Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

KPK Spol. S R.O

Caricato da

Dhanraj PatilTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

KPK Spol. S R.O

Caricato da

Dhanraj PatilCopyright:

Formati disponibili

11/6/2015

KPK spol. s r.o., Martin - SLOVAKIA - ERIAVY - CRANES - JEBY

Classification of Hoisting Mechanism

The classification of KPK cranes and their mechanisms according to the standards STN ISO 4301 and FEM

(Federation Europeenne de la Manutention) specifies the group into which the crane and its mechanisms are

classified.

It serves:

a) for commercial and technical negotiations between buyer and crane manufacturer for determination of required

crane performance

b) as a bases for the designer to prepare the analyses of crane and its mechanisms.

The crane and its mechanisms classification class is specified on the base of assumed kind of operation (light,

medium, heavy, very heavy) and of the operation cycles number. The correct classification ensures the correct

dimensioning of the equipment. The high classification classis, for example FEM 3m(M6), FEM 4(M7) and A6-A8 (J3J6) are typical for cranes with high operating speeds and cranes loaded with loads corresponding to the crane carrying

capacity, or for cranes operating in automatic mode.

The KPK specialists are always ready to provide help by classifying the crane according to the above standards.

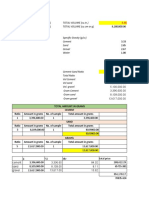

The following table shows several examples of classification for cranes and their mechanisms depending on

crane application.

Group classification

of hoisting mechanism according

to FEM 9.511 (STN ISO 4301)

of crane as a complete unit

according to STN ISO 4301 (STN

270103)

1Bm (M3)

A3 till A4 (J1 till J2)

1Am (M4)

A3 till A5 (J2 till J3)

Workshop use

1Bm till 1Am (M3 to M4)

A3 till A5 (J2 till J3)

Warehouse cranes

2m till 3m (M5 to M6)

A4 till A6 (J2 till J3)

Magnet cranes

3m till 4m (M6 to M7)

A6 till A8 (J3 till J6)

Automatic and special

cranes

4m till 5m (M7 to M8)

A6 till A8 (J3 till J6)

Application

Maintenance and assembly

cranes for occasional use

Assembly cranes for regular

use

By selection of hoist type (hoisting mechanism) it is important besides the specification of hoist carrying capacity

according to the maximum weight of transporting load also the correct classification of hoisting mechanism.

The classification of hoisting mechanism depends on the average daily operating time Tm and on the load

spectrum (rate of loading) .

Tab.2- Determination of hoisting mechanism classification according to load spectrum and average daily

operating time Tm

http://www.kpk.sk/ang/klasifik.htm

1/4

11/6/2015

KPK spol. s r.o., Martin - SLOVAKIA - ERIAVY - CRANES - JEBY

Tab.3 - Relation between the classification according to FEM , ISO and GOST.

ISO 4301-1

M1

M2

M3

M4

M5

M6

M7

M8

FEM 9.511

1Dm

1Cm

1Bm

1Am

2m

3m

4m

5m

GOST

1M

2M

3M

4M

5M

% ED

25

30

40

50

60

150

180

240

300

360

c/h

90

120

Short Time rating

360

Intermittent Rating (%ED)

Max.Number of Starts Per Hour

%ED = [ (t1 + t3) / (t1 + t2 + t3 + t4 ) ] * 100

1/ Average daily operating time Tm :

Depends on operation time per day.It is calculated according to the following formula:

Tm = ( 2 * H * C * T ) / ( 60 * V )

http://www.kpk.sk/ang/klasifik.htm

[ hour / day ]

2/4

11/6/2015

KPK spol. s r.o., Martin - SLOVAKIA - ERIAVY - CRANES - JEBY

Average hook path H [m]

H - Average hook path [ m ]

C - number of cycles per hour [ - ]

T -- working hours per day [ hour ]

V - hoisting speed [ m/min ]

2/ Mechanism load spectrum:

- occasional lifting of maximum load

- medium load from suspension means, for

example from traverse-beam

light

- occasional lifting of maximum load

- regular lifting of low weight load

- medium load from suspension means, for

example from traverse-beam

http://www.kpk.sk/ang/klasifik.htm

3/4

11/6/2015

KPK spol. s r.o., Martin - SLOVAKIA - ERIAVY - CRANES - JEBY

medium

- frequent lifting of maximum load

- regular lifting of load with medium weight

- big load from suspension means, for example

from traverse-beam

heavy

- regular lifting of maximum load

- very big load from suspension means, for

example from traverse-beam

very heavy

Example of classification calculation:

1.1 - Input data:

- maximum weight of transported load Q = 5 000 kg

- average hook path H = 4 m

- number of cycles per hour C = 20

- required lifting speed V = 8 m/min

- working hours lifting mechanism T = 8 hours per day

- medium mechanism group

1.2-Calculation:

Average daily operating time Tm:

Tm = ( 2 * H * C * T ) / ( 60 * V ) = ( 2 * 4 * 20 * 8 ) / (60 * 8) = 2,66 hours

According to Table 2 for medium operation is the lifting mechanism classification FEM

- 2m (ISO -M5)

1.3- Choice of hoist:

For lifting the load it is necessary to chose the hoist with carrying capacity 5000 kg, lifting speed 8 m/min and with

classification according FEM 2m.

http://www.kpk.sk/ang/klasifik.htm

4/4

Potrebbero piacerti anche

- Classification of CranesDocumento1 paginaClassification of Cranespradeep shindeNessuna valutazione finora

- Full Scale Derailment Testes On Freight WagonsDocumento19 pagineFull Scale Derailment Testes On Freight WagonsFelipe Campos100% (1)

- Classification of CranesDocumento1 paginaClassification of CraneswfjerrNessuna valutazione finora

- Balkan HoistsDocumento26 pagineBalkan HoistslifttecNessuna valutazione finora

- Adams Simulation For Ropeway TechnologyDocumento11 pagineAdams Simulation For Ropeway TechnologyDavid Andrés Bessalle ReyesNessuna valutazione finora

- SzkodaM LifeCycleDocumento10 pagineSzkodaM LifeCycleThe Minh NguyenNessuna valutazione finora

- Pod em Crane - Electrical Wire Rope Hoists (ENG)Documento24 paginePod em Crane - Electrical Wire Rope Hoists (ENG)vancozNessuna valutazione finora

- FEM9.512 EnglDocumento12 pagineFEM9.512 EnglFDLTLSNessuna valutazione finora

- SH E096qDocumento24 pagineSH E096qkanstopthankNessuna valutazione finora

- Condition Monitoring of Rolling Stock Using Wheel/rail ForcesDocumento9 pagineCondition Monitoring of Rolling Stock Using Wheel/rail ForcesSuman MaharanaNessuna valutazione finora

- Track Modulus 9Documento12 pagineTrack Modulus 9Marius DiaconuNessuna valutazione finora

- Testing The Dynamic Behaviour of Vehicles: Normalisation of Test Conditions by Use of Multi Linear RegressionsDocumento12 pagineTesting The Dynamic Behaviour of Vehicles: Normalisation of Test Conditions by Use of Multi Linear RegressionsVitor GomesNessuna valutazione finora

- Design of Railway Bogies in Compliance With New EN 13749 European Standard Giampaolo Mancini, Alessandro CeraDocumento11 pagineDesign of Railway Bogies in Compliance With New EN 13749 European Standard Giampaolo Mancini, Alessandro Cerasivadas .bNessuna valutazione finora

- D2.3-Public-Terminal Technology and Systems-Final V2-Islam-24012008 PDFDocumento48 pagineD2.3-Public-Terminal Technology and Systems-Final V2-Islam-24012008 PDFmaxamaxaNessuna valutazione finora

- WBK WD LonginDocumento10 pagineWBK WD Longinsofronije2005Nessuna valutazione finora

- Load Classification of CranesDocumento4 pagineLoad Classification of CranesNarayan Prasad100% (3)

- 05Documento84 pagine05hammouche_soufianeNessuna valutazione finora

- Trakblaze 2011Documento27 pagineTrakblaze 2011LeGaCykojiNessuna valutazione finora

- Paper Review PDFDocumento8 paginePaper Review PDFJohanFaqar ZainNessuna valutazione finora

- 3 D Modelling and Finite Element Analysis of Eot CraneDocumento4 pagine3 D Modelling and Finite Element Analysis of Eot CraneKenneth ShumNessuna valutazione finora

- Electric Chain Hoists VK SeriesDocumento16 pagineElectric Chain Hoists VK SeriesNemanja Mido DjuricNessuna valutazione finora

- Uic Code: Classification of Lines For The Purpose of Track MaintenanceDocumento9 pagineUic Code: Classification of Lines For The Purpose of Track MaintenanceHARINessuna valutazione finora

- Application of Eurocodes For BridgesDocumento54 pagineApplication of Eurocodes For Bridgessammy_viorel21Nessuna valutazione finora

- Study and Performance of Belt Conveyor System With Different Type ParameterDocumento3 pagineStudy and Performance of Belt Conveyor System With Different Type ParameterIJIRSTNessuna valutazione finora

- Performance Evaluation Criteria For The Analysis of Class-4 Electric TruckDocumento20 paginePerformance Evaluation Criteria For The Analysis of Class-4 Electric TruckAlexei MorozovNessuna valutazione finora

- Summary of Control & Signaling Line2 (VOLUME1)Documento30 pagineSummary of Control & Signaling Line2 (VOLUME1)m_afuni80Nessuna valutazione finora

- EN1991 9 TschumiDocumento37 pagineEN1991 9 TschumiNguyễn Văn BanNessuna valutazione finora

- Gcrt5023 Iss 1Documento9 pagineGcrt5023 Iss 1ernycueaNessuna valutazione finora

- Kitaeva 2015 IOP Conf. Ser. Mater. Sci. Eng. 81 012113Documento12 pagineKitaeva 2015 IOP Conf. Ser. Mater. Sci. Eng. 81 012113Rosa Angelica Castro RodriguezNessuna valutazione finora

- 415 Hitachi Hoist SH FH Monorail TrolleyDocumento24 pagine415 Hitachi Hoist SH FH Monorail TrolleyPhillip FrencilloNessuna valutazione finora

- M54 Unit 4 Traffic Load On Other BridgesDocumento10 pagineM54 Unit 4 Traffic Load On Other BridgesPhilip YapNessuna valutazione finora

- Background To Fatigue Load ModelsDocumento11 pagineBackground To Fatigue Load ModelsrwaidaabbasNessuna valutazione finora

- Freight Transportation Services - Declaration and Reporting of Environmental Performance in Freight Transport ChainsDocumento11 pagineFreight Transportation Services - Declaration and Reporting of Environmental Performance in Freight Transport ChainschuchuleeNessuna valutazione finora

- Eurocode Train LoadDocumento58 pagineEurocode Train LoadMohd Faizal100% (2)

- General Laying ProceduresDocumento20 pagineGeneral Laying ProceduresLiladhar Ganesh Dhoble100% (1)

- Ehv Power Transformer Testing PDFDocumento72 pagineEhv Power Transformer Testing PDFRamesh Epili100% (1)

- Trambeam CatalogDocumento252 pagineTrambeam CatalogMuthu Barathi ParamasivamNessuna valutazione finora

- 90497-Article Text-191902-1-10-20170127Documento22 pagine90497-Article Text-191902-1-10-20170127Ajay lokhandeNessuna valutazione finora

- CEFIC Guidelines Transport Equipment Packed Cargo (2010)Documento7 pagineCEFIC Guidelines Transport Equipment Packed Cargo (2010)sl1828Nessuna valutazione finora

- Journal of Vibration and ControlDocumento16 pagineJournal of Vibration and ControlTarek SetifienNessuna valutazione finora

- Research On Fatigue Test Method of Car Body For High-Speed TrainsDocumento7 pagineResearch On Fatigue Test Method of Car Body For High-Speed TrainsGAUTAM DUANessuna valutazione finora

- Nbe Ah GT 104Documento36 pagineNbe Ah GT 104Samsudin AhmadNessuna valutazione finora

- The Analysis and Calculation Procedure For Shovel-Truck Systems With A Crusher and ConveyorsDocumento8 pagineThe Analysis and Calculation Procedure For Shovel-Truck Systems With A Crusher and Conveyorschristian waduyNessuna valutazione finora

- sw7675 c010 PDFDocumento24 paginesw7675 c010 PDFRasdinantaTariganNessuna valutazione finora

- C2R Spring2007 ValidationTrainsDocumento4 pagineC2R Spring2007 ValidationTrainspavloneNessuna valutazione finora

- Goods and Attendant Lift: Technical SpecificationsDocumento24 pagineGoods and Attendant Lift: Technical SpecificationsjackyNessuna valutazione finora

- Magnetically Levitated Trains (Maglev) : Dedicated To Crr/Ministry of Railways/Indian Railways/RdsoDocumento14 pagineMagnetically Levitated Trains (Maglev) : Dedicated To Crr/Ministry of Railways/Indian Railways/RdsoAnand ShivannaNessuna valutazione finora

- Assessment of Locomotive and Multi-Unit Fatigue Strength Considering The Results of Certifi Cation Tests in Ukraine and EU CountriesDocumento8 pagineAssessment of Locomotive and Multi-Unit Fatigue Strength Considering The Results of Certifi Cation Tests in Ukraine and EU CountriesLeonardo Antônio Pereira100% (1)

- Riel GerardoDocumento17 pagineRiel GerardoJHON EDWARD LIZARAZO PARADANessuna valutazione finora

- Port Terminals System - Conveyor and Equipment MaintenanceDa EverandPort Terminals System - Conveyor and Equipment MaintenanceNessuna valutazione finora

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlDa EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlValutazione: 5 su 5 stelle5/5 (1)

- Metal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringDa EverandMetal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringValutazione: 3.5 su 5 stelle3.5/5 (5)

- Railroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975Da EverandRailroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975Arnold D. KerrValutazione: 5 su 5 stelle5/5 (1)

- Theory and Technology for Improving High-Speed Railway Transportation CapacityDa EverandTheory and Technology for Improving High-Speed Railway Transportation CapacityNessuna valutazione finora

- Train Doctor: Trouble Shooting with Diesel and Electric TractionDa EverandTrain Doctor: Trouble Shooting with Diesel and Electric TractionNessuna valutazione finora

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12Da EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12Nessuna valutazione finora

- Safety Theory and Control Technology of High-Speed Train OperationDa EverandSafety Theory and Control Technology of High-Speed Train OperationValutazione: 5 su 5 stelle5/5 (2)

- Handbook of Optimization in the Railway IndustryDa EverandHandbook of Optimization in the Railway IndustryRalf BorndörferNessuna valutazione finora

- Electric: For Dummies Everything Need KnowDocumento2 pagineElectric: For Dummies Everything Need KnowDhanraj PatilNessuna valutazione finora

- What Is The Role of Ammonia in An Aquaponics SystemDocumento3 pagineWhat Is The Role of Ammonia in An Aquaponics SystemDhanraj PatilNessuna valutazione finora

- Lab 4 PulleyDocumento4 pagineLab 4 PulleyDhanraj PatilNessuna valutazione finora

- When and How To Adjust A Load-Sensing Hydraulic PumpDocumento5 pagineWhen and How To Adjust A Load-Sensing Hydraulic PumpDhanraj PatilNessuna valutazione finora

- Hydroponic NutrientsDocumento9 pagineHydroponic NutrientsDhanraj PatilNessuna valutazione finora

- Aquaponics Filtration Systems Explained - How To AquaponicDocumento6 pagineAquaponics Filtration Systems Explained - How To AquaponicDhanraj PatilNessuna valutazione finora

- What Is Role of Dissolved Oxygen in AquaponicsDocumento4 pagineWhat Is Role of Dissolved Oxygen in AquaponicsDhanraj PatilNessuna valutazione finora

- Hydrostatic DriveDocumento13 pagineHydrostatic DriveDhanraj PatilNessuna valutazione finora

- Dutch Bucket Recovery SystemDocumento1 paginaDutch Bucket Recovery SystemDhanraj Patil100% (1)

- Hydraulic TroubleshootingDocumento10 pagineHydraulic TroubleshootingDhanraj PatilNessuna valutazione finora

- Hydraulic FiltrationDocumento35 pagineHydraulic FiltrationDhanraj PatilNessuna valutazione finora

- Hydraulic FittingDocumento124 pagineHydraulic FittingDhanraj PatilNessuna valutazione finora

- Pressol - Air Grease Pum - Instruction ManualDocumento14 paginePressol - Air Grease Pum - Instruction ManualDhanraj PatilNessuna valutazione finora

- Air Operated Grease Ratio Pumps 50:1 BGRP: Instruction Manual S1350, Rev BDocumento12 pagineAir Operated Grease Ratio Pumps 50:1 BGRP: Instruction Manual S1350, Rev BDhanraj PatilNessuna valutazione finora

- Part A Marks 50Documento4 paginePart A Marks 50Dhanraj PatilNessuna valutazione finora

- Lecture 9 PDFDocumento6 pagineLecture 9 PDFDhanraj PatilNessuna valutazione finora

- Hybrid Electric Vehicles: Author: E-Mail: Course: Class/Year: Main Functional Requirement: Design ParameterDocumento7 pagineHybrid Electric Vehicles: Author: E-Mail: Course: Class/Year: Main Functional Requirement: Design ParameterDhanraj PatilNessuna valutazione finora

- Hot Work Permit ChecklistDocumento1 paginaHot Work Permit ChecklistDhanraj PatilNessuna valutazione finora

- Verilog Implementation of Reed - Solomon CodeDocumento16 pagineVerilog Implementation of Reed - Solomon CodeManik Prabhu ChillalNessuna valutazione finora

- SA-6 Press KitDocumento53 pagineSA-6 Press KitBob Andrepont100% (1)

- MEMS-Based Uncooled Infrared Bolometer Arrays - A ReviewDocumento15 pagineMEMS-Based Uncooled Infrared Bolometer Arrays - A ReviewMarco LicofonteNessuna valutazione finora

- Brige Lauching Cap 1 PDFDocumento16 pagineBrige Lauching Cap 1 PDFAnonymous VkzquW39Nessuna valutazione finora

- Autovue IntegrationDocumento4 pagineAutovue IntegrationmansrallyNessuna valutazione finora

- LCD TV: Service ManualDocumento74 pagineLCD TV: Service Manualismosch50% (2)

- Paper: Theory/Week: Credits: Mobile Application Development Using Android Hours: IA: ExamDocumento1 paginaPaper: Theory/Week: Credits: Mobile Application Development Using Android Hours: IA: ExamHaseeb MogralNessuna valutazione finora

- Cloud Paas and Iaas Playbook 2993836Documento35 pagineCloud Paas and Iaas Playbook 2993836Blizard80Nessuna valutazione finora

- Data Warehousing Quick GuideDocumento66 pagineData Warehousing Quick Guidejacktheking2010Nessuna valutazione finora

- Machine Element Design CheatsheetDocumento25 pagineMachine Element Design CheatsheetDarien ChiaNessuna valutazione finora

- Qdoc - Tips Bs en Iso 19285 2017 Non Destructive Testing of WeDocumento30 pagineQdoc - Tips Bs en Iso 19285 2017 Non Destructive Testing of WeDave CheungNessuna valutazione finora

- 5209 Aerospace T SealDocumento20 pagine5209 Aerospace T SealNicolasSuchNessuna valutazione finora

- Welder and Welding Operator Qualification Test Record (Asme Ix Code)Documento1 paginaWelder and Welding Operator Qualification Test Record (Asme Ix Code)Neil TaneoNessuna valutazione finora

- Language Translation Software Market Industry Size, Share, Growth, Trends, Statistics and Forecast 2014 - 2020Documento9 pagineLanguage Translation Software Market Industry Size, Share, Growth, Trends, Statistics and Forecast 2014 - 2020api-289551327Nessuna valutazione finora

- Worksheet # 7 - Free Body DiagramDocumento2 pagineWorksheet # 7 - Free Body DiagramyabalabahiyaNessuna valutazione finora

- ASTM E1417 Penetrant Testing - 9 PDFDocumento11 pagineASTM E1417 Penetrant Testing - 9 PDFbikaNessuna valutazione finora

- ASSAM - Uniform Zoning Regulation 2000Documento35 pagineASSAM - Uniform Zoning Regulation 2000rajatesh1Nessuna valutazione finora

- 05 MathematicalReference PDFDocumento484 pagine05 MathematicalReference PDFHassanKMNessuna valutazione finora

- CU-2RE PBE Service ManualDocumento110 pagineCU-2RE PBE Service ManualcoronaqcNessuna valutazione finora

- Sagana Kutus 132kv Transmission Line and SubstationDocumento324 pagineSagana Kutus 132kv Transmission Line and Substationshivvaram-1100% (1)

- DMPCDocumento49 pagineDMPCiprassandyNessuna valutazione finora

- OTN Training-Lv1-Fonst 3000 Equipment IntroductionDocumento28 pagineOTN Training-Lv1-Fonst 3000 Equipment IntroductionJenny Rodriguez Aguirre100% (1)

- Remote Log-In, Electronic Mail and File Transfer: Solutions To Odd-Numbered Review Questions and ExercisesDocumento2 pagineRemote Log-In, Electronic Mail and File Transfer: Solutions To Odd-Numbered Review Questions and ExercisesAnurag UpadhyayNessuna valutazione finora

- Computation For Concrete Mix 120221Documento3 pagineComputation For Concrete Mix 120221MASGRO BUILDERSNessuna valutazione finora

- Assignment 1 Low Temperature and SuperconductivityDocumento3 pagineAssignment 1 Low Temperature and SuperconductivityNadhrah MuradNessuna valutazione finora

- Design and Evaluation of Inflatable Wings For UavsDocumento290 pagineDesign and Evaluation of Inflatable Wings For UavsmegustalazorraNessuna valutazione finora

- SOPM EmbraerDocumento398 pagineSOPM EmbraerRener Junior100% (1)

- DATA SHEET Industrial Enamel BlancoDocumento4 pagineDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNessuna valutazione finora

- 500 Technical Questions Safety&Fire-1Documento26 pagine500 Technical Questions Safety&Fire-1Saad GhouriNessuna valutazione finora

- Ihs Kingdom Hot Keys ReferenceDocumento1 paginaIhs Kingdom Hot Keys ReferenceMuhammad Jahangir100% (1)