Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FSGP & PT370 - Pipe Fittings

Caricato da

gerrydimayugaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FSGP & PT370 - Pipe Fittings

Caricato da

gerrydimayugaCopyright:

Formati disponibili

BABCOCK-HITACHI (PHILIPPINES) INC.

SPEC. NO.

PS 199 0202

San Roque, Bauan, Batangas

REV. NO.

Philippines

SHEET. NO.

1 of 6

TITLE

PURCHASE ORDER SPECIFICATION FOR FSGP &

PT 370 FITTING MATERIAL

.

..

1111111

CUSTOMER

APECO

PROJECT

APECO-ISK

PLANT

ISK SINGAPORE PTE LTD

ITEM NAME

NG FIRED PACKAGED TYPE BOILER (48TPH CAPACITY)

WORK NUMBER :

9111990110

REVISION CONTROL

REV. NO.

DESCRIPTION

PREPARED FOR ORDER

PREPARED

CHECKED

APPROVED

PURCHASE ORDER SPECIFICATION

SPEC NO.

REV. NO.

SHEET NO.

:

:

:

PS 199 0202

0

2 of 6

1. General

1.1Scope

This specification is in accordance to Japanese Industrial Standard (JIS)

which specifies the steel pipe fittings to be fitted by butt-welding to ordinary

pipings as specified in JIS G 3452 used for carrying steam, water, oil, gas,

air , etc. at comparatively low working pressure and to pipe fittings mainly to

pressure service pipings as specified in JIS G 3454.

1.2General Requirements

In case of conflict between this specification and applicable code, the more

stringent requirement shall govern.

1.3Deviation and Clarification

(1) The Contractor is able to offer the alternatives and/or deviation from the

requirements defined in this specification where those alternatives

and/or deviation shall have cost reduction with satisfying the

performance, quality and/or liability, and the requirements to be

guaranteed.

(2) The alternative and deviation shall be clearly indicated in the tendering

documents and shall be cross-indexed with the published standards

and/or Contractor's practices to the specified Codes and Standards. No

alternatives and deviations shall be allowed without prior to approval of

the Purchaser.

1.4Quality Program

(1) The Contractor shall establish the Quality Program in compliance with

the requirements for quality assurance in design, development,

production, installation and servicing defined in ISO-9000 Series or

ISO-9002 as a minimum or their equivalent provisions.

(2) If defectives and nonconformance to the requirements of this

procurement specification and descriptive documents are found, the

Contractor shall submit promptly notification of such nonconformance

and corrective action plan in accordance with the requirements of

provision stipulated in GENERAL CONDITIONS OF PURCHASE

CONTRACT FOR EQUIPMENT.

2. Applicable Material Specification

2.1 Applicable Material Specification and Grade:

(1) FSGP (NON-GALVANIZED) ERW

(2) PT 370 - Seamless

JIS B 2311 (1991)

JIS B 2312 (1991)

PURCHASE ORDER SPECIFICATION

SPEC NO.

REV. NO.

SHEET NO.

:

:

:

PS 199 0202

0

3 of 6

2.2 Applicable Code Edition and Standard :

Applicable Code Edition and Standard shall conform to Japanese

Industrial Standard (JIS), 2001 Edition.

3. Manufacturing Process

Manufacturing process shall comply with the requirements of applicable

Material Specification.

4. Chemical Composition

4.1 Materials to be procured are listed in the Material Ordered List.

4.2 Chemical composition of the material shall meet the requirements of

Applicable Material Specification.

4.3 Maximum percentage of infinitesimal compositions without cost up,

especially sol. AL, N and P+S shall be submitted for approval by Purchaser,

and other target or controlling infinitesimal compositions shall be submitted

also with Estimate.

5. Fitting Manufacture

5.1 Fitting shall be manufactured in accordance with the requirements specified

in the Material Ordered List.

5.2 The relation between outside diameter and thickness that is able to

manufacture the fitting without hexagon shall be submitted for approval.

5.3 Fitting shall be furnished bevel end as per JIS.

6. Heat Treatment

Fitting shall be heat treated in accordance with applicable Material Specification.

7. Mechanical Properties

Tensile Requirement

Tensile strength, yield strength and elongation shall meet the requirements of

applicable Material Specification.

PURCHASE ORDER SPECIFICATION

SPEC NO.

REV. NO.

SHEET NO.

:

:

:

PS 199 0202

0

4 of 6

8. Hydrostatic Test and Nondestructive Electric Test

All fitting shall be subjected to the hydrostatic test or, instead of this test, a

nondestructive electric test may be used.

9. Material Designation, Type, Grade, Finish and Size

The Material Designation, Type, Grade, Finish (Black or Galvanized),

Size(outside diameter and nominal thickness), length and weight are specified

in the Material Ordered List.

10. Permissible Variations in Outside and Thickness

Permissible variations in outside and thickness shall comply with the

requirements of applicable Material Specification.

11. Surface Condition (Workmanship, Finish and Appearance)

11.1Surface condition and straightness of pipe fittings shall comply with the

requirements of applicable Material Specification.

11.2The target or controlling value of inside surface roughness shall be

submitted with Estimate, as the surface roughness have influence on

pressure drop of fluids. The value shall be indicated by parameter "Ra"

conformed to ISO486-1982 "Surface Roughness" or equivalent.

12. Product Marking

Product marking

Specification.

shall

meet

the

requirements

of

applicable

Material

13. Certified Test Report

The producer or supplier shall finish a Certified Test Report in accordance with

the requirements of applicable Material Specification.

PURCHASE ORDER SPECIFICATION

SPEC NO.

REV. NO.

SHEET NO.

:

:

:

PS 199 0202

0

5 of 6

14. Inspection Witnesses

All mechanical tests, nondestructive examination, dimensional inspection and

visual inspection of surface shall be conducted in the presence of

representatives of BHPI, Customer and Authorized Inspection Agency (AIA) as

required. The manufacturer is required to grant the quality control

representatives of BHPI, Customer and AIA free access to his facilities,

manufacturing operations, inspections and tests at all time while work on the

contract are being performed.

15. Painting

15.1 External surface of fittings shall be cleaned and coated to protect from

corrosion.

For internal surface, VPI shall be put into fittings.

(VAPOR PROHIBIT INHIBITOR)

16. Packing

The care shall be taken in packaging and shipping the products to prevent

damage during transportation.

PURCHASE ORDER SPECIFICATION

SPEC NO.

REV. NO.

SHEET NO.

:

:

:

PS 199 0202

0

6 of 6

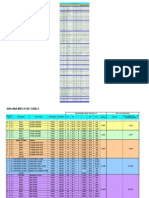

17. Documents to be Submitted

If a proposal is submitted and the contract is awarded for this Procurement

Specification, the following documents and notices shall be required to be

deliverable.

Submittal item

(to be received no later than)

1

2

Deviation and Clarification

Certified Test Report

Contents are as follows:

(1) Chemical composition table

(numerical)

(2) Record for heat treatment

(3) Results of mechanical property

test(numerical)

(4) Results of nondestructive examination or hydrostatic test

(5) Results of inspections of dimensions and exterior surface

3

4

Notice of Shop Witness Test

Manufacturing and Inspection

Procedure

5 Non-destructive Examination Procedure

6 Hydrostatic Test Procedure if any

7 Painting Procedure

8 Cleaning and Preservation Procedure

9 Packing Procedure

10 Documents required in par. 5.2 & 11.2

Copy Reprod Calendar Event/Date

ucible

8

2

upon

Bid Day

8

2

14after Test and

Inspection

5

5

2

1

15before Tests

30after Contract Award

5

5

5

5

5

5

1

1

1

1

1

1

30after

30after

30after

30after

30after

30after

Contract Award

Contract Award

Contract Award

Contract Award

Contract Award

Contract Award

(Remarks) Certified Test Report shall bear, as a minimum Work Number,

Specification Sheet Number and BHPI Purchase Spec. No. (PS1990202).

.

Potrebbero piacerti anche

- Pocket Guide to Preventing Process Plant Materials Mix-upsDa EverandPocket Guide to Preventing Process Plant Materials Mix-upsNessuna valutazione finora

- Attachment X - Specifications For Prefabrication PipingDocumento25 pagineAttachment X - Specifications For Prefabrication PipingmahendraNessuna valutazione finora

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryDa EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryNessuna valutazione finora

- G3ir 1000 50 SP 9015 - R3Documento20 pagineG3ir 1000 50 SP 9015 - R3Ramu NallathambiNessuna valutazione finora

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Technical Specification - LPG HeaterDocumento94 pagineTechnical Specification - LPG Heaterhbsheen100% (1)

- Se TLPC TN 3746 Gi Bolts Spec PQRDocumento13 pagineSe TLPC TN 3746 Gi Bolts Spec PQRMl JainNessuna valutazione finora

- TDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Documento1 paginaTDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Tanpreet SinghNessuna valutazione finora

- FOAM TANK KEAMARI (14200 Litres) : 1.0 GeneralDocumento3 pagineFOAM TANK KEAMARI (14200 Litres) : 1.0 GeneralirfanlarikhotmailcomNessuna valutazione finora

- Pigs Material and Equipment StandardDocumento10 paginePigs Material and Equipment Standardreza329329Nessuna valutazione finora

- Technical Specification For FlangesDocumento13 pagineTechnical Specification For FlangesRahul GangulyNessuna valutazione finora

- Technical Specification For FastenersDocumento8 pagineTechnical Specification For FastenersRahul GangulyNessuna valutazione finora

- 22 66 KV LA R4 Jan 11 PDFDocumento17 pagine22 66 KV LA R4 Jan 11 PDFDin CuyNessuna valutazione finora

- Specifications IS 2062 GRBDocumento6 pagineSpecifications IS 2062 GRBruchit solankiNessuna valutazione finora

- Technical Specification For PipesDocumento13 pagineTechnical Specification For PipesRahul GangulyNessuna valutazione finora

- Final - FIRE FIGHTINGDocumento24 pagineFinal - FIRE FIGHTINGDineshkumarNessuna valutazione finora

- IMI Group Requirements PCB Suppliers v2016.1Documento10 pagineIMI Group Requirements PCB Suppliers v2016.1sudar1477Nessuna valutazione finora

- 7 - 220 - 132 - 220 - KV - NCT - 2147Documento20 pagine7 - 220 - 132 - 220 - KV - NCT - 2147Sheraz azamNessuna valutazione finora

- Mustang PDFDocumento159 pagineMustang PDFermusatNessuna valutazione finora

- Inspection and Test ProcedureDocumento8 pagineInspection and Test Proceduregaehdd1100% (1)

- Astm B517-09Documento3 pagineAstm B517-09Srinivasan KrishnamoorthyNessuna valutazione finora

- Technical Specification For FittingsDocumento13 pagineTechnical Specification For FittingsRahul GangulyNessuna valutazione finora

- SM 001 SRV SpecDocumento5 pagineSM 001 SRV Specvardan_vardanNessuna valutazione finora

- 6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRDocumento8 pagine6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRMuthu AlaguRajNessuna valutazione finora

- Cable Tray Technical SpecificationDocumento11 pagineCable Tray Technical SpecificationVikas TanejaNessuna valutazione finora

- Technical Specification For GasketsDocumento10 pagineTechnical Specification For GasketsRahul GangulyNessuna valutazione finora

- Instrumentation RequirementsDocumento140 pagineInstrumentation RequirementsArchana SharmaNessuna valutazione finora

- 6 400KV CB PirDocumento36 pagine6 400KV CB PirRAPRATSINNessuna valutazione finora

- Induction Bends - COPIDocumento12 pagineInduction Bends - COPIAdvis100% (1)

- Fichtner I & CDocumento23 pagineFichtner I & CMathivanan AnbazhaganNessuna valutazione finora

- Damaged Spool Replacement GuideDocumento12 pagineDamaged Spool Replacement GuideMohsen KeramatiNessuna valutazione finora

- 04 HW Accs Zebra Conductor PDFDocumento23 pagine04 HW Accs Zebra Conductor PDFelsayedNessuna valutazione finora

- Centrifugal Fan Technical RecommendationDocumento12 pagineCentrifugal Fan Technical RecommendationTrang Doan VanNessuna valutazione finora

- (0153) 4664-MSP-008 Fired HeatersDocumento16 pagine(0153) 4664-MSP-008 Fired HeatersSixto Gerardo Oña Anaguano100% (1)

- Technical Specification for GasketsDocumento8 pagineTechnical Specification for GasketsShivashankar Durga MedisettiNessuna valutazione finora

- Specification For Manufacture of Heat Exchangers For Sodium SystemDocumento39 pagineSpecification For Manufacture of Heat Exchangers For Sodium SystemZaneta ZhafirahNessuna valutazione finora

- Specification of LT Panel Board - 400A LT Panel Board - R3 Dec - 2012Documento22 pagineSpecification of LT Panel Board - 400A LT Panel Board - R3 Dec - 2012sarat100% (1)

- Bakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverDocumento8 pagineBakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverIbad AlamNessuna valutazione finora

- CW6 Part 2Documento34 pagineCW6 Part 2Steve CowanNessuna valutazione finora

- 0-WD380-EP200-00004 - Rev.A Steel Flanges Tech. Spec.Documento34 pagine0-WD380-EP200-00004 - Rev.A Steel Flanges Tech. Spec.carlos tapia bozzoNessuna valutazione finora

- 1.method Fabrication Spool (r2)Documento13 pagine1.method Fabrication Spool (r2)sethu109175% (20)

- 2 66kV Isolator R3 Jan13Documento33 pagine2 66kV Isolator R3 Jan13akhilesh205Nessuna valutazione finora

- Thermocouples Specification and Data SheetsDocumento8 pagineThermocouples Specification and Data SheetsRakesh NayakNessuna valutazione finora

- 6 - Linetrap - 400kv - 10mH - 3150 - A - R - 0Documento17 pagine6 - Linetrap - 400kv - 10mH - 3150 - A - R - 0Hassan KhaterNessuna valutazione finora

- N.pip - GSP.001 - 3B Piping General SpecificationDocumento145 pagineN.pip - GSP.001 - 3B Piping General SpecificationAiskel PazNessuna valutazione finora

- 5903f - Inert Gas GeneratorDocumento18 pagine5903f - Inert Gas GeneratorAvinash PatilNessuna valutazione finora

- 22 Ts 110v Battery ChargerDocumento22 pagine22 Ts 110v Battery ChargerRamesh AnanthanarayananNessuna valutazione finora

- Anubar SpecDocumento8 pagineAnubar SpecSHIVAJI CHOUDHURYNessuna valutazione finora

- Material and Equipment Standard: IPS-M-PI-170Documento10 pagineMaterial and Equipment Standard: IPS-M-PI-170Anonymous cuOIjrLINessuna valutazione finora

- Spec - LA 11,22,33 KV LA R1 Sep10Documento14 pagineSpec - LA 11,22,33 KV LA R1 Sep10Amarjit KulkarniNessuna valutazione finora

- 3 66 KV CT PT R6 Metering Dec 12Documento34 pagine3 66 KV CT PT R6 Metering Dec 12dkshtdkNessuna valutazione finora

- Technical Requirements for Foam Tank FabricationDocumento3 pagineTechnical Requirements for Foam Tank FabricationirfanlarikhotmailcomNessuna valutazione finora

- 80080-TCH-0000-SP-005_SIGNED-PMI Procedure.Documento8 pagine80080-TCH-0000-SP-005_SIGNED-PMI Procedure.Paul NieNessuna valutazione finora

- Weld Repair ProcedureDocumento15 pagineWeld Repair Proceduremohd as shahiddin jafriNessuna valutazione finora

- TECHNICAL POINTS_CS and Alloy Steel Smls PipesDocumento5 pagineTECHNICAL POINTS_CS and Alloy Steel Smls PipesPaul NieNessuna valutazione finora

- Antifog Disc InsulatorDocumento35 pagineAntifog Disc InsulatorJayant Kumar DasNessuna valutazione finora

- Piping Welding SpecificationDocumento16 paginePiping Welding SpecificationAHMED AMIRANessuna valutazione finora

- M. F. Sullivan: 9/27/2016 Dr. Sandor Somogyi 1Documento38 pagineM. F. Sullivan: 9/27/2016 Dr. Sandor Somogyi 1Muhammad Haris BaigNessuna valutazione finora

- COPI - Welding Spec For Flowlines To API 1104-1999Documento12 pagineCOPI - Welding Spec For Flowlines To API 1104-1999AdvisNessuna valutazione finora

- Itp HeDocumento15 pagineItp HeAldeline SungahidNessuna valutazione finora

- ProfileDCT Mar15 Web PDFDocumento245 pagineProfileDCT Mar15 Web PDFshazanNessuna valutazione finora

- Weld Detail 1Documento1 paginaWeld Detail 1gerrydimayugaNessuna valutazione finora

- Design of Cold-Formed Steel Structures ASI PDFDocumento104 pagineDesign of Cold-Formed Steel Structures ASI PDFgerrydimayugaNessuna valutazione finora

- SUB60039452-A Table of revised conditioDocumento13 pagineSUB60039452-A Table of revised conditiogerrydimayugaNessuna valutazione finora

- Engineering Basis of NZS 3604 - Updated7 PDFDocumento112 pagineEngineering Basis of NZS 3604 - Updated7 PDFJeanette MillerNessuna valutazione finora

- 13/14, 17 & 17T Series: Multichoice Valve Trim Installation Instructions Owners ManualDocumento94 pagine13/14, 17 & 17T Series: Multichoice Valve Trim Installation Instructions Owners ManualgerrydimayugaNessuna valutazione finora

- Design Capacity Tables For Structural Steel Hollow SectionsDocumento180 pagineDesign Capacity Tables For Structural Steel Hollow Sectionsdoshi7850% (2)

- Eurocodes Worked ExamplesDocumento185 pagineEurocodes Worked ExamplesPaskal Drazhich100% (8)

- Stress & SupportDocumento23 pagineStress & Supportkarthickmectr100% (1)

- Material Take-Off - Takuma 5r - FinalDocumento42 pagineMaterial Take-Off - Takuma 5r - FinalgerrydimayugaNessuna valutazione finora

- Water Heating: Types of Residential Water HeatersDocumento9 pagineWater Heating: Types of Residential Water HeatersgerrydimayugaNessuna valutazione finora

- Bolting and WeldingDocumento73 pagineBolting and Weldinggerrydimayuga100% (2)

- Notes of F.MDocumento159 pagineNotes of F.Mnidhalsaada100% (1)

- (For SHI-UNA RFQ) Latest Revised MTO For TUBES - For MaterialDocumento1 pagina(For SHI-UNA RFQ) Latest Revised MTO For TUBES - For MaterialgerrydimayugaNessuna valutazione finora

- (For SHI-UNA RFQ) MTO For Non-Pressure Parts (Plates and OtheDocumento2 pagine(For SHI-UNA RFQ) MTO For Non-Pressure Parts (Plates and OthegerrydimayugaNessuna valutazione finora

- MTO Summary for Round Bars, Angles, Flats and Other Structural ItemsDocumento14 pagineMTO Summary for Round Bars, Angles, Flats and Other Structural ItemsgerrydimayugaNessuna valutazione finora

- (Shi-Una) Mto For Tubes-pipes-fins-Forge Roundbar - For MateriDocumento5 pagine(Shi-Una) Mto For Tubes-pipes-fins-Forge Roundbar - For MaterigerrydimayugaNessuna valutazione finora

- Stainless Steel For High Pressure Piping in SWRO Plants. Are There Any OptionsDocumento6 pagineStainless Steel For High Pressure Piping in SWRO Plants. Are There Any OptionsgerrydimayugaNessuna valutazione finora

- Structural SpecificationDocumento26 pagineStructural SpecificationgerrydimayugaNessuna valutazione finora

- EXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH FormulasDocumento29 pagineEXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH Formulasgerrydimayuga100% (1)

- 267 Pipe Stress Analysis ReportsDocumento11 pagine267 Pipe Stress Analysis ReportsRaymond MetselaarNessuna valutazione finora

- B31.3 Process Piping Course - 07 Layout and SupportDocumento15 pagineB31.3 Process Piping Course - 07 Layout and SupportgerrydimayugaNessuna valutazione finora

- EXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH FormulasDocumento29 pagineEXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH Formulasgerrydimayuga100% (1)

- Calculation of The Reaction ForceDocumento3 pagineCalculation of The Reaction Forceahmad_korosNessuna valutazione finora

- Beam Design For Moment, Shear & TorsionDocumento6 pagineBeam Design For Moment, Shear & TorsiongerrydimayugaNessuna valutazione finora

- Timber Structures: Donald W. Neal, P.EDocumento58 pagineTimber Structures: Donald W. Neal, P.EsunndaihannNessuna valutazione finora

- Design Calculation Sheet: Chilled Water Secondary PumpsDocumento2 pagineDesign Calculation Sheet: Chilled Water Secondary PumpsgerrydimayugaNessuna valutazione finora

- Base Plate and Bolt DesignDocumento6 pagineBase Plate and Bolt DesigngerrydimayugaNessuna valutazione finora

- ASME B31 3 Calculator V2Documento11 pagineASME B31 3 Calculator V2gerrydimayuga100% (3)

- Cube Test ReportDocumento12 pagineCube Test ReportWeei Zhee70Nessuna valutazione finora

- Plated Through Hole Soldering: Materials by Lindsay CraigDocumento22 paginePlated Through Hole Soldering: Materials by Lindsay Craigamalia dyashintaNessuna valutazione finora

- Analysis of Toy Industry and Children's Recreation Industry ParametersDocumento9 pagineAnalysis of Toy Industry and Children's Recreation Industry ParametersSreekanth PSNessuna valutazione finora

- SM6 2017Documento156 pagineSM6 2017Alfredo ApNessuna valutazione finora

- Operations Management - Final ExamDocumento7 pagineOperations Management - Final ExamMuhammad Ben Mahfouz Al-Zubairi75% (4)

- Bay LesDocumento29 pagineBay LesViji LakshmiNessuna valutazione finora

- Welcome: K.S.K College of Engineering and Technology Department of Mechanical EngineeringDocumento26 pagineWelcome: K.S.K College of Engineering and Technology Department of Mechanical EngineeringRisath AhamedNessuna valutazione finora

- Mathcad - Design Resistance For Individual FastnersDocumento3 pagineMathcad - Design Resistance For Individual FastnersValentinNessuna valutazione finora

- Honeywell Purge Timer S427B, CDocumento2 pagineHoneywell Purge Timer S427B, CRyan TrialsNessuna valutazione finora

- Effective Use of Waste Marble Powder As Partial 1Documento29 pagineEffective Use of Waste Marble Powder As Partial 1AkashDashNessuna valutazione finora

- PT Teknocal Energi Bersinar Company ProfileDocumento3 paginePT Teknocal Energi Bersinar Company ProfileJamal LamajNessuna valutazione finora

- Portable Generator Power Needs GuideDocumento1 paginaPortable Generator Power Needs GuideJuan Dela CruzNessuna valutazione finora

- BoqDocumento3 pagineBoqaerorockNessuna valutazione finora

- Reference Guide: When You Are Making A Polyurethane Rubber Mold - .Documento2 pagineReference Guide: When You Are Making A Polyurethane Rubber Mold - .Sergio Marcos KettmayerNessuna valutazione finora

- CSU Non Sparking Safety Tools CatalogDocumento88 pagineCSU Non Sparking Safety Tools CatalogJhon SanfraNessuna valutazione finora

- Customer Supplier RelationshipDocumento9 pagineCustomer Supplier RelationshipBenNessuna valutazione finora

- Ammonia Paper Little TheoryDocumento59 pagineAmmonia Paper Little TheoryThabangNessuna valutazione finora

- Specification For Support and HangerDocumento6 pagineSpecification For Support and Hangerdee1985Nessuna valutazione finora

- A Feasibility Study On Implementing Agile Manufacturing in A Pump Manufacturing IndustryDocumento11 pagineA Feasibility Study On Implementing Agile Manufacturing in A Pump Manufacturing IndustryVarunNessuna valutazione finora

- CH 5 Operations Planning & ControlDocumento64 pagineCH 5 Operations Planning & ControlYaredNessuna valutazione finora

- Lego StudentDocumento7 pagineLego StudentPookguy100% (1)

- Supply Range of AISI M42 Tool Steel High SpeedDocumento4 pagineSupply Range of AISI M42 Tool Steel High SpeedSama UmateNessuna valutazione finora

- Dr. Martin Christopher Managing Supply Chain Complexity in An Age of UncertaintyDocumento16 pagineDr. Martin Christopher Managing Supply Chain Complexity in An Age of UncertaintyAnonymous wUibDfJNessuna valutazione finora

- 7 Common Weld DefectsDocumento12 pagine7 Common Weld DefectsMarlon Ty ManaloNessuna valutazione finora

- Specification FOR 53gradeordinaryportlandcement: Indian StandardDocumento20 pagineSpecification FOR 53gradeordinaryportlandcement: Indian StandardVivekChaudharyNessuna valutazione finora

- Hoja Datos Danfoso TermostotaosDocumento2 pagineHoja Datos Danfoso TermostotaosAlex Lopez0% (1)

- Technical Training Guide LinconDocumento48 pagineTechnical Training Guide LinconiwantfreeNessuna valutazione finora

- Basic Metallurgy For Welding and Fabricating ProfessionalsDocumento190 pagineBasic Metallurgy For Welding and Fabricating ProfessionalsdaemsalNessuna valutazione finora

- User 30491892013merriwellDocumento3 pagineUser 30491892013merriwellLuis AlanyaNessuna valutazione finora

- About TVS Logistics PVTDocumento4 pagineAbout TVS Logistics PVTSaif Ul IslamNessuna valutazione finora