Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Classimate Fualt Description

Caricato da

Saad NaseemCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Classimate Fualt Description

Caricato da

Saad NaseemCopyright:

Formati disponibili

USTER CLASSIMAT

QUANTUM

APPLICATION REPORT

Analysis of yarns by a

sophisticated classifying

system

THE YARN CLASSIFICATION SYSTEM

S. Dnmez Kretzschmar

R. Furter

May 2008

SE 620

THE YARN CLASSIFICATION SYSTEM

Copyright 2008 by Uster Technologies AG

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, translated or transmitted in any form or by any means, electronically, mechanically, photocopying, recording or otherwise, without the prior permission in writing of the copyright owner.

Veronesi\Textile_Technology\Schulung_Dokumente\Off-Line\ClassimatQuantum\SE_620_Analysis of yarns by a sophisticated classifying system

2 (16)

USTER CLASSIMAT QUANTUM

THE YARN CLASSIFICATION SYSTEM

Contents

1

Introduction ...............................................................................5

Classification of seldom-occurring thick and thin places ......6

Origin of seldom-occurring yarn faults....................................7

Description of the data output of the classifying system .......8

4.1

The scatter plot............................................................................8

4.2

Detection of foreign fibers............................................................9

4.3

Classification matrix for foreign fibers ........................................ 10

4.4

Scatter plot of foreign fibers....................................................... 11

Benchmarking for USTER CLASSIMAT classification......... 12

Conclusion............................................................................... 13

Literature.................................................................................. 14

USTER CLASSIMAT QUANTUM

3 (16)

THE YARN CLASSIFICATION SYSTEM

4 (16)

USTER CLASSIMAT QUANTUM

THE YARN CLASSIFICATION SYSTEM

Introduction

Today, the selection of the right yarn for the right product is crucial for economic reasons. A continuous incoming inspection guarantees a constant

satisfactory quality of the end product. In this respect yarn clearing and

classifying systems are playing a very important role. At the beginning of

electronic yarn clearing the setting of the clearing curve has been quite

difficult and has required specialists. In 1968 Uster Technologies launched

an electronic system by the name of USTER CLASSIMAT which was a

revolution in yarn clearing at that time. The purpose of the system was the

analysis of seldom-occurring or disturbing thick places and the setting of an

optimum clearing curve on the winding machine to eliminate the really disturbing yarn faults and to simultaneously keep the efficiency of the winding

machine as high as possible. For this purpose the yarn was classified into

four length and in four thick place classes.

This analyzing system was not only used by spinners. The yarn buyers

(traders, weavers, knitters, garment makers, etc.) also detected this system

as a tool to separate yarns into first grade, second grade, etc., or to establish minimum conditions for the acceptance of yarns.

As already mentioned, the first classifying system was introduced in the

market in 1968. Therefore, the year 2008 marks the 40th anniversary of this

analyzing tool. Fig. 1 also shows that the system was permanently improved in the past 40 years.

2002

USTER CLASSIMAT QUANTUM

+ additional function

compared to the

previous model

1994

+ 4 classes for small thick places

(A0, B0, C0, D0)

+ 6 classes for short thin places

+ Scatter plot of yarn faults

+ Comparison with Uster Statistics

+ Trend analysis

1978

+ 3 classes for long thick places (E, F, G)

+ 4 classes for long thin places (H1, H2, I1, I2)

+ Results absolute and per 100 km

+ Automatic print-out of results

+ Automatic length measurement (option)

1968

+ Classification according to Quantum

+ Classification according to CMT3

+ 27 classes for foreign fibers

+ Clearing with CAY

+ Yarn fault simulation

+ Fabric simulation

USTER CLASSIMAT 3

USTER CLASSIMAT 2

Classification of thick places

in 16 classes A4 B4 C4 D4

A3 B3 C3 D3

A2 B2 C2 D2

A1 B1 C1 D1

1968 1970

Fig. 1

1975

USTER CLASSIMAT

1980

1985

1990

1995

2000

2005

2010

Improvements of the USTER CLASSIMAT system

USTER CLASSIMAT QUANTUM

5 (16)

THE YARN CLASSIFICATION SYSTEM

Today with the USTER CLASSIMAT QUANTUM generation, the cleared

and uncleared yarn can be checked; the classification of thick and thin

places, neps and foreign fibers in the yarn can be fulfilled. This system also

helps the user in determining the optimal limits for yarn clearing, in analyzing new material, and supports with experience values which can be used

for benchmarking and evaluation.

In this article, we will try explain the most important features of the USTER

CLASSIMAT QUANTUM and its possible usage in improving the quality of

yarns.

Classification of seldom-occurring thick and

thin places

Classifications are used in spinning mills either as on-line monitoring system as a feature of the clearing system on automatic winding machines or

as an analyzing instrument on manual winding machines in textile laboratories and they have played a very important role to analyze seldomoccurring yarn faults.

Fig. 2 shows the classification matrix of this analyzing system with a few

examples of seldom-occurring yarn faults for the thick place classes A1 to

D4 which are assigned by the system to the respective classes.

Fig. 2

6 (16)

Classes of the USTER CLASSIMAT QUANTUM system

USTER CLASSIMAT QUANTUM

THE YARN CLASSIFICATION SYSTEM

It is obvious that the appearance of seldom-occurring faults in a grey fabric

depends on various items:

The cross-section of the fault compared to the mean value

The length of the fault

The count of the yarn

The yarn density in the fabric

The type of fabric (weaving or knitting)

With USTER CLASSIMAT QUANTUM, there is also a possibility of defining new customized classes called Tailored classes. The system can

classify and present the events in the tailored classes for thick places, thin

places and foreign fibers.

Origin of seldom-occurring yarn faults

A basic rule in quality management is a preventive maintenance rather than

corrections afterwards. Unfortunately, this is not yet possible with the technology of today. Textile specialists in spinning mills who have to conquer

disturbing yarn fault have to find the origin of such yarn faults.

Table 1shows a selection of sources which produced seldom-occurring

faults in the respective categories. It is a collection of reasons over many

years why such events happened.

Classes

Possible reason of faults

A (Thick place)

A0

Extended class, mainly used for ply yarn

A1

Bad condition of carding, blow room, trash in yarn

A2

Bad condition of carding, blow room, trash in yarn

A3

Neps, fluff, foreign matters, dirty drafting zone

A4

Ring front zone dirty, fly waste in trumpet

B0

Extended class, mainly used for ply yarn

B1

Fibers damage in process, spindle without aprons

B2

Fibers damage in process, spindle without aprons

B3

Fluff in travelers, unsuitable travelers, bad piecing

B4

Slub from ring spinning department

C0

Extended class, mainly used for ply yarn

C1

Bad piecing in cans, sliver entanglements

C2

Bad piecing in cans, sliver entanglements

C3

Piecing, ring spinning

(Unacceptable faults)

C4

Floating fibers, fly, slub

(Unacceptable faults)

D0

Extended class, mainly used for ply yarn

D1

Floating fibers

B (Thick place)

C (Thick place)

D (Thick place)

USTER CLASSIMAT QUANTUM

Comments

(Short thick places)

(Unacceptable faults)

(Short thick places)

(Unacceptable faults)

(Short thick places)

7 (16)

THE YARN CLASSIFICATION SYSTEM

Classes

Possible reason of faults

Comments

D2

Gauge problem of roving frame, spacer problem

(Unacceptable faults)

D3

Fluff in ring spinning department

(Unacceptable faults)

D4

Fluff in ring spinning department

(Unacceptable faults)

E (Thick place)

Double yarn

(Spinners double)

F (Thick place)

Bad piecing in ring yarns, roving & back process

(Long thick places)

G (Thick place)

Bad piecing in ring, roving & back process etc.

(Long thick places)

H (Thin place)

H1

Mostly eccentric bobbins on roving & ring frames, eccentric spindles

(Thin places)

H2

Poor handling of material during processes

(Thin places)

I1

This type of faults is produced by separation of parts of

sliver or roving prior to spinning

(Long thin places)

I2

This type of faults is produced by separation of parts of

sliver or roving prior to spinning

(Long thin places)

I (Thin place)

Table 1 Classimat defects / Classification and sources of origin

Description of the data output of the classifying

system

4.1

The scatter plot

The scatter plot is a very important feature of USTER CLASSIMAT

QUANTUM which helps the user in analyzing the exact place of each event

in the classification matrix and indicates the yarn faults of both the standard

classes and the extended classes as points in the classification matrix. The

exact length and cross-section increase of the individual yarn faults can

easily be determined with the horizontal and vertical scales.

In order to show the usage of the scatter plots, two yarns of two mills were

given (Ne 30, 100% cotton, carded) as an example. 100 km of these two

yarns were measured with USTER CLASSIMAT QUANTUM and the neps,

short thick, long thick and thin places (NSLT) were counted and classified.

In Fig. 3, we can see the scatter plot of a yarn produced in a mill with a

good quality management having less number of faults. These faults are

shown according to the CLASSIMAT Classes (NSLT) as green colored

points. In Fig. 4 the scatter plot of a low quality yarn is shown having a high

number of faults. When we compare these two yarns, for example in the B1

class, the first yarn (left) had only 9 short thick places; Fig. 4 shows, as a

contrast, a yarn with 488 short thick places in the same class. The faults in

the B1 class can be the result of a wrong raw material, fiber damages in

spinning or other processing problems. The difference between these two

yarns is enormous, and by the help of the scatter plot the user can analyze

and choose the yarn having better quality easily.

8 (16)

USTER CLASSIMAT QUANTUM

THE YARN CLASSIFICATION SYSTEM

Fig. 3

100% cotton, carded, Ne 30, ring spun yarn, per

100 km (low number of faults)

Fig. 4

100% cotton, carded, Ne 30, ring spun yarn, per

100 km (high number of faults)

The yarn of Fig. 4 also has much more faults in the thin place area (part

below the zero line of the scatter plot).

4.2

Detection of foreign fibers

Foreign fibers are one of the major problems in spinning mills. The global

ITMF survey on cotton contamination in 2007 showed that in the perception

of spinners from around the world contamination remains a serious problem. During the past 18 years the degree of contaminated cotton bales was

increasing steadily from 14% to 22%. Organic matters are still the main

contaminants, followed by fabrics of cotton and plastic film, strings of jute

and plastic [1]. These fibers can be of different origin, character, structure,

or color other than the original fibers of the yarn (for example synthetic fibers in a cotton yarn). There are distinct benefits to early detection and

removal of unwanted fibrous material since later processing stages open up

and spread out these foreign fibers. This can result in the contamination

of many yarn packages [2]. Schenek named that due to the fact that fabrics

containing foreign fibers can not be dyed homogeneously, these fibers can

cause a lot of quality problems especially after finishing [3]. Lord mentioned

that these foreign fibers and materials adversely affect processing and produces error and also affect the properties such as dye uptake, fiber reflectance and the appearance of the final product [4].

Fig. 5 shows the risk of a spinning mill which has the foreign fiber challenge

not under control.

USTER CLASSIMAT QUANTUM

9 (16)

THE YARN CLASSIFICATION SYSTEM

34800

36000

32000

Sales prices in USD

28000

24000

18000

20000

16000

12000

7320

8000

3840

4000

600

1320

0

Bale

Yarn (Nec 30,

combed)

Raw fabric

Finished fabric

(bleached)

Shirts

Retailer

Fig. 5

Foreign fiber risk calculated

for a spinning mil

In this example, the calculation is based on a bale of 500 lbs (227 kg) and

the price for the bale was USD 600. The yarns made of this bale were sold

for USD 1320 and the raw fabric price was USD 3840. Finally, the finished

fabric was sold for USD 7320.

Because the foreign fibers were only detected after bleaching, the finishing

plant did not send the complaint to the cotton producer or cotton trader, but

to the spinner. Therefore, the finishing plant had a damage of USD 7320

per bale which had to be paid by the spinner, but the spinner only earned

USD 720 for the processing of the entire bale.

4.3

Classification matrix for foreign fibers

In addition to the standard classification, this system also allows the user to

measure foreign fibers and vegetables in a yarn and classify these faults in

27 foreign fiber classes.

With the vegetable filter, it is possible to differentiate between organic and

synthetic foreign fibers. Based on the fact that vegetables mostly do not

have a disturbing effect on the appearance of fabrics, because they can be

bleached and can absorb the same dyestuff, these particles are allowed to

remain in the yarn for many fabrics and, as a result, it saves a considerable

number of cuts on the winding machine and reduces the formation of

splices.

The USTER CLASSIMAT QUANTUM uses the basic matrix for foreign

fiber classification of the USTER QUANTUM, but the classes B1, B2, C1,

D1 and E1 have been further divided. Because the most frequent foreign

fibers occur mainly in the classes B1, B2 and C1, these classes and the

class D1 are further divided (Fig. 7).

10 (16)

USTER CLASSIMAT QUANTUM

THE YARN CLASSIFICATION SYSTEM

Since the basic matrix is retained, this means, for example:

B11 + B12 +B13 + B14 = B1 or

B21 + B22 = B2

Fig. 6 and Fig. 7 shows the structure of the classification matrix for foreign

fibers, which represents the appearance (in %) and length (in cm). The appearance corresponds to the visibility of a fault. No classification data is

available for the A1 class, because there is too high accumulation of foreign

fibers. The foreign fiber matrix is divided into 21 (Fig. 6) or 27 (Fig. 7) foreign fiber classes depending on a coarse or fine setting.

Appearance

Appearance

A4

B4

C4

D4

E4

30%

B3

C3

D3

E3

F

20%

A2

B2

C2

D2

D4

E4

A3

B3

C3

D3

E3

F

A2

B21 B22

C2

D2

E2

B13 B14

C12

D12

E12

10%

C1

B1

no counts

4.4

C4

20%

E2

10%

Fig. 6

B4

30%

A3

5%

A4

1.0

2.0

D1

3.0

E1

5.0

no

counts

7%

5%

7.0 cm Fault length

l

Structure of the classification matrix for foreign fibers

Coarse setting

Fig. 7

B11 B12

1.0

1.4

E11

D11

C11

2.0

3.0

5.0

7.0 cm

Length

l

Structure of the classification matrix for foreign

fibers Fine setting

Scatter plot of foreign fibers

With the scatter plot (Fig. 8 and Fig. 9), the distribution of foreign fibers in

the yarn can be seen at one glance. Furthermore, vegetables are distinguished from actual foreign fibers by the vegetable filter and displayed

separately (olive-green).

In Fig. 8 and Fig. 9, we can see the foreign fiber scatter plots of the same

yarns mentioned above (In Fig. 3 and Fig. 4, Ne 30, 100% cotton, carded).

In Fig 8, the scatter plot shows a yarn with a low amount of foreign fibers.

These faults are shown as green colored points and vegetables are shown

in olive-green. In Fig. 9, the scatter plot shows a yarn with a high number of

foreign fibers. When we compare these two yarns, for example in the Class

B1, the yarn in Fig. 8 has only 103 foreign fibers and 24 vegetables; Fig. 9

shows, as a contrast, a yarn with 673 foreign fibers and 238 vegetables in

the B1 class. Again the user can analyze and choose the yarn having a

lower number of foreign fibers by using the scatter plot.

USTER CLASSIMAT QUANTUM

11 (16)

THE YARN CLASSIFICATION SYSTEM

Fig. 8

100 % cotton, carded, Ne 30, ring spun yarn, per

100 km (less faults)

Fig. 9

100 % cotton, carded, Ne 30, ring spun yarn, per

100 km (high number of faults)

The difference between the two yarns, what foreign fibers are concerned, is

enormous, and also has considerable consequences on the appearance of

the fabric. The comparison also shows that the yarn in Fig. 9 has much

more remaining vegetables (olive-green dots).

Both yarns were processed on a winding machine with no foreign fiber

clearing. However, in order to avoid a considerable drop of the efficiency of

the winding machine it is only allowed to remove the most significant foreign fibers in the yarn of Fig. 9.

Benchmarking for USTER CLASSIMAT classification

In 1975, Uster Technologies introduced the USTER STATISTICS for the

USTER CLASSIMAT for the first time. Uster Technologies has carried out

many tests with yarns coming from all over the world and the results were

published in 2003 as the first USTER STATISTICS for foreign fibers and in

2007, the new USTER STATISTICS 2007 were introduced to the market.

95%

75%

25%

5%

Fig. 10

Cotton 100%, carded, Ne 10 to

Ne 40, ring-spun, for knitted

fabrics

12 (16)

USTER CLASSIMAT QUANTUM

THE YARN CLASSIFICATION SYSTEM

In Fig. 10 the red symbol (on the right hand side) explains the significance

of statistical values and indicates the range from 5 to 95 %. A foreign fiber

content on the 95% level means that 95% of all spinning mills worldwide

are below this figure. A value on the 5% level, however, indicates that only

5% of all spinning mills worldwide could achieve this quality level.

Fig. 10 shows for example that the spinning mills with the lowermost number of foreign fibers only have 15 events in the B21 class whereas the mills

with the highest level have 600 and more foreign fibers in the same category.

Conclusion

It is well known that the yarn quality is very important for the quality of the

end product. Weak places, for example, mainly affect the productivity (machine stops caused by end breaks) whereas coarse yarn faults in woven or

knitted fabrics result in costly rejects. Today, the selection of the right yarn

for the right product is crucial for economic reasons. A continuous incoming

inspection guarantees a constant satisfactory quality of the end product. In

this respect classifying systems are playing a very important role. For example many of the foreign fiber problems are only detected after finishing,

and the spinner is finally made responsible for the damage. For this reason,

the sooner they are detected, the lower the costs and the better the quality.

The costs and claims due to foreign fibers can be prevented by setting up a

quality management system to eliminate or minimize the number of foreign

fibers in yarns.

Within the scope of a modern quality assurance program it is now possible

that test reports, which serve as a quality guarantee for the observance of

supplier agreements or certificates, are requested with every yarn delivery.

As a result of 40 years of continuous experience in yarn clearing and classification, the USTER CLASSIMAT QUANTUM can be used not only as a

tool in order to examine the yarns to be purchased for remaining disturbing

thick places, thin places and foreign fibers but also as a sophisticated classifying system which can help the user to determine and set his own yarn

quality standards.

USTER CLASSIMAT QUANTUM

13 (16)

THE YARN CLASSIFICATION SYSTEM

Literature

1. Schindler C., ITMF COTTON CONTAMINATION SURVEY 2007, 29th International Cotton Conference, Proceedings, Bremen, April 2 - 5, 2008.

2. Oxhenam W., Preparing for Change, Yarn preparation faces questions as

to what the future holds

http://www.textileworld.com/Articles/2000/April/Features/Preparing_For_Ch

ange.html

3. Schenek A.,Lexikon Garne und Zwirne: Eigenschaften und Herstellung

textiler Fden, Deutscher Fachverlag GmbH, Fankfurt am Main, 174-175,

2006.

4. Lord, P. R., Handbook of yarn production: Technology, science and economics, Woodhead Publishing Limited, 2005.

5. Furter, R. Experience with foreign material removal systems for cotton,

Uster Technologies, Application Report, SE 594, 2006.

6. Edalat-Pour, S.,USTER CLASSIMAT QUANTUM Application Handbook,

Classification of thick and thin places, classification of foreign fibers, 304

100- 89720, 2005.

14 (16)

USTER CLASSIMAT QUANTUM

THE YARN CLASSIFICATION SYSTEM

USTER CLASSIMAT QUANTUM

15 (16)

THE YARN CLASSIFICATION SYSTEM

Uster Technologies AG

Wilstrasse 11

CH-8610 Uster / Switzerland

Phone +41 43 366 36 36

Fax

+41 43 366 36 37

www.uster.com

sales@uster.com

16 (16)

USTER CLASSIMAT QUANTUM

Potrebbero piacerti anche

- Uster ClassimatDocumento10 pagineUster ClassimatAbu Bakkar71% (7)

- Uster Classimat 5Documento9 pagineUster Classimat 5Shoaib ArifNessuna valutazione finora

- Uster Classimat Fault ChartDocumento7 pagineUster Classimat Fault Chartstylish eagle100% (3)

- Yarn Clearing SystemsDocumento11 pagineYarn Clearing SystemsLohit MohapatraNessuna valutazione finora

- HTTP WWW - UsterDocumento38 pagineHTTP WWW - UsterKurnia RiniNessuna valutazione finora

- USTERDocumento5 pagineUSTERchiragNessuna valutazione finora

- Arif ProjectDocumento75 pagineArif ProjectWaqas Mehmood BaigNessuna valutazione finora

- ClassimatDocumento11 pagineClassimatRonak JoshiNessuna valutazione finora

- How To Assess Mill's Productivity ?Documento44 pagineHow To Assess Mill's Productivity ?cottontrade91% (34)

- Application Handbook USTER Statistics 2013Documento38 pagineApplication Handbook USTER Statistics 2013Kaushik Mukherjee100% (2)

- Fabric DefectsDocumento33 pagineFabric DefectsAzeem Akbar92% (13)

- Yarn Evenness CVDocumento10 pagineYarn Evenness CVRanganatham Ummadisetty100% (1)

- Improving Productivity of Ring FramesDocumento8 pagineImproving Productivity of Ring FramesAmrit virkNessuna valutazione finora

- Classification of Yarn Faults and Possible SourceDocumento4 pagineClassification of Yarn Faults and Possible SourceNagarajan Sivathanu Pillai50% (2)

- Calculate Crimp Percentage of Woven FabricDocumento2 pagineCalculate Crimp Percentage of Woven FabricSoyeb HassanNessuna valutazione finora

- Investigative Study of Periodic Yarn Faults and Its Removal by Using Gearing AnalysisDocumento59 pagineInvestigative Study of Periodic Yarn Faults and Its Removal by Using Gearing AnalysisJuan Cubas100% (1)

- Blow RoomDocumento27 pagineBlow Roomapi-377494789% (19)

- Yarn WindingDocumento22 pagineYarn WindingPRAKASH B. MALAKANE0% (1)

- Thick, Thin PlacesDocumento56 pagineThick, Thin PlacesAmir Shahzad100% (5)

- yarn-II NoteDocumento118 pagineyarn-II NoteMoshiur Rahman Kayes100% (1)

- Textile Machineries MaintenanceDocumento13 pagineTextile Machineries Maintenancerkhan9392100% (1)

- IPI Stands For Imperfection Index of YarnsDocumento1 paginaIPI Stands For Imperfection Index of YarnsShoreless Shaikat100% (5)

- 2.1 Quailty Control in SpinningDocumento31 pagine2.1 Quailty Control in SpinningRounoque ShishirNessuna valutazione finora

- WarpingDocumento10 pagineWarpingKalyan Ray GuptaNessuna valutazione finora

- Blowroom CalculationDocumento14 pagineBlowroom CalculationIrfan Ali100% (1)

- YARN Quality ComplaintsDocumento27 pagineYARN Quality ComplaintsManojSharma100% (1)

- 004 USTER HVI 1000, Best Operating Practices For Lab Technicians, 2008Documento19 pagine004 USTER HVI 1000, Best Operating Practices For Lab Technicians, 2008郭哲宏Nessuna valutazione finora

- Auto Cone ComparisonDocumento8 pagineAuto Cone ComparisonMuhammad Talha100% (1)

- Finisher Draw Frame AutolevellerDocumento30 pagineFinisher Draw Frame AutolevellerRuhi gnext100% (1)

- Assignment ON Combing ProcessDocumento11 pagineAssignment ON Combing ProcessBoier Sesh Pata0% (2)

- Imperfection Index of YarnsDocumento2 pagineImperfection Index of YarnsMohammed Atiqul Hoque ChowdhuryNessuna valutazione finora

- Textile in DepthDocumento59 pagineTextile in DepthBoopathi Sadasivam50% (2)

- Ring Frame - Technological AspectsDocumento43 pagineRing Frame - Technological AspectsAliAhmad67% (3)

- Classimat 5 HelpDocumento214 pagineClassimat 5 HelpPoint To Point100% (1)

- Simplex Gearing DiagramDocumento3 pagineSimplex Gearing DiagramShan Imtiaz67% (3)

- Ring FrameDocumento13 pagineRing FrameAnkit Kumar0% (1)

- HVIDocumento13 pagineHVIDIPAK VINAYAK SHIRBHATE100% (3)

- AFIS PRO 2 A New Single PDFDocumento24 pagineAFIS PRO 2 A New Single PDFlalit kashyapNessuna valutazione finora

- Impact of Cotton Parameters On Yarn QualityDocumento4 pagineImpact of Cotton Parameters On Yarn Qualityغلام جیلانی100% (6)

- Spinpact Fine Tuning HandbookDocumento10 pagineSpinpact Fine Tuning Handbookselvakumar100% (1)

- Spin PLanDocumento3 pagineSpin PLanntunewspoint100% (4)

- Mélange YarnDocumento11 pagineMélange YarnshahinNessuna valutazione finora

- Draft CalculationDocumento17 pagineDraft CalculationDyeing Dyeing100% (1)

- Blending at BlowroomDocumento3 pagineBlending at Blowroommoosking100% (1)

- Yarn Faults: Types Causes RemediesDocumento20 pagineYarn Faults: Types Causes Remediesஹரி கிருஷ்ணன் வாசு71% (7)

- Carding: Q. Define Carding/Heart of SpinningDocumento31 pagineCarding: Q. Define Carding/Heart of SpinningSantoshNessuna valutazione finora

- Cotton Yarn - Quality Depends On Mixing Strategy - Spinning & Weaving - Features - The ITJDocumento12 pagineCotton Yarn - Quality Depends On Mixing Strategy - Spinning & Weaving - Features - The ITJsureshNessuna valutazione finora

- LRT HandbookDocumento41 pagineLRT HandbookAshok Kumar60% (5)

- Clearer Cuts Summary ReportDocumento34 pagineClearer Cuts Summary ReportTowfic Aziz Kanon100% (1)

- Twist MultiplierDocumento1 paginaTwist MultiplierAniket Mahajan100% (5)

- Yarn Manufacturing 2Documento16 pagineYarn Manufacturing 2Muhammad Farooq Kokab60% (5)

- Classimat Yarn Faults - 16174 PDFDocumento10 pagineClassimat Yarn Faults - 16174 PDFAnonymous Pt7NHkat9Nessuna valutazione finora

- Uster Technologies Regularly Publishes Standards Such As USTERDocumento12 pagineUster Technologies Regularly Publishes Standards Such As USTERHeba AlaaNessuna valutazione finora

- CLASSIMATDocumento6 pagineCLASSIMATBhaskar MitraNessuna valutazione finora

- B.Sc. Textile Engineering: Textile Testing and Quality ControlDocumento8 pagineB.Sc. Textile Engineering: Textile Testing and Quality ControlSaqib SiddiquiNessuna valutazione finora

- Main ContentsDocumento16 pagineMain ContentsPricopNessuna valutazione finora

- U Z HL400 HairinessDocumento16 pagineU Z HL400 HairinessarunmythreyeeNessuna valutazione finora

- E Ka01 WindingDocumento12 pagineE Ka01 WindingMadhavKumar ThangavelNessuna valutazione finora

- SMEDA Maize Starch and Related ProductsDocumento25 pagineSMEDA Maize Starch and Related ProductsSaad NaseemNessuna valutazione finora

- SMEDA Maize Starch and Related ProductsDocumento31 pagineSMEDA Maize Starch and Related ProductsTatek Dinberu0% (1)

- Denim Jeans Stitching UnitDocumento25 pagineDenim Jeans Stitching UnitSaad NaseemNessuna valutazione finora

- Layer Farming 10000 BirdsDocumento17 pagineLayer Farming 10000 BirdsSaad NaseemNessuna valutazione finora

- Compact YarnDocumento9 pagineCompact YarnSaad NaseemNessuna valutazione finora

- Organic Chemical TechnologyDocumento5 pagineOrganic Chemical TechnologykayeNessuna valutazione finora

- Abaca Fibre PDFDocumento4 pagineAbaca Fibre PDFYanoNessuna valutazione finora

- Polymer-Based Composite Structures - Processing and ApplicationsDocumento36 paginePolymer-Based Composite Structures - Processing and ApplicationsFlor GINessuna valutazione finora

- A Study On Mechanical Behaviour of Hair Fiber Reinforced Epoxy CompositesDocumento26 pagineA Study On Mechanical Behaviour of Hair Fiber Reinforced Epoxy CompositesJERIN K GEORGENessuna valutazione finora

- Abaca Fiber As A Retrofitting MaterialDocumento6 pagineAbaca Fiber As A Retrofitting MaterialYuri ValenciaNessuna valutazione finora

- TY BTech Textile PDFDocumento13 pagineTY BTech Textile PDFSwapnil UbaleNessuna valutazione finora

- Ocpsf GuidanceDocumento110 pagineOcpsf Guidanceapi-3733731Nessuna valutazione finora

- Mrunmai Mangoli 25 ABC 3ADocumento5 pagineMrunmai Mangoli 25 ABC 3AMrunmai MangoliNessuna valutazione finora

- Business SchemesDocumento22 pagineBusiness Schemesjyotiranjan1982Nessuna valutazione finora

- Carbon - Carbon CompositesDocumento43 pagineCarbon - Carbon CompositesPapu yadavNessuna valutazione finora

- Mitutoyo - Trzpienie Pomiarowe, Końcówki I Akcesoria - PRE983017 (4) - 2017 ENDocumento56 pagineMitutoyo - Trzpienie Pomiarowe, Końcówki I Akcesoria - PRE983017 (4) - 2017 END.T.Nessuna valutazione finora

- Unknown Crafts PersonDocumento10 pagineUnknown Crafts Personsatyam BhutadaNessuna valutazione finora

- Presentation On Textile IndustryDocumento20 paginePresentation On Textile IndustrySteve IwuchukwuNessuna valutazione finora

- Sikafiber® Novocon® He-1050 HT: Product Data SheetDocumento3 pagineSikafiber® Novocon® He-1050 HT: Product Data SheetCsillag JanosNessuna valutazione finora

- Key Factors To Be Considered For Reactive Dyeing Right First TimeDocumento12 pagineKey Factors To Be Considered For Reactive Dyeing Right First TimeLasitha Nawarathna50% (2)

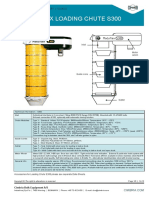

- 102.05.02 Moduflex Sheet Data S300Documento3 pagine102.05.02 Moduflex Sheet Data S300Metra ServiceNessuna valutazione finora

- Carpet Brochure 2 POLYAMIDE Single PagesDocumento16 pagineCarpet Brochure 2 POLYAMIDE Single PagesNguyễn Huy CườngNessuna valutazione finora

- Studies On The Mechanical Properties of Carbonized/Uncarbonized Cornhub Powder Filled Natural Rubber/Acrylonitrile Butadiene Rubber BicompositeDocumento13 pagineStudies On The Mechanical Properties of Carbonized/Uncarbonized Cornhub Powder Filled Natural Rubber/Acrylonitrile Butadiene Rubber BicompositeIheoma Chukwujike NwuzorNessuna valutazione finora

- Iso 10325 2018Documento9 pagineIso 10325 2018Julio Andrés Casal Ramos0% (1)

- SpandexDocumento35 pagineSpandexNift MfmNessuna valutazione finora

- Experimental Investigation of Compressive Strength of Concrete by Using Coconut FibresDocumento57 pagineExperimental Investigation of Compressive Strength of Concrete by Using Coconut FibresHarshada WankhedeNessuna valutazione finora

- Active Materials Forecast A W 24 25 enDocumento18 pagineActive Materials Forecast A W 24 25 enАнна БычковаNessuna valutazione finora

- Dimensional DrawingsDocumento96 pagineDimensional DrawingsSagar TradingNessuna valutazione finora

- POLYMER and GeotextileDocumento6 paginePOLYMER and GeotextileRCBacayNessuna valutazione finora

- NyconXLSheet042015-macro FibrillatedDocumento2 pagineNyconXLSheet042015-macro Fibrillateduğur alparslanNessuna valutazione finora

- Dojcak-Beton S Rozptylenou Vystuzou enDocumento16 pagineDojcak-Beton S Rozptylenou Vystuzou enDaniel ZabalaNessuna valutazione finora

- An Introduction To The Chemistry of CelluloseDocumento561 pagineAn Introduction To The Chemistry of CelluloseBananNessuna valutazione finora

- Ipi TrivediDocumento55 pagineIpi TrivediROHAN KULKARNINessuna valutazione finora

- An Evaluation of The Mechanical and Self-Healing Properties of WarmDocumento15 pagineAn Evaluation of The Mechanical and Self-Healing Properties of WarmCarolina GonzalezNessuna valutazione finora

- RRL Pineapple FibersDocumento2 pagineRRL Pineapple FibersAlexandria OrayeNessuna valutazione finora