Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Testing of Control Panel

Caricato da

sasikumarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Testing of Control Panel

Caricato da

sasikumarCopyright:

Formati disponibili

GREENKO INTEGRATED MANAGEMENT SYSTEMS

PROCEDURE FOR CONTROL PANEL

(Factory and Site acceptance Tests)

1. PURPOSE:

To have a common practices to accept the manufacturing Quality of the product

and to ensure the Installation quality of the Control Panel.

2. SCOPE:

Factory acceptance test & site acceptance test.

3. RESPONSIBILITY:

Factory acceptance test by manufacturer & witness by Greenko Central

Quality and Greenko Site QA/QC for site acceptance test.

4. REFERENCE DOCUMENTS:

IS 8623- part 1 &2, Approved GTP & Approved Drawings, IEC 61439.

5. PROCEDURE:

5.1.

Factory acceptance test of Control Panel & Busbar trunking

systems :

All the factory acceptance test observations should be recorded on Material

Quality inspection report- F-CO-QA06-01.

5.1.1. For control panel:

Components incorporated in the control panel shall comply with the relevant IEC

standards.

The components shall be suitable for the particular application with respect to

the external design of the ASSEMBLY (control panel) (e. open type or enclosed),

their rated voltages, rated currents, service life, making and breaking capacities

short-circuit withstand strength, etc.

Components having a short circuit withstand strength and/or a breaking capacity

which is insufficient to withstand the stresses likely to occur at the place of

installation, shall be protected by means f current-limiting protective devices,

for example fuses or circuit-breakers. When selecting current limiting protective

devices for built-in switching devices, account shall be taken of the maximum

permissible values specified by the manufacturer of the device, having due

regard to co-ordination.

Co-ordination of components, for example co-ordination of motor starters with

short-circuit protective devices, shall comply with the relevant I EC standards.

PRO-XXX-YYY-NN

7

Revision No: xx

dd/mm/yyyy

Completeness Rigor and Accuracy for Excellence

1 of

GREENKO INTEGRATED MANAGEMENT SYSTEMS

PROCEDURE FOR CONTROL PANEL

(Factory and Site acceptance Tests)

5.1.1.1. Type tests: (Only review of Test certificates issued by

CPRI, ERDA & Validity period up to 5 years only)

Type tests are intended to verily compliance with the requirements laid down in

this standard for a given type of ASSEMBLY.

Type tests will be carried out on a sample of such an ASSEMBLY or on such parts

of ASSEMBLIES manufactured to the same or a similar design.

They shall be carried out on the initiative of the manufacturer.

Specification limits should be as perIS 8623- part 1:

Type tests include:

5.1.1.1.1.

Verification

5.1.1.1.2.

Verification

5.1.1.1.3.

Verification

5.1.1.1.4.

Verification

circuit.

5.1.1.1.5.

Verification

distances.

5.1.1.1.6.

Verification

5.1.1.1.7.

Verification

of

of

of

of

temperature-rise limits.

the dielectric properties.

the short-circuit strength.

the continuity of the protective

of clearances and creepage

of mechanical operation.

of the degree of protection.

These tests may be carried out in any order and/or on different samples of the

same type.

5.1.1.2. Routine Tests:

Routine tests are intended to detect faults in materials and workmanship. They

are carried out on every new ASSEMBLY after its assembly or on each transport

unit. Another routine test at the place of installation is not required.

ASSEMBLIES which are assembled from standardized components outside the

works of the manufacturer of these components, by the exclusive use of parts

and accessories specified or supplied by the manufacturer for this purpose, shall

be routine-tested by the firm which has assembled the ASSEMBLY.

Routine tests include:

Specification limits should be as perIS 8623- part 1:

5.1.1.2.1.

Inspection of the ASSEMBLY including

inspection of wiring and, if necessary, electrical

operation test.

We have to verify the assembly of control panel as

per approved BOM, GA and schematic diagram.

PRO-XXX-YYY-NN

7

Revision No: xx

dd/mm/yyyy

Completeness Rigor and Accuracy for Excellence

2 of

GREENKO INTEGRATED MANAGEMENT SYSTEMS

PROCEDURE FOR CONTROL PANEL

(Factory and Site acceptance Tests)

5.1.1.2.2.

5.1.1.2.2.1.

Dielectric test.

Requirement of Equipments for testing:

HV tester- (0-5) KV

5.1.1.2.2.2.

Testing procedure:

The test voltage shall be applied:

5.1.1.2.2.2.1.

Between all live parts and the

interconnected exposed conductive parts of the

ASSEMBLY;

5.1.1.2.2.2.2.

Between each pole and all the other poles

connected for this test to the interconnected

exposed conductive parts of the ASSEMBLY.

The test voltage at the moment of application shall not exceed 50% of the values

given in test voltage selection table that given below. It shall then be increased

steadily within a few seconds to this full value specified in the table and

maintained for 1 min. The a.c. power sources shall have sufficient power to

maintain the test voltage irrespective of any leakage currents. The test voltage

shall have a practically sinusoidal waveform and a frequency between 45 Hz and

62 Hz.

5.1.1.2.2.3.

Selection of test Voltage:

For main circuits:

Rated insulation voltage Ui (v)

Ui 60

60 < Ui 300

300 < Ui 660

660 <Ui 800

800 < Ui 1000

1000 <Ui 1500 ( for DC only)

Dielectric test voltage (ac) ( r m s ) ( v

)

1000

2000

2500

3000

3500

3500

For Auxiliary circuits:

Rated insulation voltage Ui (v)

Ui 12

12< Ui 60

Ui> 60

5.1.1.2.2.4.

Dielectric test voltage (ac) ( r m s ) ( v

)

250

500

2 Ui + 1000 with a minimum of 1500.

Results to be obtained:

The test is considered to have been passed if there is no

puncture or flash-over.

PRO-XXX-YYY-NN

7

Revision No: xx

dd/mm/yyyy

Completeness Rigor and Accuracy for Excellence

3 of

GREENKO INTEGRATED MANAGEMENT SYSTEMS

PROCEDURE FOR CONTROL PANEL

(Factory and Site acceptance Tests)

5.1.1.2.3.

Checking of protective measures and of

the electrical continuity of the protective circuit.

Continuity of protective circuits shall be ensured by effective interconnections

either directly

or by means of protective conductors.

5.1.1.2.3.1.

When a part of the ASSEMBLY is removed from

the enclosure, for example for routine maintenance, the

protective circuits for the remainder of the ASSEMBLY

shall not be interrupted.

Means used for-assembling the various metal parts of an ASSEMBLY are

considered sufficient for ensuring continuity of the protective circuits if the

precautions taken guarantee permanent good conductivity and a current

carrying capacity sufficient to withstand the earth fault current that may flow

in the ASSEMBLY.

NW. - Flexible metal conduits should not be used as protective conductors.

5.1.1.2.3.2.

When removable or withdrawable parts are

equipped with metal supporting surfaces, these surfaces

are considered sufficient for ensuring continuity of

protective circuits provided that the pressure exerted on

them is sufficiently high. Precautions may have to be

taken to guarantee permanent good conductivity. The

protective circuit of a withdrawable part shall remain

effective from the connected position to the test

position inclusively.

5.1.1.2.3.3.

For lids, doors, cover plates and the like, the

usual metal screwed connections and metal hinges are

considered sufficient to ensure continuity provided that

no electrical equipment is attached to them.

5.1.1.2.3.4.

All parts of the protective circuit within the

ASSEMBLY shall be so designed that they are capable of

withstanding the highest thermal and dynamic stresses

that may occur at the place of installation of the

ASSEMBLY.

5.1.1.2.3.5.

When the enclosure of an ASSEMBLY is used as

part of a protective circuit, the cross-sectional area of

this enclosure shall be at least electrically equivalent to

the minimum cross-sectional area specified in below

table

PRO-XXX-YYY-NN

7

Revision No: xx

dd/mm/yyyy

Completeness Rigor and Accuracy for Excellence

4 of

GREENKO INTEGRATED MANAGEMENT SYSTEMS

PROCEDURE FOR CONTROL PANEL

(Factory and Site acceptance Tests)

Cross-sectional area of

phase conductors S(mm2)

S 16

16< S 35

S > 35

Minimum cross-sectional

area of the corresponding

protective conductor S( mm2)

S

16

S/2

These tests may be carried out in any order.

5.1.2. For Busbar trunking systems:

5.1.2.1. Type test for Busbar trunking systems:

Specification limits should be as perIS 8623- part 2:

5.1.2.1.1.

Verification of temperature-rise limits.

5.1.2.1.2.

Verification of the dielectric properties.

5.1.2.1.3.

Verification of the short-circuit strength.

5.1.2.1.4.

Verification of the continuity of the protective

circuit.

5.1.2.1.5.

Verification of clearances and creepage

distances.

5.1.2.1.6.

Verification of mechanical operation.

5.1.2.1.7.

Verification of the degree of protection.

5.1.2.1.8.

Verification of resistance and reactance.

5.1.2.1.9.

Verification of structural strength.

5.1.2.1.10.

Verification of the endurance of trunking

systems with trolley type tap-off facilities.

These tests may be carried out in any order and/or on different samples of the

same type.

If modifications are made to the components of the assembly, new type tests

have to be carried out only in so far as such modifications are likely to adversely

affect the results of these tests.

5.1.2.2. Routine tests for Busbar trunking systems:

Specification limits should be as per IS 8623- part 2:

5.1.2.2.1.

Inspection of the ASSEMBLY including

inspection of wiring and, if necessary, electrical

operation test.( same as 5.1.1.2.1 clause of this

procedure)

5.1.2.2.2.

Dielectric test. (same as 5.1.1.2.2 clause of

this procedure)

5.1.2.2.3.

Checking of protective measures and of

the electrical continuity of the protective circuit.

(same as 5.1.1.2.3 clause of this procedure)

5.1.2.2.4.

Verification of resistance and reactance.

PRO-XXX-YYY-NN

7

Revision No: xx

dd/mm/yyyy

Completeness Rigor and Accuracy for Excellence

5 of

GREENKO INTEGRATED MANAGEMENT SYSTEMS

PROCEDURE FOR CONTROL PANEL

(Factory and Site acceptance Tests)

5.1.2.2.4.1.

Direct measurement of resistance

and reactance:

The mean values of resistance and reactance are determined on a test specimen

having a total length of at least 6 meter including at least one joint.

R= the mean ohmic resistance value of the trunking system per metre length per

phase.

X= the mean reactance value of the trunking system per metre length per

phase.

The method of determination shall be chosen by the manufacturer. An example

of calculation from measurements is given below for a three phase A.C. Busbar

trunking System.

5.1.2.2.5.

Calculation of resistance and reactance:

The following measurements shall be recorded from the test data obtained

during the temperature- rise test:

V= the average r.m.s. line to line voltage drop in volts.

V12 + V23 + V31

V=

3

I= the average r. m. s. current in amperes

I1 + I2 + I3

I=

3

P = the total three- phase power in watts.

L= the length in metres from the voltmeter leads connected at the input end to

the point where the bus bars are connected together at the output end.

Calculate the impedance Z, the alternating current resistance R, and the

reactance X, in ohms per metre on line to neutral basis, as follows:

V

Z=

3 I L

P

R =

PRO-XXX-YYY-NN

7

Revision No: xx

3 I2 L

dd/mm/yyyy

Completeness Rigor and Accuracy for Excellence

6 of

GREENKO INTEGRATED MANAGEMENT SYSTEMS

PROCEDURE FOR CONTROL PANEL

(Factory and Site acceptance Tests)

X= (Z 2 R2)

0.5

The values measured directly should match with calculated value.

5.2.

Incoming Inspection at site:

Incoming Inspection shall be done as per the Incoming material site Inspection

report F-CO-QA06-02 & observation shall be recorded on it.

5.3.

Site acceptance test of Control panel:

Site acceptance test as per Vendor or Greenko- Inspection and test plan and

observation shall be recorded on Check list for erection of Control panel- F-COQA-16-01.

6. RECORDS:

6.1.Material Quality Inspection report

6.2.Incoming material site Inspection report 6.3.Erection Checklist of Control panel

-

PRO-XXX-YYY-NN

7

Revision No: xx

F-CO-QA06-01.

F-CO-QA06-02.

F-CO-QA-16-01.

dd/mm/yyyy

Completeness Rigor and Accuracy for Excellence

7 of

Potrebbero piacerti anche

- Electrical Control Panel Design and FabricationDocumento40 pagineElectrical Control Panel Design and FabricationSarthak Saxena100% (2)

- Q A P (Qap) - DCCC: Uality Ssurance LANDocumento4 pagineQ A P (Qap) - DCCC: Uality Ssurance LANsasikumarNessuna valutazione finora

- Electrical MachinesDocumento403 pagineElectrical Machinessasikumar100% (9)

- Q A P (Qap) - PV C: Uality Ssurance LAN ELLDocumento5 pagineQ A P (Qap) - PV C: Uality Ssurance LAN ELLsasikumarNessuna valutazione finora

- Short Circuit CalculationsDocumento44 pagineShort Circuit Calculationssasikumar100% (2)

- VFD Commissioning FormatDocumento2 pagineVFD Commissioning FormatJun Lumayno100% (2)

- Transformer Test ReportDocumento47 pagineTransformer Test Reportravi142857100% (3)

- Type Tests Defined in IEC 61439Documento18 pagineType Tests Defined in IEC 61439Mahesh DaveNessuna valutazione finora

- CMC 356Documento138 pagineCMC 356ajeez86100% (1)

- Electrical Switchgear Routine TestingDocumento14 pagineElectrical Switchgear Routine TestingSabari KhanNessuna valutazione finora

- Checklist Control PanelDocumento2 pagineChecklist Control PanelAnjar AjjaNessuna valutazione finora

- Is 10028 3 1981Documento27 pagineIs 10028 3 1981sasikumarNessuna valutazione finora

- My Experience in Drafting The Layout of An LV Switchgear Equipment Inside InstallationsDocumento21 pagineMy Experience in Drafting The Layout of An LV Switchgear Equipment Inside InstallationsBruno SamosNessuna valutazione finora

- Switchgear Inspection and Test Procedure: MV SystemsDocumento20 pagineSwitchgear Inspection and Test Procedure: MV Systemsramadani bimaNessuna valutazione finora

- Easy Siddha MedicinesDocumento132 pagineEasy Siddha Medicinessanti_1976Nessuna valutazione finora

- Substation Pre Commissioning TestsDocumento13 pagineSubstation Pre Commissioning Testsrasheed313100% (2)

- Commissioning Test Report For Circuit Breaker SiteDocumento3 pagineCommissioning Test Report For Circuit Breaker SiteGuru MishraNessuna valutazione finora

- Q A P (QAP) - S Inverter: Uality Ssurance LAN OlarDocumento5 pagineQ A P (QAP) - S Inverter: Uality Ssurance LAN Olarsasikumar100% (2)

- Notes On Testing and Maintenance of Electrical MachinesDocumento25 pagineNotes On Testing and Maintenance of Electrical Machinesdattatray kulkarni50% (2)

- AFAR Problems PrelimDocumento11 pagineAFAR Problems PrelimLian Garl100% (8)

- Earth Resistance Testing ReportDocumento2 pagineEarth Resistance Testing ReportGalif Aftabul Mamood100% (1)

- Assignment 03 Investments in Debt SecuritiesDocumento4 pagineAssignment 03 Investments in Debt SecuritiesJella Mae YcalinaNessuna valutazione finora

- QAP - LT Panel PDFDocumento8 pagineQAP - LT Panel PDFAkshay Ajay100% (2)

- 1 Cable Shedule Table PDFDocumento9 pagine1 Cable Shedule Table PDFHamid KhanNessuna valutazione finora

- Testing of CTDocumento17 pagineTesting of CTsasikumarNessuna valutazione finora

- Testing of CTDocumento17 pagineTesting of CTsasikumarNessuna valutazione finora

- Siemens SIVACON S8, IEC 61439 Switchgear and Control PanelDocumento43 pagineSiemens SIVACON S8, IEC 61439 Switchgear and Control PanelGyanesh Bhujade100% (2)

- QAP of HT Breaker Panel SchneiderDocumento1 paginaQAP of HT Breaker Panel Schneidermadhu_bedi12Nessuna valutazione finora

- 11 KV Ring Main Units and AccessoriesDocumento35 pagine11 KV Ring Main Units and AccessoriesAbdus Salam0% (1)

- Substationsfinal2013 PDFDocumento137 pagineSubstationsfinal2013 PDFManoj RanaNessuna valutazione finora

- LT Panel PDI SOPDocumento4 pagineLT Panel PDI SOPShrikanth Sola100% (2)

- Protection Relay FAT Using Omicron PDFDocumento96 pagineProtection Relay FAT Using Omicron PDFhizbi7Nessuna valutazione finora

- Test Procedure - BusbarDocumento4 pagineTest Procedure - Busbarmayur dhande100% (2)

- Electrical Switchboard Test and Commissioning ProcedureDocumento4 pagineElectrical Switchboard Test and Commissioning ProcedureAodman4u100% (2)

- List of IEC StandardsDocumento3 pagineList of IEC Standardsabeelc100% (1)

- ATS Test Report 34Documento3 pagineATS Test Report 34Rami Badran63% (8)

- Operation and Manual For LV SWGR - enDocumento72 pagineOperation and Manual For LV SWGR - engiau richkyNessuna valutazione finora

- Lighting Arrestor Specifications and Boq (SMS)Documento1 paginaLighting Arrestor Specifications and Boq (SMS)Ruchir ChaturvediNessuna valutazione finora

- Surge Arrest Test ProceduresDocumento11 pagineSurge Arrest Test Proceduresmarevey100% (3)

- What Is VLFDocumento9 pagineWhat Is VLFnysa6987Nessuna valutazione finora

- Construction Manual For Sub-StationsDocumento150 pagineConstruction Manual For Sub-Stationspankaj_electrical0% (1)

- HVM Partial Discharge Testing and Monitoring Cables R06 11Documento4 pagineHVM Partial Discharge Testing and Monitoring Cables R06 11Ahmed Mohamed HassanNessuna valutazione finora

- LV Panel ChecklistDocumento1 paginaLV Panel ChecklistvaradharajanNessuna valutazione finora

- MCC Check ListDocumento6 pagineMCC Check ListAndres AguirreNessuna valutazione finora

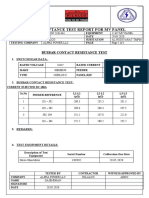

- Bus Bar Contact Resistance TestDocumento1 paginaBus Bar Contact Resistance TestGajendran Sriram100% (1)

- Iec 61439Documento34 pagineIec 61439Virendra SahdevNessuna valutazione finora

- APTRANSCO Technical Reference Book 2011 Vol IDocumento327 pagineAPTRANSCO Technical Reference Book 2011 Vol IAshok Kumar Krishnamurthy100% (4)

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocumento29 pagineInsulation Resistance (IR) Values - Electrical Notes & ArticlesNikhil Chakravarthy Vatsavayi100% (1)

- Checklist For Erection of USSDocumento3 pagineChecklist For Erection of USSsasikumarNessuna valutazione finora

- Inspection and Test Procedures For CableDocumento6 pagineInspection and Test Procedures For Cablemajid8080Nessuna valutazione finora

- Insulation Resistance TestDocumento5 pagineInsulation Resistance TestMoses TorkudzorNessuna valutazione finora

- 1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Documento21 pagine1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Muhammad Ibad AlamNessuna valutazione finora

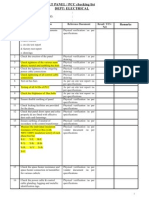

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocumento3 pagineLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- Cable GlandsDocumento20 pagineCable GlandsBalaji VenkatesanNessuna valutazione finora

- NGR Routine Test ProcedureDocumento6 pagineNGR Routine Test Procedurezaheer ahamedNessuna valutazione finora

- Test and Inspection For Low Voltage Cubicle SwitchboardDocumento3 pagineTest and Inspection For Low Voltage Cubicle Switchboardnidnitrkl051296Nessuna valutazione finora

- DCF ModelDocumento14 pagineDCF ModelTera ByteNessuna valutazione finora

- Training Report On Control Relay PanelDocumento50 pagineTraining Report On Control Relay PanelShubham Pal75% (4)

- A Compilation by Virendra SahdevDocumento108 pagineA Compilation by Virendra SahdevVirendra Sahdev100% (1)

- PLC Panel Check ListDocumento6 paginePLC Panel Check ListPATEL AKASHNessuna valutazione finora

- Cable Repair Kit Raychem PDFDocumento156 pagineCable Repair Kit Raychem PDFChandrakanthan RamiahNessuna valutazione finora

- CT & PTDocumento34 pagineCT & PTsasikumar100% (4)

- HT Panel QapDocumento2 pagineHT Panel QapAlla Naveen KumarNessuna valutazione finora

- Bus DuctDocumento4 pagineBus Ductsardarmkhan100% (1)

- LT Panel SOP For Test ProcedureDocumento5 pagineLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- Polaraization IndexDocumento4 paginePolaraization IndexsasikumarNessuna valutazione finora

- Transformer Companies in ChennaiDocumento5 pagineTransformer Companies in ChennaisasikumarNessuna valutazione finora

- Computer Graphics Mini ProjectDocumento25 pagineComputer Graphics Mini ProjectGautam Singh78% (81)

- Checklist For Erection of Control & Relay Panel-Busbar Protection.Documento2 pagineChecklist For Erection of Control & Relay Panel-Busbar Protection.sasikumarNessuna valutazione finora

- Checklist For Erection Power TransformerDocumento6 pagineChecklist For Erection Power Transformersasikumar67% (3)

- Rotating Machinery (ETD 15) - Electrotechnical Division-Public Safety Standards of IndiaDocumento6 pagineRotating Machinery (ETD 15) - Electrotechnical Division-Public Safety Standards of IndiasasikumarNessuna valutazione finora

- Adding Print PDF To Custom ModuleDocumento3 pagineAdding Print PDF To Custom ModuleNguyễn Vương AnhNessuna valutazione finora

- Busbar TightnessDocumento11 pagineBusbar Tightnesssanjeev267Nessuna valutazione finora

- 11KV Kiosk Panel DrawingDocumento12 pagine11KV Kiosk Panel Drawingerkamlakar223483% (6)

- LCC Bus Coupler - Functional TestDocumento7 pagineLCC Bus Coupler - Functional TestAmr ElkadyNessuna valutazione finora

- Cable Lugs Price List: Kelani Cables PLCDocumento1 paginaCable Lugs Price List: Kelani Cables PLCHishan KavindaNessuna valutazione finora

- DG SET-Technical Specs PDFDocumento26 pagineDG SET-Technical Specs PDFankur yadavNessuna valutazione finora

- Catalogue Pragati Instrument TransformerDocumento8 pagineCatalogue Pragati Instrument TransformerRatilal M Jadav50% (2)

- Flat, Trofoil & TriplexDocumento12 pagineFlat, Trofoil & Triplexphanibarama100% (1)

- Masibus-8208 Manual PDFDocumento36 pagineMasibus-8208 Manual PDFfaisal2106Nessuna valutazione finora

- Tariff Metering PanelsDocumento2 pagineTariff Metering PanelsSaraswatapalitNessuna valutazione finora

- Prok DVs - ACCL - CatalougeDocumento3 pagineProk DVs - ACCL - CatalougekapilNessuna valutazione finora

- T. in The Case of Current-Limiting Fuses, The Maximum Arc Energy May Occur at Current LevelsDocumento20 pagineT. in The Case of Current-Limiting Fuses, The Maximum Arc Energy May Occur at Current Levelsnandana_849065438Nessuna valutazione finora

- GTI RoutineTests 1HC0007010ADEnDocumento12 pagineGTI RoutineTests 1HC0007010ADEnMOHAMMED ALINessuna valutazione finora

- GTI - Standard Routine Tests of GIS Typ ELKDocumento14 pagineGTI - Standard Routine Tests of GIS Typ ELKMd Nadimur RahmanNessuna valutazione finora

- Cuponal Busbar Technical Data: AC/DC Current Ratings: ExtrusionsDocumento4 pagineCuponal Busbar Technical Data: AC/DC Current Ratings: ExtrusionsPrakash19Nessuna valutazione finora

- Cuponal Busbar Technical Data: AC/DC Current Ratings: ExtrusionsDocumento4 pagineCuponal Busbar Technical Data: AC/DC Current Ratings: ExtrusionsPrakash19Nessuna valutazione finora

- AlternatorDocumento24 pagineAlternatorJoseEduardoSantaCruzNessuna valutazione finora

- Insulators - FreshDocumento6 pagineInsulators - FreshsasikumarNessuna valutazione finora

- Technical SpecificationsDocumento36 pagineTechnical SpecificationsPavanNessuna valutazione finora

- India Solar Map 2015 FinalDocumento2 pagineIndia Solar Map 2015 FinalsasikumarNessuna valutazione finora

- A-Panel Dual Polarization Half-Power Beam Width Adjust. Electr. DowntiltDocumento2 pagineA-Panel Dual Polarization Half-Power Beam Width Adjust. Electr. DowntiltUzair AkbarNessuna valutazione finora

- 2 1 PDFDocumento18 pagine2 1 PDFالمهندسوليدالطويلNessuna valutazione finora

- Uporedna Tabela Addinol-Ovih UljaDocumento4 pagineUporedna Tabela Addinol-Ovih UljaasimpeksNessuna valutazione finora

- Sop Urilyzer 100Documento4 pagineSop Urilyzer 100misriyantiNessuna valutazione finora

- CERES News Digest - Week 11, Vol.4, March 31-April 4Documento6 pagineCERES News Digest - Week 11, Vol.4, March 31-April 4Center for Eurasian, Russian and East European StudiesNessuna valutazione finora

- Steinway Case - CH 03Documento5 pagineSteinway Case - CH 03Twēéty TuiñkleNessuna valutazione finora

- E14r50p01 800 MhaDocumento4 pagineE14r50p01 800 Mha'Theodora GeorgianaNessuna valutazione finora

- RA 9184 & RA 3019 NotesDocumento5 pagineRA 9184 & RA 3019 Notesleng_evenNessuna valutazione finora

- Home Work (Satistics AIUB)Documento5 pagineHome Work (Satistics AIUB)fukscribdNessuna valutazione finora

- Supply DemandProblems With Solutions, Part 1Documento16 pagineSupply DemandProblems With Solutions, Part 1deviNessuna valutazione finora

- UK LL M Thesis - Builders' Liability in UK Law Under TortDocumento16 pagineUK LL M Thesis - Builders' Liability in UK Law Under TortRajan UppiliNessuna valutazione finora

- Midterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsDocumento3 pagineMidterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsGarp Barroca100% (1)

- Risk, Return & Capital BudgetingDocumento18 pagineRisk, Return & Capital BudgetingMuhammad Akmal HussainNessuna valutazione finora

- KFF in OAF Page-GyanDocumento4 pagineKFF in OAF Page-Gyangyan darpanNessuna valutazione finora

- Payment Systems Worldwide: Appendix Country-by-Country AnswersDocumento306 paginePayment Systems Worldwide: Appendix Country-by-Country Answersravinewatia27Nessuna valutazione finora

- Capitol Medical Center, Inc. v. NLRCDocumento14 pagineCapitol Medical Center, Inc. v. NLRCFidel Rico NiniNessuna valutazione finora

- CIE Physics IGCSE: General Practical SkillsDocumento3 pagineCIE Physics IGCSE: General Practical SkillsSajid Mahmud ChoudhuryNessuna valutazione finora

- E Rpms Portfolio Design 3 1Documento52 pagineE Rpms Portfolio Design 3 1jebNessuna valutazione finora

- Summative-Test-3-5 Tve ExploratoryDocumento3 pagineSummative-Test-3-5 Tve ExploratoryMjnicole MartejaNessuna valutazione finora

- Guide On Multiple RegressionDocumento29 pagineGuide On Multiple RegressionLucyl MendozaNessuna valutazione finora

- Organization of Brigada Eskwela Steering and Working CommitteesDocumento2 pagineOrganization of Brigada Eskwela Steering and Working CommitteesCherry Lou RiofrirNessuna valutazione finora

- Radix Sort - Wikipedia, The Free EncyclopediaDocumento13 pagineRadix Sort - Wikipedia, The Free EncyclopediasbaikunjeNessuna valutazione finora

- An Analytical Study On Impact of Credit Rating Agencies in India 'S DevelopmentDocumento14 pagineAn Analytical Study On Impact of Credit Rating Agencies in India 'S DevelopmentRamneet kaur (Rizzy)Nessuna valutazione finora

- Pertemuan - 12 MetopenDocumento40 paginePertemuan - 12 MetopenulviaNessuna valutazione finora

- Negative Sequence Current in Wind Turbines Type 3 1637954804Documento6 pagineNegative Sequence Current in Wind Turbines Type 3 1637954804Chandra R. SirendenNessuna valutazione finora