Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Operation and Troubleshooting Guide For The Bromma Twin Twenty Detection System (TTDS)

Caricato da

Ashley DeanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Operation and Troubleshooting Guide For The Bromma Twin Twenty Detection System (TTDS)

Caricato da

Ashley DeanCopyright:

Formati disponibili

Twin Twenty Detection System (TTDS)

OPERATION AND

TROUBLESHOOTING

GUIDE FOR THE

BROMMA

TWIN TWENTY

DETECTION SYSTEM

(TTDS)

MARCH 2001

Revised APRIL 2002

Revised AUGUST 2002

Revised AUGUST 2004

Revised OCTOBER 2004

Revised NOVEMBER 2007

Revised DECEMBER 2009

Revised APRIL 2010

Revised DECEMBER 2010

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

Table of Content

Introduction ................................................................................................... 3

System Description ........................................................................................................ 3

Sensing The Gap Between Containers ........................................................................ 6

Detecting a Container ................................................................................................... 6

Sensor Settings ............................................................................................................... 7

Interface with Spreader and Crane Control............................................................... 8

Twin Twenty Detection By-Pass ................................................................................ 10

Maintenance ................................................................................................................. 10

False Signals ................................................................................................................. 10

Functional Description ................................................................................................ 11

Limitations ................................................................................................... 13

Procedure To Adjust Photoelectric Sensor On Bromma Twin Twenty

Detection System (TTDS) ........................................................................... 14

Operation Mode Setting.............................................................................................. 14

Distance Setting ........................................................................................................... 14

Indication Lights ......................................................................................................... 14

Testing The Twin Twenty Detection System ............................................ 16

Wiring .......................................................................................................... 17

Pin Layout.................................................................................................... 18

Spares ........................................................................................................... 19

Troubleshooting .......................................................................................... 20

Procedure to Trouble Shoot the Twin Twenty Detection System ........................... 20

Procedure to Replace A Twin-Twenty Detection System Sensor ........................... 23

Procedure to Replace A Twin-Twenty Detection System Controller (TTDC) ...... 24

Procedure to Checking Cable to TTDS Controller .................................................. 25

Procedure to Checking Sensor ................................................................................... 27

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

Introduction

System Description

The Bromma Twin Twenty Detection System (TTDS) is designed to sense the existence of twotwenty foot containers in a forty foot ships cell by detecting the gap between the two containers

or the sagging of the two containers. The twin twenty detection system is a tool to assist the

operator in detecting the dangerous situation of two twenty foot containers under a spreader

positioned in the 40 foot position.

The majority of twin twenty conditions consist of two typical containers, although there are

several other variables to consider. The Bromma Twin Twenty Detection System was designed

to detect as many types of flatrack and tank containers as possible without unnecessarily shutting

down operations.

Bromma Twin Twenty Detection System uses a seven sensor cluster to avoid many of the false

indications that plague other twin twenty detection systems. Many twin twenty detection systems

cannot differentiate between a twin twenty condition and an open top container, canvas tops, tank

container, and lifts with overheights. The Bromma twin twenty detection system is designed to

give a go signal during these lifts. By reducing the amount of false twin twenty indications that

need to be bypassed, Bromma can offer a more reliable and productive system.

The Bromma Twin Twenty Detection System uses a cluster of seven photoelectric sensors

located in the center of the main frame. See Figure 1. The five inner sensors are used to locate a

gap between two containers. The two outer sensors, S95 and S96, along with the two outer

sensors on the center cluster, S90 and S94 are used to detect the existence of the containers. The

system can detect a 38mm (1-1/2) gap with a range of plus or minus 28mm (1-1/8) from the

center of the spreader.

The Bromma Twin Twenty Detection System can also detect an unsafe twin twenty lift even if

the containers are butted together and there is no gap. The idea is based on the fact that an unsafe

twin twenty lift will lift the ends of the containers that are locked on to the spreader and ends at

the center will not be lifted. By setting the outer sensors lower than the inner sensors, there will

be an area where the TTDS will send an unsafe twin twenty lift even when no gap exists. When

the outer ends of the container are lifted beyond the setting of the inner sensors, the TTDS go

permissive will be switched off. The outer sensors should still detect the presence of the

containers. The TTDS will interrupt the go permissive until the spreader is lifted beyond the

range of the outer sensors. This means when the twistlocks are locked and the TTDS senses an

unsafe lift, the hoisting should stop. Figure 2 shows the condition where the twistlock are locked

and the outer ends of the containers are being lifted, but the ends at the center are not. The TTDS

will determine that this condition is an unsafe twin twenty lift and discontinue the go permissive.

Figure 3 show a typical unsafe twin twenty lift that will be detected by the TTDS.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

Figure 1

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

Figure 2

Figure 3

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

The Bromma TTDS can be mounted anywhere along the center of the spreader. It is

recommended that the TTDS be mounted inside the main frame for maximum protection.

The twin twenty detection system is designed so a failure of a sensor will not cause the system to

fail and send a "go" signal during a twin twenty condition. Because the definition of a gap is two

or more sensors, the system will not shut down if one of the gap sensors fails. The system will

become more sensitive to a twin twenty condition. A failure is defined by a failure of the sensor,

the relay wired to the sensor, or a loose connection.

The Bromma Twin Twenty Detection System (TTDS) is not intended nor will it detect all

possible twin twenty conditions. The Limitation Section outlines the situations where the twin

twenty detection system may give a false twin twenty indication or fail to give an indication.

Sensing The Gap Between Containers

The Bromma TTDS can detect a minimum of 38mm (1-1/2) gap between the containers. The

Bromma TTDS defines a gap as two or more consecutive sensors not detecting an obstruction in

their view path. Two consecutive sensors are used to define a gap to avoid false readings due to

damage or variations of the containers.

The center of the gap between containers does not have to fall in the center of the spreader. The

spreader could be as much as 28 mm (1-1/8) from the center of the gap due to the spreader being

landed toward one end of the container, floating twistlocks, or the flexibility of the spreader. For

this reason, the gap sensing cluster is made up of five sensors to achieve a plus or minus 28mm

(1-1/8) range. Because of the physical size of the sensors, the sensors are mounted in two rows.

The two rows are staggered so any one sensor is halfway between the sensors before and after.

Detecting a Container

The two outer sensors, S95 and S96, of the twin twenty detection system are the primary sensors

for detecting the existence of a container. The two outer sensors of the gap cluster, sensors S90

and S94, are used as secondary container sensors for tank containers and flat racks. If these four

sensors do not detect a container, the twin twenty detection system will allow the container to be

locked and lifted. This situation will occur on forty foot open top containers or loose fitting

canvas topped containers.

If any of the four container sensing sensors detects a container, the control is transferred to the

gap sensing sensors. If two consecutive sensors do not detect the container, the TTDS will not

give the go permissive.

The two outer sensors, S96 and S95, are located 114mm (4-1/2) from the center of the spreader

to ensure that two twenty foot containers are detected no matter where they are in the ship cell.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

Sensor Settings

The inner sensors should be set low enough to detect sagging canvas tops but not too low where it

will detect the load in an open top container. It is a known fact that two twenty foot containers

can be lifted in a cell by a spreader in single container mode. The bottom of the containers will

ride the cell guide and allow the crane to lift the two containers. Once the containers leave the

cell, the ends at the center will drop and in most cases the container will fall. Even in the cells the

ends of the container at the center will be lower in relation to the ends attached to the spreader.

The inner sensors must be set so they go from high to low state in the event that two twenty foot

containers are lifted in the cells.

When two twenty foot containers are lifted in a cell, the end of the container at the center will be

5.4 inches [137 mm] lower than the ends supported by the spreader. To ensure that the inner

sensors do not detect the container in this configuration, the inner sensors should be set so that the

range is 5 1/4 inches [133.4 mm] below the twistlock housings. Deflection of the spreader and

the 9/16 inch [14 mm] difference between the seated and the loaded position will ensure that the

inner sensor will not detect the container if this condition occurs. Since the TTDS is located in

different positions and the sensors are not mounted at the same elevation, it is best to set the

sensors based on the bottom of the main beam. The type of spreader will determine the range of

the inner sensors. See Table 1 for recommended inner sensor settings for different spreaders.

Since the spreader will travel lower than the theoretical spreader height when it is landed on a

container, the inner sensors will extend approximately 7 inches [178 mm] past the top of the

container when the spreader is landed. On all but canvas top containers, this engagement should

be adequate. The amount of the sag in the canvas top will determine if a canvas top container

will give a false indication.

In the case where an unsafe twin twenty lift occurs outside the cells, the ends at the center will not

be lifted. This means the outer sensors need to be set so that once the go permissive has been

interrupted, the hoist should stop before the containers are lifted out of the range of the outer

sensors. On faster cranes where the stopping distance is too long, logic in the crane should be

added to watch for the interruption of the go permissive with the twistlock locked and the

spreader not landed. Once a predetermined time period without the go permissive has been

reached with the twistlock locked, the hoist should be stopped, even if the go permissive returns.

When the containers have been lifted high enough the outer sensors will no longer be able to

detect the containers and the go permissive will be given. Bromma recommend a sensor setting

of 12 inches [305 mm] greater than the inner sensors. The stopping distance of the crane will

determine if additional crane logic will be needed. The difference between the inner sensor

setting and the outer sensor setting needs to be greater than the stopping distance of the crane, or

additional crane logic will be needed to properly detect the unsafe twin twenty condition. If the

settings are less than the stopping distance of the crane, the hoist will be interrupted and then the

hoist will coast until the containers are outside the range of the outer sensors then the go

permissive will be given and the hoist will be able to rise again. Only a pause will be seen.

See Table 1 for recommended outer sensor settings for different spreaders.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

Table 1 Sensor Settings for Different Spreaders

Type of Spreader

New Type ASX-7 & BSL-6, AST-6, & BST-6

(12 1/4 from Bottom T/L Housing to Gable Tube)

AST-6SCH

(12 1/4 from Bottom T/L Housing to Gable Tube)

Old Style ASX-7 and BSL-6

(9 from Bottom T/L Housing to Gable Tube)

ASX-7 & BSL-6, AST-6, & BST-6 Spreaders with INRS

Gable Ends

AST-6SCH

with INRS Gable Ends

SSX40, SSX45, STR40, STR45 & STS45 with Standard

Gable ends (6 3/4 [172 mm] from Bottom T/L Housing to

Gable Tube)

SSX40, SSX45, STR40, STR45 & STS45 with Bromma

Classic Gable ends (12 3/4 [342 mm] from Bottom T/L

Housing to Gable Tube)

SSX40, SSX45, STR40, STR45 & STS45

with INRS Gable Ends

EH170U, EH5U with Standard End Beams

Inner Sensor Setting

(Inches from Bottom of

Main Beam)

[Millimeters]

16

[405 mm]

15 1/8

[384 mm]

13

[337 mm]

18

[457 mm]

17 1/8

[435 mm]

16

[425 mm]

Outer Sensor Setting

(Inches from Bottom

of Main Beam)

[Millimeters]

28

[710 mm]

27 1/8

[689 mm]

25

[640 mm]

30

[762 mm]

29 1/8

[740 mm]

28

[730 mm]

22 3/8

[568 mm]

34 3/8

[873 mm]

23 7/8

[606 mm]

35 7/8

[911 mm]

13 5/8

[345 mm]

25 5/8

[650]

Interface with Spreader and Crane Control

The Bromma Twin Twenty Detection System should be tied into the spreader position circuit to

deactivate the system when the spreader is in the 20 or 45 foot position. In the case of a twin

twenty spreader, the system should also be tied into the center housing down circuit so the system

is deactivated when the housings are down. The TTDS should be tied into the hoisting circuit. In

the event the system is fooled by a small gap between the containers, the twistlocks can be locked

and the containers could be lifted. As the two containers are lifted, the outer ends of the container

are lifted beyond the setting of the inner sensors, the TTDS go permissive will be switched off.

The hoist should then stop, only if the system is tied into the locked hoist permit. The twin

twenty detection indication should not affect the lowering of the spreader or the unlocking of the

twistlocks.

The stopping distance of the crane determines if the hoisting of the container will stop within the

range of the outer sensors. The stopping distance of the crane is based on a number of

parameters, acceleration rate, deceleration rate and the hoist speed. Since each crane is set up

differently, testing the actual crane may be the only way to determine if the 12 inches [305 mm]

difference between the inner and outer sensors will be enough to stop the hoist. A test to

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

determine if only the difference in sensor settings will be enough to stop the hoist is described

below.

On faster cranes the sensor settings may not be enough to stop the hoist. When the TTDS is

fooled by the two containers butted together and the two containers are lifted, the go permissive

will be interrupted, but since the crane can not stop quickly, the spreader will be lifted passed the

range of the outer sensors and the go permissive will be sent again. If no other logic is in the

crane PLC, the hoist will start again. To avoid this, one of the two crane logic options should be

added to the PLC.

The first option would be to place TTDS latching logic to stop the hoist and keep it

stopped if the go permissive is interrupted for a half a second to one second when the

twistlocks are locked. The only way to hoist would be to cycle the twistlocks to the

unlock position or active the Twin Twenty Detection bypass. The TTDS latching logic

would need to be added in the PLC. It should be noted that is not a good idea to stop the

hoist and keep it stopped based on just the interruption of the go permissive. As the

spreader is landing or the containers are lifted, the TTDS will interrupt the go permissive

momentarily as the sensors adjust to a different status. The interruption of the go

permissive should be continuous over a period of time from 0.5 to 1 seconds.

The second option would be to keep the hoist in slowdown mode for 2 second after lifting

the containers. This would allow the hoist to be stopped within the range of the outer

sensors.

Testing the Stopping Distance of the Crane

The following test can be done to check if the TTDS sensor setting and crane controls are

properly set to stop an unsafe twin twenty lift.

The first test should be performed without addition TTDS latching logic in the PLC to check if

the sensor settings would be all that is necessary.

Properly set the TTDS sensors.

Place two empty twenty foot containers on the ground so that the ends are butted

together.

Land the spreader on the containers with the center housings up.

Tape a large piece of cardboard (18 by 24) to the top of the containers directly under

the TTDS sensors.

Lock the twistlocks to the outside ends of the containers.

The operator should lift the containers at full stick. (Note: The containers should only be

lifted about two to three feet)

If the TTDS is set properly and the proper hoist interrupts are in place, the TTDS will

stop the hoist and it should remain stopped.

Activate the Twin Twenty Detection Bypass to see if it is working properly.

Check to see if the crane can hoist the containers with the Twin Twenty Detection Bypass

active. (Only lift the containers slightly).

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Twin Twenty Detection System (TTDS)

If the test properly stops the hoisting of the containers, repeat the test two more times. If all three

attempts are successfully, then additional logic in the PLC is not needed.

If any of the attempts fail to stop the hoist, the TTDS latching logic or the hoist slowdown needs

to be included in the PLC logic and the test should be repeated. If the TTDS latching logic is

used, start with a timer set for 1 second. Continue to reduce the time setting until the TTDS

properly stops the hoisting of the containers.

Twin Twenty Detection By-Pass

Since there is a possibility that the TTDS will indicate a twin twenty condition when it is landed

on a forty foot container or flat rack, the system must be equipped with a method to override the

system. To do this, a twin twenty bypass should be placed either on the crane or on the spreader.

The bypass should be keyed and only operated by authorized maintenance personnel. The bypass

should be used only after the situation has been checked thoroughly. When the twin twenty

bypass is activated, an audible alarm should be sounded to warn the workers that the bypass is

active. It is the customers responsibility to determine if a twin twenty condition exists when the

bypass is activated.

Maintenance

Normal maintenance of the system includes testing the system according to the Testing the Twin

Twenty Detection System Section (attached) and cleaning the lenses. The operation of the system

should be checked at every maintenance period to ensure the proper operation of the system. The

lenses should also be cleaned at every maintenance period. The sensor will become more

sensitive as the lens become dirty and the system will indicate a twin twenty condition where

there is none.

False Signals

Some ports have encounter false twin twenty indications during heavy rains. A puddle can form

directly beneath the sensor cluster and the wind and rain can produce ripple in the puddle. The

reflective nature of the puddle and the ripples abnormally disperses the light from the sensors,

leading to the TTDS indicating a twin twenty condition. The system should be bypassed until the

container is unloaded.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

10

Twin Twenty Detection System (TTDS)

Functional Description

The twin twenty detection system (TTDS) is designed to stop the twistlocks from locking if a

twin twenty condition is detected. The system is also tied into the locked hoist permissive to stop

the hoist if the system is fooled and the twistlocks are locked. The twin twenty detection signal

should only stop the twistlocks from locking when the spreader is in the 40 foot position or the

position of the spreader is unknown and the center housings are up. A keyed bypass switch

labeled TWIN TWENTY DETECTION BYPASS, should be installed in a convenient location to

bypass the twin twenty detection system. The bypass should only be used after the twin twenty

situation has been checked. An alarm should sound when the bypass switch is activated to warn

the worker that a bypass is active.

The crane logic must contain the following interlocks for proper use of the TTDS:

The crane logic must block the operator from locking the twistlocks when a TTDS go

permissive is not given.

The crane logic must block the operator from hoisting the spreader and container when the

twistlocks are locked and a TTDS go permissive is not given.

The TTDS is bypassed under certain condition and a TTDS go permissive will be sent from the

spreader. The logic in the crane should also include the bypasses to mimic the spreader. The

valid TTDS go permissives that need to be supplied by the crane logic are as follows.

Valid TTDS go permissives supplied by crane control:

Spreader in 20 foot position.

Spreader in 45 foot position.

Center Housings are down.

The Twin Twenty Detection Bypass is activated

The twin twenty detection indication should not affect anything when the spreader is in the 20 or

45 foot position, the twistlocks are unlocked or the center housings are down. The twin twenty

detection indication should not effect the lowering of the spreader or the unlocking of the

twistlocks.

If the twin twenty detection indication effects the lowering of the hoist, then the crane may be

stuck in a position it cannot recover. If the system is fooled and the twistlocks are locked, the

TTDS can sense the sagging of the container at the center of the spreader and interrupt the go

permissive and stop the hoist. Without the ability to lower the spreader and unlock the twistlocks,

the containers will be stuck partial lifted.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

11

Twin Twenty Detection System (TTDS)

If the twin twenty detection indication effects the hoisting of the crane with the twistlocks

unlocked, the operator will not be able to raise the spreader to put down the center housing or the

spreader will not be able to be removed to check to see if there are two twenty foot containers.

Both of these conditions can be overcome using the twin twenty indication bypass, but frequent

use of the bypass will be a nuisance. If the use of the bypass becomes routine, then the operator

may use the bypass when there is a twin twenty condition just out of habit. Bromma strongly

recommends that each twin twenty occurrence be thoroughly checked before the bypass is used.

The logic for the twin twenty detection system is contained on the spreader. The logic on the

spreader should be imitated in the PLC. The logic must be installed and maintained to ensure the

safe operation of the spreader.

There may be a momentary loss of the twin twenty detection permissive during the landing of the

container as the photosensors adjust to their new status.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

12

Twin Twenty Detection System (TTDS)

Limitations

The limitations of the twin twenty detection system are (see Figure 4):

1. There must be a 1-1/2 inch gap between the containers where the twin twenty detection

system is sensing.

2. There must be a support between the end corner castings near the top of the container or flat

rack. The support must be at least 3 inches thick and the side of the support cannot be more

than 2 inches from the end of the corner castings.

3. The maximum recess along the top of a container between the corner castings is 2".

4. The twin twenty detection system has given false twin twenty indications during heavy rains.

Figure 4

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

13

Twin Twenty Detection System (TTDS)

Procedure To Adjust Photoelectric Sensor On Bromma Twin

Twenty Detection System (TTDS)

Use the attached Figure 5 as reference

Operation Mode Setting

1.

The operation mode screw is mounted on the front face of the sensor.

2.

Rotate the mode screw to D for Dark On or to L for Light On.

3.

Photoelectric Sensors S90 thru S94 are set Light On. Photoelectric Sensors S95 and 96 are

set Dark On.

Distance Setting

1.

Determine the type of spreader. Using Table 1, find the settings for the inner and outer

sensors for the spreader.

2.

Place a black mat object the proper distance +/- inches [6 mm] from the bottom of the

main beam for setting the inner sensors.

3.

Rotate the sensor distance adjustment screw on the inner sensors until the photoelectric

sensor is activated.

4.

Repeat the procedure until all five inner photoelectric sensors are set.

5.

Place a black mat object the proper distance +/- inches [6 mm] from the bottom of the

main beam for setting the outer sensors.

6.

Rotate the sensor distance adjustment screw on the outer sensors until the photoelectric

sensor is activated.

7.

Repeat the procedure until both the outer photoelectric sensors are set.

Indication Lights

The green indicating light is illuminated when there is a stable light or dark condition.

The red indicating light is illuminated when the output is active.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

14

Twin Twenty Detection System (TTDS)

Figure 5

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

15

Twin Twenty Detection System (TTDS)

Testing The Twin Twenty Detection System

Items in parenthesis are for Twin Twenty Spreaders Only

Accepted

(Initials)

Description

Check each sensor individually to see if the green LED lights on each

sensor are illuminated.

Check each sensor individually to see that the red LED lights changes state

when an object is place 150 mm (6") below the sensor.

With the twistlocks unlocked, (the center housings up) and the spreader in

the 40-foot position, place an object about 150 mm (6") below all the

sensors. The LED lights on each sensor should be checked to make sure the

sensor is tripped. The twistlocks should lock and the twin twenty light

should not light.

Clear the area 1020 mm (40") inches from the bottom of the Main Beam.

With the twistlocks unlocked, the plungers up, (the center housings up) and

the spreader in the 40-foot position, check to see if the twistlocks will lock.

The twistlocks should lock and the twin twenty light should not light.

With the twistlocks unlocked, the plungers up, (the center housings up) and

the spreader in the 40-foot position, place an object approximately 150 mm

(6") directly below one of the outer sensors. Check to see if the twistlocks

will lock. The twistlocks should not lock and the twin twenty light should

light.

With the twistlocks unlocked, the plungers up, (the center housings up) and

the spreader in the 40-foot position, place an object approximately 150 mm

(6") directly below the other outer sensors. Check to see if the twistlocks

will lock. The twistlocks should not lock and the twin twenty light should

light.

With the twistlocks unlocked, the plungers up, (the center housings up) and

the spreader in the 40-foot position, place an object approximately 150 mm

(6") directly below all of the sensors. Check to see if the twistlocks will

lock. The twistlocks should lock and the twin twenty light should not light.

With the twistlocks unlocked, the plungers up, (the center housings up) and

the spreader in the 20-foot position, place an object approximately 150 mm

(6") directly below one of the outer sensors. Check to see if the twistlocks

will lock. The twistlocks should lock and the twin twenty light should not

light.

With the twistlocks unlocked, the plungers up, (the center housing up) and

spreader in the 45-foot position, place an object approximately 150 mm (6")

directly below one of the outer sensors. Check to see if the twistlocks will

lock. The twistlocks should lock and the twin twenty light should not light.

With the twistlocks unlocked, the plungers up, the center housing down and

spreader in the 40-foot position, place an object approximately 150 mm (6")

directly below one of the outer sensors. Check to see if the twistlocks will

lock. The twistlocks should lock and the twin twenty light should not light.

(This step is for Twin Twenty Spreaders Only)

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

16

Date

Twin Twenty Detection System (TTDS)

Wiring

Figure 6 shows the typical wiring scheme for the TTDS. See the electrical schematic of the

spreader to determine the actual wiring.

Figure 6

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

17

Twin Twenty Detection System (TTDS)

Pin Layout

10 m

Main Cable with Plug

Male Socket on TTDS

The following is the pin layout for the main cable.

Wire No.

1

2

YL/GR

3

4

5

6

7

8

9

Pin No.

A

B

C

D

E

F

G

H

I

J

Function

Power

Neutral

Equipment Ground

Common Supply Relay 1

TTDS Fault Relay 1 (N.C.) (TTDS Fault)

TTDS Fault Relay 1 (N.O.) (TTDS Permissive)

Common Supply Relay 2

TTDS Fault Relay 2 (N.C.) (TTDS Fault)

TTDS Fault Relay 2 (N.O.) (TTDS Permissive)

Fault Override (115 VAC)

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

18

Twin Twenty Detection System (TTDS)

Spares

The following is a list of typical spares. See the electrical wiring diagram of the spreader to

determine the actual parts used.

Part No.

38272

38273

38271

38274

RST3RKWT4/3-631/.6M

UZD355A

Description

Twin Twenty Detection Controller (TTDC) for 120 VAC

Twin Twenty Detection Controller (TTDC) for 220 VAC

Twin Twenty Detection Controller (TTDC) for 24 VDC

Main Cable

Cable Between TTDC and Sensors

Photoelectric Sensor

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

19

Twin Twenty Detection System (TTDS)

Troubleshooting

Procedure to Trouble Shoot the Twin Twenty Detection System

This procedure is used for Twin Twenty Detection Systems with the Bromma TTDS controller

another procedure is used to troubleshoot the TTDS with relays.

Position the spreader so it is raised at least three (3) feet from the ground in the area of the twin

twenty detection system. There will be one relay mounted in the main junction box that is the

go permissive for the twin twenty detection system. Check the electrical schematic for the

spreader to determine the relay number for the go permissive. For this document, the go

permissive relay will be called R100. When Relay 100 is powered, the go permissive is given. If

Relay 100 is not on, then the twin twenty detection system is indicating a twin twenty condition.

See Figure 1 for the sensor configuration.

Check to see that the cables number corresponds to the sensor number. See Figure 1 for the

sensor configuration. Cable S90 is on sensor S90, Cable S91 is on sensor S91, Cable S92

is on sensor S92, Cable S93 is on sensor S93, Cable S94 is on sensor S94, Cable S95 is on

sensor S95 and Cable S96 is on sensor S96.

Reconnect the cables to the proper sensors if the cabling is not correct.

When there is no object under the sensor cluster, the green LED lights should be lit on all

the sensors. The red LED light should be illuminated on sensors S95 and S96. The LED

light on Relay 100 should be illuminated.

If the green LED light on some sensors is not illuminated and illuminated on other

sensors, the cable to the sensor may be bad, the sensor may be bad or the controller

may be bad. First, check the sensor according to the attached, Procedure For Checking

Sensors. If the sensor is not bad, check the cable to the bad sensor according the

attached, Procedure For Checking Sensor Cable. If the cable to the sensor is not bad,

replace the TTDS controller according to the attached, Procedure to Replace Twin

Twenty Detection System Controller.

If none of the green LED lights on the sensors are illuminated, the cable to the

controller may be bad or the controller is bad. First, check the wiring to the

controller according to the attached, Procedure For Checking Cable to

Controller. If the wiring is not bad, replace the TTDS controller according

attached, Procedure to Replace Twin Twenty Detection System Controller.

TTDS

TTDS

TTDS

to the

Place masking tape over the face of the outside sensor S95. The red LED light should go

off. The LED light in Relay 100 will not be illuminate.

If the red LED light does not go out, check the sensor according to the attached,

Procedure For Checking Sensors.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

20

Twin Twenty Detection System (TTDS)

Remove the masking tape from sensor S95. Place masking tape over the face of sensor

S96. The red LED light should go off. The LED light in Relay 100 will not be illuminate.

If the red LED light does not go out, check the sensor according to the attached,

Procedure For Checking Sensors.

If the LED light in Relay R100 does not go out, the cable to the sensor may be bad, the

cable to the TTDS controller may be bad, or the controller may be bad. First, check the

wiring to the TTDS controller according to the attached, Procedure For Checking

Cable to TTDS Controller. If the wiring to the TTDS controller is not bad, check the

cable to the bad sensor according the attached, Procedure For Checking Sensor

Cable. If the cable to the sensor is not bad, replace the TTDS controller according to

the attached, Procedure to Replace Twin Twenty Detection System Controller.

Place the masking tape back onto sensor S95, then individually add masking tape to sensors

S90, S91, S92, S93 and S94. When the tape is placed on the sensor, the red LED light on

the sensor should illuminate.

If the red LED light does not illuminate, check the sensor according to the attached,

Procedure For Checking Sensors.

After all the sensors have been covered. The LED light on Relay 100 should illuminate.

If the LED light in Relay R100 does not go out, the cable to the sensor may be bad, the

cable to the TTDS controller may be bad, or the controller may be bad. First, check the

wiring to the TTDS controller according to the attached, Procedure For Checking

Cable to TTDS Controller. If the wiring to the TTDS controller is not bad, check the

cable to the bad sensor according the attached, Procedure For Checking Sensor

Cable. If the cable to the sensor is not bad, replace the TTDS controller according to

the attached, Procedure to Replace Twin Twenty Detection System Controller.

If the LED light in Relay R100 does not illuminate, the cable to the TTDS controller

may be bad, or the controller may be bad. First, check the wiring to the TTDS

controller according to the attached, Procedure For Checking Cable to TTDS

Controller. If the wiring to the TTDS controller is not bad replace the TTDS

controller according to the attached, Procedure to Replace Twin Twenty Detection

System Controller.

Check the logic in the TTDS controller by removing the tape from two sensors. See the list

below for the proper pair of sensors. The LED light in Relay 100 should go out. If the

LED light in Relay 100 goes out, replace the tape and uncover the next pair.

Sensors S90 and S91

Sensors S91 and S92

Sensors S92 and S93

Sensors S93 and S94

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

21

Twin Twenty Detection System (TTDS)

If the LED light in Relay R100 does not go out, the cable to the sensor may be bad, the

cable to the TTDS controller may be bad, or the controller may be bad. First, check the

wiring to the TTDS controller according to the attached, Procedure For Checking

Cable to TTDS Controller. If the wiring to the TTDS controller is not bad, check the

cable to the bad sensor according the attached, Procedure For Checking Sensor

Cable. If the cable to the sensor is not bad, replace the TTDS controller according to

the attached, Procedure to Replace Twin Twenty Detection System Controller.

If everything has worked properly to this point and the system is still not functioning

properly on the spreader, check the wirings to the relay according to the attached

Procedure to Check the Wiring to the Go Permissive Relay

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

22

Twin Twenty Detection System (TTDS)

Procedure to Replace A Twin-Twenty Detection System Sensor

Remove the sensor cluster from the spreader by removing the bottom locknuts on the

cluster shock mounts (See Figure 1).

Remove cluster from mounting brackets.

Remove screws and wiring from sensor. The sensors are held in place by two screws.

Separate the bad sensors from the other sensors. Note the location of sensors in cluster.

Unscrew the sensor cable form the sensor.

Reinstall the sensor cable onto the new sensor.

Reinstall the sensor back into the cluster and make sure all sensors are back in their proper

order.

Place the sensor cluster back on the support brackets and replace the shock mount nuts.

Set the new sensor according to Procedure To Adjust Photoelectric Sensor On Bromma

Twin Twenty Detection System (TTDS)

Retest the Twin Twenty Detection System according to Procedure to Trouble Shoot TwinTwenty Detection System.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

23

Twin Twenty Detection System (TTDS)

Procedure to Replace A Twin-Twenty Detection System Controller (TTDC)

Disconnect the cables to the sensors at the TTDC.

Disconnect the main cable to the TTDC.

Remove the nut holding the TTDC.

Remove the TTDC.

Place the new TTDC on the shock mounts.

Reinstall the nut on the shock mounts.

Reinstall the main cable to the TTDC.

Reinstall the sensor cable to the TTDC. Make sure the cables are connected to the proper

connections.

Retest the Twin Twenty Detection System according to Procedure to Trouble Shoot TwinTwenty Detection System.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

24

Twin Twenty Detection System (TTDS)

Procedure to Checking Cable to TTDS Controller

Before checking the cable, check all the connections of the cable to the terminal strips.

Look for loose screws, bad crimps and frayed strands.

If a spare cable is available, temporarily wire the cable in the junction box. Disconnect the

existing cable and plug in the spare cable. Retest the TTDS.

If the meter does not show any voltage, measure and verify with the voltmeter that the

proper voltage in on the wire terminations in the junction box. If not repair the problem

in the junction box. If the proper voltage exists on the wire terminations, replace the

cable.

If the meter reads the proper voltage, Carefully with an voltmeter meter, place one probe on

Pin G and the other to Pin B. The ohm meter should read the proper voltage (24 VDC, 115

VAC or 220 VAC). See the electrical schematic to determine the proper voltage.

If the TTDS operates properly, then replace the existing cable. If the TTDS is not

functioning properly, reconnect the existing cable and follow the Procedure to Trouble

Shoot the TTDS to determine the cause of the problem.

If a spare cable is not available, unplug the cable from the TTDC with the power off. Turn

on the power. Carefully with a voltmeter meter, place one probe on Pin A and the other to

Pin B. The voltmeter meter should read the proper voltage (24 VDC, 115 VAC or 220

VAC). See the electrical schematic to determine the proper voltage.

If any bad connections are found, repair and retest the TTDS

If the meter does not show any voltage, measure and verify with the voltmeter that the

proper voltage in on the wire terminations in the junction box. If not repair the problem

in the junction box. If the proper voltage exists on the wire terminations, replace the

cable.

If the meter reads the proper voltage, remove the power on the spreader. With the ohm

meter set to check for continuity, check each of the wires for continuity. The following

chart shows the pin out for the cable.

Wire No.

1

2

YL/GR

3

4

5

6

7

Pin No.

A

B

C

D

E

F

G

H

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

Function

Power

Neutral

Equipment Ground

Common Supply Relay 1

TTDS Fault Relay 1 (N.O.)

TTDS Fault Relay 1 (N.C.)

Common Supply Relay 2

TTDS Fault Relay 2 (N.O.)

25

Twin Twenty Detection System (TTDS)

8

9

I

J

TTDS Fault Relay 2 (N.C.)

Fault Override (115 VAC)

If the meter shows any breaks in the cable, replace the cable.

If no breaks are found, follow the Procedure to Trouble Shoot the TTDS to determine the

cause of the problem.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

26

Twin Twenty Detection System (TTDS)

Procedure to Checking Sensor

If a spare cable is available, remove the suspected cable and install the spare cable. Retest

the TTDS.

If a spare cable is not available, unplug the cable from the TTDC and the sensor.

With the ohm meter set to check for continuality, check each of the wires for

continuity.

If the TTDS operates properly, then keep the spare cable installed. If the TTDS

is not functioning properly, reconnect the existing cable and look for another

problem.

If the meter shows any breaks in the cable, replace the cable.

If no breaks are found, follow the Procedure to Trouble Shoot the TTDS to determine the

cause of the problem.

BROMMA TTDS Troubleshooting Guide

Revised DECEMBER 2010

27

Potrebbero piacerti anche

- Ficha SpreaderDocumento4 pagineFicha SpreaderMarcos Rivera0% (1)

- SSX40 TrainingDocumento20 pagineSSX40 TrainingDavid Adeola OgunyemiNessuna valutazione finora

- "Big Red": Empty Container Handler Preliminary SpecificationsDocumento4 pagine"Big Red": Empty Container Handler Preliminary SpecificationsNeil DesaiNessuna valutazione finora

- BGS ManualDocumento144 pagineBGS ManualSubhaanNessuna valutazione finora

- 6.3.1 Electrical Circuit Diagram Br1702806: Bromma ManualDocumento45 pagine6.3.1 Electrical Circuit Diagram Br1702806: Bromma ManualMalindaNessuna valutazione finora

- 2632-1266-9900 StinisDocumento302 pagine2632-1266-9900 StinisJugaro OscarNessuna valutazione finora

- Part of My Book of Preventive MaibtenanceDocumento5 paginePart of My Book of Preventive MaibtenanceMohamed Elnagdy0% (1)

- Hydraulic Valve Block and SolenoidDocumento8 pagineHydraulic Valve Block and SolenoidThanh CongNessuna valutazione finora

- RT378 379 Spreader Electrical Schematics BRMY ARF 1849-15-21268 70 - ADocumento44 pagineRT378 379 Spreader Electrical Schematics BRMY ARF 1849-15-21268 70 - AMIGUEL PEÑANessuna valutazione finora

- PSA Crane Spreader Cable Reel Data ProjeDocumento72 paginePSA Crane Spreader Cable Reel Data ProjeCristel Rodríguez BarríaNessuna valutazione finora

- Operations Manual: Bromma Telescopic SpreaderDocumento290 pagineOperations Manual: Bromma Telescopic Spreaderkron32Nessuna valutazione finora

- RTG 05 Hoist Wire Rope DamageDocumento3 pagineRTG 05 Hoist Wire Rope DamageMohammed AtefNessuna valutazione finora

- Terex Gottwald Model 3 Harbour Crane: The Entry Model For The 100-Tonne SegmentDocumento36 pagineTerex Gottwald Model 3 Harbour Crane: The Entry Model For The 100-Tonne SegmentAri Yandoko100% (1)

- Weight Reduction of Reach Stacker (Konecrane)Documento111 pagineWeight Reduction of Reach Stacker (Konecrane)Bruno SantosNessuna valutazione finora

- Profibus KitDocumento18 pagineProfibus Kitkelvin abdo0% (1)

- Sistema Giro Spreader ElmeDocumento3 pagineSistema Giro Spreader ElmeHERNANDO A BECERRANessuna valutazione finora

- Eng SOP 031 Twistlock Inspection & Replacement V 3.1Documento9 pagineEng SOP 031 Twistlock Inspection & Replacement V 3.1ncthanhck0% (1)

- Konecranes SMV 16-1200 SpecificationDocumento2 pagineKonecranes SMV 16-1200 SpecificationNafees ShaikhNessuna valutazione finora

- Liebherr MHC LHM 420Documento8 pagineLiebherr MHC LHM 420Reza Tamba100% (1)

- ZPMC Section 3 Maintenance InstructrueDocumento39 pagineZPMC Section 3 Maintenance Instructrueitalo sanhuezaNessuna valutazione finora

- Dana32 Presentation (Read-Only) (Compatibility Mode)Documento43 pagineDana32 Presentation (Read-Only) (Compatibility Mode)ncthanhck100% (1)

- Bromma Spreader Ysx45e Actual DrawDocumento28 pagineBromma Spreader Ysx45e Actual DrawLUIS FERNANDO DELGADILLO CORONANessuna valutazione finora

- Stinnis HMKDocumento296 pagineStinnis HMKrais80% (5)

- QC Technical Specification - Schedule 5 BCT 14 Jan 13 PoprDocumento160 pagineQC Technical Specification - Schedule 5 BCT 14 Jan 13 PoprCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Technical Deviation List - Cable Reel RTG CargotecDocumento6 pagineTechnical Deviation List - Cable Reel RTG CargotectuanvupnNessuna valutazione finora

- 19850-53 STS45 en r0Documento408 pagine19850-53 STS45 en r0Rafael Quintero SevillaNessuna valutazione finora

- Services Quick Reference Guide: QRG-2021-02-26-revision - Indd 1Documento104 pagineServices Quick Reference Guide: QRG-2021-02-26-revision - Indd 1MahmoudNessuna valutazione finora

- SCU Teach PanelDocumento18 pagineSCU Teach PanelMahen PereraNessuna valutazione finora

- Handleiding Ic4c Incosa Feb2014 v4 enDocumento20 pagineHandleiding Ic4c Incosa Feb2014 v4 enLeninNessuna valutazione finora

- Terex Empty Container HandlersDocumento7 pagineTerex Empty Container HandlersRahmah RohaniNessuna valutazione finora

- SCU System ManualDocumento61 pagineSCU System ManualMahen PereraNessuna valutazione finora

- G HMK 3405 Mobile Harbor Crane: Translation of User's ManualDocumento205 pagineG HMK 3405 Mobile Harbor Crane: Translation of User's Manualthanh100% (3)

- Grove-RT9130E Product Guide PDFDocumento27 pagineGrove-RT9130E Product Guide PDFdacem torres cruzNessuna valutazione finora

- ZP10-1430 Stinger Winch Operator's ManualDocumento22 pagineZP10-1430 Stinger Winch Operator's ManualIvan MaltsevNessuna valutazione finora

- C1574 (Q432118) User Manual Emerson IMHC1210 ItalGruuDocumento39 pagineC1574 (Q432118) User Manual Emerson IMHC1210 ItalGruumliugongNessuna valutazione finora

- 03-17-V1risk Assessment (Wire Rope Replacement) v1Documento4 pagine03-17-V1risk Assessment (Wire Rope Replacement) v1Mohamed ElnagdyNessuna valutazione finora

- B-Repair Ad Maintenance Manual - Rev0Documento82 pagineB-Repair Ad Maintenance Manual - Rev0Carlos Alberto Cortes OlivanNessuna valutazione finora

- Empty Container Handlers: H10-12XM-12ECDocumento16 pagineEmpty Container Handlers: H10-12XM-12ECRami AbdelaalNessuna valutazione finora

- 07 Circuit Diagram Bromma DN4759070 A 1Documento21 pagine07 Circuit Diagram Bromma DN4759070 A 1phanhiep356Nessuna valutazione finora

- Technical Data: Kalmar Contmaster Drs4531-S5Documento4 pagineTechnical Data: Kalmar Contmaster Drs4531-S5ВиталийNessuna valutazione finora

- Steering Axle: RS45-30CH, RS45-27IH, RS46-33CH, RS46-30IH, RS46-36CH, RS46-33IH (A222)Documento22 pagineSteering Axle: RS45-30CH, RS45-27IH, RS46-33CH, RS46-30IH, RS46-36CH, RS46-33IH (A222)stefan corjuc100% (1)

- D3549 2Documento14 pagineD3549 2Minh Canh100% (1)

- SCU IntroductionDocumento10 pagineSCU IntroductionMahen PereraNessuna valutazione finora

- Technical Data: SMV 6/7 Ecb 100 DsDocumento2 pagineTechnical Data: SMV 6/7 Ecb 100 DsNoer Rach100% (1)

- Container Gantry Crane: MaintenanceDocumento46 pagineContainer Gantry Crane: MaintenanceNQTNessuna valutazione finora

- File 3 - ZPMC Brochure, Catalog, Company ProfileDocumento34 pagineFile 3 - ZPMC Brochure, Catalog, Company Profileedark2009Nessuna valutazione finora

- Non-Driven Wheel DIN15090 Series 223 enDocumento1 paginaNon-Driven Wheel DIN15090 Series 223 enayavuzbvsNessuna valutazione finora

- EOT Crane Alignment, Diagonal Checking & Wheel Alignment (Federal Engineers)Documento9 pagineEOT Crane Alignment, Diagonal Checking & Wheel Alignment (Federal Engineers)Hassan ShabbirNessuna valutazione finora

- Operations Manual For BROMMA Telescopic Spreader Type EH170UDocumento474 pagineOperations Manual For BROMMA Telescopic Spreader Type EH170UReinaldo Zorrilla100% (5)

- BR1700850a ApprovalDocumento30 pagineBR1700850a ApprovalMIGUEL PEÑA100% (1)

- 06 Drive AxleDocumento25 pagine06 Drive AxlegsrNessuna valutazione finora

- P H Omega T 250 25 TonDocumento9 pagineP H Omega T 250 25 TonUday Pratap0% (1)

- Hyster j2 2 3 5xnDocumento12 pagineHyster j2 2 3 5xnBraveBoy JalloNessuna valutazione finora

- 06 Drive AxleDocumento36 pagine06 Drive AxleMartin Vargas PedroNessuna valutazione finora

- Test Instructions Slewing Bearing Maximum Allowable Wear: Page 1 Von 3Documento3 pagineTest Instructions Slewing Bearing Maximum Allowable Wear: Page 1 Von 3Ranil KanchanaNessuna valutazione finora

- Caja Allison 4500Documento2 pagineCaja Allison 4500Claudio Duran Caballero0% (1)

- Bucket Elevator Monitoring PDFDocumento7 pagineBucket Elevator Monitoring PDFbulentbulutNessuna valutazione finora

- Fancier Manual (UK)Documento26 pagineFancier Manual (UK)jorgesilva061969Nessuna valutazione finora

- Installers Guide: Acc-Svn18C-EnDocumento12 pagineInstallers Guide: Acc-Svn18C-EnEric WalterNessuna valutazione finora

- MYLAPS RC Manual Vjan2010Documento18 pagineMYLAPS RC Manual Vjan2010pabg76Nessuna valutazione finora

- Rated Loads For Grade 80 (System 8) Alloy Steel Chain SlingsDocumento5 pagineRated Loads For Grade 80 (System 8) Alloy Steel Chain SlingsAshley DeanNessuna valutazione finora

- USL Issue 2Documento3 pagineUSL Issue 2Ashley DeanNessuna valutazione finora

- Rotex Tipo Zs DKM H InglesDocumento1 paginaRotex Tipo Zs DKM H InglesAshley DeanNessuna valutazione finora

- Dura RampDocumento8 pagineDura RampAshley Dean100% (1)

- Bridgestone Cell FenderDocumento53 pagineBridgestone Cell FenderAshley Dean100% (1)

- Wire Rope Forensics Letter PDFDocumento50 pagineWire Rope Forensics Letter PDFAshley DeanNessuna valutazione finora

- Superlift MetricDocumento2 pagineSuperlift MetricAshley DeanNessuna valutazione finora

- Smartlock SL-1 Product DokuDocumento2 pagineSmartlock SL-1 Product DokuAshley DeanNessuna valutazione finora

- Space Mountain at Euro Disney: A 120 Million Dollar Wire Rope Test MachineDocumento18 pagineSpace Mountain at Euro Disney: A 120 Million Dollar Wire Rope Test MachineAshley DeanNessuna valutazione finora

- Brochure PDFDocumento47 pagineBrochure PDFAshley DeanNessuna valutazione finora

- E MOLO MC001 E6 - Disc - CDocumento121 pagineE MOLO MC001 E6 - Disc - CthailanNessuna valutazione finora

- Rail Clip 22 130Documento2 pagineRail Clip 22 130Ashley Dean100% (1)

- Emg Eldro enDocumento20 pagineEmg Eldro enAshley DeanNessuna valutazione finora

- Sprockets Information 1Documento8 pagineSprockets Information 1Ashley DeanNessuna valutazione finora

- Herc Alloy 1000Documento16 pagineHerc Alloy 1000Ashley DeanNessuna valutazione finora

- Pad Eye Design With Side Load 25Documento6 paginePad Eye Design With Side Load 25Ashley DeanNessuna valutazione finora

- Care and Inspection of Wire Rope: National Safety Council Data Sheet 667 Reaf. 89 Rev. June 2005Documento7 pagineCare and Inspection of Wire Rope: National Safety Council Data Sheet 667 Reaf. 89 Rev. June 2005Ashley DeanNessuna valutazione finora

- The Difference Among Three Reference Standards Used in The Performance Evaluation of Wire Rope EMT InstrumentDocumento7 pagineThe Difference Among Three Reference Standards Used in The Performance Evaluation of Wire Rope EMT InstrumentAshley DeanNessuna valutazione finora

- RGP Lens MeasurementDocumento5 pagineRGP Lens MeasurementSumon SarkarNessuna valutazione finora

- XG-646U Service Manual 1 PDFDocumento7 pagineXG-646U Service Manual 1 PDFmiguel angel100% (1)

- KVM Usb Switch 2 Port - Google SearchDocumento1 paginaKVM Usb Switch 2 Port - Google SearchNaveen Gowdru ChannappaNessuna valutazione finora

- 6 Hamilton Syringes and AccessoriesDocumento19 pagine6 Hamilton Syringes and AccessoriesbokedNessuna valutazione finora

- C55-4 (Engineering Recommendation)Documento31 pagineC55-4 (Engineering Recommendation)Yayang Hendriana100% (1)

- DAS Complete System - With S6 ThicknessDocumento47 pagineDAS Complete System - With S6 ThicknessJun Rong FooNessuna valutazione finora

- SVR Order 123498 - VesNatSer - MV ELBRUNNER (IMO 9395563)Documento6 pagineSVR Order 123498 - VesNatSer - MV ELBRUNNER (IMO 9395563)RICARDO FELIPE PAREDES ADOLFONessuna valutazione finora

- X-Ray KVP Meter - Mas Meter - Model 820. X-Ray Calibration & MeasuringDocumento3 pagineX-Ray KVP Meter - Mas Meter - Model 820. X-Ray Calibration & MeasuringAli IbrahimNessuna valutazione finora

- Ix Astronic BlockdiagramDocumento34 pagineIx Astronic BlockdiagramЕвгений АксёновNessuna valutazione finora

- Analyser - Schematic (As of 2021-01-21)Documento11 pagineAnalyser - Schematic (As of 2021-01-21)aryo ganda pakpahanNessuna valutazione finora

- Activity 4 CompleteDocumento12 pagineActivity 4 CompleteMelissa CamargoNessuna valutazione finora

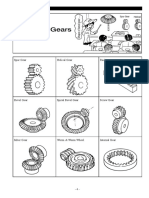

- Type of GearsDocumento8 pagineType of GearsGururaja TantryNessuna valutazione finora

- Dc30 040 QW 400, QW 420, QW 420 D, QW 420 S Service Manual RDocumento56 pagineDc30 040 QW 400, QW 420, QW 420 D, QW 420 S Service Manual RYolanda Peña100% (1)

- Electrical Diagr 962M PDFDocumento57 pagineElectrical Diagr 962M PDFStefan UngurNessuna valutazione finora

- 8x4 Sparepartlistreport (Cyak22100044) Update Part PT WeiDocumento228 pagine8x4 Sparepartlistreport (Cyak22100044) Update Part PT Weiaryaa lorenzoNessuna valutazione finora

- Bag Valve Mask IntersurgicalDocumento4 pagineBag Valve Mask IntersurgicalPeter ChristopherNessuna valutazione finora

- HTW201Documento13 pagineHTW201seenubalaNessuna valutazione finora

- HRSG Chemical Dosing SystemDocumento21 pagineHRSG Chemical Dosing SystemSCE CCGT3Nessuna valutazione finora

- 321DLCR#209Documento1 pagina321DLCR#209Kyaw Thet AungNessuna valutazione finora

- PHD-4 Capillary Leak: Model 969-3540Documento4 paginePHD-4 Capillary Leak: Model 969-3540Sándor Tamás ForczekNessuna valutazione finora

- Home About Us Products Innovation DesignDocumento2 pagineHome About Us Products Innovation DesignAnibalNessuna valutazione finora

- Electrical Team Consumable ItemsDocumento4 pagineElectrical Team Consumable ItemsHamid Khan100% (1)

- Selection and Analysis For Hydraulic Rotary Apparatus of The Deck Hydraulic CraneDocumento4 pagineSelection and Analysis For Hydraulic Rotary Apparatus of The Deck Hydraulic CraneSaravanakumar NNessuna valutazione finora

- Mitsubishi Limiservo X E Series Instruction ManualDocumento144 pagineMitsubishi Limiservo X E Series Instruction ManualLuis Caba RamirezNessuna valutazione finora

- GL PRO Rid en 113Documento27 pagineGL PRO Rid en 113Radenko Skoro25% (4)

- September '96: 709 CARRARO AXLES REF. 122634-122146 For "CASE" IH P100 Spare Parts ListDocumento9 pagineSeptember '96: 709 CARRARO AXLES REF. 122634-122146 For "CASE" IH P100 Spare Parts Listmarc danielNessuna valutazione finora

- DP 460 330L Parts Ver2Documento149 pagineDP 460 330L Parts Ver2Ivan WengerNessuna valutazione finora

- Alta - DSP Jaw Crushers DCDocumento18 pagineAlta - DSP Jaw Crushers DCSergeiNessuna valutazione finora

- 4120 Network Installation InstructionsDocumento4 pagine4120 Network Installation InstructionswaerwNessuna valutazione finora