Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Saravanathamizhan 2008

Caricato da

احمد جاسم شكارهTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Saravanathamizhan 2008

Caricato da

احمد جاسم شكارهCopyright:

Formati disponibili

2976

Ind. Eng. Chem. Res. 2008, 47, 2976-2984

Tanks in Series Model for Continuous Stirred Tank Electrochemical Reactor

R. Saravanathamizhan, R. Paranthaman, and N. Balasubramanian*

Department of Chemical Engineering, A.C. Tech Campus, Anna UniVersity-Chennai, Chennai-600025, India

C. Ahmed Basha

Department of Pollution Control, Central Electrochemical Research Institute, Karaikudi-630 006, India

It is attempted in the present investigation to study the residence time distribution of electrolyte in a continuous

stirred tank electrochemical reactor. The electrolyte flow behavior has been experimented on by using both

pulse and step input techniques. The exit age distribution curves obtained under various operating conditions

are critically analyzed. A theoretical model based on tanks in series has been developed to describe the

electrolyte flow behavior inside the continuous stirred tank electrochemical reactor, and the model simulations

are validated with experimental observations.

Introduction

Day-to-day human activities and the industrial revolution have

influenced the generation of large quantity of effluent. The

treatment of industrial effluent has become indispensable as such

effluent contaminates bodies of water and may be toxic to many

life forms. Since most of the industrial effluents are difficult to

degrade, the disposal of industrial effluent has become a major

environmental issue. In general, industrial effluents are characterized to have a large amount of suspended solids, high

chemical oxygen demand and biological oxygen demand, and

varying pH.

Conventionally, industrial effluents are treated by physical,

chemical, and biochemical techniques. Because of the large

complexity of the composition of effluent, most of these

traditional methods are becoming inadequate. As the environmental regulations becoming more stringent day by day, new

and novel processes for efficient treatment of effluent at low

operating cost are needed. In this perspective, researchers are

focusing on advanced oxidation processes such as electrochemical technique, wet air oxidation, ozonation, and a photocatalytic

method for the degradation of organic compounds present in

the wastewater. Among these advanced oxidation processes,

electrochemical treatment has been receiving greater attention

due to its unique features such as complete degradation without

generation of solid sludge, energy efficiency, automation, and

cost effectiveness.1,2

In electrochemical technique, electron is used to degrade all

the organics present in the effluent without generating any

secondary pollutant or biproduct/sludge. The advantage of the

electrochemical technique is high removal efficiencies with low

temperature requirements compared to nonelectrochemical treatment. In addition to the operating parameters, the pollutant

degradation rate depends on the anode material. When electrochemical reactors operate at high cell potential, the anodic

process occurs in the potential region of water discharge and

hydroxyl radicals are generated. On the other hand, if chloride

is present in the electrolyte, an indirect oxidation via active

chlorine can be operative,3 which has been successfully adopted

for treatment of several industrial effluents. In our earlier

investigations, in situ catalytic oxidation of textile effluent using

* Corresponding author. E-mail: nbsbala@annauniv.edu. Tel.:

91-44-22203501.

oxide coated electrodes and the reuse of treated wastewater for

dyeing applications have been attempted.4-6

Different types of electrochemical reactors ranging from

conventional plate and frame cell to advanced electrodes such

as three-dimensional electrodes are used for electrochemical

processes. The design or selection of suitable electrochemical

reactor is very important in electrochemical process as the

reactor geometry plays an important role in the process yield.

Extensive work has been reported on the analysis of

performance of various electrochemical reactors. Bengoa et al.7

studied the flow behavior of electrolyte in a filter press type

electrochemical reactor and reported residence time distribution

using a commercial ElectroSyn cell. The authors observed both

the axial and lateral dispersion phenomena in a plug flow

behavior. Lidia and Marta8 have experimented the treatment of

textile effluent of reactive dye Red Procion H-EXGL using an

electrochemically generated redox mediator in a filter press cell

and developed a model for exit age distribution. The authors

reported that the electrolyte flow behavior is close to plug flow.

Trinidad and Walsh9 verified dispersion and Schneider-Smith

models for a laboratory filter press reactor using the pulse tracer

technique and observed wide deviation of these models from

the ideal plug flow model, while the authors10 reported the

conversion expression for batch, plug flow, and continuous

stirred electrochemical reactors in terms of mass transfer

coefficient.

Carpenter and Roberts11 studied the mass transport and

residence time distribution in a parallel-plate flow oscillatory

electrochemical reactor for the reduction of ferricyanide and

reported that the oscillatory flow enhances the mass transport

rate. Jose Gonza lez-Garcya et al.12 studied the hydrodynamic

behavior in a filter-press electrochemical reactor, assembled with

three-dimensional carbon felt electrodes. Polcaro et al.13 experimented water disinfection process and hydrodynamics study

in a stirred tank electrochemical reactor using a boron-doped

diamond electrode and developed model for two CSTERs in

parallel configuration.

The flow characteristic of electrolyte in an electrochemical

reactor is of great importance. The objective of the present

investigation is to study the residence time distribution in a

continuous stirrer tank electrochemical reactor. A theoretical

model based on tanks in series has been proposed to describe

the electrolyte flow behavior, and the model simulations have

been verified with the experimental observations.

10.1021/ie071426q CCC: $40.75 2008 American Chemical Society

Published on Web 04/03/2008

Ind. Eng. Chem. Res., Vol. 47, No. 9, 2008 2977

Substituting eq 8 in eq 5 and rearranging the equation results

in

CAi - CA )

k1CA - k2CB

(1 + D1 + D2)

(9)

where D1 and D2 are Damkohler numbers for the forward and

reverse reactions, which can be defined as

D1 )

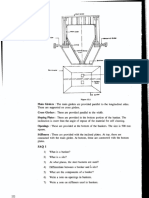

Figure 1. Schematic of the continuous stirred tank electrochemical reactor.

Continuous Stirred Tank Reactor Model

Let us consider a simple electrode reaction as given below

A + ne- T B+

iL ) nFkmC

i

nF

1+

k2

(1 + D1 + D2)

(k1 + k2)

(11)

(1 + D1 + D2)

For an irreversible reaction the term k2 becomes zero, and

then the eq 11 is reduced to

CA

1

)

CAi (1 + P)

P)

(4)

(5)

where k1 and k2 represent the reaction rate constants for forward

and reverse reactions, respectively, and CSA and CSB are surface

concentrations. The current density can be expressed in terms

of the mass transport of A for steady-state operation as

i

) kL1(CA - CSA)

nF

CA

)

CAi

1+

(12)

where

where CAi and CA refer to initial and final concentrations and

refers to the interfacial area of the electrode. The electrode

kinetics is assumed to follow Butler-Volmer type equation,

i.e.

i

) k1CSA - k2CSB

nF

(10)

Substituting for CB in eq 9 and rearranging the results gives

(3)

The eq 3 can be written in term of residence time as

CAi - CA )

CAi ) CA + CB

(2)

where km refers to the mass transfer coefficient and C refers to

the bulk concentration. If the reaction takes place in a continuous

stirred tank electrochemical reactor [Figure 1], then the material

balance can be written as

iS

V(CAi - CA) )

nF

The overall material balance for the reactor in terms of

concentration can be written as

(1)

where n refers to number of electrons. The above reaction

can be controlled by either by kinetic or mass transfer. The

limiting current density can be related to the mass transfer

coefficient as14

k1

k2

and D2 )

kL1

kL2

(6)

k1

(1 + D1)

The eq 12 represents the conversion equation for a continuous

stirred tank electrochemical reactor. For CSTERs connected in

series the eq 12 can be modified as

CAN

)

CAN-1

1+

1

k1

(13)

(1 + D1)

where N represents the number of tanks in series. The eq 13

can be rearranged as16

k1

CAN

) 1+

CAi

(1 + D1)

-N

(14)

Tanks in Series Model

where kL1 represents the mass transfer coefficient of A. The eq

6 can be written in terms of mass transport of B as

i

) kL2(CSB - CB)

nF

(7)

where kL2 represents the mass transfer coefficient of B.

Combining eqs 5-7, the surface concentration is eliminated

resulting the reaction rate in terms of bulk concentration,15 i.e.

k1CA - k2CB

i

)

k1

k2

nF

1+

+

kL1 kL2

(8)

Tanks in Series model has been proposed to describe the flow

characteristics of the electrolyte in a CSTER. It is assumed that

the CSTER consists of three tanks connected in series [Figure

1]. Accordingly the tracer material balance for the tank 1 can

be written as

dC1

) C o - C1

dt

(15)

where 1 represents the residence time of electrolyte in tank 1;

Co and C1 refer to the inlet and outlet tracer concentration of

tank 1. Similarly the tracer material balance can be developed

for second and third tanks as given below.

2978

Ind. Eng. Chem. Res., Vol. 47, No. 9, 2008

The material balance for tank 2 can be written as

Differentiating eq 21 results in exit age distribution, i.e.

dC2

) C 1 - C2

dt

(16)

E(t) )

1e-t/1

(3 - 1)(2 - 1)

2e-t/2

(1 - 2)(3 - 2)

3e-t/3

The material balance for tank 3 can be given as

(1 - 3)(2 - 3)

dC3

) C 2 - C3

dt

(17)

where C2 and C3 represent tracer outlet concentrations of second

and third tanks, respectively, while 2 and 3 represent the

residence time of electrolyte in tanks 2 and 3, respectively. The

model is further extended for age distribution analysis for the

following conditions.

Case I: The volumes of the three tanks are unequal (i.e., V1

* V2 * V3).

Case II: The volumes of the three tanks are equal (i.e., V1 )

V2 ) V3).

Case III: The volumes of tanks 1 and 3 are equal, and the

volume of tank 2 is higher than those of the other tanks (i.e.,

V1 ) V3; V2 > V1, V3).

All the above three cases have been considered for the

simulation to find the active volume involved during the process

in CSTER.

Case I: As stated earlier, it is assumed that the reactor has

three tanks of unequal volume separated by the electrodes. The

electrolyte enters at tank 1 and leaves at tank 3. The total volume

of the reactor is the summation of the volumes of all three tanks,

i.e.

V ) V 1 + V2 + V3

(18)

where V1, V2, and V3 represent the volumes of tanks 1, 2, and

3, respectively, and V refers to the reactor total volume. The

exit age distribution analysis has been performed by both step

and pulse input techniques. Solving the eqs 15 to 17 for the

pulse input, the F(t) can be written for the three tanks connected

in series as (For all the three cases the analytical solution given

in the annexure)

F(t) ) 1

1e-t/1

(1 - 2)(1 - 3)

2e-t/2

-t/3

(3 - 2)(3 - 1)

E(t) )

F(t) ) 1 -

(3 - 1)(2 - 1)

t2e-t/

23

(24)

t

t2e-t/

- e-t/ 1 +

2

(25)

Equation 24 is used for the E(t) for the step input since the

volumes are equal.

Case III: In this case, it is assumed that tanks 1 and 3 are

equal in volume and the volume of tank 2 is higher than the

others. Accordingly, eqs 15-17 are solved for pulse input, i.e.

F(t) )

12

1

te-t/1 +

(e-t/2 - e-t/1)

(1 - 2)

(1 - 2)

(26)

(27)

E(t) can be obtained by differentiating eq 26, i.e.

E(t) )

12

1

te-t/1 +

(e-t/2 - e-t/1)

1(1 - 2)

(1 - 2)

1(22 - 1)e-t/1

(2 - 1)2

22e-t/2

(1 - 2)(3 - 2)

(1 - 22)e-t/1

(2 - 1)2

32e-t/3

(1 - 3)(2 - 3)

22e-t/2

te-t/1

(28)

(2 - 1) (2 - 1)2

Differentiating eq 28 with respect to time results in the

following expression for E(t);

E(t) )

Solving eqs 15-17 for the step input and rearranging results

in the following expression for F(t), i.e.

(23)

While eqs 15-17 are solved for the step tracer input results,

the following expression for F(t) is seen

( ( ))

t

e-t/1

11

(2 - 1)

+

2e-t/2

e-t/3

(20)

(2 - 3)(3 - 1)

12e-t/1

t2e-t/

22

Equations 15-17 are solved for the exit age distribution for

pulse input

(19)

-t/2

e

e

+

+

(1 - 2)(3 - 1) (1 - 2)(2 - 3)

F(t) ) 1 -

F(t) )

F(t) ) 1 +

Differentiating eq 19 results in the exit age distribution E(t),

i.e.

Case II: In this case, the three tanks are assumed to be equal

in volume, i.e., V1 ) V2 ) V3. Solving eqs 15 to 17 for the

pulse input results in the following equation17

3e

E(t) ) 1

(22)

Similarly eqs 15-17 are solved for the step input as

(2 - 1)(2 - 3)

-t/1

(2 - 1)2

(29)

The model in eqs 19-29 gives the residence time distribution

analysis of CSTER for different geometries. These equations

are solved numerically and examined for critical operating

conditions.

Experimental Section

(21)

The experimental setup given in Figure 2 consists of a glass

beaker of 300 mL capacity with PVC lid having provision for

Ind. Eng. Chem. Res., Vol. 47, No. 9, 2008 2979

Figure 2. Schematic of continuous stirred tank electrochemical reactor

experimental setup: (1) overhead tank; (2) dc power supply; (3) anode; (4)

cathode; (5) magnetic stirrer; (6) tracer injection point.

Figure 5. Simulated F(t) distribution in a CSTER for a pulse input at

different flow rates. Volume ratio ) 1:10:1.

Figure 3. Comparison of model simulation of exit age distribution with

experimental observation for the pulse input. Q ) 35 mL min-1; volume

ratio ) 1:3:2.

Figure 6. Simulated E(t) distribution in a CSTER for a pulse input at

different flow rates. Volume ratio ) 1:2:1.

Figure 4. Comparison of model simulation of exit age distribution with

experimental observation for the pulse input. Q ) 35 mL min-1; volume

ratio ) 1:1:1.

an anode and a cathode. RuO2/Ti and a stainless steel sheet of

6.5 5 cm2 were used as anode and cathode, respectively. The

uniform electrolyte concentration inside the reactor has been

maintained with the help of magnetic stirrer. Experiments were

conducted on electrooxidation of dye effluent and residence time

distribution to find the nonideality of the system without an

electrochemical reaction.

For electrooxidation, synthetic effluent of Acid Red 88 dye

has been prepared at various initial concentrations. The electrolysis was carried out under galvanostatic conditions using a

dc-regulated power source (HIL model 3161). The effluent flow

rate has been adjusted by adjusting throat valve and the samples

were collected for analysis of color removal at steady state. For

residence time distribution studies, the reactor was operated with

water as electrolyte. The tracer of 10 mL of 1000 ppm Acid

Red 88 dye solution was injected at steady state and sampled

periodically at the outlet of the reactor and analyzed using a

colorimeter.

Figure 7. Simulated F(t) distribution in a CSTER for a step input at

different flow rates. Volume ratio ) 1:10:1.

Results and Discussion

The electrolyte flow behavior in a continuous stirred tank

electrochemical reactor has been simulated for both pulse and

step tracer input using the model equations developed in the

previous section. The exit age distribution E(t) can be calculated

from the tracer output using the following equation18

E(t) )

c(t)

(30)

c(t) dt

where c(t) represent the exit tracer concentration at time t .

2980

Ind. Eng. Chem. Res., Vol. 47, No. 9, 2008

Figure 8. Simulated E(t) distribution in a CSTER for a step input at

different flow rates. Volume ratio ) 1:4:1.

Figure 9. Experimental observation of E(t) distribution in a CSTER for

pulse input.

The mean residence time, variance, and the number of tanks in

series can be calculated using the following equation.

The mean residence time distribution, for CSTER can be

given as

0 tE(t) dt

(31)

The variance for CSTER can be written as

2 )

0 (t - )2E(t) dt

(32)

The number of tanks, N, can be given as

N)

2

2

(33)

The number of tanks in the tanks in series model can be

calculated using eq 33. The experimental observations and

theoretical analysis of all three cases are discussed below.

Case I. The model equations developed in the earlier section

[i.e., equations 19 to 22] have been solved for E(t) and F(t)

distribution under various flow conditions. Figure 3 shows the

simulated exit age distribution along with experimental observation for the pulse input. It can be ascertained from Figure 3

that the simulated exit age distribution shows wide deviation

from experimental observations. Similar observation has been

recorded for all the flow conditions. This may be the fact that

the assumption considered in case I may not be realistic in

electrochemical system.

Case II. Equations 23-25 have been solved for E(t) and F(t)

distribution for both pulse and step inputs. Figure 4 compares

the simulated exit age distribution along with experimental

observation for pulse input. It can be noticed from Figure 4

that the simulated exit age distribution shows a much greater

difference with the experimental observation. The deviation can

be explained by the fact that the assumption of equal division

of electrochemical reactor into three tanks in series does not

reflect a realistic representation of the system. Similar observations have been noticed for all the other flow conditions also.

Case III. Equations 26-29 have been solved for F(t) and

E(t) distribution for both step and pulse inputs for various

electrolyte flow rates at different volume ratio of the tanks.

Further the tanks in CSTER (tanks 1, 2, and 3) are assumed to

have three volume ratios, i.e., 1:2:1; 1:4:1 and 1:10:1. Accordingly, the simulations have been carried out for the three volume

ratios under various electrolyte flow rates, and the simulated

results are presented in Figures 5 and 6. Figure 5 shows the

Figure 10. Experimental observation of F(t) distribution in a CSTER for

step input.

simulated F(t) for pulse input for the volume ratio 1:10:1. It

can be ascertained from the figure that the F(t) decreases with

increase in the electrolyte flow rate. This is due to the fact that

the volume by volumetric flow rate of the electrolyte decreases

with increase in electrolyte flow rate resulting reduction in mean

residence time distribution. It can also be observed from Figure

5 that the average residence time is decreases with increase in

electrolyte flow rate. Similar observation has been recorded for

the other volume ratios.

Figure 6 shows the simulated exit age distribution function

E(t) for pulse input at a 1:2:1 volume ratio. It can be ascertained

from the figure that the E(t) decreases with increase in electrolyte

flow rate. This can be explained that the volume by volumetric

flow rate decreases with increase in electrolyte flow rate

resulting reduction in mean residence time distribution. Further

it can be observed from Figure 6 that the average residence

time decreases with an increase in electrolyte flow rate. On the

other hand, Figures 7 and 8 show the simulation of F(t) at 1:10:1

volume ratio and E(t) simulation at 1:4:1 volume ratio,

respectively. A similar observation has been observed for F(t)

and E(t) distributions for the step input.

The experimental, analyzed for E(t) and F(t) distributions for

different flow rates are given in Figures 9 and 10. It can be

observed that the distributions of E(t) and F(t) decrease with

an increase in flow rate of the electrolyte. Figure 11 shows the

comparison of experimental observation with simulation for

different volume ratios. It can be observed from the figure that

the simulated results obtained for a volume ratio of 1:10:1

Ind. Eng. Chem. Res., Vol. 47, No. 9, 2008 2981

Figure 11. Comparison of simulated E(t) distribution with experimental

observation in a CSTER for pulse input. Q ) 35 mL min-1.

Figure 13. Comparison of model simulations of F(t) distribution with the

experimental observations, Q ) 100 mL min-1.

Table 1. Variation of Reactor Active Volumes (V1, V2) with

Electrolyte Flow Rate

Q (mL min-1

V1 (cm3)

V2 (cm3)

35

75

100

25

23

21

250

254

258

Table 2. Comparison of Theoretical and Experimental

Decolorization Efficiency in the CSTER for Current Density 10 mA

cm-2, Initial Effluent Concentration 100 mg L-1, and Supporting

Electrolyte Concentration 1000 mg L-1.

% decolorization

S. no.

Q

(mL min-1 )

(min)

no. of

tanks

theor

exptl

1

2

3

35

75

100

7.08

3.09

2.40

1.18

1.49

1.59

67.42

54.79

49.98

60.50

52.23

42.67

occupied by the side compartment also was subjected to the

process due to increased mixing with the electrolyte flow rates.

Decolorization Efficiency. The theoretical analysis further

extended to calculate the color removal efficiency using eq 14.

Table 1 gives the number of tanks connected in series and the

mean residence time. The mass transfer coefficient can be

calculated using the following equation:

Ln

Figure 12. Comparison of model simulations of E(t) distribution with the

experimental observations: (a) Q ) 75 mL min-1; (b). Q ) 100 mL min-1.

matches satisfactorily with the experimental observation. While

the other volume ratios (1:2:1 &1:4:1) give wide difference with

the experiential observation. In fact the volume ratio of 1:10:1

refers to the point that tank 2 has a higher volume than the

other two tanks, resulting in a maximum volume availability

for the electrode process. This is a new observation recorded

in the present investigation. The same trend has been recorded

for all the electrolyte flow rates used in the present investigation.

Figures 12 and 13 show the comparison of simulated E(t)

and F(t) with the experimental observation for pulse input and

step input for the volume ratio of 1:10:1. It can be ascertained

from the figures the simulated E(t) and F(t) distribution

satisfactorily matches with the experimental observation. The

effective volume of the tanks and for the different flow rates

are given in Table 1. It can be observed from the table that the

active volume (i.e., V2) increased marginally with the flow rate

of the electrolyte. The marginal increase in active volume

()

- k mS

C

t

)

Ci

V

(34)

km is the mass transfer coefficient. The experimental percentage

color removal can be calculated using the following relation:

% decolorization )

Ci - C

100

Ci

(35)

The theoretical decolorization efficiency is good agreement

with the experimental decolorization efficiency and the values

are also given in Table 2.

Conclusion

Experiments were carried out in a continuous stirrer electrochemical reactor to study the residence time distribution and

color removal covering a wide range in operating conditions.

The electrolyte flow behavior has been experimented upon using

both pulse and step input techniques, and the exit age distribution

curves obtained under various operating conditions are critically

analyzed. A tanks in series model has been developed to describe

the electrolyte flow behavior inside the reactor and the model

has been simulated under various conditions. It has been

2982

Ind. Eng. Chem. Res., Vol. 47, No. 9, 2008

observed that the simulation for the volume ratio of 1:10:1 match

well with experimental observations. Further it has been

observed that the flow rate increases the reactor active volume.

The model simulation has been used to determine the color

removal efficiency and observed that the color removal efficiency predicted using present model matches satisfactorily

with experimental observations.

Appendix

Analytical Solution for the Model Proposed. Case I. All

three tanks are of different volumes. So the residence time of

the each tank is different and is represented by 1, 2, and 3

for tank 1, tank 2, and tank 3, respectively.

For the first tank, the tracer material balance can be written

as

The eq A8 value is substituted into eq A2, and the equation

solution can written as

C2

1e-t/1 2e-t/2

)1+

C0

1 - 2 1 - 2

(A9)

The eq A9 value is substituted into eq A3, and C3 can be

written as

12e-t/1

22e-t/2

C3

) F(t) ) 1 C0

(3 - 1)(2 - 1) (1 - 2)(3 - 2)

32e-t/3

(1 - 3)(2 - 3)

(A10)

The A10 equation is differentiated and the E(t) become

dC1

1

) C 0 - C1

dt

(A1)

E(t) )

For tank 2, the material balance can be written as

dC2

2

) C 1 - C2

dt

(3 - 1)(2 - 1)

C1

) e-t/1

C0

(A4)

The A4 value is substituted into eq A2, and the solution can

be written as

1

1

2 2 1

(e

-e

-t/2

(A5)

-t/1

-t/2

1e

2e

C3

) F(t) ) 1

+

+

C0

(1 - 2)(1 - 3) (2 - 1)(2 - 3)

3e-t/3

(3 - 2)(3 - 1)

(A6)

(A11)

dC1

) C 0 - C1

dt

(A12)

Tank 2 can be written as

dC2

) C 1 - C2

dt

(A13)

dC3

) C 2 - C3

dt

(A14)

Similarly, for tank 3

e-t/1

e-t/2

+

+

(1 - 2)(3 - 1) (1 - 2)(2 - 3)

e-t/3

(A7)

(2 - 3)(3 - 1)

Then eqs A1-A3 are solved for step input of tracer. Equation

A1 becomes

C1

) 1 - e-t/1

C0

C1

) e-t/

C0

(A15)

Substitute the C1 into eq A13 and C2/C0 becomes

C2 te-t/

)

C0

(A16)

Substitute the above value into eq A14 and C3/C0 can be

written as

Equation A6 is differentiated, and E(t) becomes

E(t) ) 1

Equations A12-A14 are solved for pulse input of tracer.

Equation A12 can be written as

The eq A5 value is substituted into eq A3 and the solution

becomes

(1 - 3)(2 - 3)

(A3)

Equations A1-A3 are solved for pulse input of tracer, and

then eq A1 becomes

-t/1

(1 - 2)(3 - 2)

Case II. All the three tanks are of equal volume, and the

residence time () of each tank is same in all of the tanks.

The material balance of the tank 1 can be written as

dC3

) C 2 - C3

dt

2e-t/2

3e- t/3

C2

)

C0

(A2)

Similarly, for tank 3, the balance becomes

1e-t/1

(A8)

C3

t2e-t/

) F(t) )

C0

22

(A17)

Differentiating the F(t), E(t) becomes

E(t) )

t2e-t/

23

(A18)

Equations A12-A14 are solved for step input of tracer, and

C1 can be written as

Ind. Eng. Chem. Res., Vol. 47, No. 9, 2008 2983

C1

) 1 - e-t/

C0

C2

1e-t/1 2e-t/2

)1+

C0

1 - 2 1 - 2

(A19)

Substitute the C1 value into eq A13 to get the C2 value

-t/

C2

te

)1- e-t/

C0

(A20)

(A31)

C2 is substituted into eq A25, and C3 is written as

C3

1(22 - 1)e-t/1

22e-t/2

te-t/1

) F(t) ) 1 +

+

C0

(2 - 1) ( - )2

( - )2

2

Substitute this value into eq A14 to get the C3

2 -t/

(A32)

C3

te

t

) F(t) ) 1 - e-t/ 1 +

2

C0

(A21)

t2e-t/

23

dC1

) C 0 - C1

dt

(A23)

For tank 2, the balance becomes

dC2

) C 1 - C2

dt

(A24)

dC3

) C 2 - C3

dt

(A25)

Similarly for tank 3

Equations A23-25 can be solved for pulse input of tracer.

C1 can be written as

C1

) e-t/1

C0

(A26)

The above value is substituted into eq 24, and C2 becomes

C2

)

C0

1

(e-t/1 - e-t/2)

1

1

2 2 1

(A27)

The C2 value is substituted into eq A25, and C3 becomes

C3

12e-t/2 -t/2

1

) F(t) )

te-t/1 +

- e-t/1)

(e

C0

1 - 2

(1 - 2)

Differentiating eq A28, the E(t) equation becomes

E(t) )

(A28)

12

1

te-t/1 +

(e-t/2 - e-t/1) (A29)

1(1 - 2)

(1 - 2)

Equations A23-A25 can be solved for step input of tracer

C1

) 1 - e-t/1

C0

C1 is substituted into eq A24, and C2 is written as

(1 - 22)e-t/1

(2 - 1)2

(A30)

( ( ))

e-t/1

t

1

(2 - 1)

1

2e-t/2

(A22)

Case III. In this case tank 1 and tank 2 are of equal volumes

and the tank 3 volume is greater than these two. 1 and 3 are

residence times of tanks 1 and 3 respectively, and 2 is the

residence time of tank 2.

For tank 1, the tracer material balance can be written as

Differentiating eq A32, the E(t) equation becomes

E(t) )

Equation A21 is differentiated, and E(t) becomes

E(t) )

(2 - 1)2

(A33)

Nomenclature

V ) volumetric flow rate

CAi ) inlet concentration

CA ) outlet concentration

CSA and CSB ) surface concentration of reactant and product at

the electrode

I ) applied current

i ) current density

S ) surface area of the electrode

n ) number of electrons

N ) number of tanks in series

F ) Faraday law constant

)surface area per unit volume

) residence time

2 ) variance

kL1 and kL2 ) mass transfer coefficients

D1 and D2 ) Damkohler numbers

Literature Cited

(1) Razo-Flores, E.; Luijten, M.; Donlon, B.; Lettinga, G.; Field, J.

Biodegradation of selected azo dyes under methanogenic conditions. Water

Sci. Technol. 1997, 36, 65.

(2) Lin, S. H.; Peng, F. C. Treatment of textile wastewater by

electrochemical methods. Water Res. 1994, 2, 277.

(3) Walsh, F. C. Electro chemical technology for environmental treatment

and clean energy conversion. Pure Appl. Chem. 2001, 73, 1819.

(4) Mohan, N.; Balasubramanian, N.; Subramanian, V. Electrochemical

treatment of simulated textile effluent. Chem. Eng. Technol. 2001, 24, 749.

(5) Mohan, N.; Balasubramanian, N. In situ electro catalytic oxidation

of acid violet 12 dye effluent. J. Hazard. Mater. 2006, B136, 239.

(6) Mohan, N.; Balasubramanian, N.; Ahmed Basha, C. Electro chemical

oxidation of textile wastewater and its reuse. J. Hazard. Mater. 2007, 147,

644.

(7) Bengoa, C.; Montillet, A.; Legentilhomme, A.; Legrand. J. Flow

visualization and modelling of a filter-press type electrochemical reactor.

J. Appl. Electrochem. 1997, 27, 1313.

(8) Szpyrkowicz, L.; Radaelli, M. Scale-up of an electrochemical reactor

for treatment of industrial wastewater with an electrochemically generated

redox mediator. J. Appl. Electrochem. 2006, 36, 1151.

(9) Trinidad, P.; Walsh, F. C. Hydrodynamic Behavior of the FM01LC reactor. Electrochim. Acta 1996, 41, 493.

(10) Trinidad, P.; Walsh, F. Conversion expressions for electrochemical reactors which operate under mass transport controlled reaction

conditions, Part I: Batch Reactor, PFR and CSTR. Int. J. Eng. Ed. 1998,

14, 431.

(11) Carpenter, N. G.; Roberts, E. P. L. Mass transport and residence

time characteristics of an oscillatory flow electrochemical reactor. Chem.

Eng. Res. Des. 2007, 77, 212.

2984

Ind. Eng. Chem. Res., Vol. 47, No. 9, 2008

(12) Gonza lez-Garcya, J.; Montiel, V.; Aldaz, A.; Conesa, J. A.; Perez,

J. R.; Codina, G. Hydrodynamic behavior of a filter-press electro chemical

reactor with carbon felt as a three-dimensional electrode. Ind. Eng. Chem.

Res. 1998, 37, 4501.

(13) Polcaro, A. M.; Vacca, A.; Mascia, M.; Palmas, S.; Pompei,

R.; Laconi, S. Characterization of a stirred tank electrochemical

cell for water disinfection processes Electrochim. Acta 2007, 52,

2595.

(14) Scott. K. The continuous stirred tank electrochemical reactor. An

overview of dynamic and steady state analysis for design and modeling. J.

Appl. Electrochem. 1991, 21, 945.

(15) Vijayasekaran, B.; Ahmed Basha, C. Modeling in electrochemical

engineering-a critical review. Trans. SAEST 2005, 40, 1.

(16) Scott, K. Electrochemical Reaction Engineering; Academic Press:

London, 1991.

(17) Scott Fogler, H. Elements of Chemical Reaction Engineering, 2nd

ed.; Prentice Hall International: Englewood Cliffs, NJ, 1992.

(18) Levenspiel, O. Chemical Reaction Engineering; John Wiley &

Sons: New York, 1999.

ReceiVed for reView October 21, 2007

ReVised manuscript receiVed January 31, 2008

Accepted February 12, 2008

IE071426Q

Potrebbero piacerti anche

- Runyankore-Rukiga Dictionary Launch: President Yoweri Museveni's SpeechDocumento28 pagineRunyankore-Rukiga Dictionary Launch: President Yoweri Museveni's SpeechThe New Vision50% (2)

- Contemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceDocumento25 pagineContemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceGrace06 Labin100% (7)

- Window Functions and Time-Domain Plotting in ANSYS HFSS and ANSYS SIwaveDocumento8 pagineWindow Functions and Time-Domain Plotting in ANSYS HFSS and ANSYS SIwaveاحمد جاسم شكارهNessuna valutazione finora

- 14p-220 Mud PumpDocumento2 pagine14p-220 Mud PumpMurali Sambandan50% (2)

- CFD Analysis of Eductor Agitation in Electroplating TankDocumento7 pagineCFD Analysis of Eductor Agitation in Electroplating TankrrrogggerrrNessuna valutazione finora

- Provision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field DevelopmentDocumento7 pagineProvision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field Developmentriandi100% (1)

- Pediatric EmergenciesDocumento47 paginePediatric EmergenciesahmedNessuna valutazione finora

- Two-Phase Flow ModelingDocumento388 pagineTwo-Phase Flow Modelingاحمد جاسم شكاره100% (2)

- Tuberculosis PowerpointDocumento69 pagineTuberculosis PowerpointCeline Villo100% (1)

- Stirred Tank by MAUREENDocumento27 pagineStirred Tank by MAUREENJimNessuna valutazione finora

- Combined Shear and TensionDocumento16 pagineCombined Shear and TensionDAN MARK OPONDANessuna valutazione finora

- Modeling Alkaline Electrolyzers 2003 Int J of Hydrogen EnergyDocumento13 pagineModeling Alkaline Electrolyzers 2003 Int J of Hydrogen Energyadrian_63Nessuna valutazione finora

- Arbor APS STT Unit 01 Design Basics 25 Jan2018Documento31 pagineArbor APS STT Unit 01 Design Basics 25 Jan2018masterlinh2008Nessuna valutazione finora

- Reactor Design and Analysis (MHU)Documento164 pagineReactor Design and Analysis (MHU)Chengsi WuNessuna valutazione finora

- Numerical Investigations On Ethanol Electrolysis For Production of Pure Hydrogen From Renewable SourcesDocumento6 pagineNumerical Investigations On Ethanol Electrolysis For Production of Pure Hydrogen From Renewable SourcesSanchez JorgeNessuna valutazione finora

- Electrochemical Hydrodynamics Modeling Approach For A Copper Electrowinning CellDocumento15 pagineElectrochemical Hydrodynamics Modeling Approach For A Copper Electrowinning CellpruebasclNessuna valutazione finora

- (2010) Comparison of Tanks-In-series and Axial Dispersion Models For An Electrochemical ReactorDocumento5 pagine(2010) Comparison of Tanks-In-series and Axial Dispersion Models For An Electrochemical ReactorPranav NakhateNessuna valutazione finora

- The Effects of Pore Constriction On The Behavior of Electrochemical Fixed Bed Reactor: Mathematical Modeling and Computer SimulationDocumento10 pagineThe Effects of Pore Constriction On The Behavior of Electrochemical Fixed Bed Reactor: Mathematical Modeling and Computer SimulationtheijesNessuna valutazione finora

- International Journal of Engineering Research and DevelopmentDocumento10 pagineInternational Journal of Engineering Research and DevelopmentIJERDNessuna valutazione finora

- 34 - О - Моделирование и симуляция пузырькового течения H 2 -H 2 O через пакет из трех ячеек в предпилотном реакторе электрокоагуляции фильтр-прессаDocumento12 pagine34 - О - Моделирование и симуляция пузырькового течения H 2 -H 2 O через пакет из трех ячеек в предпилотном реакторе электрокоагуляции фильтр-прессаТатьянаNessuna valutazione finora

- Simulation of The All-Vanadium Redox Flow Battery With Composite Arched ChannelDocumento6 pagineSimulation of The All-Vanadium Redox Flow Battery With Composite Arched ChannelJoão PedroNessuna valutazione finora

- Behin Et Al-2013-Chemical Engineering & TechnologyDocumento10 pagineBehin Et Al-2013-Chemical Engineering & TechnologyIgnacio JuanNessuna valutazione finora

- Mathematical Modelling of The Process of Electrochemical Production of Naclo From Diluted Chloride SolutionsDocumento4 pagineMathematical Modelling of The Process of Electrochemical Production of Naclo From Diluted Chloride SolutionszlobiulNessuna valutazione finora

- ManuscriptDocumento20 pagineManuscriptapi-3728640Nessuna valutazione finora

- Welcome To International Journal of Engineering Research and Development (IJERD)Documento4 pagineWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNessuna valutazione finora

- A Review of Mathematical Models For Hydrogen and Direct Methanol Polymer Electrolyte Membrane FuelDocumento27 pagineA Review of Mathematical Models For Hydrogen and Direct Methanol Polymer Electrolyte Membrane FuelpitersonNessuna valutazione finora

- Berhane Temelso Et Al - High-Level Ab Initio Studies of Hydrogen Abstraction From Prototype Hydrocarbon SystemsDocumento39 pagineBerhane Temelso Et Al - High-Level Ab Initio Studies of Hydrogen Abstraction From Prototype Hydrocarbon SystemsOmsadsiNessuna valutazione finora

- Electrochemical Reductionof CarbondioxideDocumento11 pagineElectrochemical Reductionof CarbondioxideWannarat Tan ArkardvipartNessuna valutazione finora

- Dynamic Analysis of Water TanksDocumento9 pagineDynamic Analysis of Water TanksFrancisco FaggioniNessuna valutazione finora

- Effect of Channel Dimensions On Micro PEM Fuel Cell Performance Using 3D ModelingDocumento6 pagineEffect of Channel Dimensions On Micro PEM Fuel Cell Performance Using 3D ModelingSergi C. CortadaNessuna valutazione finora

- CV ExperimentDocumento8 pagineCV ExperimentesatpehlivanNessuna valutazione finora

- Seawater Electrolysis For Hydrogen ProductionDocumento5 pagineSeawater Electrolysis For Hydrogen ProductionCapuchino HuiNingNessuna valutazione finora

- J.electrochem - Soc. 1991 Springer 2334 42Documento9 pagineJ.electrochem - Soc. 1991 Springer 2334 42DEVA NAIKNessuna valutazione finora

- Fuel CellDocumento4 pagineFuel CellTilak Raj RaiNessuna valutazione finora

- Weatherley 1984 Aquacultural-EngineeringDocumento15 pagineWeatherley 1984 Aquacultural-EngineeringJorge RodriguezNessuna valutazione finora

- Numerical Simulation of HtpemDocumento32 pagineNumerical Simulation of HtpemnareshNessuna valutazione finora

- Analysis of Ester Hydrolysis Reactions in A Chromatographic Reactor Using Equilibrium Theory and A Rate ModelDocumento10 pagineAnalysis of Ester Hydrolysis Reactions in A Chromatographic Reactor Using Equilibrium Theory and A Rate ModelCarlos Andrés Martínez CristanchoNessuna valutazione finora

- Ethylene Dichloride Production by Oxychlorination in A Fluidized Bed Reactor With CFD ModelDocumento14 pagineEthylene Dichloride Production by Oxychlorination in A Fluidized Bed Reactor With CFD ModelJam ImtiazNessuna valutazione finora

- Thiobacillus Ferrooxidans: Reaction Kinetics Model For Chalcopyrite Bioleaching UsingDocumento4 pagineThiobacillus Ferrooxidans: Reaction Kinetics Model For Chalcopyrite Bioleaching UsingMaiman LatoNessuna valutazione finora

- 2008 Minh AICHE PDFDocumento9 pagine2008 Minh AICHE PDFinf2014Nessuna valutazione finora

- Journal of The Electrochemical Society 150-3 A292-A300 2003Documento9 pagineJournal of The Electrochemical Society 150-3 A292-A300 2003Dulce BaezaNessuna valutazione finora

- Chemical Reactors: DC DT RDocumento8 pagineChemical Reactors: DC DT ROsas Jessica UwoghirenNessuna valutazione finora

- R05320802chemicalreactionengineeringiiDocumento8 pagineR05320802chemicalreactionengineeringiiSanthosh KumarNessuna valutazione finora

- Revised ManuscriptDocumento23 pagineRevised Manuscriptapi-3728640Nessuna valutazione finora

- Lecture 2Documento25 pagineLecture 2Virat BhangeNessuna valutazione finora

- Bioresource Technology: Young-Hyun Song, Syarif Hidayat, Han-Ki Kim, Joo-Yang ParkDocumento5 pagineBioresource Technology: Young-Hyun Song, Syarif Hidayat, Han-Ki Kim, Joo-Yang ParkNi'matul MfNessuna valutazione finora

- Paper On KDocumento7 paginePaper On KShabanaNessuna valutazione finora

- 076 PDFDocumento6 pagine076 PDFprakush01975225403Nessuna valutazione finora

- Influence of Series RC Circuit Parameters On The - Streamer Discharge Process of Gas Spark SwitchDocumento11 pagineInfluence of Series RC Circuit Parameters On The - Streamer Discharge Process of Gas Spark SwitchMIKS DARKNessuna valutazione finora

- Performance of Type of ElectrolyzerDocumento11 paginePerformance of Type of ElectrolyzerRandomV D.ENessuna valutazione finora

- Roux Technology PaperDocumento9 pagineRoux Technology Papersebastian_javier_bNessuna valutazione finora

- Airlift Simulation CFDDocumento10 pagineAirlift Simulation CFDlrodriguez_892566Nessuna valutazione finora

- Liu2008 PDFDocumento6 pagineLiu2008 PDFheri rustamajiNessuna valutazione finora

- Electrochemical Water Softening: Principle and ApplicationDocumento14 pagineElectrochemical Water Softening: Principle and ApplicationThao DophuongNessuna valutazione finora

- Titanium Carbide Mxene Shows-An-Electrochemical-Anomaly-In-Water-In-Salt-ElectrolytesDocumento33 pagineTitanium Carbide Mxene Shows-An-Electrochemical-Anomaly-In-Water-In-Salt-ElectrolytesMuhamad Doris Bagindo SatiNessuna valutazione finora

- Tanaka 2011Documento13 pagineTanaka 2011ALAM DEWANTORO JATINessuna valutazione finora

- AELTERMAN Et Al 2006 Microbial Fuel Cells For Wastewater TreatmentDocumento7 pagineAELTERMAN Et Al 2006 Microbial Fuel Cells For Wastewater TreatmentEr Mohammad ImranNessuna valutazione finora

- Modelling and Experimental Analysis of A Polymer EDocumento19 pagineModelling and Experimental Analysis of A Polymer E1212Nessuna valutazione finora

- Schalenbach 2016 J. Electrochem. Soc. 163 F3197Documento13 pagineSchalenbach 2016 J. Electrochem. Soc. 163 F3197Avishek JaiswalNessuna valutazione finora

- Models - Fce.aec Shunt CurrentsDocumento31 pagineModels - Fce.aec Shunt CurrentsSaidFerdjallahNessuna valutazione finora

- 10 1 1 1017 6199 PDFDocumento21 pagine10 1 1 1017 6199 PDFCelrose FernandezNessuna valutazione finora

- Modelling and Simulation of Counter-Current and Confined Jet Reactors For Continuous Hydrothermal Flow Synthesis of Nano-MaterialsDocumento6 pagineModelling and Simulation of Counter-Current and Confined Jet Reactors For Continuous Hydrothermal Flow Synthesis of Nano-Materialsprakush_prakushNessuna valutazione finora

- Theoretical Study On The Alkylation of O-Xylene WithDocumento23 pagineTheoretical Study On The Alkylation of O-Xylene WithPrasad BolisettyNessuna valutazione finora

- Representing Vapor-Liquid Equilibrium For An Aqueous MEA-CO System Using The Electrolyte Nonrandom-Two-Liquid ModelDocumento11 pagineRepresenting Vapor-Liquid Equilibrium For An Aqueous MEA-CO System Using The Electrolyte Nonrandom-Two-Liquid Modeldjc49Nessuna valutazione finora

- Laboratory Study of Electro-Coagulation - Otation For Water TreatmentDocumento15 pagineLaboratory Study of Electro-Coagulation - Otation For Water TreatmentazerfazNessuna valutazione finora

- Pumps, Channels and Transporters: Methods of Functional AnalysisDa EverandPumps, Channels and Transporters: Methods of Functional AnalysisNessuna valutazione finora

- Sustainable and Green Electrochemical Science and TechnologyDa EverandSustainable and Green Electrochemical Science and TechnologyNessuna valutazione finora

- Biofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationDa EverandBiofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationNessuna valutazione finora

- Supercapacitors Based on Carbon or Pseudocapacitive MaterialsDa EverandSupercapacitors Based on Carbon or Pseudocapacitive MaterialsNessuna valutazione finora

- It Programming in ArabicDocumento147 pagineIt Programming in Arabicاحمد جاسم شكارهNessuna valutazione finora

- ME 477 - Fall 2014Documento2 pagineME 477 - Fall 2014احمد جاسم شكارهNessuna valutazione finora

- CFD Calculations of Cuttings Transport Through Drilling Annuli at Various AnglesDocumento14 pagineCFD Calculations of Cuttings Transport Through Drilling Annuli at Various Anglesاحمد جاسم شكارهNessuna valutazione finora

- Lecture Notes 1 CadcamDocumento14 pagineLecture Notes 1 CadcamNicolas LuchmunNessuna valutazione finora

- APPENDIX IEEE Line Limit (MW) P.U PDFDocumento19 pagineAPPENDIX IEEE Line Limit (MW) P.U PDFاحمد جاسم شكارهNessuna valutazione finora

- PX26 Series: 0-1 To 0-250 Psi (0-0.07 To 17.2 Bar) Gage and DifferentialDocumento1 paginaPX26 Series: 0-1 To 0-250 Psi (0-0.07 To 17.2 Bar) Gage and Differentialاحمد جاسم شكارهNessuna valutazione finora

- Chemkin-Cfd and ANSYS Fluent Software: 12.0 ReleaseDocumento2 pagineChemkin-Cfd and ANSYS Fluent Software: 12.0 Releaseاحمد جاسم شكارهNessuna valutazione finora

- Safety Data Sheet CYCLO®Copper Anti-SeizeDocumento12 pagineSafety Data Sheet CYCLO®Copper Anti-Seizeاحمد جاسم شكارهNessuna valutazione finora

- Register As A StudentDocumento2 pagineRegister As A Studentاحمد جاسم شكارهNessuna valutazione finora

- JournalDocumento1 paginaJournalاحمد جاسم شكارهNessuna valutazione finora

- Z77 Memory ReportDocumento2 pagineZ77 Memory Reportاحمد جاسم شكارهNessuna valutazione finora

- M1 Lec-1Documento5 pagineM1 Lec-1احمد جاسم شكارهNessuna valutazione finora

- 44 592Documento7 pagine44 592احمد جاسم شكارهNessuna valutazione finora

- Kinematics in One DimensionDocumento4 pagineKinematics in One DimensionAldrin VillanuevaNessuna valutazione finora

- FemDocumento4 pagineFemAditya SharmaNessuna valutazione finora

- Main Girders: CrossDocumento3 pagineMain Girders: Crossmn4webNessuna valutazione finora

- Murata High Voltage CeramicDocumento38 pagineMurata High Voltage CeramictycristinaNessuna valutazione finora

- IV. Network Modeling, Simple SystemDocumento16 pagineIV. Network Modeling, Simple SystemJaya BayuNessuna valutazione finora

- Introduction To LCCDocumento32 pagineIntroduction To LCCGonzalo LopezNessuna valutazione finora

- Electric ScootorDocumento40 pagineElectric Scootor01fe19bme079Nessuna valutazione finora

- Sat Vocabulary Lesson and Practice Lesson 5Documento3 pagineSat Vocabulary Lesson and Practice Lesson 5api-430952728Nessuna valutazione finora

- Assignment 2 Unit 20 Fully Completed - ReviewedDocumento5 pagineAssignment 2 Unit 20 Fully Completed - Reviewedchris.orisawayiNessuna valutazione finora

- Biomedical Engineering Handbook Revised 5 2015Documento37 pagineBiomedical Engineering Handbook Revised 5 2015Teja GuttiNessuna valutazione finora

- MarbiehistoryDocumento6 pagineMarbiehistoryMarbie DalanginNessuna valutazione finora

- Proefschrift T. Steenstra - tcm24-268767Documento181 pagineProefschrift T. Steenstra - tcm24-268767SLAMET PAMBUDINessuna valutazione finora

- Anxiety Disorders - Causes, Types, Symptoms, & TreatmentsDocumento5 pagineAnxiety Disorders - Causes, Types, Symptoms, & Treatmentsrehaan662Nessuna valutazione finora

- De Vault 1996Documento22 pagineDe Vault 1996Harumi OONessuna valutazione finora

- Presentation On 4G TechnologyDocumento23 paginePresentation On 4G TechnologyFresh EpicNessuna valutazione finora

- Tree Growth CharacteristicsDocumento9 pagineTree Growth CharacteristicsMunganNessuna valutazione finora

- Market AnalysisDocumento4 pagineMarket AnalysisSaniya CharaniyaNessuna valutazione finora

- Potassium Fixation As Affected by Alternate Wetting and Drying in Some Soil Series of JharkhandDocumento4 paginePotassium Fixation As Affected by Alternate Wetting and Drying in Some Soil Series of JharkhandDr Amrit Kumar JhaNessuna valutazione finora

- WPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFDocumento88 pagineWPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFbabuzducNessuna valutazione finora

- Mean Variance Portfolio TheoryDocumento85 pagineMean Variance Portfolio TheoryEbenezerNessuna valutazione finora

- Electrowetting - Wikipedia, The Free EncyclopediaDocumento5 pagineElectrowetting - Wikipedia, The Free EncyclopediaDwane AlmeidaNessuna valutazione finora

- Basic Geriatric Nursing 6th Edition Williams Test BankDocumento10 pagineBasic Geriatric Nursing 6th Edition Williams Test Bankmaryrodriguezxsntrogkwd100% (49)