Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

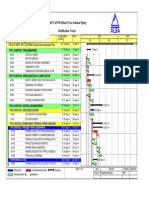

Yarnima Power Station Construction Schedule (Updated On 07-02-14)

Caricato da

arslanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Yarnima Power Station Construction Schedule (Updated On 07-02-14)

Caricato da

arslanCopyright:

Formati disponibili

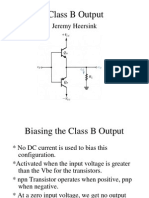

YARNIMA POWER STATION

5242-C-53000

CONSTRUCTION SCHEDULE

Activity ID

Activity Name

YARNIMA YARNIMA PS ACTUALISED Draft CP Rev 02

YARNIMA.1 PROJECT MILESTONES

Original

Duration

Start

Finish

Budgeted

Labor Units

Total

Float

Activity % S

Complete

495

15-10-2012 A

29-06-2014

371579

YARNIMA YARNIMA PS ACTUA

494

15-10-2012 A

27-06-2014

YARNIMA.1 PROJECT MILEST

15-10-2012 A

A1000

Approval of Preliminary Work

100%

A1020

Full Award of Contract

03-01-2013 A

100%

A3390

Stage 1 Complete (GT3 Pre-Commissioned)

27-09-2013 A

100%

A1010

BSDG Installed

24-03-2014

95

0%

A1030

Project Complete

27-06-2014*

0%

16-01-2013 A

55

YARNIMA.1.1 PAYMENT MILESTONES 1

21-12-2012 A

Schedule 4 Deliverables Approved Prior to Mobilisation to Site

21-12-2012 A

100%

A4270

Completion of Mobilisation

16-01-2013 A

100%

27-09-2013 A

27-09-2013 A

11-03-2014

108

A4290

GTG3 Pre-Commissioning Complete

27-09-2013 A

0

19

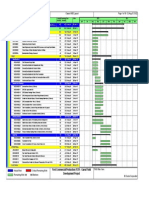

YARNIMA.1.3 PAYMENT MILESTONES 3

20-02-2014

Approval of Preliminary Work

Full Award of Contract

Stage 1 Complete (GT3 Pre-Commissioned)

BSDG Installed

Project Complete

YARNIMA.1.1 PAYMENT MILESTONES 1

A4260

YARNIMA.1.2 PAYMENT MILESTONES 2

Schedule 4 Deliverables Approved Prior to Mobilisation to Site

Completion of Mobilisation

YARNIMA.1.2 PAYMENT MILESTONES 2

100%

GTG3 Pre-Commissioning Complete

YARNIMA.1.3 PAYMENT MILESTONES 3

A4300

Finish Installation of Gas Turbine Generator (GTG) - 2

20-02-2014

127

0%

A4310

Finish Installation of Gas Turbine Generator (GTG) - 1

11-03-2014

108

0%

12-06-2014

15

Finish Installation of Gas Turbine Generator (GTG

YARNIMA.1.4 PAYMENT MILEST

Finish Installation of Heat Recovery Steam Ge

71

YARNIMA.1.4 PAYMENT MILESTONES 4

02-04-2014

Finish Installation of Gas Turbine Generator (GTG) -

A4320

Finish Installation of Heat Recovery Steam Generator (HRSG) - 3

02-04-2014

86

0%

A4360

Finish Installation of Cooling Tower 2

11-04-2014

77

0%

Finish Installation of Cooling Tower 2

A4340

Finish Installation of Heat Recovery Steam Generator (HRSG) - 2

15-04-2014

73

0%

Finish Installation of Heat Recovery Steam G

A4350

Finish Installation of Steam Turbine Generator (STG) - 1

05-05-2014

53

0%

Finish Installation of Steam Turbine Gene

A22860

Finish Installation of Cooling Tower 1

11-05-2014

47

0%

Finish Installation of Cooling Tower 1

A4330

Finish Installation of Heat Recovery Steam Generator (HRSG) - 1

16-05-2014

42

0%

Finish Installation of Heat Recovery Ste

A4370

Finish Installation of Steam Turbine Generator (STG) - 2

12-06-2014

15

0%

YARNIMA.5 PRELIMINARIES

21

15-10-2012 A

21-12-2012 A

Finish Installation of Steam Turbine

YARNIMA.5 PRELIMINARIES

A4400

Lodgement of Securities

14

15-10-2012 A

21-12-2012 A

100%

A4410

Cert of Currency for Insurances

14

15-10-2012 A

07-11-2012 A

100%

A4420

Construction Management Plan

21

15-10-2012 A

16-11-2012 A

100%

Construction Management Plan

A4440

Construction Schedule

21

15-10-2012 A

15-11-2012 A

100%

Construction Schedule

A4450

HSEP

21

15-10-2012 A

12-11-2012 A

100%

HSEP

A4460

HSMP

21

15-10-2012 A

12-11-2012 A

100%

A4470

Quality Management Plan

21

15-10-2012 A

07-11-2012 A

100%

A4480

MDR Index & Contents Prep

21

15-10-2012 A

12-11-2012 A

100%

MDR Index & Contents Prep

A4490

Engineering Management Plan

21

15-10-2012 A

07-11-2012 A

100%

Engineering Management Plan

A4510

TNA

21

15-10-2012 A

12-11-2012 A

100%

TNA

A4590

Environmental Management Plan

21

15-10-2012 A

12-11-2012 A

100%

Environmental Management Plan

A4600

HR/IR/ER Management Plan

21

15-10-2012 A

12-11-2012 A

100%

A4620

CRAW

21

15-10-2012 A

06-11-2012 A

100%

A4610

Contractor Contracts & Procurement Plan

14

02-11-2012 A

16-11-2012 A

100%

23

02-01-2013 A

28-01-2013 A

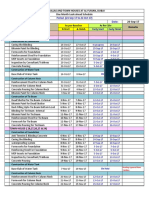

YARNIMA.12 MOBILISATION & SITE SETUP

Lodgement of Securities

Cert of Currency for Insurances

HSMP

Quality Management Plan

HR/IR/ER Management Plan

CRAW

Contractor Contracts & Procurement Plan

YARNIMA.12 MOBILISATION & SITE SETUP

A1500

Site Access

02-01-2013 A

100%

A1510

Mobilise Construction Personnel & Equipment

18

02-01-2013 A

18-01-2013 A

100%

A1510-1

Mobilization Personal

02-01-2013 A

28-01-2013 A

100%

A1510-2

Unloading of 400T Crawler Crane

06-01-2013 A

09-01-2013 A

100%

Unloading of 400T Crawler Crane

A1510-3

Unloading and Set-Up of Site Facilities

10-01-2013 A

13-01-2013 A

100%

Unloading and Set-Up of Site Facilities

A1510-6

VOC Training

10-01-2013 A

20-01-2013 A

100%

A1530-1

Main Office

11-01-2013 A

12-01-2013 A

100%

Main Office

A1510-5

Unloading Plant and Equipment

12-01-2013 A

15-01-2013 A

100%

Unloading Plant and Equipment

A1510-4

Assembly of 400T Crawler Crane

13-01-2013 A

16-01-2013 A

100%

Assembly of 400T Crawler Crane

A1530-2

2 * Cribs Huts

13-01-2013 A

14-01-2013 A

100%

2 * Cribs Huts

Actual Work

Primary Baseline

Remaining Work

Baseline Milestone

Critical Remaining Work

Milestone

Summary

Page 1 of 38

Data Date 07-02-2014

Date

19-Dec-12

21-11-2013

07-02-2014

Revision

APPROVED CONSTR SCHED BASELINE REV O

APPROVED ACP Rev 01

Updated Construction Schedule

Site Access

Mobilise Construction Personnel & Equipment

Mobilization Personal

VOC Training

Checked

Approved

WC

KU

KU

TL

Document Number: C1034-22.1-00PRJ-PL-001d

Project ID: YAR - PROGRAM-1

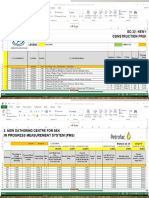

Activity ID

Activity Name

Original

Duration

Start

Finish

Budgeted

Labor Units

Total

Float

Activity % S

Complete

A1520

Commence Major Works

14-01-2013 A

100%

Commence Major Works

A1530-3

Toilet Block

14-01-2013 A

15-01-2013 A

100%

Toilet Block

A1530

Establish Site Facilities (priliminaries)

16-01-2013 A

17-01-2013 A

100%

Establish Site Facilities (priliminaries)

A1530-4

Temporary Crib Huts

17-01-2013 A

18-01-2013 A

100%

Temporary Crib Huts

A2140

Survey (to Commence Works)

18-01-2013 A

19-01-2013 A

100%

Survey (to Commence Works)

256

14-03-2013 A

01-12-2013 A

YARNIMA.2 Delay Events

139

30-07-2013 A

01-12-2013 A

YARNIMA.2.3 Cooling Tower

YARNIMA.2 Delay Events

YARNIMA.2.3 Cooling Tower

NCR-S166

BOP: STG Trench Set Out

30-07-2013 A

31-07-2013 A

100%

NCR-S170

BOP: KBE DN1000 SDR13.6 12m Pipe Length Does Not Meet AS4130 (internal)

13

01-08-2013 A

14-08-2013 A

100%

HP1050

Delayed access for Hamon _ Foundation and Plynths North of Cooling Towers

09-09-2013 A

100%

NCR-S347

Cable Ladder Tie in - Piperack to BSDG Switchroom

15-11-2013 A

21-11-2013 A

100%

Cable Ladder Tie in - Piperack to BSDG Switchroom

NCR-S362

Cooling Tower Fan Gearbox Non-Conformance

27-11-2013 A

01-12-2013 A

100%

29-11-2013 A

29-11-2013 A

Cooling Tower Fan Gearbox Non-Conformance

YARNIMA.2.4 Civil Works by Others

YARNIMA.2.4 Civil Works by Others

HP1040

Access to complete Cable Tray Support Structures at all HRSG's North

YARNIMA.2.1 Cooling Water Piping

DE1000

Delayed Access to Allow Excavation

YARNIMA.4 Variation Works

YARNIMA.4.3 GPRS Installation

29-11-2013 A

14-03-2013 A

26-04-2013 A

14-03-2013 A

26-04-2013 A

09-03-2013 A

25-11-2013 A

10157

192

12-04-2013 A

25-11-2013 A

6779

BOP: KBE DN1000 SDR13.6 12m Pipe Length Does Not Meet AS4130 (internal)

Delayed access for Hamon _ Foundation and Plynths Nor

100%

Access to complete Cable Tray Support Structures at all H

YARNIMA.2.1 Cooling Water Piping

311

BOP: STG Trench Set Out

100%

Delayed Access to Allow Excavation

YARNIMA.4 Variation Works

YARNIMA.4.3 GPRS Installation

A19690

Electrical Pre-commissioning

02-07-2013 A

19-07-2013 A

130

100%

Electrical Pre-commissioning

A19790

Mechanical Pre-Commissioning

16-07-2013 A

19-07-2013 A

260

100%

Mechanical Pre-Commissioning

VEGPRS100

VE GPRS - Commission Assistance, Install 00DB060 and 00BJA60, Install FOC and Pipe

31 Support

19-07-2013 A

16-08-2013 A

901

100%

VE GPRS - Commission Assistance, Install 00DB060 and 00BJA60, Install FOC a

VEGPRS110

VE GPRS -RMWS 80 Install PTFE Insulation Strips on the sections of piping requiring 2U bolts 28-08-2013 A

29-08-2013 A

50

100%

VE GPRS -RMWS 80 Install PTFE Insulation Strips on the sections of piping re

VEGPRS120

VE GPRS - Install temporary earth for spark gap arrestor. MWR 131 and commissioning

13 support

10-09-2013 A

24-09-2013 A

69

100%

VE GPRS - Install temporary earth for spark gap arrestor. MWR 131 and c

VEGPRS130

VE GPRS - Punchlisting items Worley Parson Directed, and commissioning support 12

30-09-2013 A

13-10-2013 A

104

100%

VE GPRS - Punchlisting items Worley Parson Directed, and commission

VEGPRS140

VE GPRS - GPRS mods, Cathodic Protection Installation, provide scaffolding access, Mods

13 to PLatforms)

25-10-2013 A

07-11-2013 A

246

100%

VE GPRS - GPRS mods, Cathodic Protection Installation, provide sc

VEGPRS150

VE GPRS - Punchlist - Cable Ladder Cover and Sealing conduits, and Cathodic Protection

3

Installation

23-11-2013 A

25-11-2013 A

48

100%

VE GPRS - Punchlist - Cable Ladder Cover and Sealing conduits,

YARNIMA.4.3.1 Electrical Works

YARNIMA.4.3.1 Electrical Works

A19620

Site Earthing Installation

116

15

03-05-2013 A

03-05-2013 A

02-09-2013 A

07-07-2013 A

1517

670

100%

Site Earthing Installation

184

100%

EI&C LV Cable Installation

A19670

EI&C LV Cable Installation

14-05-2013 A

25-06-2013 A

A19630

Cable Ladder Installation

22-05-2013 A

22-05-2013 A

61

100%

A19650

Lighting & Small Power Installation

24-05-2013 A

16-07-2013 A

141

100%

NCR-S104

Conduit and cable ladder installation in GPRS area

13

04-06-2013 A

17-06-2013 A

100%

NCR-S105

Posy junction box is not suitable for the size of cable in GPRS area

25

04-06-2013 A

30-06-2013 A

100%

NCR-S106

GPRS: The light fitting does not suit the pole light

13

04-06-2013 A

17-06-2013 A

100%

A19680

EI&C LV Cable Termination

19-06-2013 A

19-07-2013 A

275

100%

EI&C LV Cable Termination

A19660

Electrical Equipment / Instrumentation Installation

08-07-2013 A

18-07-2013 A

186

100%

Electrical Equipment / Instrumentation Installation

NCR-S150

Light Pole Washers In GPRS Area Do Not Comply With AS4100

08-07-2013 A

11-07-2013 A

100%

NCR-S199

GPRS: Location of Surge Divertor

25-08-2013 A

02-09-2013 A

100%

YARNIMA.4.3.2 Mechanical and Piping

NCR-S066

GPRS: Water Baths Heater Skid Mounting holes Incorrect

102

43

12-04-2013 A

12-04-2013 A

04-08-2013 A

27-05-2013 A

2897

0

100%

Cable Ladder Installation

Lighting & Small Power Installation

Conduit and cable ladder installation in GPRS area

Posy junction box is not suitable for the size of cable in GPRS area

GPRS: The light fitting does not suit the pole light

Light Pole Washers In GPRS Area Do Not Comply With AS4100

GPRS: Location of Surge Divertor

YARNIMA.4.3.2 Mechanical and Piping

GPRS: Water Baths Heater Skid Mounting holes Incorrect

A19730

Fit Up Pipework

07-06-2013 A

26-06-2013 A

1417

100%

NCR-S108

GPRS Area Handrails & Gridmesh Non Compliant

08-06-2013 A

14-06-2013 A

100%

A19700

Install PVC Skid Stairs

09-06-2013 A

10-06-2013 A

560

100%

Install PVC Skid Stairs

A19710

Install Crossover 1

09-06-2013 A

09-06-2013 A

28

100%

Install Crossover 1

A19740

Weld Pipework

09-06-2013 A

09-06-2013 A

132

100%

Weld Pipework

NCR-S112

GPRS - Company Supplied Piping Cleanliness

21

09-06-2013 A

01-07-2013 A

100%

GPRS - Company Supplied Piping Cleanliness

A19720

Install Crossover 2

10-06-2013 A

28-06-2013 A

112

100%

Install Crossover 2

NCR-S121

GPRS Area Missing Equipment

18

16-06-2013 A

04-07-2013 A

100%

GPRS Area Missing Equipment

NCR-S122

GPRS Area - Pipe Support Required

16-06-2013 A

20-06-2013 A

100%

GPRS Area - Pipe Support Required

A19750

NDT

26-06-2013 A

10-07-2013 A

100%

NDT

A20860

Install Control Hut

07-07-2013 A

15-07-2013 A

518

100%

Install Control Hut

A19640

Painting

08-07-2013 A

15-07-2013 A

130

100%

Painting

A19770

Pneumatic Testing

10-07-2013 A

17-07-2013 A

100%

Pneumatic Testing

NCR-S160

GPRS Water Bath Heater Switchboard Roof

11

24-07-2013 A

04-08-2013 A

100%

Actual Work

Primary Baseline

Remaining Work

Baseline Milestone

Critical Remaining Work

Milestone

Summary

Page 2 of 38

Data Date 07-02-2014

Date

19-Dec-12

21-11-2013

07-02-2014

Revision

APPROVED CONSTR SCHED BASELINE REV O

APPROVED ACP Rev 01

Updated Construction Schedule

Fit Up Pipework

GPRS Area Handrails & Gridmesh Non Compliant

GPRS Water Bath Heater Switchboard Roof

Checked

Approved

WC

KU

KU

TL

Document Number: C1034-22.1-00PRJ-PL-001d

Project ID: YAR - PROGRAM-1

Activity ID

Activity Name

YARNIMA.4.3.3 Civil Works

A19760

Grouting

Original

Duration

Start

Finish

Budgeted

Labor Units

Total

Float

Activity % S

Complete

64

3

12-06-2013 A

12-06-2013 A

15-07-2013 A

10-07-2013 A

557

210

100%

Civil Works

18-06-2013 A

15-07-2013 A

347

100%

NCR-S133

Verticality of Control Hut @ GPRS

13

21-06-2013 A

04-07-2013 A

100%

220

09-03-2013 A

30-07-2013 A

3378

09-03-2013 A

13-05-2013 A

818

100%

VO's #10, #11

09-04-2013 A

30-07-2013 A

2560

100%

360

15-10-2012 A

03-12-2013 A

37907

30

15-10-2012 A

01-02-2013 A

30

0

0

15-10-2012 A

24-11-2012 A

24-11-2012 A

01-02-2013 A

24-11-2012 A

0

0

0

100%

24-11-2012 A

100%

0

0

17-10-2012 A

17-10-2012 A

0

0

HRSG 3 GA & Detailed Assembly Dwgs

YARNIMA.11.5.1.2 CIVIL

100%

Stage 1 Buried ServicesTrench Layout Dwgs AFC

17-10-2012 A

100%

YARNIMA.11.5.1.3 STRUCTURAL

A5380

Stage 1 Piperack Dwgs AFC

0

0

15-10-2012 A

15-10-2012 A

15-10-2012 A

0

0

Stage 1 Buried Pit Dwgs AFC

YARNIMA.11.5.1.3 STRUCTURAL

100%

YARNIMA.11.5.1.4 MECHANICAL

A5450

Stage 1 Valve List Issued

42

0

01-11-2012 A

01-11-2012 A

01-02-2013 A

0

0

Stage 1 Piperack Dwgs AFC

YARNIMA.11.5.1.4 MECHANICAL

100%

A5970

HRSG 3 GA & Detailed Assembly Dwgs

YARNIMA.11.5.1.2 CIVIL

A5360

Stage 1 Buried ServicesTrench Layout Dwgs AFC

A5840

Stage 1 Buried Pit Dwgs AFC

17-10-2012 A

Stage 1 Valve List Issued

A5430

Stage 1 GAs & Mechanical Sections Issued

01-02-2013 A

100%

A5870

Stage 1 Ancillary Services Piping Isometrics Issued

01-02-2013 A

100%

2

0

30-10-2012 A

30-10-2012 A

0

0

Stage 1 Ancillary Services Piping Isometrics Issued

YARNIMA.11.5.1.5 ELECTRICAL

Stage 1 Gas Pipe Isometrics Issued

Stage 1 GAs & Mechanical Sections Issued

100%

Stage 1 Common Cable Sched & Electrical MTO Issued

A5470

GT3 Electrical Dwgs AFC

04-11-2012 A

100%

GT3 Electrical Dwgs AFC

A13620

HRSG3 Electrical Dwgs AFC

04-11-2012 A

100%

YARNIMA.11.5.1.6 INSTRUMENTATION

A5540

GT3 Instrument Data Sheets & Cable Sched AFC

22

0

19-11-2012 A

19-11-2012 A

0

0

HRSG3 Electrical Dwgs AFC

YARNIMA.11.5.1.6 INSTRUMENTATION

100%

GT3 Instrument Data Sheets & Cable Sched AFC

19-11-2012 A

100%

35

0

0

30-11-2012 A

30-11-2012 A

30-11-2012 A

0

0

0

GT3 Instrument Location & Termination Information Issued

YARNIMA.11.5.2 CONSTRUCTION DELIVERABLES

YARNIMA.11.5.2.1 CIVIL WORKS

25-01-2013 A

30-11-2012 A

100%

GT3 Fnd Ready for Equip

A5700

HRSG3 Fnd Ready for Equip

30-11-2012 A

100%

HRSG3 Fnd Ready for Equip

A5710

Stage 1 Culverts & Fnds (Switchrooms- Piperacks & Battery Rooms) Ready for Equip 0

30-11-2012 A

100%

0

0

25-01-2013 A

25-01-2013 A

25-01-2013 A

0

0

Stage 1 Culverts & Fnds (Switchrooms- Piperacks & Battery Rooms) Ready for Equip

YARNIMA.11.5.2.2 ELECTRICAL WORKS

100%

77

05-11-2012 A

11-03-2013 A

77

0

05-11-2012 A

05-11-2012 A

11-03-2013 A

0

0

100%

YARNIMA.11.5.2.2 ELECTRICAL WORKS

A1110

Stage 1 MV Cables Supplied

YARNIMA.11.7 COMPANY SUPPLIED ITEMS

YARNIMA.11.7.2 GAS TURBINE 3 & ASSOCIATED EQUIPMENT

A1120

GT3 & Assoc Equipment

GT3 Auxillary 1.5 MVA Transformer

13-02-2013 A

100%

A1140

GT3 Switchroom

11-03-2013 A

100%

A1150

GT3 Battery Room

11-03-2013 A

100%

21

0

14-02-2013 A

14-02-2013 A

0

0

100%

01-03-2013 A

100%

127

15-10-2012 A

23-04-2013 A

127

64

21

15-10-2012 A

17-10-2012 A

17-10-2012 A

27-03-2013 A

08-03-2013 A

15-11-2012 A

0

0

0

100%

A1760

HRSG3 Instruments- Sampling- CEMS & Heat Exchangers

YARNIMA.11.6 PROCUREMENT

YARNIMA.11.6.2 MECHANICAL

YARNIMA.11.6.2.5 PIPE SUPPORTS

A10260

Finalise tender package for Stage 1 Pipe Supports

01-03-2013 A

Stage 1 MV Cables Supplied

YARNIMA.11.7 COMPANY SUPPLIED ITEMS

YARNIMA.11.7.2 GAS TURBINE 3 & ASSOCIATED EQUIPMENT

A1130

YARNIMA.11.7.3 HRSG 3 BYPASS STACK

A1300

HRSG3 Bypass Stack

GT3 & Assoc Equipment

GT3 Auxillary 1.5 MVA Transformer

GT3 Switchroom

GT3 Battery Room

YARNIMA.11.7.3 HRSG 3 BYPASS STACK

HRSG3 Bypass Stack

HRSG3 Instruments- Sampling- CEMS & Heat Exchangers

YARNIMA.11.6 PROCUREMENT

YARNIMA.11.6.2 MECHANICAL

YARNIMA.11.6.2.5 PIPE SUPPORTS

Finalise tender package for Stage 1 Pipe Supports

A10280

Shop Detailing Stage 1 Pipe Supports

14

15-12-2012 A

05-03-2013 A

100%

Shop Detailing Stage 1 Pipe Supports

A10270

Fabricate Stage 1 Pipe Supports

17

02-01-2013 A

01-03-2013 A

100%

Fabricate Stage 1 Pipe Supports

A10290

Surface Treatment Stage 1 Pipe Supports

17

16-01-2013 A

07-03-2013 A

100%

Surface Treatment Stage 1 Pipe Supports

A10300

Delivery Stage 1 Pipe Supports

04-03-2013 A

08-03-2013 A

100%

92

21

15-10-2012 A

15-10-2012 A

12-03-2013 A

12-11-2012 A

0

0

Delivery Stage 1 Pipe Supports

YARNIMA.11.6.2.1 PIPERACK

100%

YARNIMA.11.6.2.1 PIPERACK

A1340

Finalise tender package for Stage 1 Piperack

Actual Work

Primary Baseline

Remaining Work

Baseline Milestone

Critical Remaining Work

Milestone

Summary

Page 3 of 38

Data Date 07-02-2014

Date

19-Dec-12

21-11-2013

07-02-2014

GT 3 GA & Detailed Assembly Dwgs

100%

YARNIMA.11.5.2 CONSTRUCTION DELIVERABLES

YARNIMA.11.5.2.1 CIVIL WORKS

A5690

GT3 Fnd Ready for Equip

YARNIMA.11.5.1 ENGINEERING DELIVERABLES

YARNIMA.11.5.1.1 GA & DETAILED ASSEMBLY DWGS

GT3 Instrument Location & Termination Information Issued

YARNIMA.11.5 COMPANY DELIVERABLES

21-12-2012 A

A5550

YARNIMA.11 PHASE 1

19-11-2012 A

VO's #10, #11

Stage 1 Gas Pipe Isometrics Issued

04-11-2012 A

VO's #2, #5

A5400

YARNIMA.11.5.1.5 ELECTRICAL

A5520

Stage 1 Common Cable Sched & Electrical MTO Issued

Verticality of Control Hut @ GPRS

YARNIMA.4.4 Approved Events

VO's #2, #5

YARNIMA.11.5.1 ENGINEERING DELIVERABLES

YARNIMA.11.5.1.1 GA & DETAILED ASSEMBLY DWGS

A5960

GT 3 GA & Detailed Assembly Dwgs

Civil Works

A23000

YARNIMA.11.5 COMPANY DELIVERABLES

Grouting

A23010

YARNIMA.11 PHASE 1

YARNIMA.4.3.3 Civil Works

A20850

YARNIMA.4.4 Approved Events

Revision

APPROVED CONSTR SCHED BASELINE REV O

APPROVED ACP Rev 01

Updated Construction Schedule

Finalise tender package for Stage 1 Piperack

Checked

Approved

WC

KU

KU

TL

Document Number: C1034-22.1-00PRJ-PL-001d

Project ID: YAR - PROGRAM-1

Activity ID

Activity Name

Original

Duration

Start

Finish

Budgeted

Labor Units

Total

Float

Activity % S

Complete

A5610

Shop Detailing Stage 1 Piperack

28

14-12-2012 A

07-02-2013 A

100%

Shop Detailing Stage 1 Piperack

A5580

Fabricate Stage 1 Piperack

19

14-01-2013 A

05-02-2013 A

100%

Fabricate Stage 1 Piperack

A5920

Surface Treatment Stage 1 Piperack

13

05-02-2013 A

12-03-2013 A

100%

Surface Treatment Stage 1 Piperack

A5930

Delivery Stage 1 Piperack

22

10-02-2013 A

10-03-2013 A

100%

58

21

21-10-2012 A

21-10-2012 A

27-03-2013 A

17-12-2012 A

0

0

Delivery Stage 1 Piperack

YARNIMA.11.6.2.3 GAS PIPE & FITTINGS

100%

Finalise Vendor Design Deliverables

18-12-2012 A

100%

Confirm Vendor

YARNIMA.11.6.2.3 GAS PIPE & FITTINGS

A8600

Finalise Vendor Design Deliverables

A8610

Confirm Vendor

A8620

Client Review & Comment

18-12-2012 A

24-12-2012 A

100%

A8630

Include Comments

01-01-2013 A

04-01-2013 A

100%

Include Comments

A8640

Submit For Final Approval

04-01-2013 A

100%

Submit For Final Approval

A8650

Client Final Approval

05-01-2013 A

12-01-2013 A

100%

Client Final Approval

A8660

Issue PO

13-01-2013 A

14-01-2013 A

100%

Issue PO

A8670

Manufacture & Deliver Gas Piping & Fittings

16

14-01-2013 A

27-03-2013 A

100%

127

7

01-11-2012 A

01-11-2012 A

02-03-2013 A

21-12-2012 A

0

0

100%

Finalise Vendor Design Deliverables

21-12-2012 A

100%

Confirm Vendor

YARNIMA.11.6.2.4 GAS VALVES

A8680

Finalise Vendor Design Deliverables

A8700

Client Review & Comment

21-12-2012 A

21-12-2012 A

100%

Client Review & Comment

A8710

Include Comments

21-12-2012 A

21-12-2012 A

100%

Include Comments

A8720

Submit For Final Approval

21-12-2012 A

100%

Submit For Final Approval

A8730

Client Final Approval

21-12-2012 A

20-01-2013 A

100%

A8740

Issue PO

01-02-2013 A

02-02-2013 A

100%

A8750

Manufacture & Deliver Gas Valves

103

02-02-2013 A

02-03-2013 A

100%

56

56

15-12-2012 A

15-12-2012 A

21-03-2013 A

21-03-2013 A

0

0

Manufacture & Deliver Gas Valves

YARNIMA.11.6.2.8 HDPE PIPING

100%

107

16

16

11-11-2012 A

11-11-2012 A

11-11-2012 A

23-04-2013 A

02-03-2013 A

02-03-2013 A

0

0

0

Stage 1 HDPE Piping (Review- Procure & Deliver)

YARNIMA.11.6.3 ELECTRICAL

YARNIMA.11.6.3.1 STAGE 1 ELECTRICAL EQUIPMENT

100%

125

28

26-11-2012 A

26-11-2012 A

08-03-2013 A

06-03-2013 A

0

0

GT3 Electrical Equip (Review- Procure & Deliver)

YARNIMA.11.6.3.2 STAGE 1 CABLE

100%

Stage 1 Cable & Elec Equip (Review- Procure & Deliver)

90

30-12-2012 A

08-03-2013 A

100%

99

7

19-11-2012 A

19-11-2012 A

23-04-2013 A

21-12-2012 A

0

0

Stage 1 VSD & Other Specialist Cable (Review- Procure & Deliver)

YARNIMA.11.6.3.4 STAGE 1 INSTRUMENTATION

100%

Finalise Vendor Design Deliverables

21-12-2012 A

100%

Confirm Vendor

YARNIMA.11.6.3.2 STAGE 1 CABLE

A5630

Stage 1 Cable & Elec Equip (Review- Procure & Deliver)

A7950

Stage 1 VSD & Other Specialist Cable (Review- Procure & Deliver)

YARNIMA.11.6.3.4 STAGE 1 INSTRUMENTATION

A8760

Finalise Vendor Design Deliverables

Client Final Approval

Issue PO

A8770

Confirm Vendor

A8780

Client Review & Comment

21-12-2012 A

21-12-2012 A

100%

Client Review & Comment

A8790

Include Comments

21-12-2012 A

21-12-2012 A

100%

Include Comments

A8800

Submit For Final Approval

21-12-2012 A

100%

Submit For Final Approval

A8810

Client Final Approval

21-12-2012 A

21-12-2012 A

100%

Client Final Approval

A8820

Issue PO

22-12-2012 A

08-01-2013 A

100%

A8830

Manufacture & Deliver Stage 1 Instr & Controls

80

26-01-2013 A

23-04-2013 A

100%

342

02-01-2013 A

03-12-2013 A

37907

52

52

0

02-01-2013 A

02-01-2013 A

02-01-2013 A

11-03-2013 A

31-01-2013 A

0

0

0

YARNIMA.11.8 PHASE 1 CONSTRUCTION

YARNIMA.11.8.5 PRELIMINARIES

YARNIMA.11.8.5.1 SERVICES

A1950

Receipt Verification of Stage 1 Culverts & Fnds (Switchroom & Battery Room)

Issue PO

Manufacture & Deliver Stage 1 Instr & Controls

YARNIMA.11.8 PHASE 1 CONSTRUCTION

YARNIMA.11.8.5 PRELIMINARIES

YARNIMA.11.8.5.1 SERVICES

100%

Receipt Verification of Stage 1 Culverts & Fnds (Switchroom & Battery Room)

A7810

Receipt Verification of Stage 1 Culverts

02-01-2013 A

100%

Receipt Verification of Stage 1 Culverts

A9020

Receipt Verification of Stage 1 Piperack Fnds

03-01-2013 A

100%

Receipt Verification of Stage 1 Piperack Fnds

A9110

Receipt Verification of Stage 1 MV Cables

31-01-2013 A

100%

52

0

02-01-2013 A

02-01-2013 A

0

0

YARNIMA.11.8.5.2 GT3

A1540

Receipt Verification of GT3 Fnd

11-03-2013 A

Receipt Verification of Stage 1 MV Cables

YARNIMA.11.8.5.2 GT3

100%

Receipt Verification of GT3 Fnd

A1550

Receipt Verification of GT3 Free Issue Material & Equip

06-01-2013 A

100%

Receipt Verification of GT3 Free Issue Material & Equip

A1870

Receipt Verification of GT3 Auxillary 1.5 MVA Transformer

14-02-2013 A

100%

A1880

Receipt Verification of GT3 Switchroom

11-03-2013 A

100%

Receipt Verification of GT3 Switchroom

A1890

Receipt Verification of GT3 Battery Room

11-03-2013 A

100%

52

0

03-01-2013 A

03-01-2013 A

0

0

Receipt Verification of GT3 Battery Room

YARNIMA.11.8.5.3 HRSG 3

100%

19-01-2013 A

100%

YARNIMA.11.8.5.3 HRSG 3

A7800

Receipt Verification of HRSG3 Fnd

A9360

Receipt Verification of HRSG 3 Free Issue Bypass Stack & Assoc Equip

Actual Work

Primary Baseline

Remaining Work

Baseline Milestone

Critical Remaining Work

Milestone

Summary

Page 4 of 38

Data Date 07-02-2014

02-03-2013 A

Date

19-Dec-12

21-11-2013

07-02-2014

Revision

APPROVED CONSTR SCHED BASELINE REV O

APPROVED ACP Rev 01

Updated Construction Schedule

Manufacture & Deliver Gas Piping & Fittings

YARNIMA.11.6.2.4 GAS VALVES

Confirm Vendor

YARNIMA.11.6.3 ELECTRICAL

YARNIMA.11.6.3.1 STAGE 1 ELECTRICAL EQUIPMENT

A5620

GT3 Electrical Equip (Review- Procure & Deliver)

Client Review & Comment

A8690

YARNIMA.11.6.2.8 HDPE PIPING

A8590

Stage 1 HDPE Piping (Review- Procure & Deliver)

Receipt Verification of GT3 Auxillary 1.5 MVA Transformer

Receipt Verification of HRSG3 Fnd

Receipt Verification of HRSG 3 Free Issue Bypass Stack & Assoc Equip

Checked

Approved

WC

KU

KU

TL

Document Number: C1034-22.1-00PRJ-PL-001d

Project ID: YAR - PROGRAM-1

Activity ID

Activity Name

A9370

Receipt Verification of HRSG 3 Instruments- Sampling- CEMS & Heat Exchangers

YARNIMA.11.8.2 SERVICES

YARNIMA.11.8.2.3 GAS PIPELINE (UNDERGROUND)

YARNIMA.11.8.2.3.1 Excavation and Bedding

A7650

Trenching & Excavation for Underground Gas Pipework & Crossovers

Original

Duration

Start

Finish

Budgeted

Labor Units

Total

Float

Activity % S

Complete

02-03-2013 A

100%

230

33

31

12

25-01-2013 A

08-04-2013 A

08-04-2013 A

08-04-2013 A

09-09-2013 A

26-06-2013 A

25-05-2013 A

25-05-2013 A

4500

1393

162

162

100%

100%

A17020

Excavation and Bedding (Section 3 & 4)

08-04-2013 A

10-04-2013 A

A17010

Excavation and Bedding (Section 1 & 2)

08-04-2013 A

24-05-2013 A

100%

YARNIMA.11.8.2.3.2 Installation and Welding

A7660

Weld & Install Underground Gas Pipework

4

4

12-04-2013 A

12-04-2013 A

31-05-2013 A

31-05-2013 A

1050

1050

100%

YARNIMA.11.8.2.3.4 Pipe Testing

A7670

Test Gas Pipeline

16

16

16-04-2013 A

16-04-2013 A

12-06-2013 A

12-06-2013 A

0

0

100%

YARNIMA.11.8.2.3.3 Backfilling

A7680

Backfill & Compaction

7

7

24-04-2013 A

24-04-2013 A

26-06-2013 A

26-06-2013 A

181

181

100%

156

121

8

08-03-2013 A

08-03-2013 A

08-03-2013 A

12-08-2013 A

05-07-2013 A

27-05-2013 A

1675

399

399

100%

NCR-S071

GTG3: C1034-NCR-S071-Line 3- Pipe Support is clashing with Exhaust Diffuser support

13 leg 28-04-2013 A

11-05-2013 A

100%

NCR-S135

BOP: Pipe Supports without Build Concrete Foundation on-site

YARNIMA.11.8.2.1 GAS PIPELINE (ABOVEGROUND & IN CULVERTS)

YARNIMA.11.8.2.1.2 Install Piperack

A7690

Install Piperack

YARNIMA.11.8.2.1.3 Installlation and Welding of Pipes in Piperack

A7700

Weld & Install Gas Pipeline & Valves in Piperack

12

23-06-2013 A

05-07-2013 A

100%

156

25

15-04-2013 A

15-04-2013 A

12-08-2013 A

19-07-2013 A

559

559

Receipt Verification of HRSG 3 Instruments- Sampling- CEMS & Heat Exchangers

YARNIMA.11.8.2 SERVICES

YARNIMA.11.8.2.3 GAS PIPELINE (UNDERGROUND)

YARNIMA.11.8.2.3.1 Excavation and Bedding

Trenching & Excavation for Underground Gas Pipework & Crossovers

Excavation and Bedding (Section 3 & 4)

Excavation and Bedding (Section 1 & 2)

YARNIMA.11.8.2.3.2 Installation and Welding

Weld & Install Underground Gas Pipework

YARNIMA.11.8.2.3.4 Pipe Testing

Test Gas Pipeline

YARNIMA.11.8.2.3.3 Backfilling

Backfill & Compaction

YARNIMA.11.8.2.1 GAS PIPELINE (ABOVEGROUND & IN CULVERTS)

YARNIMA.11.8.2.1.2 Install Piperack

Install Piperack

GTG3: C1034-NCR-S071-Line 3- Pipe Support is clashing with Exhaust Diffuser support leg

BOP: Pipe Supports without Build Concrete Foundation on-site

YARNIMA.11.8.2.1.3 Installlation and Welding of Pipes in Piperack

100%

Weld & Install Gas Pipeline & Valves in Piperack

A17510

1- Weld and Install EKG Gas Piping (North / South)

10

16-04-2013 A

17-07-2013 A

100%

1- Weld and Install EKG Gas Piping (North / South)

A7701

2- Weld and Install EKG Gas Piping (East/West)

10

21-04-2013 A

19-07-2013 A

100%

NCR-S129

GTG3: Pipe supports ST-02-C-258-350,ST-02-A-258-350 are 258mm high.

11

20-06-2013 A

01-07-2013 A

100%

NCR-S134

GTG3: Gasket Kits Not Available for Connecting SS to Carbon Steel

48

22-06-2013 A

12-08-2013 A

100%

NCR-S147

ByPass 3: ByPass Stack Mounted Pipe Supports - Incorrect Northing

06-07-2013 A

08-07-2013 A

100%

99

13

22-04-2013 A

22-04-2013 A

02-08-2013 A

26-07-2013 A

717

717

100%

22-04-2013 A

25-04-2013 A

100%

1- Install Pipe Support in the Culvert

BOP: Culvert too Short and sitting at incorrect RL

YARNIMA.11.8.2.1.5 Installlation and Welding of Pipes in Culvert

A7720

Weld & Install Gas Pipeline & Valves in Culverts (Culverts Installed by Others)

2- Weld and Install EKG Gas Piping (East/West)

GTG3: Pipe supports ST-02-C-258-350,ST-02-A-258-350 are 258mm high.

GTG3: Gasket Kits Not Available for Connecting SS to Carbon Steel

ByPass 3: ByPass Stack Mounted Pipe Supports - Incorrect Northing

YARNIMA.11.8.2.1.5 Installlation and Welding of Pipes in Culvert

Weld & Install Gas Pipeline & Valves in Culverts (Culverts Installed by Others)

A17450

1- Install Pipe Support in the Culvert

NCR-S069

BOP: Culvert too Short and sitting at incorrect RL

22-04-2013 A

25-04-2013 A

100%

A17340

2- Install EKG Gas Pipe in the Culvert

10

28-04-2013 A

24-07-2013 A

100%

A17360

4- Grout Gas Pipe Supports in Culverts

22-05-2013 A

24-05-2013 A

100%

A17430

3- Weld EKG Gas Piping

25-06-2013 A

26-06-2013 A

100%

NCR-S161

BOP: Culvert on S. Side of HRSG #2 Incorrect Northing

25-07-2013 A

02-08-2013 A

100%

5

5

23-07-2013 A

23-07-2013 A

28-07-2013 A

28-07-2013 A

0

0

BOP: Culvert on S. Side of HRSG #2 Incorrect Northing

YARNIMA.11.8.2.1.4 Pipe Testing

100%

146

13

01-04-2013 A

01-04-2013 A

01-09-2013 A

12-07-2013 A

200

60

Test Gas Pipeline

YARNIMA.11.8.2.2 UNDERGROUND PITS

100%

YARNIMA.11.8.2.1.4 Pipe Testing

A7710

Test Gas Pipeline

YARNIMA.11.8.2.2 UNDERGROUND PITS

A7730

Trenching & Excavation for Underground Pits

2- Install EKG Gas Pipe in the Culvert

4- Grout Gas Pipe Supports in Culverts

3- Weld EKG Gas Piping

Trenching & Excavation for Underground Pits

A7740

Install Underground Pits

34

04-04-2013 A

26-07-2013 A

100

100%

Install Underground Pits

A7760

Backfill & Compaction

20

30-04-2013 A

31-07-2013 A

40

100%

Backfill & Compaction

NCR-S197

BOP: Natural Ground Level on-site

10

22-08-2013 A

01-09-2013 A

100%

211

14

25-01-2013 A

25-01-2013 A

09-09-2013 A

05-07-2013 A

902

80

100%

YARNIMA.11.8.2.4 UNDERGROUND ELECTRICAL CONDUITS

A9000

Trenching & Excavation for Conduits

BOP: Natural Ground Level on-site

YARNIMA.11.8.2.4 UNDERGROUND ELECTRICAL CONDUITS

Trenching & Excavation for Conduits

A9010

Install Conduits

13

27-01-2013 A

12-07-2013 A

772

100%

Install Conduits

A9030

Backfill & Compaction

13

27-01-2013 A

11-07-2013 A

50

100%

Backfill & Compaction

NCR-S228

GTG1: Conduits Entry to Cable Pit

YARNIMA.11.8.2.5 DIRECT BURIED 11KV CABLE TRENCHES

A1660

Cable Trench Excavation- GT 3 to GT3 Switchroom

09-09-2013 A

09-09-2013 A

100%

64

2

04-04-2013 A

04-04-2013 A

30-06-2013 A

29-04-2013 A

330

55

100%

A1680

Backfill & Compact GT3 to GT3 Switchroom

03-05-2013 A

10-05-2013 A

55

100%

A1840

Cable Trench Excavation GT3 Switchroom to GT3 Step Up Transformer

14-05-2013 A

19-05-2013 A

110

100%

A1860

Backfill & Compact GT3 Switchroom to GT3 Step Up Transfor mer

06-06-2013 A

30-06-2013 A

110

100%

342

147

13

16-01-2013 A

22-01-2013 A

22-01-2013 A

03-12-2013 A

25-11-2013 A

04-02-2013 A

33407

6038

0

100%

YARNIMA.11.8.1 GAS TURBINE 3 & ASSOCIATED EQUIPMENT

YARNIMA.11.8.1.6 GTG3 - ACTUAL VARIATIONS & NON SCOPE WORKS

NCR-S001

GTG3: GT3 exhaust diffuser parts incorrect

GTG1: Conduits Entry to Cable Pit

YARNIMA.11.8.2.5 DIRECT BURIED 11KV CABLE TRENCHES

Cable Trench Excavation- GT 3 to GT3 Switchroom

Backfill & Compact GT3 to GT3 Switchroom

Cable Trench Excavation GT3 Switchroom to GT3 Step Up Transformer

Backfill & Compact GT3 Switchroom to GT3 Step Up Transfor mer

YARNIMA.11.8.1 GAS TURBINE 3 & ASSOCIATED EQUIPMEN

YARNIMA.11.8.1.6 GTG3 - ACTUAL VARIATIONS & NON SCOP

GTG3: GT3 exhaust diffuser parts incorrect

NCR-S008

GTG3: The angle cross bracing have been damaged

13

22-01-2013 A

04-04-2013 A

100%

NCR-S023

GTG3: Vendor Supplied WEICON Primer S 300 hardened

13

22-01-2013 A

04-02-2013 A

100%

GTG3: Vendor Supplied WEICON Primer S 300 hardened

NCR-S026

GTG3: Cast in plates embedded to the GT3 Generator are in wrong orientation

13

22-01-2013 A

04-02-2013 A

100%

GTG3: Cast in plates embedded to the GT3 Generator are in wrong orientation

Actual Work

Primary Baseline

Remaining Work

Baseline Milestone

Critical Remaining Work

Milestone

Summary

Page 5 of 38

Data Date 07-02-2014

Date

19-Dec-12

21-11-2013

07-02-2014

Revision

APPROVED CONSTR SCHED BASELINE REV O

APPROVED ACP Rev 01

Updated Construction Schedule

GTG3: The angle cross bracing have been damaged

Checked

Approved

WC

KU

KU

TL

Document Number: C1034-22.1-00PRJ-PL-001d

Project ID: YAR - PROGRAM-1

Activity ID

Activity Name

Original

Duration

Start

Finish

Budgeted

Labor Units

13

Total

Float

Activity % S

Complete

NCR-S003

GTG3 Diffuser expansion joint does not fit to the diffuser ring

30-01-2013 A

04-04-2013 A

100%

GTG3 Diffuser expansion joint does not fit to the diffuser ring

NCR-S004

GTG3: Length of Structural bolts on the Lube Oil Cooler supports does not comply with

13Aus. Standards

30-01-2013 A

04-04-2013 A

100%

GTG3: Length of Structural bolts on the Lube Oil Cooler supports does not comply with Aus. Standard

NCR-S005

GTG3: The Stair on the GT-Room supplied does not fit onto the platform

13

02-02-2013 A

04-04-2013 A

100%

GTG3: The Stair on the GT-Room supplied does not fit onto the platform

NCR-S006

GTG3: The supplied platform in between the GT3 and Starter Motor is 50mm too wide13

08-02-2013 A

04-04-2013 A

100%

GTG3: The supplied platform in between the GT3 and Starter Motor is 50mm too wide

NCR-S007

GTG3: Missing 4No x bolt holes on the beam -004

13

08-02-2013 A

04-04-2013 A

100%

GTG3: Missing 4No x bolt holes on the beam -004

NCR-S009

GTG3: 6 holes missing from walkway platform on the top of the Steel Enclosure

13

08-02-2013 A

04-04-2013 A

100%

GTG3: 6 holes missing from walkway platform on the top of the Steel Enclosure

NCR-S010

GTG3: The centreline of the column no. 1011027 is out by 17mm

13

10-02-2013 A

15-04-2013 A

100%

GTG3: The centreline of the column no. 1011027 is out by 17mm

NCR-S012

The mounting foot on electrical motor 3GV1210878154003 on top of GTG3 lube oil cooler

13 is cracked

14-02-2013 A

15-04-2013 A

100%

The mounting foot on electrical motor 3GV1210878154003 on top of GTG3 lube oil cooler is cracked

NCR-S013

GTG3: Hand Rails, Kick Plates, Ladders, Cages, Hoists are not paint Yellow Y14 as per

125SPEC-000-S-00061

18-02-2013 A

02-07-2013 A

100%

NCR-S014

GTG3 Clashing of conduits and platform support legs

13

19-02-2013 A

19-02-2013 A

100%

NCR-S015

GTG3 Clashing of support leg with lube oil bund

13

19-02-2013 A

04-03-2013 A

100%

GTG3 Clashing of support leg with lube oil bund

NCR-S019

GTG3: C02 Fire Extinguisher Skid Grout

14

21-02-2013 A

07-03-2013 A

100%

GTG3: C02 Fire Extinguisher Skid Grout

NCR-S020

GTG3: Item not paint yellow Y14 as per SPEC-000-S-00061- lifting beam

13

22-02-2013 A

07-03-2013 A

100%

GTG3: Item not paint yellow Y14 as per SPEC-000-S-00061- lifting beam

NCR-S021

GTG3: Short Supplied of Bolt Qty's

13

24-02-2013 A

09-03-2013 A

100%

GTG3: Short Supplied of Bolt Qty's

NCR-S022

GTG3: Sixteen Diffuser instrument require modification

25-02-2013 A

02-03-2013 A

100%

NCR-S024

GTG3: GT3 Stainless Steel Pipe Clashing to the Gridmesh

13

02-03-2013 A

15-03-2013 A

100%

GTG3: GT3 Stainless Steel Pipe Clashing to the Gridmesh

NCR-S025

GTG3: Bolt holes on the Stud beam is out by 30mm

13

03-03-2013 A

16-03-2013 A

100%

GTG3: Bolt holes on the Stud beam is out by 30mm

NCR-S027

GTG3: Duel Fuel Platform Incorrect frame

13

03-03-2013 A

16-03-2013 A

100%

GTG3: Duel Fuel Platform Incorrect frame

NCR-S031

GTG3: Bolt holes in GT3 Air Intake non-compliant with AS4100

13

11-03-2013 A

24-03-2013 A

100%

GTG3: Bolt holes in GT3 Air Intake non-compliant with AS4100

NCR-S032

GTG3: GT3 Installation of Wall Cladding: Clashing of the wall Cladding and Slurry Wall13

11-03-2013 A

24-03-2013 A

100%

GTG3: GT3 Installation of Wall Cladding: Clashing of the wall Cladding and Slurry Wall

NCR-S036

GTG3: GT3 Lube Oil Cooler: Current Cabling does not comply with AS/BHPBIO Standards

20

21-03-2013 A

11-04-2013 A

100%

NCR-S038

GTG3: GTG Generator Ventilation Inlet Duct Obstructing Electrical Cabinet

13

22-03-2013 A

04-04-2013 A

100%

NCR-S039

GTG3: GT3 FAIST Air Inlet Roof Penetration

71

22-03-2013 A

06-06-2013 A

100%

NCR-S041

GTG3: The Air Intake platform have been fabricated to superseded drawings

24

25-03-2013 A

18-04-2013 A

100%

GTG3: The Air Intake platform have been fabricated to superseded drawings

NCR-S043

GTG3: The Supplied 2 x Beams for the Air Intake Step Platform 50mm too long.

13

28-03-2013 A

10-04-2013 A

100%

GTG3: The Supplied 2 x Beams for the Air Intake Step Platform 50mm too long.

NCR-S045

GTG3 generator and hold down bolts washers deflected

13

30-03-2013 A

18-04-2013 A

100%

NCR-S046

GTG3: GT3 Lube Oil Cooler Platform not Level

01-04-2013 A

10-04-2013 A

100%

NCR-S047

GTG3: GT3 Grid mesh clashes

36

01-04-2013 A

09-05-2013 A

100%

NCR-S042

GTG3: Lube Oil Piperack clashes on the GT3 Access Ladder

13

05-04-2013 A

18-04-2013 A

100%

GTG3: Lube Oil Piperack clashes on the GT3 Access Ladder

NCR-S050

GTG3: Kick plate welded in wrong direction and bolt holes in wrong orientation

13

05-04-2013 A

18-04-2013 A

100%

GTG3: Kick plate welded in wrong direction and bolt holes in wrong orientation

NCR-S075

GTG3: GT3 Air Intake Dissimilar Metals Contact

13

09-05-2013 A

01-07-2013 A

100%

NCR-S077

GTG3 Air Intake Evaporative Cooler Bottom Pan Clash

10-05-2013 A

14-05-2013 A

100%

NCR-S086

GTG3 Filter House Module Misalignment

21-05-2013 A

27-05-2013 A

100%

NCR-S087

GTG3: The propane cabinet clashing to the cast-in conduits from the foundation

13

22-05-2013 A

04-06-2013 A

100%

GTG3: The propane cabinet clashing to the cast-in conduits from the foundation

NCR-S088

GTG3: Enclosure Ventilation Fan Outlet Clash with Pipe Support

13

22-05-2013 A

04-06-2013 A

100%

GTG3: Enclosure Ventilation Fan Outlet Clash with Pipe Support

NCR-S092

GTG3: GT-3 Generator cooling duct doesn't line up with inlet duct - 55mm too high

17

29-05-2013 A

16-06-2013 A

100%

GTG3: GT-3 Generator cooling duct doesn't line up with inlet duct - 55mm too high

NCR-S090

GTG3: GT3 Air intake support structure bolt holes misalignment

13

02-06-2013 A

15-06-2013 A

100%

GTG3: GT3 Air intake support structure bolt holes misalignment

NCR-S107

GTG3: GT3 Bleed Air Piping - Unable to Install Insulation

04-06-2013 A

10-06-2013 A

100%

GTG3: GT3 Bleed Air Piping - Unable to Install Insulation

NCR-S109

GTG3: Air Intake Water Piping Clash with Steelwork

19

08-06-2013 A

27-06-2013 A

100%

GTG3: Air Intake Water Piping Clash with Steelwork

NCR-S110

GTG3 C02 Piping - Reroute to Avoid Clashing with the Crane

08-06-2013 A

14-06-2013 A

100%

NCR-S111

GTG3: GT3 Ladder Non-conformances

70

09-06-2013 A

22-08-2013 A

100%

NCR-S115

GTG3: Conduits have not been installed as per drawings

22

09-06-2013 A

02-07-2013 A

100%

NCR-S118

GTG3 Air Intake Electrical Panel Bolting

11-06-2013 A

17-06-2013 A

100%

NCR-S119

GTG3 Enclosure - Bent Members

60

13-06-2013 A

16-08-2013 A

100%

NCR-S130

GTG3: GT3- Lube Oil Unit Piping showing signs of rusting internally

21

20-06-2013 A

11-07-2013 A

100%

NCR-S131

GTG3: GT3 Exhaust Diffuser Piping Flange Connections Clashing

21-06-2013 A

27-06-2013 A

100%

NCR-S146

GTG3: GTG Lube Oil Pipework Welding - Lack of Penetration

60

05-07-2013 A

06-09-2013 A

100%

NCR-S152

GTG3: Pipe Supports Baseplate is clashing with Diffuser baseplate

19

11-07-2013 A

31-07-2013 A

100%

GTG3: Pipe Supports Baseplate is clashing with Diffuser baseplate

RMW025

Provide Temporary 11kV supply from Substation

17

14-07-2013 A

01-08-2013 A

76

100%

Provide Temporary 11kV supply from Substation

VEGT3000

VE GTG 3 - Install extra cables for GT's, commissioning assist for switchroom, punchlists

44

17-07-2013 A

30-08-2013 A

1275

100%

NCR-S162

GTG3 Enclosure Internal Panels Too Short

12

26-07-2013 A

07-08-2013 A

100%

GTG3 Enclosure Internal Panels Too Short

NCR-S163

GTG3 Turbine Coupling Bolts Supplied Damaged

28-07-2013 A

04-08-2013 A

100%

GTG3 Turbine Coupling Bolts Supplied Damaged

NCR-S180

GTG Compressor Wash Down System SDB Clash

07-08-2013 A

14-08-2013 A

100%

NCR-S205

STG1 - missing WN Flanges on Valve

28-08-2013 A

01-09-2013 A

100%

Actual Work

Primary Baseline

Remaining Work

Baseline Milestone

Critical Remaining Work

Milestone

Summary

Page 6 of 38

Data Date 07-02-2014

Date

19-Dec-12

21-11-2013

07-02-2014

Revision

APPROVED CONSTR SCHED BASELINE REV O

APPROVED ACP Rev 01

Updated Construction Schedule

GTG3: Hand Rails, Kick Plates, Ladders, Cages, Hoists are not paint Yellow Y14 as per

GTG3 Clashing of conduits and platform support legs

GTG3: Sixteen Diffuser instrument require modification

GTG3: GT3 Lube Oil Cooler: Current Cabling does not comply with AS/BHPBIO Standards

GTG3: GTG Generator Ventilation Inlet Duct Obstructing Electrical Cabinet

GTG3: GT3 FAIST Air Inlet Roof Penetration

GTG3 generator and hold down bolts washers deflected

GTG3: GT3 Lube Oil Cooler Platform not Level

GTG3: GT3 Grid mesh clashes

GTG3: GT3 Air Intake Dissimilar Metals Contact

GTG3 Air Intake Evaporative Cooler Bottom Pan Clash

GTG3 Filter House Module Misalignment

GTG3 C02 Piping - Reroute to Avoid Clashing with the Crane

GTG3: GT3 Ladder Non-conformances

GTG3: Conduits have not been installed as per drawings

GTG3 Air Intake Electrical Panel Bolting

GTG3 Enclosure - Bent Members

GTG3: GT3- Lube Oil Unit Piping showing signs of rusting internally

GTG3: GT3 Exhaust Diffuser Piping Flange Connections Clashing

GTG3: GTG Lube Oil Pipework Welding - Lack of Penetration

VE GTG 3 - Install extra cables for GT's, commissioning assist for switchroom, p

GTG Compressor Wash Down System SDB Clash

STG1 - missing WN Flanges on Valve

Checked

Approved

WC

KU

KU

TL

Document Number: C1034-22.1-00PRJ-PL-001d

Project ID: YAR - PROGRAM-1

Activity ID

Activity Name

Original

Duration

Start

Finish

Budgeted

Labor Units

Total

Float

Activity % S

Complete

VEGT3010

VE GTG 3 - Punchlisting Mechanical, Earthing, replacing cables, Remedial works HV S/Board

44

30-08-2013 A

15-10-2013 A

3073

100%

NCR-S210

GTG3 Enclosure - Panels Buckle During C02 Dump Test

14

31-08-2013 A

14-09-2013 A

100%

NCR-S212

GTG3 Lube Oil Cooler Internal Cleanliness

28

31-08-2013 A

29-09-2013 A

100%

NCR-S212-936 Clean GTG3 Lube Oil Cooler Internals - A2040

33

31-08-2013 A

04-10-2013 A

309

100%

NCR-S210-954 GTG3 Enclosure Panels - repair

15-09-2013 A

15-09-2013 A

100%

GTG3 Lube Oil Cooler Internal Cleanliness

Clean GTG3 Lube Oil Cooler Internals - A2040

GTG3 Enclosure Panels - repair

VE GTG 3 -Punchlisting Electrical, outage items, commissioning support, Evap drain mods

11

30-10-2013 A

10-11-2013 A

679

100%

VE GTG 3 - Relocate Emergency stop, outage items, commissioning support

19-11-2013 A

25-11-2013 A

626

100%

192

5

16-01-2013 A

16-01-2013 A

18-09-2013 A

19-01-2013 A

10624

100

100%

Prepare Foundations & Fixators

VE GTG 3 -Punchlisting Electrical, outage items, commissioning supp

VE GTG 3 - Relocate Emergency stop, outage items, commission

YARNIMA.11.8.1.1 MECHANICAL GT3

A2060

Placement of Gear Box & Remove Transport Protection

16-01-2013 A

20-01-2013 A

250

100%

Placement of Gear Box & Remove Transport Protection

A2070

Placement of GT

17-01-2013 A

21-01-2013 A

190

100%

Placement of GT

A2150

Placement of Diffuser

18-01-2013 A

24-01-2013 A

190

100%

Placement of Diffuser

A2330

Install Liquid Fuel Unit

22-01-2013 A

31-05-2013 A

300

100%

A2370

Place Starter Motor

22-01-2013 A

12-06-2013 A

150

100%

A2170

Assemble Steel Enclosure

23-01-2013 A

06-03-2013 A

450

100%

A2250

Placement of Generator

23-01-2013 A

26-01-2013 A

190

100%

A2300

Install CO2 Module

24-01-2013 A

31-05-2013 A

250

100%

Install CO2 Module

A2160

Preliminary Alignment of Modules

26-01-2013 A

23-02-2013 A

500

100%

Preliminary Alignment of Modules

A2310

Install Oil Coolers (Including Handrails- Ladders)

12

26-01-2013 A

21-05-2013 A

1120

100%

Install Oil Coolers (Including Handrails- Ladders)

A2270

Install Platforms & Access Stairways

28-01-2013 A

20-05-2013 A

400

100%

Install Platforms & Access Stairways

A2190

Connect Diffuser

05-02-2013 A

03-03-2013 A

380

100%

A2180

Placement of Steel Enclosure

12-02-2013 A

16-03-2013 A

550

100%

A2200

Install Enclusure Pannels and Cladding Around Piping Penetrations

19

24-02-2013 A

10-07-2013 A

2590

100%

A2230

Install Ventilation Ducts- Platform & Access Ladder

20

04-03-2013 A

26-07-2013 A

312

100%

A2240

Assemble Intake Support Structure

13

10-03-2013 A

19-04-2013 A

275

100%

Assemble Intake Support Structure

A2260

Lift Air Intake Structure into Place

11-03-2013 A

26-04-2013 A

300

100%

Lift Air Intake Structure into Place

A2340

Final GTG Alignment

16-03-2013 A

19-07-2013 A

500

100%

Final GTG Alignment

A2380

Install Fire Extinguisher & Equipment

17-03-2013 A

26-07-2013 A

250

100%

A2290

Lift & Install Remaining Air Intake Modules

26-04-2013 A

31-05-2013 A

750

100%

A2220

Install Fuel Gas Skid (Valve Train and Propane)

20-05-2013 A

19-07-2013 A

250

100%

A2350

Install Coupling Units

09-06-2013 A

28-08-2013 A

190

100%

A2390

Install Air Filters & evaporator media

20-07-2013 A

18-09-2013 A

187

100%

107

56

13

13-02-2013 A

14-04-2013 A

14-04-2013 A

06-08-2013 A

11-07-2013 A

11-07-2013 A

3281

990

990

Install Air Filters & evaporator media

YARNIMA.11.8.1.3 PIPING GT3

YARNIMA.11.8.1.3.1 Connect Piping in Enclosure

100%

Connect Piping In Enclosure

Install Liquid Fuel Unit

Place Starter Motor

Assemble Steel Enclosure

Placement of Generator

Connect Diffuser

Placement of Steel Enclosure

Install Enclusure Pannels and Cladding Around Piping Penetrations

Install Ventilation Ducts- Platform & Access Ladder

Install Fire Extinguisher & Equipment

Lift & Install Remaining Air Intake Modules

Install Fuel Gas Skid (Valve Train and Propane)

Install Coupling Units

A18010

1. SDB Wash Water

14-04-2013 A

22-04-2013 A

100%

A18000

2. SDB Drain Water

10

02-05-2013 A

11-07-2013 A

100%

2. SDB Drain Water

A18030

3. QFA Instrument Air

10

20-05-2013 A

11-07-2013 A

100%

64

24

13-02-2013 A

13-02-2013 A

19-07-2013 A

19-07-2013 A

1200

1200

3. QFA Instrument Air

YARNIMA.11.8.1.3.2 Install Inter Skid Piping

YARNIMA.11.8.1.3.2 Install Inter Skid Piping

A2320

Install Inter Skid Piping

1. SDB Wash Water

100%

Install Inter Skid Piping

A17970

1. MBV Lube Oil Piping

13-02-2013 A

14-07-2013 A

100%

1. MBV Lube Oil Piping

A18020

2. MBN Liquid Fuel

10

11-05-2013 A

19-07-2013 A

100%

2. MBN Liquid Fuel

A18040

3. SGJ CO2 Piping

15

20-05-2013 A

19-07-2013 A

100%

17

6

27-06-2013 A

27-06-2013 A

05-07-2013 A

05-07-2013 A

125

125

3. SGJ CO2 Piping

YARNIMA.11.8.1.3.3 Install Fuel Gas Piping/Valve Train

YARNIMA.11.8.1.3.3 Install Fuel Gas Piping/Valve Train

A15620

Install Fuel Gas Skid Piping

100%

Install Fuel Gas Skid Piping

A17990

2. MBP Ignition Gas

27-06-2013 A

05-07-2013 A

100%

2. MBP Ignition Gas

A17980

1. MBP Gas Vent

27-06-2013 A

05-07-2013 A

100%

28

28

02-04-2013 A

02-04-2013 A

30-04-2013 A

30-04-2013 A

32

32

1. MBP Gas Vent

YARNIMA.11.8.1.3.4 Install Bleed Air Pipes

100%

Install Bleed Airpipes

02-04-2013 A

30-04-2013 A

100%

18

11

22-06-2013 A

22-06-2013 A

06-08-2013 A

02-08-2013 A

934

934

MBH Bleed Air Piping

YARNIMA.11.8.1.3.5 Insulation

YARNIMA.11.8.1.3.4 Install Bleed Air Pipes

A14800

Install Bleed Airpipes

A17960

MBH Bleed Air Piping

YARNIMA.11.8.1.3.5 Insulation

A2400

Install Piping Insulation

100%

Install Piping Insulation

A18050

1. Insulate Bleed Air Pipe

22-06-2013 A

06-08-2013 A

100%

1. Insulate Bleed Air Pipe

A18060

2. Insulate Gas Pipe

22-06-2013 A

04-08-2013 A

100%

314

17-02-2013 A

11-10-2013 A

10000

2. Insulate Gas Pipe

YARNIMA.11.8.1.2 ELECTRICAL GT3

YARNIMA.11.8.1.2 ELECTRICAL GT3

Actual Work

Primary Baseline

Remaining Work

Baseline Milestone

Critical Remaining Work

Milestone

Summary

Page 7 of 38

Data Date 07-02-2014

Date

19-Dec-12

21-11-2013

07-02-2014

Revision

APPROVED CONSTR SCHED BASELINE REV O

APPROVED ACP Rev 01

Updated Construction Schedule

VE GTG 3 - Punchlisting Mechanical, Earthing, replacing cables, Remed

VEGT3030

YARNIMA.11.8.1.3 PIPING GT3

YARNIMA.11.8.1.3.1 Connect Piping in Enclosure

A2210

Connect Piping In Enclosure

GTG3 Enclosure - Panels Buckle During C02 Dump Test

VEGT3020

YARNIMA.11.8.1.1 MECHANICAL GT3

A2050

Prepare Foundations & Fixators

Checked

Approved

WC

KU

KU

TL

Document Number: C1034-22.1-00PRJ-PL-001d

Project ID: YAR - PROGRAM-1

Activity ID

Activity Name

YARNIMA.11.8.1.2.1 Cable Ladder

A1630

Cable Ladder - Culverts Switchroom to GTG No.3

A1620

Cable Ladder - Underneath Switchroom & Battery Room

YARNIMA.11.8.1.2.2 Switch Room and Equipment

A1580

Install GT-3 Auxillary 1.5 MVA Transformer

Original

Duration

Start

Finish

Budgeted

Labor Units

Total

Float

Activity % S

Complete

23

12

17-02-2013 A

17-02-2013 A

29-03-2013 A

06-03-2013 A

1295

333

100%

10

24-03-2013 A

29-03-2013 A

962

100%

314

2

18-02-2013 A

18-02-2013 A

11-10-2013 A

19-02-2013 A

719

98

100%

Install GT 3 Switchroom

06-03-2013 A

12-04-2013 A

314

100%

A1600

Install GT 3 Battery Room & Battery System

07-03-2013 A

05-07-2013 A

307

100%

NCR-S072

GTG3: Line 3- Switch Room Walkway foundation support columns

154

29-04-2013 A

11-10-2013 A

100%

NCR-S065

GTG3: GT3 Switchroom Emergency Stop does not exist

30-07-2013 A

03-08-2013 A

100%

254

28

24-03-2013 A

24-03-2013 A

31-08-2013 A

26-07-2013 A

1692

1692

100%

NCR-S064

GTG3: Reconnection of external lighting in GT3

131

12-04-2013 A

30-08-2013 A

100%

NCR-S095

GTG3: Donalson power outlets do not comply with BHP SPEC

11

03-06-2013 A

13-06-2013 A

100%

NCR-S120

GTG3: GT3 Air Filter Unit

19

15-06-2013 A

04-07-2013 A

100%

NCR-S126

GTG3: Minimax Smoke & Flame Detectors

70

18-06-2013 A

31-08-2013 A

100%

NCR-S124

GTG3: The minimax emergency brake glass

13

18-06-2013 A

01-07-2013 A

100%

NCR-S063

GTG3: Replacement of Siemens power outlet in turbine enclosure - not a standard power

5 outlet

30-07-2013 A

YARNIMA.11.8.1.2.4 Cabling

A1640

LV-C & I Cabling

YARNIMA.11.8.1.2.1 Cable Ladder

A1590

YARNIMA.11.8.1.2.3 On Skid Works

A2030

Install GT3 On-Skid Electrical Equip

03-08-2013 A

100%

254

28

16-03-2013 A

16-03-2013 A

31-08-2013 A

20-06-2013 A

4276

2544

100%

Cable Ladder - Culverts Switchroom to GTG No.3

Cable Ladder - Underneath Switchroom & Battery Room

YARNIMA.11.8.1.2.2 Switch Room and Equipment

Install GT-3 Auxillary 1.5 MVA Transformer

Install GT 3 Switchroom

Install GT 3 Battery Room & Battery System

GTG3: Line 3- Switch Room Walkway foundation support columns

GTG3: GT3 Switchroom Emergency Stop does not exist

YARNIMA.11.8.1.2.3 On Skid Works

Install GT3 On-Skid Electrical Equip

GTG3: Reconnection of external lighting in GT3

GTG3: Donalson power outlets do not comply with BHP SPEC

GTG3: GT3 Air Filter Unit

GTG3: Minimax Smoke & Flame Detectors

GTG3: The minimax emergency brake glass

GTG3: Replacement of Siemens power outlet in turbine enclosure - not a standard

YARNIMA.11.8.1.2.4 Cabling

LV-C & I Cabling

A2130

Install VSD Cable

02-04-2013 A

15-04-2013 A

535

100%

A1670

11kV Cabling - GT 3 to Switchroom

14

03-04-2013 A

11-05-2013 A

327

100%

A1930

Install HV/LV Cabling GT 3 Switchroom to Aux Transformer

23-04-2013 A

30-04-2013 A

201

100%

NCR-S070

GTG3: HV cable drum No GT H-3C240-01 has unacceptable resistance level.

120

24-04-2013 A

30-08-2013 A

100%

A1850

11kV Cabling GT3 Switchroom to Step Up Transformer

13

21-05-2013 A

05-07-2013 A

669

100%

NCR-S089

BOP: The conduits coming out of the substation install by others at an incorrect depth 7

23-05-2013 A

29-05-2013 A

100%

NCR-S103

GTG3: Damaged tank heater on fuel system

83

03-06-2013 A

30-08-2013 A

100%

NCR-S096

GTG3: Supplied cables by Donalson not comply with BHP SPEC

03-06-2013 A

08-06-2013 A

100%

NCR-S097

GTG3: Gland plate provided is not suited to the amount of the cable

20

03-06-2013 A

23-06-2013 A

100%

NCR-S098

GTG3: Mounting bracket needed for gas detector

28

03-06-2013 A

02-07-2013 A

100%

NCR-S099

GTG3: Relocate cable to air lock

19

03-06-2013 A

22-06-2013 A

100%

NCR-S100

GTG3: Insufficient terminals in the HV room

13

03-06-2013 A

16-06-2013 A

100%

NCR-S101

GTG3: The temperature sensor has not been provided

64

03-06-2013 A

09-08-2013 A

100%

NCR-S113

GTG3: Cable Replacement

21

09-06-2013 A

01-07-2013 A

100%

NCR-S114

GTG3: Additional Cable Ladder required

13

09-06-2013 A

22-06-2013 A

100%

GTG3: Additional Cable Ladder required

NCR-S117

GTG3: GT3 Fin Fan Area Lighting

13

09-06-2013 A

22-06-2013 A

100%

GTG3: GT3 Fin Fan Area Lighting

NCR-S137

GTG3: Missing Items Donaldson Generator Air Intake

61

27-06-2013 A

31-08-2013 A

100%

GTG3: Missing Items Donaldson Generator Air Intake

NCR-S171

GTG3: GT3 Switchroom Cabling & GT3 Areas 3 Phase Socket

01-08-2013 A

06-08-2013 A

100%

156

57

01-04-2013 A

01-04-2013 A

27-07-2013 A

31-05-2013 A

1589

0

GTG3: GT3 Switchroom Cabling & GT3 Areas 3 Phase Socket

YARNIMA.11.8.1.2.5 Cable Terminations

100%

YARNIMA.11.8.1.2.5 Cable Terminations

NCR-S048

GTG3: No Holes Punched for Termination

A1650

LV- C & I Cable Terminations

35

10-04-2013 A

27-07-2013 A

1129

100%

A1690

11kV Cable Terminations

29

24-04-2013 A

20-07-2013 A

460

100%

NCR-S127

GTG3: GT3 Step Up Transformer Terminals

18-06-2013 A

21-06-2013 A

100%

NCR-S142

GTG3: GT3BFA10 Circuit Breaker modification

13

02-07-2013 A

03-07-2013 A

100%

134

31

06-05-2013 A

06-05-2013 A

16-08-2013 A

30-07-2013 A

0

0

100%

100%

YARNIMA.11.8.1.2.6 Earthing and Lighting Protection

A1700

Earthing & Lightning Protection

NCR-S102

GTG3: Earthing tags and earthing locations miss-alignment

13

03-06-2013 A

16-06-2013 A

NCR-S138

GTG3: GT3 Generator Earthing incorrectly installed

Install VSD Cable

11kV Cabling - GT 3 to Switchroom

Install HV/LV Cabling GT 3 Switchroom to Aux Transformer

GTG3: HV cable drum No GT H-3C240-01 has unacceptable resistance level.

11kV Cabling GT3 Switchroom to Step Up Transformer

BOP: The conduits coming out of the substation install by others at an incorrect depth

GTG3: Damaged tank heater on fuel system

GTG3: Supplied cables by Donalson not comply with BHP SPEC

GTG3: Gland plate provided is not suited to the amount of the cable

GTG3: Mounting bracket needed for gas detector

GTG3: Relocate cable to air lock

GTG3: Insufficient terminals in the HV room

GTG3: The temperature sensor has not been provided

GTG3: Cable Replacement

GTG3: No Holes Punched for Termination

LV- C & I Cable Terminations

11kV Cable Terminations

GTG3: GT3 Step Up Transformer Terminals

GTG3: GT3BFA10 Circuit Breaker modification

YARNIMA.11.8.1.2.6 Earthing and Lighting Protection

Earthing & Lightning Protection

GTG3: Earthing tags and earthing locations miss-alignment

46

29-06-2013 A

16-08-2013 A

100%

YARNIMA.11.8.1.2.7 Lighting and Small Power

A1720

Lighting & Small Power

21

21

10-04-2013 A

10-04-2013 A

25-07-2013 A

25-07-2013 A

408

408

GTG3: GT3 Generator Earthing incorrectly installed

YARNIMA.11.8.1.2.7 Lighting and Small Power

100%

YARNIMA.11.8.1.2.8 Field Equipment

A1730

Field Equipment (LCS's- J.B's- HDG conduits etc...)

14

14

09-07-2013 A

09-07-2013 A

02-08-2013 A

02-08-2013 A

21

21

Lighting & Small Power

YARNIMA.11.8.1.2.8 Field Equipment

100%

7

7

17-07-2013 A

17-07-2013 A

24-07-2013 A

24-07-2013 A

11

11

Field Equipment (LCS's- J.B's- HDG conduits etc...)

YARNIMA.11.8.1.4 INSTRUMENTS

100%

145

10

09-03-2013 A

09-03-2013 A

03-12-2013 A

03-12-2013 A

3453

0

Install Stage 1 Instruments

YARNIMA.11.8.1.5 PHASE 1 PRE-COMMISSIONING

100%

YARNIMA.11.8.1.4 INSTRUMENTS

A9040

Install Stage 1 Instruments

YARNIMA.11.8.1.5 PHASE 1 PRE-COMMISSIONING

A22990

Mechanical and Electrical Pre-Commissioning and punchlisting B & C-Items

Actual Work

Primary Baseline

Remaining Work

Baseline Milestone

Critical Remaining Work

Milestone

Summary

Page 8 of 38

Data Date 07-02-2014

Date

19-Dec-12

21-11-2013

07-02-2014

Revision

APPROVED CONSTR SCHED BASELINE REV O

APPROVED ACP Rev 01

Updated Construction Schedule

Mechanical and Electrical Pre-Commissioning and punchlisting B

Checked

Approved

WC

KU

KU

TL

Document Number: C1034-22.1-00PRJ-PL-001d

Project ID: YAR - PROGRAM-1

Activity ID

Activity Name

Original

Duration

Start

Finish

Budgeted

Labor Units

Total

Float

Activity % S

Complete

NCR-S067

GTG3: GT3 lube oil cooler headers, several plugs leaking

13

12-04-2013 A

25-04-2013 A

100%

A1570

Electrical Pre-Commissioning and punchlisting A-Items

21

31-05-2013 A

25-09-2013 A

532

100%

A3220

NDT & QA Documentation

14

20-06-2013 A

26-09-2013 A

50

100%

NDT & QA Documentation

A2040

Lube Oil Flush

10

28-06-2013 A

24-09-2013 A

80

100%

Lube Oil Flush

A1740

Mechanical Pre-Commissioning and punchlisting A-Items

33

29-06-2013 A

27-09-2013 A

650

100%

Mechanical Pre-Commissioning and punchlisting A-Items

VEGT3523

VE GTG 3 - Commissioning Assistance for Switchroom

101

09-08-2013 A

25-11-2013 A

2141

100%

A2080

Construction Verification

27-09-2013 A

100%

YARNIMA.10 PHASE 2

YARNIMA.10.10 COMPANY DELIVERABLES

YARNIMA.10.10.1 ENGINEERING DELIVERABLES

YARNIMA.10.10.1.1 GA & DETAILED ASSEMBLY DWGS

A7770

GT2 & GT1 GA & Detailed Assembly Dwgs

YARNIMA.10 PHASE 2

323515

216

15-10-2012 A

28-07-2013 A

YARNIMA.10.10 COMPANY DELIVERABLES

216

164

0

15-10-2012 A

01-02-2013 A

01-02-2013 A

28-07-2013 A

28-07-2013 A

0

0

0

YARNIMA.10.10.1 ENGINEERING DELIVERABLES

YARNIMA.10.10.1.1 GA & DETAILED ASSEMBLY DWGS

100%

05-04-2013 A

100%

A5980

ST1 & 2 GA & Detailed Assembly Dwgs

28-07-2013 A

100%

A5990

Cooling Towers 1 & 2 GA & Detailed Assembly Dwgs

28-07-2013 A

100%

0

0

21-12-2012 A

21-12-2012 A

21-12-2012 A

0

0

21-12-2012 A

21-12-2012 A

108

0

15-10-2012 A

15-10-2012 A

YARNIMA.10.10.1.3 STRUCTURAL

A5390

Stage 2 Piperack Dwgs AFC

YARNIMA.10.10.1.4 MECHANICAL

A5600

Pump Data Sheets Issued

Construction Verification

27-06-2014

Stage 2 Buried Pit Dwgs AFC

VE GTG 3 - Commissioning Assistance for Switchroom

15-10-2012 A

HRSG2 & HRSG1 GA & Detailed Assembly Dwgs

A5860

Electrical Pre-Commissioning and punchlisting A-Items

495

A7780

YARNIMA.10.10.1.2 CIVIL

A5370

Stage 2 Buried Services Trench Layout Dwgs AFC

GTG3: GT3 lube oil cooler headers, several plugs leaking

21-12-2012 A

GT2 & GT1 GA & Detailed Assembly Dwgs

HRSG2 & HRSG1 GA & Detailed Assembly Dwgs

ST1 & 2 GA & Detailed Assembly Dwgs

Cooling Towers 1 & 2 GA & Detailed Assembly Dwgs

YARNIMA.10.10.1.2 CIVIL

0

0

100%

Stage 2 Buried Services Trench Layout Dwgs AFC

100%

21-12-2012 A

0

0

Stage 2 Buried Pit Dwgs AFC

YARNIMA.10.10.1.3 STRUCTURAL

100%

30-03-2013 A

0

0

Stage 2 Piperack Dwgs AFC

YARNIMA.10.10.1.4 MECHANICAL

100%

Pump Data Sheets Issued

A5420

Large Bore HP Steam Main Isometrics Issued

05-11-2012 A

100%

A5460

Stage 2 Valve List (Stage 2) Issued

17-12-2012 A

100%

Stage 2 Valve List (Stage 2) Issued

A5560

Stage 2 Piping Isometrics Issued for CW Piping Info

21-12-2012 A

100%