions.

Full-scale burn testing has been conducted utilizing specific types of sprinkler systems; propylene glycol solutions and K 25.2 ESFR

sprinklers that have been specifically tested for the application. The listings and manufacturers installation instructions for these

propylene glycol systems are very specific with regards to the type of system, the system volume and the piping configuration. If a

system is selected to protect a cold storage occupancy using a propylene glycol solution, the fire protection designer must verify the

appropriate product listings. In addition, the manufacturers technical literature must be reviewed to ensure that the system design

is in compliance with the listings and that all of the required components have been installed.

Application

There are currently two sprinkler system configurations utilized for installation in cold storage applications that utilize piping preprimed with the propylene glycol solution. The early versions of these systems were wet pipe sprinkler systems. However through

improvements and modifications implemented to enhance system performance in cold storage environments, the optimal system

has evolved into a single interlock preaction system pre-primed with propylene glycol solution rather than pressurized air. In both

cases these systems are used in conjunction with K 25.2 sprinklers that have been specifically tested for the application. K 25.2

sprinklers allow the designer more flexibility in the design and may allow the in-rack sprinklers required for the rack storage to be

removed. In either case, a 50 % or 35% propylene glycol and water solution will be used depending on what the minimum temperature is expected to be in the cold storage environment.

In addition to evaluating manufacturers recommendations and the specific equipment required for these special sprinkler systems,

the designer must approach the hydraulic calculation with the understanding that a liquid other than water will initially be moving

through the piping network. Traditionally, when the fire protection designer is performing the hydraulic calculation for a sprinkler

system in accordance with NFPA 13, the Hazen- Williams formula for determining the friction loss is adequate. However, because

the propylene glycol solution is a much more viscous liquid than water, the system volumes are much larger than a traditional antifreeze loop, and the cold storage environment may experience sustained temperatures as low as 20 degrees Fahrenheit, the DarcyWeisbach formula must be used in one of the two required hydraulic calculations for systems utilizing a propylene glycol solution.

The Darcy-Weisbach formula for calculating friction loss is more accurate than Hazen-Williams for determining friction loss in piping

in several situations encountered in sprinkler system design including the calculations for foam concentrate (not solution) piping,

high water velocities above 40 ft/sec such as those in water mist systems and the friction loss calculations for antifreeze systems especially when these systems have a large volume and are in areas with very low temperatures such a cold storage areas. The primary

reason for this is that the Hazen-Williams formula does not allow the user to take into account a change in the viscosity of a liquid

being calculated. The Darcy-Weisbach formula does allow the user to modify the viscosity of liquid being calculated when determining a part of the equation called the Reynolds Number, which we will define later in the article.

Viscosity

Cranes Technical Paper No. 410 Flow of Fluids Through Valves, Fittings and Pipe states that the viscosity of a liquid can be expressed

as the readiness with which a fluid flows when acted upon by an external force or shear stress. It only stands to reason that the more

viscous propylene glycol will interact with the piping wall differently than the less viscous water at room temperature. In the freezer

environment, where the temperature can be maintained well below zero, the already high viscosity of propylene glycol solution will

increase dramatically, underscoring the need for the more accurate Darcy-Weisbach calculation where changes in viscosity can be

taken into account.

The viscosity units for a fluid can be expressed as either the dynamic (absolute) viscosity or the kinematic viscosity. The unit for the

absolute (dynamic) viscosity of a fluid is the poise, which is equal to 100 centipoise. For example, the viscosity of water at 60 degrees

Fahrenheit is approximately 1.02 centipoise where as the viscosity of a 50% propylene glycol solution at the same temperature is

8.13 centipoise. Kinematic viscosity is the ratio of the absolute viscosity to the mass density and is expressed as:

Viking Technical Article

Calculating Friction Loss

= /s

Where

= kinematic viscosity

= dynamic viscosity

s= specific gravity of the liquid

The unit for Kinematic viscosity is called a stoke where one stoke is equal to 100 centistokes. The designer of the system must determine which way the viscosity units (dynamic or kinematic) have been provided by the antifreeze manufacturer to ensure the DarcyWeisbach formula is performed properly. The example provided below will use the poise dynamic viscosity units.

Formula History

To gain an understanding of exactly where the differences lie between Hazen-Williams and Darcy Weisbach it is important to understand the history of each formula and the factors each takes into consideration when calculating friction loss. As described by Harold

Wass in Sprinkler Hydraulics each formula was derived from and uses the fundamental concepts developed by the French engineer

Antoine de Chezy. In Chezys formula, friction loss is calculated by using a coefficient reflecting the roughness of the pipe, the internal

hydraulic radius of the pipe and the hydraulic slope, which is the friction loss per unit length of pipe. The formula is expressed as:

v= crs

where

c= coefficient for pipe roughness

r= internal hydraulic radius

s = the hydraulic slope or friction loss per length unit

This formula was refined further by several engineers including Henri Darcy and Julius Weisbach into what is referred to today as

the Darcy-Weisbach formula. The Darcy-Weisbach formula expands on the concept of the friction factor first utilized by Chezy and

modifies the formula into:

h= f L/D x V/2g

h= friction loss (ft of head)

f= friction loss factor (from Moody Diagram)

L=length of pipe or tube (ft)

V= velocity of flow in tube (ft/sec)

D= diameter of pipe (ft)

g= gravitational constant = 32.2 ft/sec

To the experienced fire protection designer, most of the information required to complete the calculation in the Darcy-Weisbach

formula is familiar and self-explanatory. However, as we stated above the formula has expanded on the concept of the friction factor

(f). The friction factor is determined by using what is called the Moody Diagram. As of the time of the writing of this article, the

Moody Diagram is only found in two locations readily available to the fire protection designer. NFPA 750, the standard for Water

Mist Systems, and the Fire Protection Handbook both provide copies for reference and several hydraulic calculation programs have

options for Darcy-Weisbach calculations. Because the calculation of the friction factor is complicated and time consuming, this formula was later modified again into the simpler Hazen-Williams formula.

Reynolds Number

The Moody Diagram requires the fire protection designer to calculate what is called the Reynolds Number and to identify the average protuberance of the piping material. The Reynolds Number can be defined as the ratio of the dynamic forces of mass flow to

the shear stress due to viscosity. The protuberance or roughness of the piping is identified by the Greek symbol epsilon () and can

Viking Technical Article

Calculating Friction Loss

be supplied by the pipe manufacturer. When the Reynolds Number and the relative roughness have been determined, the Moody

Diagram is used to determine (the friction factor) for use in the calculation in the Darcy-Weisbach formula. It is during the calculation of the Reynolds Number that the viscosity of liquid is used in the formula. Depending on whether the propylene glycol solution

manufacturer has supplied the kinematic of dynamic viscosity units the Reynolds Number can be calculated in several ways.

If the dynamic (absolute) viscosity is provided the Reynolds number may be determined using either:

RE = 50.6Q/d

Where

Q= flow (gpm)

d= internal pipe diameter (in.)

= weight density of fluid

= dynamic (absolute) viscosity

Or by using

RE = vd/

Where

= density

v= velocity

d= internal pipe diameter (feet)

= dynamic (absolute) viscosity

If the kinematic viscosity is provided, the Reynolds number may be determined by using:

RE = vd/

Or

50.6Q/d

Where

v= velocity

d= internal pipe diameter (feet)

= kinematic viscosity

When using any of the above methods for determining the Reynolds Number the viscosity of liquid is used. Depending on the temperature of the cold storage environment the viscosity of the propylene glycol solution is going to change. The dynamic (absolute)

viscosity of propylene glycol solution at 60 degrees Fahrenheit is 8.13 Centipoise and 180 Centipoise at 20 degrees Fahrenheit.

Given the large change in viscosity it can be anticipated that the friction factor determined on the Moody Diagram will be completely different at the two temperatures.

Example

If we use the Darcy-Weisbach Formula to calculate the friction loss for 400 gallons of propylene glycol with a 50% solution flowing

through 30 feet of 2.5 inch schedule 40 steel pipe at 60 degrees Fahrenheit and then again at 20 degrees Fahrenheit we see the

following. To ensure a proper calculation designers must ensure they are using the roughness () for older pipe not new pipe. For

example the roughness () for new steel pipe is .00015 (ft); this equates to a C factor of 140 in Hazen Williams. So the roughness

Viking Technical Article

Calculating Friction Loss

factor must be adjusted to account for age and corrosion like the C factors in Hazen Williams. In this case the roughness () used will

be .00033 (ft), which equates to a C factor of 120 in Hazen Williams.

Using the above parameters at 60 degrees the friction loss is calculated at approximately 16 psi over the 30 feet of pipe. Using the

exact parameters above by adjusting the viscosity units for the decrease in temperature to 20 degrees the friction loss is calculated

at approximately 35 psi for the 30 feet of pipe. As you can see there is a 19-psi difference. If the fire protection designer did not account for the difference in the liquids viscosity the calculation of friction loss would have been corrupted.

Hazen-Williams

In the early 1900s Gardner Williams and Allan Hazen again modified the Chezy formula into the Hazen-Williams formula, as we

know it today. As with the Darcy-Weisbach formula the internal roughness of the piping, flow of water, velocity and hydraulic slope

are taken into consideration during the calculation of friction loss. However, the Hazen-William formula was not revised to take into

consideration different viscosities of liquids like the Darcy-Weisbach formula does during the calculation of the Reynolds Number.

Instead the Hazen-Williams formula uses a pipe roughness coefficient called the C factor only. The C factor is a measure of the

roughness of the pipe internal wall. The C factor can be compared to the epsilon value used in Darcy-Weisbach ccalculation; however, as we discussed before there are more variables taken into consideration to determine the f factor.

The C factors described in NFPA 13 for pipe are:

Unlined Cast or Ductile Iron

Black Steel (Dry Systems)

Black Steel (Wet Systems)

Galvanized

Cement Lined Cast or Ductile Iron

Plastic (listed)

Copper Tube

Stainless Steel

100

100

120

120

140

150

150

150

A calculation using Hazen-Williams and Darcy-Weisbach to calculate the friction loss over 30 feet of schedule steel pipe using the

same parameters we used earlier in the Darcy calculation provides a useful comparison. At room temperature the friction loss would

be calculated at approximately 15.5 psi using Hazen-Williams. These results are almost identical to Darcy-Weisbach at the same

temperature. Again the change occurs when there is a decrease in temperature and the viscosity of the propylene glycol solution

changes dramatically.

Conclusion

Regardless of which formula is being used the purpose of applying a friction loss formula is to ensure that sprinkler system design

has properly accounted for the loss of pressure within the flowing water or water antifreeze solution due to friction with the internal

pipe wall. Because fire protection hydraulics is only concerned with a few basic elements in the flow computations, additional steps

must be taken for a fluid other than water.

Historically, as Harry Hickey describes in Hydraulics for Fire calculation; however, evaluating flow in sprinkler systems we have been

able to make the following assumptions. The fluid being calculated is water. The weight of water is 62.4 pounds per cubic foot. The

water temperature range is between 45 and 75 degrees F. The Flow velocities will typically range between 5 to 18 feet per second.

Finally, we will have a known pipe roughness coefficient. Given the differences in these values that can be seen when using a propylene glycol solution it is not prudent for the fire protection designer to make these same assumptions. Although the Darcy-Weisbach

formula can be more complicated than Hazen-Williams, when designing the piping network for these special fire protection systems

with propylene glycol solution it is imperative that the designer use it to ensure an accurate calculation of friction loss.

Viking Technical Article

Calculating Friction Loss

References

Crane Technical Paper No. 410, Flow of Fluids Through Valves, Fittings, and Pipe. Crane Co., Signal Hill CA, 1988.

Hickey Harry E., Hydraulics for Fire Protection, National Fire Protection Association, Quincy MA, 1980.

Wass Harold S., Sprinkler Hydraulics and What its all about, 2nd edition, Society of Fire Protection Engineers, Bethesda MD, April

2000.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Corrosion in Fire Sprinkler Systems-JOSH TIHENDocumento40 pagineCorrosion in Fire Sprinkler Systems-JOSH TIHENSérgio Gnipper0% (1)

- Uploads Docs 2186Documento13 pagineUploads Docs 2186Sérgio GnipperNessuna valutazione finora

- CBSpk-2016-Sprinkler Protection Criteria For Rack-Stored Expanded PlasticsDocumento37 pagineCBSpk-2016-Sprinkler Protection Criteria For Rack-Stored Expanded PlasticsSérgio GnipperNessuna valutazione finora

- Basic Sprinkler Testing To PDFDocumento23 pagineBasic Sprinkler Testing To PDFSérgio GnipperNessuna valutazione finora

- Basic Sprinkler TestingDocumento23 pagineBasic Sprinkler TestingSérgio GnipperNessuna valutazione finora

- Design and Installation of Sprinkler Systems in BrazilDocumento51 pagineDesign and Installation of Sprinkler Systems in BrazilSérgio GnipperNessuna valutazione finora

- FMF 02 1044Documento8 pagineFMF 02 1044Sérgio GnipperNessuna valutazione finora

- SJM Vertical Mixed Flow PumpDocumento6 pagineSJM Vertical Mixed Flow PumpSérgio GnipperNessuna valutazione finora

- Cooling Load Reduction by Using Thermal Mass and Night Ventilation PDFDocumento7 pagineCooling Load Reduction by Using Thermal Mass and Night Ventilation PDFSérgio GnipperNessuna valutazione finora

- Vertical Turbine Fire PumpsDocumento6 pagineVertical Turbine Fire PumpsSérgio Gnipper100% (1)

- Regional Difference of Energy Consumption For Hot Water Supply SystemDocumento8 pagineRegional Difference of Energy Consumption For Hot Water Supply SystemSérgio GnipperNessuna valutazione finora

- Elkhart Brass - EsguichosDocumento33 pagineElkhart Brass - EsguichosSérgio GnipperNessuna valutazione finora

- Recommended Code of Practice For Safe Water TemperaturesDocumento15 pagineRecommended Code of Practice For Safe Water Temperaturespepito444Nessuna valutazione finora

- An Investigation of Instability in A Domestic Gas Boiler by SimulatioDocumento14 pagineAn Investigation of Instability in A Domestic Gas Boiler by SimulatioSérgio GnipperNessuna valutazione finora

- Prezentare CIBSE PT EN806Documento56 paginePrezentare CIBSE PT EN806danateoNessuna valutazione finora

- FPR en 7-2013aDocumento6 pagineFPR en 7-2013aSérgio GnipperNessuna valutazione finora

- Kinetics of Chlorine Depletion and Microbial GrowthDocumento9 pagineKinetics of Chlorine Depletion and Microbial GrowthSérgio GnipperNessuna valutazione finora

- CIBSE Green Buildings - Benefits & BarriersDocumento6 pagineCIBSE Green Buildings - Benefits & BarriersSérgio GnipperNessuna valutazione finora

- CIBSE Probe 2 Research MethodsDocumento5 pagineCIBSE Probe 2 Research MethodsSérgio GnipperNessuna valutazione finora

- Bmax Technology BrochureDocumento2 pagineBmax Technology BrochureSérgio GnipperNessuna valutazione finora

- Thermal Performance of Insulated Roof Slabs in Tropical Climatesl - HalwaturaDocumento8 pagineThermal Performance of Insulated Roof Slabs in Tropical Climatesl - HalwaturaSérgio GnipperNessuna valutazione finora

- Sprinklers & Smoke-Heat Vents - Smith, D. 24nov2010Documento7 pagineSprinklers & Smoke-Heat Vents - Smith, D. 24nov2010Sérgio GnipperNessuna valutazione finora

- Bermad Air Valves FamilyDocumento2 pagineBermad Air Valves FamilySérgio GnipperNessuna valutazione finora

- Air Valves Ir Exh Brochure Peaae11 Bic FinalDocumento4 pagineAir Valves Ir Exh Brochure Peaae11 Bic FinalSérgio GnipperNessuna valutazione finora

- Tyco Fire Rapid Response Product Guide - 5 2015Documento18 pagineTyco Fire Rapid Response Product Guide - 5 2015Sérgio GnipperNessuna valutazione finora

- KSB Centrifugal EtanormDocumento36 pagineKSB Centrifugal Etanormatmoko2100% (2)

- Tyco Fire - The Use and Maintenance of Dry Type SprinklersDocumento16 pagineTyco Fire - The Use and Maintenance of Dry Type SprinklersSérgio GnipperNessuna valutazione finora

- Tyco Fire - The Use and Maintenance of Dry Type SprinklersDocumento16 pagineTyco Fire - The Use and Maintenance of Dry Type SprinklersSérgio GnipperNessuna valutazione finora

- Welding Fire Protection Piping PDFDocumento23 pagineWelding Fire Protection Piping PDFflanker76Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Lab Science of Materis ReportDocumento22 pagineLab Science of Materis ReportKarl ToddNessuna valutazione finora

- S-Sapfico-Satyanarayanamaterial 121212Documento183 pagineS-Sapfico-Satyanarayanamaterial 121212mpsing1133Nessuna valutazione finora

- 15 Miscellaneous Bacteria PDFDocumento2 pagine15 Miscellaneous Bacteria PDFAnne MorenoNessuna valutazione finora

- Norman, K. R., Pali Philology & The Study of BuddhismDocumento13 pagineNorman, K. R., Pali Philology & The Study of BuddhismkhrinizNessuna valutazione finora

- Actron Vismin ReportDocumento19 pagineActron Vismin ReportSirhc OyagNessuna valutazione finora

- OsciloscopioDocumento103 pagineOsciloscopioFredy Alberto Gómez AlcázarNessuna valutazione finora

- How To Change Front Suspension Strut On Citroen Xsara Coupe n0 Replacement GuideDocumento25 pagineHow To Change Front Suspension Strut On Citroen Xsara Coupe n0 Replacement Guidematej89Nessuna valutazione finora

- Worked Solution Paper5 A LevelDocumento8 pagineWorked Solution Paper5 A LevelBhoosan AncharazNessuna valutazione finora

- Kiraan Supply Mesin AutomotifDocumento6 pagineKiraan Supply Mesin Automotifjamali sadatNessuna valutazione finora

- Auditing Principles and Practices-IDocumento8 pagineAuditing Principles and Practices-IMoti BekeleNessuna valutazione finora

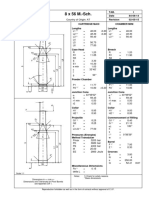

- 8 X 56 M.-SCH.: Country of Origin: ATDocumento1 pagina8 X 56 M.-SCH.: Country of Origin: ATMohammed SirelkhatimNessuna valutazione finora

- JMC MSDS Puraspec 1173 (GB)Documento10 pagineJMC MSDS Puraspec 1173 (GB)Benny Samsul B.Nessuna valutazione finora

- Canon I-SENSYS MF411dw Parts CatalogDocumento79 pagineCanon I-SENSYS MF411dw Parts Catalogmarian100% (1)

- SL Generator Ultrasunete RincoDocumento2 pagineSL Generator Ultrasunete RincoDariaNessuna valutazione finora

- Stratum CorneumDocumento4 pagineStratum CorneumMuh Firdaus Ar-RappanyNessuna valutazione finora

- ManualDocumento50 pagineManualspacejung50% (2)

- Catalogo PukangDocumento41 pagineCatalogo PukangClarita Muller LeigueNessuna valutazione finora

- SPFL Monitoring ToolDocumento3 pagineSPFL Monitoring ToolAnalyn EnriquezNessuna valutazione finora

- Current Harmonics: Electric Power System Power QualityDocumento3 pagineCurrent Harmonics: Electric Power System Power QualityAlliver SapitulaNessuna valutazione finora

- Kallatam of Kallatar (In Tamil Script Tscii Format)Documento78 pagineKallatam of Kallatar (In Tamil Script Tscii Format)rprabhuNessuna valutazione finora

- Citibank CaseDocumento6 pagineCitibank CaseLalatendu Das0% (1)

- 5 Ways To Foster A Global Mindset in Your CompanyDocumento5 pagine5 Ways To Foster A Global Mindset in Your CompanyGurmeet Singh KapoorNessuna valutazione finora

- Agrinome For Breeding - Glossary List For Mutual Understandings v0.3 - 040319Documento7 pagineAgrinome For Breeding - Glossary List For Mutual Understandings v0.3 - 040319mustakim mohamadNessuna valutazione finora

- ID25bc8b496-2013 Dse English PaperDocumento2 pagineID25bc8b496-2013 Dse English PaperSimpson WainuiNessuna valutazione finora

- Reference GuideDocumento88 pagineReference GuideAnonymous Qm0zbNk100% (1)

- Our Story Needs No Filter by Nagarkar SudeepDocumento153 pagineOur Story Needs No Filter by Nagarkar SudeepKavya SunderNessuna valutazione finora

- 1572 - Anantha Narayanan FFS CalculationDocumento1 pagina1572 - Anantha Narayanan FFS CalculationAnantha NarayananNessuna valutazione finora

- Journal of Molecular LiquidsDocumento11 pagineJournal of Molecular LiquidsDennys MacasNessuna valutazione finora

- Sage TutorialDocumento115 pagineSage TutorialChhakuli GiriNessuna valutazione finora

- Final - Anarchy One-Sheet Sell SheetDocumento2 pagineFinal - Anarchy One-Sheet Sell SheetMaddanie WijayaNessuna valutazione finora