Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WP Thermador en

Caricato da

Andrea HernandezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WP Thermador en

Caricato da

Andrea HernandezCopyright:

Formati disponibili

Bakery Engineering Excellence

Bakery Engineering Excellence

Industrial Bakery Technologies

Thermador SHORTFACTS

TECHNICAL DATA

Thermador

Belt width

mm

2.000

2,500

3,000

3,300

3,750

4,000*

Effective width

mm

1.950

2,450

2,950

3,250

3,700

3,950

Oven width*

mm

3.005

3,555

4,005

4,305

4,755

5,005

Length of baking chamber**

mm

10,50060,000

Inlet rack length

mm

1,400

1,650/1,950/2,550

Discharge rack length

mm

Oven end

mm

200

Belt height

mm

760 (plate conveyor 860)

Height of burner zone / oven zone

mm

Cyclotherm

2,500/1,900

DUOTHERM

2,750/1,900

Plate conveyor (stone / steel / grid)

2,600 mm/2,000 mm

Height of baking chamber

mm

260

Passage below steam zone

mm

Min. 165210

Lengths/version of steam zone

Head of the oven 6 m

SZ 1,500 mm/6 pipes

SZ 900 mm/4 pipes

SZ 750 mm / 2 pipes

Heating medium

Natural gas, liquid gas, fuel oil or electricity

Baking time control

At a ratio of 1:3 (others on request)

Drive unit

Conveyor load

Frequency-controlled gear motor

kg/m

3090 (higher loads on request)

Belt version

50 (higher loads on request)

Cyklotherm

Round-wire link belt, stone plate belt

Duotherm

Wide-meshed flat-wire link belt

* Not applicable to stone & grid

** The combination of baking chamber width and length depends on the conveyor carrying the

goods to be baked

Schnelle

Amortisierung

der Investitionskosten

// geringe Betriebskosten

// Prozess

FAST

AMORTISATION

OF INVESTMENT

COSTS THANKS TO //durch

LOW OPERATIONAL

COSTS // PROCESS

CONTROL

kontrolle

//

RELIABILITY// Zuverlssigkeit

// LASTING VALUE // Wertbestndigkeit

Werner & Pfleiderer Industrielle Backtechnik GmbH

Frankfurter Strae 17 | 71732 Tamm | Germany | Phone +49 7141 202-0 | Fax +49 7141 202-111 | info @wpib.de | www.wpib.de

Thermador

.

Efficient, modular and versatile

Industrial Bakery Technologies

Bakery Engineering Excellence

Thermador details

The PHILOSOPHY

Achieving premium quality in baking processes in line with the requirements imposed by each product calls for individual temperature, heat

transfer and moisture profiles. The WP solution for achieving perfect

baking results along with optimised energy use has a name: THERMADOR.

This reliable tunnel oven for continuous production of the entire range of

products unites the latest baking technology and high economic efficiency

with reliability and durability.

// INDIRECT HEATING

// HYGIENE

// AFTER SALES

// INDIVIDUAL OVEN CONFIGURATIONS

Perfect baking results are achieved thanks to the closed

CYCLOTHERM heating gas circulation system. This is

an indirect heating process, i.e. the heating gases are

separate from the baking chamber and do not come

in contact with the baked goods. Heat is transferred

to the baked articles by radiation, convection and heat

conduction. For this purpose, each control zone can

be separately adjusted for top and bottom heat.

The oven systems comply with hygiene requirements

as specified in DIN EN 1672-2 standards: extra large,

removable, subdivided cleaning and inspection doors as

well as a self-cleaning feature on the wire-mesh belt.

No combustion gases are produced in the baking chamber.

Ease of maintenance: Premium quality, durable

design and minimal maintenance requirements

ensure high availability. Remote maintenance

is possible.

The control zone design enables the oven to be

adapted to individual product requirements, achieving

an optimal baking curve for the product. The THERMADOR

oven system provides extremely fine grading options

so that temperature and moisture act on the baked

goods at the right time during the baking process and to

the extent needed.

// PRODUCT VARIETY

Pan bread // tin bread // toast // bread rolls // soft rolls

// ciabatta bread // cake // white bread // baguettes //

bagels // croissants // wheat and rye bread // flat bread //

wholegrain bread // parbaked products

This technology moves thermal radiation into the

infrared range. Consequently, the baked goods reach

the required core temperature faster, which reduces

baking time and saves energy. However, any undesired

browning of the surfaces is avoided, the product retains

a higher degree of moisture while offering improved

volume and enhanced taste properties, as well as

staying fresh for longer. All oven types can be equipped

with this technology

// MODULAR DESIGN

The unique modular design of the THERMADOR

oven system enables individual oven

configurations as well as total flexibility to

combine cyclotherm, Duotherm, infrared and

Quattro zones as required:

// closely stepped modular system between

10.5 and 60 metres for product-related zone

division

// can be flexibly combined and is universal

Example of baking curves

Temperature variation

// SPECTRA INFRARED TECHNOLOGY

Mixed rye bread

Toast

Muffins

Time

Industrial Bakery Technologies

Bakery Engineering Excellence

Thermador VARIANTS

Thermador CONVEYOR SYSTEMS

VARIANTS

CONVEYOR SYSTEMS

VARIANTS // WE PROVIDE THE RIGHT CONVEYOR

BELT ADAPTED TO THE DESIRED BAKING RESULT

// 01 Thermador Cyclo

// 02 Thermador Duo

// 03 Thermador Vario

// 04 Thermador Quattro

Classic universal oven with closed

CYCLOTHERM heating gas circulation

system.Heat transfer to the bakery

products is ensured indirectly by

radiation. Optimal moisture is always achieved in the baking chamber by targeted humidity control

processes, avoiding any uncontrolled moisture extraction. The top

and bottom heat in each control

zone can be regulated separately.

Steady baking atmosphere.

With DUOTHERM in all oven zones including the burner zone the

heat transfer is quick and intensive.

Recirculation in the baking

chamber is vertical, in addition

to this the intensity is adjustable.

High efficiency of heat transfer,

i.e. short baking times. Can also

be used as a pure radiation oven.

Crust characteristics can be precisely monitored. No uncontrolled moisture extraction.

Combination of oven sections with

radiation only (CYCLOTHERM) as

well as one or more oven sections

with recirculation unit for the

baking chamber (DUOTHERM). Large

product variety, improved browning of the products due to less

intensive thermal radiation at the

beginning and more intensive

thermal radiation at the end of the

baking process.

Intensified heat transfer as a result

of doubling the circulation volume.

Further reductions of baking times

and additional energy savings are

thus possible. Suitable for specific

pan-baked products. Frequency-

controlled fans are available as a

further option.

MODULARITY - OVERVIEW OF ZONES

Radiation Burner Radiation Radiation

Radiation

Burner

Radiation

Radiation

Cyclo // Wheat and rye bread, bread rolls, baguettes, rye bread, white bread, cup

cakes, muffins, pound cake, puff pastry, Danish pastry dough, ciabatta, soft rolls

Radiation

Burner

Radiation

DUO

Vario // Wheat and rye bread, bread rolls, baguettes, white bread, rye

bread, Danish pastries with filling (low water content), sandwich bread

DUO

Burner DUO

DUO

DUO

Burner DUO

QUATTRO

QUATTRO

Duo // Toast

DUO

Quattro // Sandwich bread, crustless, open top

Infrared

Burner

Radiation

Radiation

Cyclo Spectra // Wheat and rye bread, bread rolls, baguettes, white

bread, ciabatta bread (all products also available as semi-baked articles)

Infrared

Burner

Radiation

DUO

VARIO Spectra // Wheat and rye bread, bread rolls, baguettes, white bread,

Danish pastry with filling with water content, semi-baked products

Infrared

Burner DUO

DUO

DUO

Duo Spectra // Open top, white bread on baking sheets Examples of the

modular configuration of the production lines.

*flexible burner zone

// Thermador with wire-mesh belt

// Thermador Stone with stone-plate belt

// Thermador Grid

Various models

Industrial premium-quality produced by gentle

baking processes. High heating capacity as

well as uniform heat distribution by means of

direct heat transfer from the stone plate to

the product. Complies with high hygienic standards.

For products on which good, crunchy crusts

are desired.

Improved hygiene. Belt abrasion is avoided

by installing a chain-guided frame carrier,

consequently ensuring improved hygienic

conditions. This system is particularly suitable

for products baked on sheets and higher

charging per m.

Industrial Bakery Technologies

Bakery Engineering Excellence

Thermador EnergEe

Thermador Technologie

OVEN AUTOMATION

HIGH ENERGY UTILISATION // ENERGY CONSUMPTION

REDUCED BY UP TO 35%

// 01

Insulation

// 03

Baking chamber

// 02

External casing

Rising labour costs and competitive constraints call for automated solutions.

For this reason, THERMADOR is equipped with either semi-automatic or

fully automatic control systems. In this, Werner & Pfleiderer rely on

state-of-the-art digital control technology. User-friendly touch-screens

that can be easily understood together with logic avoid operating errors

PROCESS OPTIMISATION

RELIABLE

// 04

Inner oven body

ENERGY OPTIMISATION

Since energy costs nowadays present a continuously increasing proportion

of the overall manufacturing costs for bakery products, Werner & Pfleiderer

have developed appropriate concepts that reduce energy consumption

thus saving energy costs, while at the same time manufacturing reproducible

premium quality products:

Process control and monitoring

No surface losses thanks to optimum module design and highly

efficient heat insulation

Use of energy-efficient materials

DUO fans with increased performance

Quattro System

Controlled amount of steam supply tailored to individual needs

Low exhaust gas temperatures

Reduced baking times.

Semi- or fully-automatically controlled

ENERGY CONSUMPTION IN COMPARISON

kWh

Adapted heating system, quick heat transfer, efficient steam supply and

moisture regulation as well as short baking times ensure the manufacturing

of premium quality products with optimised energy input.

35

30

Zero error technology: The system is self-regulating

Baking time

99 different recipes can be stored

Heating gas temperature / zone temperatures (separate for top and

bottom heat)

Display of all operating data and of temperature profile along all oven zones

Amount of vapour and moisture

Reproducibility and product traceability

Display of all events and alarms

25

Temperatures of the radiation wall

20

Automatic conversion to new process data with change of product type

Comprehensive user service level for operational start-up included in the

user level,

15

Gap detection and automatic corrective adjustments of zones for top

and bottom heat

Service & maintenance possible without needing an additional

programming device

Speed and direction of rotation of DUO fans.

Remote diagnostics via Internet & telephone

10

5

0

25 kg/h

50 kg/h

75 kg/h

100 kg/h bread

Directly heated ovens

Ovens supplied by competitors

WP THERMADOR

The automatic activation of the DUO fans prevents the oven from overheating in case of suboptimal charging states. Heating gas and steam

dampers are electrically driven and integrated in the control system.

Potrebbero piacerti anche

- Megador GBDocumento12 pagineMegador GBAndrea HernandezNessuna valutazione finora

- LENTON Furnaces BrochureDocumento20 pagineLENTON Furnaces Brochureantho_lombokNessuna valutazione finora

- Tunnel OvensDocumento6 pagineTunnel OvensSerrano AndréNessuna valutazione finora

- GEA Imaforni Bakery Ovens Brochure - tcm11 77238Documento24 pagineGEA Imaforni Bakery Ovens Brochure - tcm11 77238Carlos NeyNessuna valutazione finora

- Tunnel Oven PDFDocumento20 pagineTunnel Oven PDFCarlos NeyNessuna valutazione finora

- Tunnel Baking Oven: Instructions For UseDocumento22 pagineTunnel Baking Oven: Instructions For UseIstudor AdrianaNessuna valutazione finora

- 2013 - S2E Technical and Technological - Intro - Final PDFDocumento28 pagine2013 - S2E Technical and Technological - Intro - Final PDFJose Kirby100% (1)

- Prodsheet Pb50 en 01Documento2 pagineProdsheet Pb50 en 01Amândio PintoNessuna valutazione finora

- AD 2000-Merkblatt: Safety Devices Against Excess Pressure - Bursting Safety Devices - A1Documento12 pagineAD 2000-Merkblatt: Safety Devices Against Excess Pressure - Bursting Safety Devices - A1GentelmanOnlyNessuna valutazione finora

- Welder Training EssentialsDocumento3 pagineWelder Training EssentialscordobaluisfNessuna valutazione finora

- Horizontal High Temperature Vacuum Chamber Furnace - Schmetz, PDFDocumento8 pagineHorizontal High Temperature Vacuum Chamber Furnace - Schmetz, PDFEmanuelValenciaHenao100% (1)

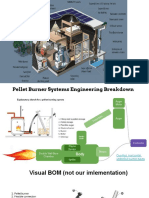

- Pellet BurnerDocumento11 paginePellet BurnerAmjad PervazNessuna valutazione finora

- Burner, Series 300-700Documento32 pagineBurner, Series 300-700Luthfi Adri Angkasa PutraNessuna valutazione finora

- Omron E5CWL PDFDocumento12 pagineOmron E5CWL PDFmaloyNessuna valutazione finora

- UNIVERSAL Steam Boiler UL-S: Main DimensionsDocumento3 pagineUNIVERSAL Steam Boiler UL-S: Main DimensionsJose Ricardo Duran0% (1)

- Hobart Cpro Cplus Installation and Maintenance Manual PDFDocumento56 pagineHobart Cpro Cplus Installation and Maintenance Manual PDFВадим КарцевNessuna valutazione finora

- Steam Microturbine BrochureDocumento2 pagineSteam Microturbine BrochureBapu612345Nessuna valutazione finora

- Ecofel Boiler Service ManualDocumento38 pagineEcofel Boiler Service ManualCristian PodaruNessuna valutazione finora

- Calculate heat load of paint baking ovenDocumento8 pagineCalculate heat load of paint baking ovenbhatrkNessuna valutazione finora

- Electric Steam Boiler SussmanDocumento2 pagineElectric Steam Boiler SussmanChriss VzzNessuna valutazione finora

- Kinemax Gas or Oil Burners: Bulletin 4200Documento26 pagineKinemax Gas or Oil Burners: Bulletin 4200agua1829Nessuna valutazione finora

- Vacuum Furnace ControlDocumento2 pagineVacuum Furnace Controlmsaadullah0% (1)

- Revolution in Welding CalculatorDocumento9 pagineRevolution in Welding CalculatorAji AshiqNessuna valutazione finora

- Line 5 - 2100 - Baking - OvenDocumento310 pagineLine 5 - 2100 - Baking - OvenM. ShoaibNessuna valutazione finora

- Connect Siemens PLCs with GP/GLC via MPIDocumento39 pagineConnect Siemens PLCs with GP/GLC via MPIJoko Suwito UtomoNessuna valutazione finora

- Furnace Simulation and Furnace Sizing Calculations With FurnxpertDocumento3 pagineFurnace Simulation and Furnace Sizing Calculations With FurnxpertSteve WanNessuna valutazione finora

- JULABO F25 HL Manual V6Documento101 pagineJULABO F25 HL Manual V6Douglas Bezerra BenizNessuna valutazione finora

- E.dot+ Electric Guns Data SheetDocumento2 pagineE.dot+ Electric Guns Data SheetNordson Adhesive Dispensing SystemsNessuna valutazione finora

- Thermax FSDocumento2 pagineThermax FSOscar Alvitez DominguezNessuna valutazione finora

- Blow MouldingDocumento18 pagineBlow MouldingShaheen ArihaNessuna valutazione finora

- Compression Molding Process ExplainedDocumento15 pagineCompression Molding Process ExplainedPradeep MahalikNessuna valutazione finora

- Rack Ovens Sveba Dahlen BrochureDocumento24 pagineRack Ovens Sveba Dahlen BrochureSteven LondonNessuna valutazione finora

- Material STDDocumento28 pagineMaterial STDanandsharma9Nessuna valutazione finora

- Boiler Manual Updated 20131Documento50 pagineBoiler Manual Updated 20131api-251989125Nessuna valutazione finora

- Strahl Grain DryersDocumento2 pagineStrahl Grain Dryerssajsigaloma1Nessuna valutazione finora

- Gico Globe enDocumento24 pagineGico Globe enslobamsNessuna valutazione finora

- Force Circulating Convection Industrial OvenDocumento13 pagineForce Circulating Convection Industrial OvenAbhishek KaraleNessuna valutazione finora

- Laboratory Furnaces: BOX Furnaces Tube Furnaces Crucible Furnaces Controllers Hot PlatesDocumento36 pagineLaboratory Furnaces: BOX Furnaces Tube Furnaces Crucible Furnaces Controllers Hot PlatesKarim AlyNessuna valutazione finora

- Ther MobileDocumento36 pagineTher MobileZablatoschi Florin Daniel100% (1)

- Hein-Luxrotor Eco2012gb WebDocumento12 pagineHein-Luxrotor Eco2012gb WebCarlos Condori AvilaNessuna valutazione finora

- Pyromaitre OvensDocumento16 paginePyromaitre OvensTherelek EngineersNessuna valutazione finora

- GUNTAMATIC Biomass Boiler Heating Range GuideDocumento24 pagineGUNTAMATIC Biomass Boiler Heating Range GuideSorin StanNessuna valutazione finora

- WP Tunnelofen Thermador - ENDocumento5 pagineWP Tunnelofen Thermador - ENmnenasratnarabotuNessuna valutazione finora

- Tugas BoilerDocumento33 pagineTugas BoilerAgus Dwi Nurcahyo JemberNessuna valutazione finora

- Ultra-Thin Flexible HeatersDocumento12 pagineUltra-Thin Flexible HeatersRon van OudenallenNessuna valutazione finora

- Fessmann Anlagen Fisch-EnDocumento16 pagineFessmann Anlagen Fisch-EnYutt WattNessuna valutazione finora

- Sensors: A Wireless Portable High Temperature Data Monitor For Tunnel OvensDocumento20 pagineSensors: A Wireless Portable High Temperature Data Monitor For Tunnel OvensAbderrahmane SmaaliNessuna valutazione finora

- Catalogo Industrial Hornos Tunel Convection inDocumento20 pagineCatalogo Industrial Hornos Tunel Convection innelo1818Nessuna valutazione finora

- Operating Instructions Universal Ovens Sterilisers Incubators UNB 100-500 UFB 400 - 500 SNB 100 - 400 SFB 400 - 500 INB 200 - 500Documento35 pagineOperating Instructions Universal Ovens Sterilisers Incubators UNB 100-500 UFB 400 - 500 SNB 100 - 400 SFB 400 - 500 INB 200 - 500Green Pengetikan dan PercetakanNessuna valutazione finora

- CARAMEL PROCESSING EQUIPMENT OPTIONSDocumento14 pagineCARAMEL PROCESSING EQUIPMENT OPTIONSSidi Bel-Abbes CherifNessuna valutazione finora

- Prezentare TecnoclimaDocumento90 paginePrezentare TecnoclimaMelenciuc AndreiNessuna valutazione finora

- OVENS - CatalogDocumento15 pagineOVENS - Catalogdéborah_rosalesNessuna valutazione finora

- Sveba Dahlen - SRP240Documento16 pagineSveba Dahlen - SRP240Paola MendozaNessuna valutazione finora

- BR Heating Ovens English USADocumento32 pagineBR Heating Ovens English USABryanJermyHendrikNessuna valutazione finora

- Oven Heat ContainmentDocumento3 pagineOven Heat ContainmentDaniela MateiNessuna valutazione finora

- Pyromat Eco-Soar HeatingDocumento8 paginePyromat Eco-Soar HeatingSuren ShanNessuna valutazione finora

- Chamber and Tube Furnaces 0001-G-EDocumento64 pagineChamber and Tube Furnaces 0001-G-EMutsikamahwe BrianNessuna valutazione finora

- Esc 620Documento2 pagineEsc 620Ableton LiveNessuna valutazione finora

- MT Series Chamber Furnaces GuideDocumento6 pagineMT Series Chamber Furnaces GuideAndyNessuna valutazione finora

- Rotoavant HR: For Bread and PastryDocumento24 pagineRotoavant HR: For Bread and PastryTarig shgool HagarNessuna valutazione finora

- Occurrence, Distribution and Distinctive Morphological Traits of Weedy Helianthus Annuus L. Populations in Spain and FranceDocumento10 pagineOccurrence, Distribution and Distinctive Morphological Traits of Weedy Helianthus Annuus L. Populations in Spain and FranceAndrea HernandezNessuna valutazione finora

- BakingEurope Summer 2015 PreviewDocumento16 pagineBakingEurope Summer 2015 PreviewAndrea HernandezNessuna valutazione finora

- Soil Conditions and Oilseed Rape EstablishmentDocumento2 pagineSoil Conditions and Oilseed Rape EstablishmentAndrea HernandezNessuna valutazione finora

- DepliantTora SeriesENDocumento19 pagineDepliantTora SeriesENAndrea HernandezNessuna valutazione finora

- Health Is More HolisticDocumento4 pagineHealth Is More HolisticAndrea HernandezNessuna valutazione finora

- Brosura Schaeffer CompacteDocumento9 pagineBrosura Schaeffer CompacteAndrea HernandezNessuna valutazione finora

- Think Big Think Cost Savings InfoDocumento2 pagineThink Big Think Cost Savings InfoAndrea HernandezNessuna valutazione finora

- Agrifood Industry Overview 2014: Key Facts on Employment, Revenue and TrendsDocumento4 pagineAgrifood Industry Overview 2014: Key Facts on Employment, Revenue and TrendsBlaNessuna valutazione finora

- 0 Natural Cancer Treatments RevealedDocumento12 pagine0 Natural Cancer Treatments RevealedAndrea HernandezNessuna valutazione finora

- Compostare Gunoi de Grajd EYSDocumento3 pagineCompostare Gunoi de Grajd EYSAndrea HernandezNessuna valutazione finora

- Meniu Gradi 11 09 2017 15 09 2017-1Documento1 paginaMeniu Gradi 11 09 2017 15 09 2017-1Andrea HernandezNessuna valutazione finora

- Alternative AlternativesDocumento4 pagineAlternative AlternativesAndrea HernandezNessuna valutazione finora

- Information - Tourism ProgrammeDocumento3 pagineInformation - Tourism ProgrammeAndrea HernandezNessuna valutazione finora

- 11 Marin Doru IoanDocumento8 pagine11 Marin Doru IoanAndrea HernandezNessuna valutazione finora

- Istrian CattleDocumento7 pagineIstrian CattleAndrea HernandezNessuna valutazione finora

- Fortuna Brochure - World of Fortuna Eng BakeryDocumento20 pagineFortuna Brochure - World of Fortuna Eng BakeryAndrea HernandezNessuna valutazione finora

- WP Datasheet Sticks enDocumento2 pagineWP Datasheet Sticks enAndrea HernandezNessuna valutazione finora

- Boli Cu Poze Floarea SoareluiDocumento10 pagineBoli Cu Poze Floarea SoareluiAndrea HernandezNessuna valutazione finora

- Prezentacja 2015engv3Documento52 paginePrezentacja 2015engv3Andrea HernandezNessuna valutazione finora

- Variobake GBDocumento2 pagineVariobake GBAndrea HernandezNessuna valutazione finora

- Fortuna Brochure - World of Fortuna Eng BakeryDocumento20 pagineFortuna Brochure - World of Fortuna Eng BakeryAndrea HernandezNessuna valutazione finora

- The Best Technology For Your Beer.: Kaspar SchulzDocumento7 pagineThe Best Technology For Your Beer.: Kaspar SchulzAndrea HernandezNessuna valutazione finora

- Pros Laminieren 2009-GbDocumento12 paginePros Laminieren 2009-GbAndrea HernandezNessuna valutazione finora

- Magicline GBDocumento28 pagineMagicline GBAndrea HernandezNessuna valutazione finora

- Preserving Food Drying Fruits and VegetablesDocumento12 paginePreserving Food Drying Fruits and Vegetablespdxpharris100% (1)

- CONDUX Universal-Mill CUM E-4cb06fDocumento12 pagineCONDUX Universal-Mill CUM E-4cb06fAndrea Hernandez100% (1)

- CornWetMilling BrochureDocumento8 pagineCornWetMilling BrochureAndrea HernandezNessuna valutazione finora

- Available in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BDocumento32 pagineAvailable in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BHarikrishnanNessuna valutazione finora

- Topic 7 Flexible Pavement DesignDocumento22 pagineTopic 7 Flexible Pavement DesignHanaNessuna valutazione finora

- Klip Lok 700 Brochure 2015Documento6 pagineKlip Lok 700 Brochure 2015Andreas KamwankaNessuna valutazione finora

- Irganox 3114: Technical Data SheetDocumento3 pagineIrganox 3114: Technical Data SheetWing ZenandNessuna valutazione finora

- Lab ReportDocumento3 pagineLab ReportKerby OmasasNessuna valutazione finora

- Compact Variable CompressorsDocumento2 pagineCompact Variable CompressorsIvan GrayNessuna valutazione finora

- Total Water Management in Thermal Power StationsDocumento8 pagineTotal Water Management in Thermal Power StationsSarah FrazierNessuna valutazione finora

- Secondary Physics Temp NotesDocumento3 pagineSecondary Physics Temp NotesHarish PrabhuNessuna valutazione finora

- Chapter 3 - Mix DesignDocumento16 pagineChapter 3 - Mix DesignAbel MulugetaNessuna valutazione finora

- BMI Division ... : Iso Metric Screw ThreadsDocumento10 pagineBMI Division ... : Iso Metric Screw ThreadsAbdul Qadir TambeNessuna valutazione finora

- Material Safety Data Sheet: Product Name: Mobil SHC Hydraulic Eal 68Documento11 pagineMaterial Safety Data Sheet: Product Name: Mobil SHC Hydraulic Eal 68Dheeraj Chowdary DhanekulaNessuna valutazione finora

- Advantages of Precast Concrete ConstructionDocumento12 pagineAdvantages of Precast Concrete Constructionvalerie samarNessuna valutazione finora

- Properties of SteamDocumento27 pagineProperties of SteamVishal DhimanNessuna valutazione finora

- Palm Kernel Oil Mill ProjectDocumento8 paginePalm Kernel Oil Mill Projectsjr141071100% (2)

- MSDS G12Documento4 pagineMSDS G12JayNessuna valutazione finora

- Ah 9315Documento1 paginaAh 9315scanmidiaNessuna valutazione finora

- Hilton EMEA Energy Water-Efficient Design Companion Guide - Final - V - 1.0Documento41 pagineHilton EMEA Energy Water-Efficient Design Companion Guide - Final - V - 1.0virtechNessuna valutazione finora

- Plastic and Environmental PollutionDocumento13 paginePlastic and Environmental PollutionAli KhalidNessuna valutazione finora

- DistillationDocumento15 pagineDistillationRahul PalsNessuna valutazione finora

- R5000 PriceInfoSheetDocumento2 pagineR5000 PriceInfoSheetDominique OnealNessuna valutazione finora

- Alternators and Starter Motors 2003 PDFDocumento106 pagineAlternators and Starter Motors 2003 PDFjovopavlovic100% (4)

- Additive Manufacturing For 3-Dimensional (3D) Structures: (Emphasis On 3D Printing)Documento153 pagineAdditive Manufacturing For 3-Dimensional (3D) Structures: (Emphasis On 3D Printing)mohammadmehrabi9640Nessuna valutazione finora

- H1 SteeringDocumento225 pagineH1 SteeringVinay Kumar NeelamNessuna valutazione finora

- Wind Loads Per ASCE 7-98 or 1997 UBC 2Documento13 pagineWind Loads Per ASCE 7-98 or 1997 UBC 2dksheaNessuna valutazione finora

- Mba Pom Exam 122019Documento6 pagineMba Pom Exam 122019Ped SalvadorNessuna valutazione finora

- Appendix I - AirDocumento155 pagineAppendix I - AirTown of Colonie LandfillNessuna valutazione finora

- Anchorage To Concrete - Means and MethodsDocumento28 pagineAnchorage To Concrete - Means and MethodsMustafaNessuna valutazione finora

- Technical Data Sheet for Zinc PrimerDocumento4 pagineTechnical Data Sheet for Zinc PrimerBiju_PottayilNessuna valutazione finora

- Data Industri JabodetabekDocumento669 pagineData Industri JabodetabekBudy Nugraha88% (24)

- Metal Spinning Machines Technical Data 2007Documento2 pagineMetal Spinning Machines Technical Data 2007Andres Lp100% (1)