Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DFZC 7985 1 91 en - GB 1211

Caricato da

RogerioTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DFZC 7985 1 91 en - GB 1211

Caricato da

RogerioCopyright:

Formati disponibili

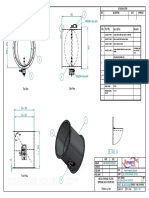

Hammer Mill, Feeder

DFZC-0655 / DFZC-400

Genuine Bhler

spare parts for

longer life cycles.

Grain Processing

Customer Service

PITSTOP Maintenance

The Bhler DFZC hammer mill can be used for finegrinding materials in petfood and aquafeed

production and coarse-grinding products in feed

production, flour milling, and the biomass industry.

A consistently high capacity is crucial for your business

success. In order to avoid a drop in capacity or even an

interruption of production, Bhler experts recommend

you to carry out regular maintenance and to keep a local

stock of the most important parts at your site.

If requested, experienced Bhler service technicians will

perform the inspection and maintenance jobs listed.

Benefits

-

Prevention of production losses by keeping a local

stock of wear parts at your site

Reduction of unforeseen production stoppages by

planning maintenance

Maintaining the machines value by performing

preventive maintenance

Hammer Mill, Feeder

DFZC-0655 / DFZC-400

Incorrect hammer arrangement and the use of

half-worn hammers together with new ones will

create dangerous vibrations and imbalance

Empty gravity separator, clean magnet

Check the condition of the hammers, if

necessary reverse or replace them. Replace

hammers with bores worn out due to

excessive vibrations

Do not replace merely individual hammers, but

always the entire set

DFZH-50043-010

Clean the machine surface

Check the condition of the screens, if

necessary reverse or replace them

Check the inlet wear plates (2 units), the top

wear plates (2 units), and the bottom wear

plate (1 unit) for wear and if necessary

replace them

Inlet wear plate

Top wear plate

Bottom wear plate

DFZC-80001-810

DFZC-80006-810

DFZC-80030-810

Check the condition of the hammer pins and

if necessary replace them

Inlet traces in combination with worn hammers

may result in damage to the screens

DFZC-10520-010

Check the rotor and hammer bearing face

for wear

A high content of foreign matter (e.g. sand) will

lead to increased rotor wear

Check the seals on the door and bearings

and if necessary replace them

DFZC-80037-040

UNN -44035-360

Check the electrical installations for damage

Check the safety circuits

Check the feed roll for wear

Annually /

2000h

Check machine for vibrations and unusual

noises

Part number

Monthly

Remarks

Weekly

Preventive maintenance DFZC

Daily

PITSTOP Maintenance Schedule

DFZC-10116-010

BHLER PITSTOP DFZC Hammer Mill

Hammer Mill, Feeder

DFZC-0655 / DFZC-400

PITSTOP Wear Parts

Wear parts, fine grinding

Part number

Quantity per

machine

Product

throughput

Remarks

Qty

Fine-hole screen D 0.3

DFZC-10122-010

250 350 t

Fine-hole screen D 0.4

DFZC-10122-020

250 350 t

Fine-hole screen D 0.5

DFZC-10122-030

250 350 t

Fine-hole screen D 0.6

DFZC-10122-040

250 350 t

Fine-hole screen D 0.8

DFZC-10122-050

250 350 t

Fine-hole screen D 1.0

DFZC-10122-060

250 350 t

Fine-hole screen D 1.25

DFZC-10122-070

250 350 t

Fine-hole screen D 1.5

DFZC-10122-080

250 350 t

Fine-hole screen D 0.35

DFZC-10122-090

250 350 t

Hammers 155X60X6

DFZH-50043-010

120

750 1200 t

Wear parts, coarse

grinding

Round-hole screen D 1.25

Part number

Produkt-Durchsatz

DFZC-10635-010

Quantity per

machine

2

Remarks

Qty

Round-hole screen D 1.5

DFZC-10635-020

2500 6500 t

Round-hole screen D 2.0

DFZC-10635-030

2500 6500 t

Round-hole screen D 2.5

DFZC-10635-040

2500 6500 t

Round-hole screen D 3.0

DFZC-10635-050

2500 6500 t

Round-hole screen D 3.5

DFZC-10635-060

2500 6500 t

Round-hole screen D 4.0

DFZC-10635-070

2500 6500 t

Round-hole screen D 5.0

DFZC-10635-080

2500 6500 t

Round-hole screen D 6.0

DFZC-10635-090

2500 6500 t

Round-hole screen D 8.0

DFZC-10635-100

2500 6500 t

Hammers 155X60X6

DFZH-50043-010

64

4000 16000 t

Wear parts, hammer mill

Part number

Hammer pins

DFZC-10520-010

Quantity per

machine

8

Intervals

Remarks

Qty

Inlet wear plate

DFZC-80001-810

12 M

Rotor

15Y

Upper section

Top wear plate

DFZC-80006-810

Bottom wear plate

DFZC-80030-810

6 12 M

Upper section

26M

Rubber profile 25/20x2900

Machine frame

DFZC-80037-040

UNN -44035-360

12Y

12Y

Door

Set of seals D 60

Wear parts, feeder

Part number

Quantity per

machine

Intervals

Remarks

Roll shell

DFZC-10116-010

25Y

For DFZC 400 feeder

2500 6500 t

Rotor bearings

Qty

The intervals specified for the wear parts are approximate. Wear depends greatly on the product processed and the impurities contained in

the product, e.g. sand. The intervals refer to 8-hour, 5-day operation.

BUHLER PITSTOP DFZC Hammer Mill

Hammer Mill, Feeder

DFZC-0655 / DFZC-400

PITSTOP Wear parts / Spare parts / Accessories / Options

Critical spare parts

DFZC-0655 hammer mill

Part number

Recomm.

stock

Point of installation

Slide gate 51X35X0,4

DFZC-50152-010

Rotor

Fastening tabs

DFZC-10525-010

Rotor

Key with slit

DFZC-10523-010

Rotor

Feather key 18/11x50

UNN -28002-453

Rotor

Heavy-type spring pin D 5

UNN -18000-058

Rotor

Self-aligning ball bearing D 60

UNN -56005-114

Rotor bearings

Extension spring

DDK -05593-020

Hammer mill

Zero-speed detector 24-240V

UXE -36014-011

Hammer mill

Temp. sensor with lead L = 5 m, ATEX

UXE -26551-021

Grinding chamber / bearings

Pillow block bearing housing

DFMF-50100-020

Temperature monitor of bearings

Temperature controller 100...240VAC

UXE -36113-042

Grinding chamber / bearing ch. (option)

Temperature controller 24VDC/AC

UXE -36113-053

Grinding chamber / bearing ch. (option)

Capacitive proximity switch

UNE -26350-001

High-level probes top/bottom surge

(buffer) hoppers

Critical spare parts

DFZC-400 feeder

Part number

Recomm.

stock

Point of installation

Linear drive, stroke 130 mm

UXM -56011-013

Hammer mill and feeder

Safety door interlock

UXE -40042-231

Hammer mill and feeder

Options / retrofit packs

Part number

Quantity per

machine

Vibration detector

DFZC-10289-001

Consisting of sensor and lead

Temperature monitor, grinding chamber

DFZC-10340-001

With 1x temperature sensor PT-100

Temperature monitor, bearing chamber

DFZC-10338-001

With 2x temperature sensors PT-100

Qty

Qty

Qty

Machine number

(please always specify)

Company

Name / first name

Street / No.

Post code / place / country

Phone

E-mail

Place / date

Signed

Remarks

Bhler AG

Grain Processing Customer Service

CH-9240 Uzwil, Switzerland

T +41 (0)71 955 30 40

F +41 (0)71 955 33 05

service.gp@buhlergroup.com

www.buhlergroup.com

BUZ/GPCS41 DFZC-7985-1-91-en_GB-1211

Request for quotation

Potrebbero piacerti anche

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDa EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNessuna valutazione finora

- Classicmill CLM 1-2-3 Instruction ManualDocumento87 pagineClassicmill CLM 1-2-3 Instruction ManualJeremy ShaneNessuna valutazione finora

- Equations For The Design of Standard Sprocket TeethDocumento4 pagineEquations For The Design of Standard Sprocket TeethvanjaurkeNessuna valutazione finora

- Drawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMDocumento1 paginaDrawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMjonodo89Nessuna valutazione finora

- Power Powders: The inDocumento6 paginePower Powders: The insalkan_rahmanovic810Nessuna valutazione finora

- m0043 016 2 PDFDocumento1 paginam0043 016 2 PDFajarekarga ajarekarNessuna valutazione finora

- A554 y 730 HV DWG Hva 300Documento1 paginaA554 y 730 HV DWG Hva 300josephNessuna valutazione finora

- Be 4800 Spec Sheet 2Documento1 paginaBe 4800 Spec Sheet 2Nhero DulatreNessuna valutazione finora

- 11-2756-b Elevator Boot Assy 28SIDocumento1 pagina11-2756-b Elevator Boot Assy 28SIBoanerges BritoNessuna valutazione finora

- 50055781Documento14 pagine50055781Monu SharmaNessuna valutazione finora

- Donaldson UK Manual TDS PDFDocumento19 pagineDonaldson UK Manual TDS PDFPatricio TamayoNessuna valutazione finora

- Hammer Mill ManualDocumento20 pagineHammer Mill Manualdatnguyen789jNessuna valutazione finora

- Plan Elevation: Job No. ClientDocumento1 paginaPlan Elevation: Job No. Clientriz2010Nessuna valutazione finora

- 185-170-5-300-M44-0055 RevBDocumento1 pagina185-170-5-300-M44-0055 RevBVashish RamrechaNessuna valutazione finora

- Notes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512Documento2 pagineNotes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512antoine131Nessuna valutazione finora

- SEMA AH Hook Block Assly. Sheet 2 3Documento1 paginaSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraNessuna valutazione finora

- 50 Cu Yd (Heaped) Aggregate Bin 225 BBL (MAX) Cement I Bin: Rear ViewDocumento1 pagina50 Cu Yd (Heaped) Aggregate Bin 225 BBL (MAX) Cement I Bin: Rear ViewDavid SarccoNessuna valutazione finora

- NW1213 GA Primary (With TK11-42-2V)Documento1 paginaNW1213 GA Primary (With TK11-42-2V)darko1969Nessuna valutazione finora

- Test Fixture Optical MountDocumento1 paginaTest Fixture Optical Mounti50229Nessuna valutazione finora

- BMG-BMG/X: Single Channel Square PlansifterDocumento4 pagineBMG-BMG/X: Single Channel Square PlansifterToufik Ahmed Emon100% (1)

- DWG 415-019 REV 0Documento7 pagineDWG 415-019 REV 0jonodo89Nessuna valutazione finora

- Weld Map Control RoomDocumento12 pagineWeld Map Control RoomAry Cipta KusumaNessuna valutazione finora

- Draw Ing Approval Required: Nord Gear Corporation QUOTE: 85-050416HA N/A N/A N/ADocumento1 paginaDraw Ing Approval Required: Nord Gear Corporation QUOTE: 85-050416HA N/A N/A N/ADiego MejiaNessuna valutazione finora

- RTP DRYER SYSTEM DIAGRAMDocumento16 pagineRTP DRYER SYSTEM DIAGRAMPotential SupportNessuna valutazione finora

- Sliding Elastomeric Bearing - 301 MTDocumento1 paginaSliding Elastomeric Bearing - 301 MTAnusha KishoreNessuna valutazione finora

- Chipper Knives For The Wood IndustryDocumento5 pagineChipper Knives For The Wood IndustryX800XLNessuna valutazione finora

- Part 1 - Trolley WheelDocumento1 paginaPart 1 - Trolley WheellexatrinNessuna valutazione finora

- Conveyorchains HitachiDocumento173 pagineConveyorchains HitachiLLNessuna valutazione finora

- Machine Afzar Shams: Bearing HousingDocumento8 pagineMachine Afzar Shams: Bearing HousingmasoodkamaliNessuna valutazione finora

- 0740 19a PDFDocumento1 pagina0740 19a PDFDavid SarccoNessuna valutazione finora

- Structural steel beam design detailsDocumento1 paginaStructural steel beam design detailsPRASHANTHNessuna valutazione finora

- Bucket Elevator NewDocumento5 pagineBucket Elevator NewLabib Zainul AzizNessuna valutazione finora

- Intercambiador de Calor PDFDocumento10 pagineIntercambiador de Calor PDFShalber Jhoel Garcia SaraviaNessuna valutazione finora

- Approval Required: Material ListDocumento2 pagineApproval Required: Material ListJorge VarelaNessuna valutazione finora

- Conveyor Cross Section at Each Typical Segment r0 - c3Documento1 paginaConveyor Cross Section at Each Typical Segment r0 - c3Harish KumarNessuna valutazione finora

- Manual Da Deslintadeira-200 SerrasDocumento56 pagineManual Da Deslintadeira-200 SerrasAilson Silva AlvesNessuna valutazione finora

- Renold Conveyor Chain Catalogue Designer GuideDocumento41 pagineRenold Conveyor Chain Catalogue Designer Guidedeep200Nessuna valutazione finora

- R-5 - Cuhayon Rice MillDocumento7 pagineR-5 - Cuhayon Rice MillJonathan RodolfoNessuna valutazione finora

- Belt Conveyor 600x12000 (k2) - Belt Conveyor TataDocumento1 paginaBelt Conveyor 600x12000 (k2) - Belt Conveyor TataAde SNessuna valutazione finora

- Spur Gear DesignDocumento2 pagineSpur Gear DesignRamji RaoNessuna valutazione finora

- Sae Insert S1yt3232 DWG 0Documento1 paginaSae Insert S1yt3232 DWG 0kaliya12Nessuna valutazione finora

- KSUBANDSAW-320 Operation ManualDocumento30 pagineKSUBANDSAW-320 Operation Manualamri sofyanNessuna valutazione finora

- Detail H Scale 1: 3: Section E-E SCALE 1: 10Documento2 pagineDetail H Scale 1: 3: Section E-E SCALE 1: 10Brahamadandi Achyuth KumarNessuna valutazione finora

- Sample - Belt Bucket Elevator DesignDocumento7 pagineSample - Belt Bucket Elevator DesignAli DandamunNessuna valutazione finora

- Sprocket PT Petrodrill Manufacture IndonesiaDocumento1 paginaSprocket PT Petrodrill Manufacture Indonesiaer_winwibowoNessuna valutazione finora

- Conveyor Design DataDocumento2 pagineConveyor Design Datamrmp bbiNessuna valutazione finora

- Auto SamplerDocumento25 pagineAuto Samplerucb2_ntpcNessuna valutazione finora

- Preliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingDocumento1 paginaPreliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingbarrosojmsNessuna valutazione finora

- GA-150027-1 (003) Ffetbigbore1750 PDFDocumento1 paginaGA-150027-1 (003) Ffetbigbore1750 PDFriinNessuna valutazione finora

- Horizontal Band SawDocumento17 pagineHorizontal Band SawOscar AdrianNessuna valutazione finora

- S.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen BoltDocumento1 paginaS.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen Boltsabir hussainNessuna valutazione finora

- 185-170-5-300-M44-0058 RevDDocumento1 pagina185-170-5-300-M44-0058 RevDVashish RamrechaNessuna valutazione finora

- STD Drainage Drawings Page 2 PDFDocumento1 paginaSTD Drainage Drawings Page 2 PDFcherielyn.riveraNessuna valutazione finora

- Electromagnetic Feeders Light CapacityDocumento4 pagineElectromagnetic Feeders Light CapacityBANGGANessuna valutazione finora

- 45T 01 000.dwgDocumento196 pagine45T 01 000.dwgjuanNessuna valutazione finora

- Item Section Size Material Grade Length (MM) Mass (KG) Per ItemDocumento1 paginaItem Section Size Material Grade Length (MM) Mass (KG) Per ItemMohammad AdilNessuna valutazione finora

- Item Parts ListDocumento3 pagineItem Parts ListMiltongrimi GrimilNessuna valutazione finora

- Chain Appron Conveyor R1a01-BushingDocumento1 paginaChain Appron Conveyor R1a01-Bushinger_winwibowoNessuna valutazione finora

- DFZP 8120 1 91 en - GB 1311Documento4 pagineDFZP 8120 1 91 en - GB 1311RogerioNessuna valutazione finora

- Hammer Mill, Feeder DFZC-0655 / DFZC-400: Pitstop - MaintenanceDocumento4 pagineHammer Mill, Feeder DFZC-0655 / DFZC-400: Pitstop - Maintenanceghazi trikiNessuna valutazione finora

- Advanced Engineering Mathematics With MATLAB by Dean G. DuffyDocumento646 pagineAdvanced Engineering Mathematics With MATLAB by Dean G. DuffyRogerioNessuna valutazione finora

- SolidWorks Motion Tutorial 2013Documento32 pagineSolidWorks Motion Tutorial 2013bhumijayaNessuna valutazione finora

- ADAMS - BASIC - TRAINING - and - EXAMPLES - B5Documento172 pagineADAMS - BASIC - TRAINING - and - EXAMPLES - B5dragishaNessuna valutazione finora

- Datasheet ArcMate 120ic 12LDocumento1 paginaDatasheet ArcMate 120ic 12LmuertesalvajeNessuna valutazione finora

- Thermal and Stress Analysis With The Finite Element Method: Petr KryslDocumento385 pagineThermal and Stress Analysis With The Finite Element Method: Petr KryslRogerioNessuna valutazione finora

- Wes Mosler - The Piping and Tubing Design Guide For SolidWorks Routing 2011 - 2011Documento160 pagineWes Mosler - The Piping and Tubing Design Guide For SolidWorks Routing 2011 - 2011Mahdi Daly100% (7)

- 01 Propeller Tutorial PDFDocumento20 pagine01 Propeller Tutorial PDFMarko MatićNessuna valutazione finora

- Automatic Control For Mechanical Engineers by M. Galal Rabie - OptDocumento176 pagineAutomatic Control For Mechanical Engineers by M. Galal Rabie - OptRogerioNessuna valutazione finora

- Automatic Control For Mechanical Engineers by M. Galal Rabie - OptDocumento176 pagineAutomatic Control For Mechanical Engineers by M. Galal Rabie - OptRogerioNessuna valutazione finora

- Wes Mosler - The Piping and Tubing Design Guide For SolidWorks Routing 2011 - 2011Documento160 pagineWes Mosler - The Piping and Tubing Design Guide For SolidWorks Routing 2011 - 2011Mahdi Daly100% (7)

- Learning Slides VBADocumento250 pagineLearning Slides VBAswelitshhNessuna valutazione finora

- Introductory Finite Element TextbookDocumento239 pagineIntroductory Finite Element TextbookRogerioNessuna valutazione finora

- VBA Book PDFDocumento121 pagineVBA Book PDFAriadiKetutNessuna valutazione finora

- Nastran PrimerDocumento376 pagineNastran Primerfred flintstoneNessuna valutazione finora

- Windmill Tutorial 13bDocumento43 pagineWindmill Tutorial 13bAndrei CiunganNessuna valutazione finora

- Mechanical Vibration - Willian J. Palm IIIDocumento6 pagineMechanical Vibration - Willian J. Palm IIIRogerio0% (5)

- Autodesk Nastran User's Manual 2018Documento629 pagineAutodesk Nastran User's Manual 2018Amit Nirmal100% (1)

- Machine Drawing 3rd EditionDocumento463 pagineMachine Drawing 3rd EditionRogerioNessuna valutazione finora

- Intro To Adv Finite Element Analysis... !!!!Documento66 pagineIntro To Adv Finite Element Analysis... !!!!Samarjit Kalsi100% (1)

- Introductory Finite Element TextbookDocumento239 pagineIntroductory Finite Element TextbookRogerioNessuna valutazione finora

- Lecture Notes On Finite Element II Victor SaoumaDocumento64 pagineLecture Notes On Finite Element II Victor SaoumaIbrahim SuryaNessuna valutazione finora

- Lecture Notes On Finite Element II Victor SaoumaDocumento64 pagineLecture Notes On Finite Element II Victor SaoumaIbrahim SuryaNessuna valutazione finora

- Solving Problems in Dynamics and Vibrations Using MATLABDocumento104 pagineSolving Problems in Dynamics and Vibrations Using MATLABVivek ChauhanNessuna valutazione finora

- Basic DynamicsDocumento398 pagineBasic DynamicsRogerioNessuna valutazione finora

- Numerical PDFDocumento283 pagineNumerical PDFRogerioNessuna valutazione finora

- A Matlab Tutorial 2012Documento182 pagineA Matlab Tutorial 2012RogerioNessuna valutazione finora

- Mountainboard Design Project Student 2010 LR ENG PDFDocumento541 pagineMountainboard Design Project Student 2010 LR ENG PDFErin WalkerNessuna valutazione finora

- Resistencia de Materiales - N. M. Belyaev - Strength of Materials - Mir PDFDocumento650 pagineResistencia de Materiales - N. M. Belyaev - Strength of Materials - Mir PDFlitalomp05Nessuna valutazione finora

- Projeto de Uma Catapulta em SolidWorksDocumento68 pagineProjeto de Uma Catapulta em SolidWorksRogerioNessuna valutazione finora

- Goniophotometer T1: OxytechDocumento6 pagineGoniophotometer T1: OxytechGustavo CeccopieriNessuna valutazione finora

- 01-Jul-21 03:32 PMDocumento6 pagine01-Jul-21 03:32 PMramNessuna valutazione finora

- LC IN SCIENCE and MathDocumento14 pagineLC IN SCIENCE and MathCharity Anne Camille PenalozaNessuna valutazione finora

- Sensors 22 09378 v2Documento13 pagineSensors 22 09378 v2FahdNessuna valutazione finora

- 0001981572-JAR Resources in JNLP File Are Not Signed by Same CertificateDocumento13 pagine0001981572-JAR Resources in JNLP File Are Not Signed by Same CertificateAnonymous AZGp1KNessuna valutazione finora

- RelativedensityipgDocumento2 pagineRelativedensityipgapi-310625232Nessuna valutazione finora

- Displaymax JR 1500 SpecsDocumento1 paginaDisplaymax JR 1500 SpecsFRANCISCONessuna valutazione finora

- Sequelize GuideDocumento5 pagineSequelize Guidemathur1995Nessuna valutazione finora

- Craig Vaughan CHPTR 07Documento44 pagineCraig Vaughan CHPTR 07Jorge CananeaNessuna valutazione finora

- Impeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLDocumento1 paginaImpeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLSenthilkumar RamalingamNessuna valutazione finora

- NEC Article 250Documento42 pagineNEC Article 250unknown_3100% (1)

- Design & Fabrication of a Cost-Effective Agricultural DroneDocumento57 pagineDesign & Fabrication of a Cost-Effective Agricultural DroneFatima Nasir R:29Nessuna valutazione finora

- Instrument Resume OIL and GAS.Documento3 pagineInstrument Resume OIL and GAS.RTI PLACEMENT CELLNessuna valutazione finora

- PTP - Level MethodsDocumento23 paginePTP - Level Methodssasikiran mNessuna valutazione finora

- FOT - CG Limitation A320neo - Web ConferenceDocumento7 pagineFOT - CG Limitation A320neo - Web Conferencerohan sinha100% (2)

- PF-CIS-Fall 2022 LABDocumento4 paginePF-CIS-Fall 2022 LABMuhammad FaisalNessuna valutazione finora

- Potenciometro 15KDocumento8 paginePotenciometro 15Kra101208Nessuna valutazione finora

- Hot Rolled Sheet Pile SHZ Catalogue PDFDocumento2 pagineHot Rolled Sheet Pile SHZ Catalogue PDFkiet eelNessuna valutazione finora

- © Ncert Not To Be Republished: AlgebraDocumento12 pagine© Ncert Not To Be Republished: Algebrakritagyasharma29Nessuna valutazione finora

- RMA 3000 Remote Meter Assemblies Specifications: 34-ST-03-81, July 2017Documento8 pagineRMA 3000 Remote Meter Assemblies Specifications: 34-ST-03-81, July 2017Amir LopezNessuna valutazione finora

- PresiometroDocumento25 paginePresiometrojoseprepaNessuna valutazione finora

- SERVICE MANUAL CRAWLER EXCAVATOR R210LC-7Documento1 paginaSERVICE MANUAL CRAWLER EXCAVATOR R210LC-7DmitryNessuna valutazione finora

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingDocumento10 pagineA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJENessuna valutazione finora

- OracleDocumento23 pagineOracleriza arifNessuna valutazione finora

- LTE and SchedulingDocumento25 pagineLTE and SchedulingKrunoslav IvesicNessuna valutazione finora

- PM Master Data Template v1Documento72 paginePM Master Data Template v1Naseer SultanNessuna valutazione finora

- NewsDocumento26 pagineNewsMaria Jose Soliz OportoNessuna valutazione finora

- Sensor CatalogueDocumento72 pagineSensor Cataloguefurious man67% (3)

- DSD - Assignment 1 2018Documento3 pagineDSD - Assignment 1 2018Naveen KumarNessuna valutazione finora

- Pneumatic Tyres: CMR Engineering CollegeDocumento17 paginePneumatic Tyres: CMR Engineering CollegeHemanth Rama Krishna YernagulaNessuna valutazione finora