Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rock Characterization at El Teniente Mine PDF

Caricato da

Emanuel NicolásDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rock Characterization at El Teniente Mine PDF

Caricato da

Emanuel NicolásCopyright:

Formati disponibili

Cave mining-the state of the art

"

~

by D.H. Laubscher*

Synopsis

Introduction

Caving is the lowestcost underground

mining method provided

that the drawpoint

spacing, drawpoint size,

and ore-handling

facilities are designed to

suit the caved material,

and that the drawpoint

horizon can be

malntalnedfor the life

qfthe draw. In the near

future, several open-pit

mines that produce more

than 50 kt per dqy will

have to examine the

feasibility qf converting

to low-cost, large-scale

underground operations.

Several other largescale, low-grade

underground operations

will experience mqjor

changes in their mining

environments as large

dropdowns are

implemented

These changes

demand a more realistic

approach to mine

planning than in the

past, where existing

operations have been

prqjected to increased

depths with little

consideration qf the

change in mining

environment that will

occur. As economics

force the consideration

qf underground mining

qf large, competent

Cave mining refers to all mining operations in

which the orebody caves naturally after

undercutting and the caved material is recovered

through drawpoints. This includes block caving,

panel caving, inclined-drawpoint

caving, and

front caving. Caving is the lowest-cost

underground mining method provided that the

drawpoint size and handling facilities are

tailored to suit the caved material and that the

extraction horizon can be maintained for the life

of the draw.

The daily production from cave-mining

operations throughout the world is approximately

370 kt per day, with the following breakdown

from different layouts:

Grizzly

Slusher

LHD*

kt

90

35

245

Total

370

Load-haul-dumpunits

By comparison, South African gold mines

produce 350 kt per day.

In the near future, several mines that

currently produce in excess of 50 kt per day from

open-pit mines will have to examine the

feasibility of implementing low-cost, large-scale

underground mining methods. Several cave mines

that produce high tonnages from underground are

planning to implement dropdowns of 200 m or

more. This will result in a considerable change in

their mining environments. These changes will

necessitate detailed mine planning, rather than

the simple projection of current mining methods

to greater depths.

As more attention is directed to the mining

oflarge, competent orebodies by low-cost

underground methods, it is necessary to derIDe

the role of cave mining. In the past, caving has

been considered for rockmasses that cave and

fragment readily. The ability to better assess the

cavability and fragmentation of orebodies, and

the availability of robust LHDs, an

understanding of the draw-control process,

suitable equipment for secondary drilling and

blasting, and reliable cost data have shown that

competent orebodies with coarse fragmentation

can be cave-mined at a much lower cost than

with drill-and-blast methods. However, once a

cave layout has been developed, there is little

scope for change.

Aspects that have to be addressed are

cavability, fragmentation, draw patterns for

different types of ore, drawpoint or drawzone

spacing, layout design, undercutting sequence,

,md support design.

Table I shows that there are significant

anomalies in the quoted performance of different

cave operations.

. p.a. Box 95,

Explanation

Boesmansriviermond

6190. Cape Province.

Under-evaluation

<9 The South 4frican

Institute if Mining and

Metallurgy, 1994. SA

ISBN 0038-223X/3.00

+

0.00. Paper received,

Drawpoints

of The

South

African

and dilution zone

Institute

of Mining

and

Metallurgy

of the

being drawn in isolation

A large range in fragmentation.

the dilution zone

Sept 1993; revised paper

receivedAzg. 1994.

The Journal

of the orebody

A case of highly irregular draw and under-evaluation

dilution

OCTOBER 1994

and irregular, high values in

279

....

Cave mining-the state of the art

orebodies by low-cost

methods, the role qf

cave mining will have

to be dUined In the

past, caving was

generallY consideredfor

rockmasses that cave

andfragment readilY.

The ability to define

cavability andfragmentation, the availability

qf large, robust

load-haul-dump units,

a better understanding

qf draw-control

requirements, improved

drilling equipment for

secondary blasting, and

reliable cost data have

shown that competent

orebodies with coarse

fragmentation

can be

exploited by cave

mining at a much lower

cost than by drill-andblast methods.

It is common to find that old established

mines, which have developed standards during

the course of successfully mining the easy

tonnage in the upper levels of the orebody, have a

resistance to change and do not adjust to the

ground-control problems that occur as mining

proceeds to greater depths, or as the rock types

change. Mines that have experienced continuous

problems are more amenable to adopting new

techniques to cope with a changing mining

situation. Detailed knowledge of local and

regional structural geology, the use of an accepted

rockmass classification to characterize the

rockmass, and knowledge of the regional and

induced stress environment are prerequisites for

good mine planning. It is encouraging to note that

these aspects are receiving more and more

attention.

The Laubscher rockmass classification

system that provides both rockmass ratings and

rockmass strength is necessary for design

purposes. The rockmass ratings (RMR) define

the geological environment, and the adjusted or

mining rockmass ratings (MRMR) consider the

effect of the mining operation on the rockmass.

The ratings, details of the mining environment,

and the way in which this affects the rockmass

and geological interpretation are used to define

the cavability, subsidence angles, failure zones,

fragmentation, undercut-face shape, cave-front

orientation, undercutting sequence, overall

mining sequence, and support design.

Factors Affecting Caving Operations

Twenty five parameters that should be

considered before the implementation of any

cave mining operation are set out in Table H. The

parameters in capital letters are a function of the

parameters that follow in the same box. Many of

the parameters are uniquely defined by the

orebody and the mining system, and are not

discussed further. The parameters considered

later are common to all cave-mining systems and

need to be addressed if any form of cave mining

is contemplated.

Cavability

Monitoring of a large number of caving

operations has shown that two types of caving

can occur. These have been defined as stress and

subsidence caving.

Stress caving occurs in virgin cave blocks

when the stresses in the cave back exceed the

strength of the rockmass. Caving can stop when

a stable arch develops in the cave back. The

undercut must be increased in size, or boundary

weakening must be undertaken to induce further

caving.

Subsidence caving occurs when adjacent

mining has removed the lateral restraint on the

block being caved. This can result in rapid

propagation of the cave, with limited bulking.

Figure 1 illustrates the effect of removing the

lateral restraint from block 16 at Shabani. Block

16 had a hydraulic radius of 28 with an MRMR

of 64 and a stable, arched back. The adjacent

block, no. 7, was caved and resulted in a

reduction in the MRMR in block 16 to 56, at

which stage caving occurred. For a range of

MRMR, Figure 1 illustrates worldwide caving

and stable situations.

The stresses in the cave back can be

modified to an extent by the shape of the cave

front. Numerical modelling can be a useful tool,

helping the engineer to determine the stress

pattern associated with several possible mining

sequences. An undercut face, concave towar~s

the caved area, provides better control of major

structures. In orebodies with a range of MRMR,

the onset of continuous caving will be based on

the lower rating zones if these are continuous in

plan and section. This is illustrated in Figure 2B,

where the class 5 and 4B zones are shown to be

continuous. In Figure 2A, the pods of class 2

rock are sufficiently large to influence caving,

and the cavability should be based on the rating

of these pods.

All rockmasses will cave. The manner of

their caving and the resultant fragmentation size

distribution need to be predicted if cave mining

is to be implemented successfully. The rate of

caving can be slowed down by control of the

draw since the cave can propagate only if there

is space into which the rock can move. The rate

of caving can be increased by a more rapid

advance of the undercut, but problems can arise

if this allows an air gap to form over a large

area. In this situation, the intersection of major

structures, heavy blasting, and the influx of

water can result in damaging airblasts. Rapid,

uncontrolled caving can result in an early influx

of waste dilution.

The rate of undercutting (RV) should be

controlled so that rate of caving (RC) is faster

than the rate of damage (RD);

RC>RU>RD.

280

OCTOBER

1994

The Joumal of The South African Institute of Mining and Metaliurgy

Cave mining-the state of the art

Table 11

Parameters to be considered before the implementation of cave mining

PRIMARY

FRAGMENTATION

Rockmass strength (MRMR)

Geological structures

Joint/fracture spacing

Joint condition ratings

Stress or subsidence caving

Induced stress

LAYOUT

Fragmentation

Drawpoint spacing

Method of draw

and size

UNDERCUTTING

SEQUENCE

(pre/advance/post)

Regional stresses

Rockmass strength

Rockburst potential

Rate of advance

Ore requirements

DEVELOPMENT

Layout

Sequence

Production

Drilling and blasting

PRACTICAL

EXCAVATION

SIZE

Rockmass strength

In situ stress

Induced stress

Caving stresses

Secondary blasting

DRAWPOINT

INTERACTION

Drawpoint spacing

Fragmentation

Time frame of working

SECONDARY

drawpoints

BLASTING/BREAKING

Secondary fragmentation

Draw method

Drawpoint size

Size of equipment and grizzly spacing

SUPPORT

REPAIR

Tonnage drawn

Point and column loading

Brow wear

Secondary blasting

The Joumal of The South African Institute of Mining and Metallurgy

OCTOBER

1994

281

....

Cavemining-the state of the art

100

STABLE:

80

TRANSITIONAL:

Supportable in upper band, with arching

in middle band and intermittent caving/arching in lower

band depending on outside influences such as blasting,

water.

70

CA VING: Progressive caving of cave back or walls into

previously caved areas.

~60

Cavability,

90

::E

Only local support required.

~::E

function of:

Rockmass strength

Geological structure

In situ stress

Water

Induced stress

50

40

0

~

30

MRMR

]

Stable

Transitional

. Caving

20

10

0

I

0

10

20

50

30

I

100

HYDRAULIC

40

50

150

60

I

200

80metres

70

I

250

feet

=Area/perimeter

RADIUS

Figure 1-A stability diagram for various mines worldwide

CROSS SECTION BLOCK WEST/2

CROSS SECTION BLOCK 7/2

.'., ..'

; .

A

ClASS lA,B

0 10 20

ClASS 2A,B

50

ClASS 3A,B

~~11

Figure 2-Geomechanics

~ 282

lOOm

ClASS 4A,B

ClASS 5A,B

I:;;~"~',":;;':"I

classification data

OCTOBER

1994

The Journal of The South African Institute of Mining and Metallurgy

Cave mining-the state of the art

Good geotechnicaIinformation,as wellas

monitoring of the rate of caving and rockmass

damage, is needed to fine-tune this relationship.

Fragmentation

In caving operations, fragmentation has a

bearing on the following:

>- Drawpoint spacing

>- Dilution entry into the draw column

>- Draw control

>- Drawpoint productivity

>- Secondary blasting/breaking costs

>- Secondary blasting damage.

The input data needed for the calculation of

the primary fragmentation and the factors that

determine the secondary fragmentation as a

function of the caving operation are shown in

Figure 3.

Caving results in primary fragmentation,

which can be defined as the size distribution of

the particles that separate from the cave back

and enter the draw column. The primary

fragmentation from stress caving is generally

finer than that from subsidence caving owing to

the rapid propagation of caving in the latter case,

with disintegration of the rockmass, primarily

along favourably oriented joint sets, and little

shearing of intact rock. The orientation of the

cave front or back with respect to the joint sets

and direction of principal stress can have a

significant effect on the primary fragmentation.

INPUT

DATA

Secondary fragmentation is the reduction

in size of the original particle that enters the

draw column as it moves through the draw

column. The processes to which particles are

subjected determine the fragmentation size

distribution in the particles that report to the

drawpoints. A strong, well-jointed material can

result in a stable particle shape at a low draw

height. Figure 4 shows the decrease in fragmentation for different draw heights and less-jointed

(coarse) to well-jointed (fine) rockmasses. A

range in rockmass ratings will result in a wide

range in fragmentation size distribution as

compared with that produced by rock with a

single rating, since the fine material produced by

the former tends to cushion the larger blocks and

prevents further attrition of these blocks. This is

illustrated in Figure 2B, in which class 5 and

class 4 material is shown to cushion the larger

primary fragments from class 3. A slow rate of

draw allows a higher probability of timedependent failure as the caving stresses work on

particles in the draw column.

Fragmentation is the major factor

determining drawpoint productivity. Experience

has shown that 2 m3 is the largest size of block

that can be moved by a 6 yd LHD and still allow

an acceptable rate of production to be

maintained. In Figure 5 the productivity of a

layout using 3,5 yd, 6 yd, and 8 yd LHDs and a

grizzly are related to the percentage of fragments

larger than 2 m3. The usage of secondary

explosives is based on the amount of oversize

that cannot be handled by a 6 yd LHD.

Orientation-Cave

Front/Joints

CAVING

OPERATION

PRODUCTION

Secondary Blasting

Damage and Costs

=

Operational Costs and Overall Productivity

Figure ~nput

The Joumal

data for the calculation of fragmentation

of The South African Institute of Mining and Metallurgy

OCTOBER

1994

283

....

Cave mining-the state of the art

350mm

14" Gr

500mm

20' Gr

3yd IJID

6yd lJID

100

.S

""

(f)

90

80

(f)

70

'"'" 80

" 50

~

~... 30

40

"

" 20

'"

10

0,1

0.1

0.01

1.0

SIZE

m3

10.0

105m

350

1300

""'"

325

'"

E-

Fragmentation

>.

<0

""

1200

300

1100

275

1000

250

900

225

200

'"

c3

I

BOO

<Z>

[; 700

0..

Secondary

distribution of cave fragmentation

1400

--'

:a

100.0

DrawHeight

Primary Fragmentation

-* - - -

15% Drilled and Blasted

= 8% of Operating Cosls

Figure 4-Size

2.0

175

"

'"

.:=.

'"

150

~

i(J

i:C

500

125

400

100

300

75

200

50

100

25

600

""....

'e

<=>

i:'

i

~

0

0,1

Percentage

+ 2m3

5

- Secondary

10 2030

Fragmentation

5070

Figure 5-LHD productivity on a round trip of 100 m with 60 per cent utilization

Sand-model tests have shown that there is a

relationship between the spacing of drawpoints

and the interaction of drawzones. Widely spaced

drawpoints develop isolated drawzones, with

diameters defined by the fragmentation. When

drawpoints are spaced at 1,5 times the diameter

of the isolated drawzone (IDZ) , interaction

occurs. The interaction improves as the

drawpoint spacing is decreased, as shown in

Figure 7. The flow lines and the stresses that

develop around a drawzone are shown in Figure

8. The sand-model results have been confirmed

by observation of the fine material extracted

during cave mining and by the behaviour of

material in bins. The question is whether the

interactive theory based on isolated drawzones

can be wholly applied to coarse material, where

arch spans of 20 m have been observed. The

collapse of large arches will affect the large area

overlying the drawpoint, as shown in Figure 9.

The formation and failure of arches lead to wide

drawzones in coarse material, so that the

drawzone spacing can be increased to the

spacings shown in Figure 9. The frictional

properties of the caved material must also be

recognized. Low-friction material could flow

greater distances when under high overburden

load, and this could mean a wider drawzone

spacing.

There is still a need to continue with threedimensional model tests to establish some poorly

defined principles, such as interaction across

major apexes when the spacing of groups of

interactive drawzones is increased. Numerical

modelling could possibly provide the solutions

for the draw behaviour of coarse-fragmented

cave material.

Draw Control

A computer simulation program has been

developed for the calculation of primary and

secondary fragmentation.

Drawzone

Spacing

Drawpoint spacings for grizzly and slusher

layouts reflect the spacing of the drawzones

because of the close spacing of the drawpoints.

However, in the case ofLHD layouts with a

nominal drawpoint spacing of 15 m, the

drawzone spacing can vary across the major

apex (pillar) from 18 to 24 m, depending on the

length of the drawbell (Figure 6). This situation

occurs when the length of the drawpoint crosscut

is increased to ensure that the LHD is straight

before it loads. In this case, the major consideration, optimum ore recovery, is prejudiced by

incorrect usage of equipment or a desire to

achieve idealized loading conditions.

~ 284

OCTOBER

1994

The draw-control requirements are shown in

Figure 10 and Table Ill. The grade and fragmentation distribution for the dilution zone must be

known if sound draw control is to be practised.

Figure 11 shows the value distribution for

columns A and B. Both columns have the same

average grade of 1,4 per cent, but the value

distribution is different. The high grade at the

top of column B means that a larger tonnage of

dilution can be tolerated before the shutoff grade

is reached.

In LHD layouts, a major factor in poor draw

control is the drawing of fine material at the

expense of coarse material. A strict draw-control

discipline is required in that the coarse ore must

be drilled and blasted at the end of the shift in

which it reported in the drawpoint.

The Joumal of The South African Institute of Mining and Metallurgy

Cave mining-the state of the art

Drawbell

Dranone

Drawpoinl

18m

22m

11

1411.1

jl12mljjl

I 11 I

I I

24m

11111"11.111111"'11.111

Illllljl8mlljlljl~mll

I I j I I I I I I I

I I I I

j I I I

I?~jjlljlllll~~lj~~1

1?~II

j / '11 / '1IIIlllljllfl\III(l\1

[12m

I}

\ riJ24mll

I I I Iloml...J2omll I} \

W18l.J

II

\ I I L..-~ I j I \ I j L ~ I I L ~ I I L ~ j

~~..l

:(

~1

en

..

)WdW

..

30m

Figure &-Maximum

Wd~tj:

"

Produclion

Level

and minimum drawzone spacing (isolated drawzone = 10 m area of influence = 225 m')

Vedle.1 Stress

Inere.sed by

.dj.eent working

drorpoint

Lor

Pressure

Zone

11

- -

iPlX

A. DIPs @ 2.2 X IDZ DIAM.

DIL. ENTRY 15%

B. DIPs @ 1.5 X IDZ DIAM.

DIL. ENTRY 60%

DII.IJBlU.

APD:

IT-

-TI~

IT-

-TI~

Vedle.t

R.dl.1

DRAIBlU.

---

c. DIPs @ 1.1 X IDZ DIAM.

DIL. ENTRY 85%

@

1.1 X IDZ WORKED

D. DPs

IN ISOLATION DIL. ENTRY 25%

Figure 7- The results of three-dimensional sand-model experiments

Figure 8-Flow lines and inferred stresses between

adjacent working operations

The Joumal of The South African Institute of Mining and Metallurgy

OCTOBER

1994

285

....

Cave mining-the state of the art

Rockmass

5

50-7

0.01-0.3m

Class

FF/m

Rock

Size Range

Loading

3

5-0.4

0.4-5m

Isolated Drawzone Diameter

Width

5m =

4m =

3m =

2m =

4m =

3m =

2m =

Areaof

ionuence

m'

2

1.5-0.2

1.5-9m

13m

12.5m

12m

9m

a.5m

am

6.5m

6m

Loading Width

5m =

Figure 9-Maximum/minimum

4

20-1.5

0.1-2m

I!aximum/llinimum Spacing of DraYZones

15/Bm

13/7m

12/6m

10/5m

9/4m

- -~

spacing of drawzones

95

--

~160

20/llm

IB/IOm

16/9m

- -~290

24/14m

22/13m

21/12m

--~360

based on isolated drawzone diameter

INPUT DATA =

EFFECT OF

LAYOUT =

PRODUCTION

INFLUENCE

Ore Recovered

Figure 1o-Draw-control

+ Dilution

=Production

requirements

It has been established that the draw will

angle towards less dense areas. This principle

can be used to move the material overlying the

major apex by the differential draw of lines of

drawbells so that zones of varying density are

created.

286

Tonnage and Grade

OCTOBER

1994

Dilution Entry

The percentage of dilution entry is the

percentage of the ore column that has been

drawn before dilution appears in the drawpoint,

and is a function of the amount of mixing that

occurs in the draw columns. The mixing is a

function of the following:

The Joumal of The South Afdcan InstItute of Mining and Metallurgy

Cave mining-the state of the art

The range in fragmentation size distribution

and the minimum drawzone spacing across the

major apex will give the height of the interaction

zone (HIZ). This is illustrated in Figure 12.

There is a volume increase as the cave

propagates, so that a certain amount of material

is drawn before the cave reaches the dilution

zone. The volume increase or swell factors are

based on the fragmentation and are applied to

column height. The following are typical swell

factors: fine fragmentation 1,16, medium 1,12,

coarse 1,08.

A draw-control factor is based on the

variation in tonnages from working drawpoints.

This is illustrated in Figure 13. If production

data are not available, the draw-control engineer

must predict a likely draw pattern. A formula

based on the above factors has been developed

to determine the dilution entry percentage:-

Application

Calculation of tonnage

Recording of tonnages produced

Controlling the draw

0

02

0

0.2

0.4 0.4

Unpay

0.6 0.6

0.8 1.6

1.2 2.0

1.6 1.2

2.0 0.8

Value of

%Dra.

A

B

20%

[

[

40%

1.9%

0.9%

1.4%

70%

100%

% Ora. [

Average Ore Grade

I

1.0%

1.4%

1.4%

= 1.4%

150%

1

0.7%

1.1%

Shut off Grade

200

Dilution entry

Drawpoints

1

1

0.5%

0.7%

Ore Recovery

85%

96%

~

~

~

~

= (A -B)/A

x Cx 100,

where

A = Draw-column height x swell factor

B = Height of interaction

C = Draw-control factor.

= 0.7%

The graph for dilution entry was originally

drawn as a straight line, but underground

observations show that, where there is early

dilution, the rate of influx follows a curved line

with a long ore 'tail', as shown in Figure 14.

Figure 15 shows that dilution entry is also

affected by the attitude of the drawzone, which

can angle towards higher overburden loads.

analysis

Figure 11-Grade

128%

1

1

Ore draw height

Range in fragmentation of both ore and

waste

Drawzone spacing

Range in tonnages drawn from drawpoints.

RMR OF ALL MATERIAL IN THE POTENTIAL DRAW COLUMN TO BE USED IN CALCULATION AS FINES FLOW MUCH FURTHER THAN COARSE

MINJ},{ill! SPACING OF DRA1fZONES

ACROSS THE MAlOR APEX

9m

15m

12m

-- IBm--

,,

C :-A-

,,

'41

80

60

20

40

RMR Range

15 - 29

30 - 49

+50

VERTICAL LINE "(!'

LOCATED AT HIGHEST RATING OF MATERIAL IN DRAW COLUMN

Figure

12-Height

14

of the interaction

zone

60

80 90

120 140

HEIGHT OF INTERACTION ZONE IllZ

Curves

NO.l

NO.2

No.3

No.4

40

20

RMR

Examples

A

Ratings

50 - 60

Range

10

D.Z.Spacing

21m

H.I.Z

45m

5 - 60

55

21m

90m

(HIZ)

The Joumal of The South African Institute of Mining and Metallurgy

OCTOBER

1994

287

....

Cave mining-the state of the art

Layouts

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

2

ID

11

Standard Deviation x 100 of Tonnage of Working Drawpoints

DiPs

Wll

Ell

Monthly

2000

800

Tonnage

Mean

W12 E/2 w/3 E/3 w/4 E/4

1000 2500 600 1500 800 1800

= 1375

Standard Deviation

Draw Control Factor

Figure 13- The draw-control

= 0.6

factor

A-B x C x 100

A

A = Ore Draw Column Height x Swell Factor

B = Height of Interaction Zone

C = Draw-control Factor

= 168m

= 90m

= 0.6

168 - 90 x 0.6 x 100

168

= Dilution Entry

200

100

C 9

0 80

M 70

P

60

0

S 50

I 40

T 30

I 20

0

N 10

0

Undercutting

28%

250

DILUTION /W ASTE

20

40

60

80

200

100

Percentage

Figure 14-Calculation

= 682/100 = 7

288

of dilution entry

OCTOBER 1994

Draw

A factor that needs to be resolvedis the correct

shape of the major apex. It is considered that a

shaped pillar will assist in the recovery of fine

ore. Where coarse material results in major

arching, a square-topped major apex (pillar) is

preferable in terms of arch failure and brow

wear, as shown in Figure 16. The main area of

brow wear is immediately above the drawpoint.

If the vertical height of pillar above the brow is

small, as shown in Figure 16A, failure of the top

section will reduce the strength of the lower

section and result in aggravated brow wear.

More thought must be given to the design of

LHD layouts in order to provide the maximum

amount of manoeuvring space for the minimum

size of drift opening so that larger machines can

be used within the optimum drawzone spacings.

Another aspect that needs attention is the design

of LHDs to reduce the length and increase the

width. Whilst the use of large machines might be

an attraction, it is recommended that caution be

exercised and that a decision on machine size be

based on the correct assessment of the required

drawzone spacing in terms of fragmentation. The

loss of revenue that can result from high dilution

and ore loss far exceeds the lower operating

costs associated with larger machines.

Eight different horizontal LHD layouts and

two inclined drawpoint LHD layouts are in use at

various operating mines. An example of an

inclined LHD layout is shown in Figure 17.

250

Undercutting is one of the most important

aspects of cave mining since, not only is a

complete undercut necessary to induce caving,

but the undercut method can reduce the

damaging effect of induced stresses.

The normal undercutting sequence is to

develop the drawbell and then to break the

undercut into the drawbell, as shown in Figure 18.

In environments of high stress, the pillars and

brows are damaged by the advancing abutment

stresses. The Henderson Mine technique of

developing the drawbell with long holes from the

undercut level reduces the time interval and

extent of damage associated with post

undercutting. In order to preserve stability,

Henderson Mine has also found it necessary to

delay the development of the drawbell drift until

the bell has to be blasted (Figure 19).

The damage caused to pillars around drifts

and drawbells by abutment stresses is

significant, being the major factor in brow wear

and excavation collapse. Rockbursts are also

located in these areas. The solution is to

complete the undercut before the development of

the drawpoints and drawbells. The 'advanced

undercut' technique is shown in Figure 20.

The

Journal

of The

South

African

Institute

of Mining

and

Metallurgy

Cave mining-the state of the art

A.

Average Loading Above Drawpoints

B. Higher Loading To Side Of Drawpoints

SIMULATED

HILL

FEATURE

ffiGHER

OVERBURDEN

LOADING

t t t ~t

~

MODEL

CORNER

EFFECT

.n

...

f ~ ::::

FOOTWALL

un

DRA WPOINTS

Figure 15-lnclined

drawpoint layout showing the effect of different overburden

loading (three-dimensional

sand-model

experiments)

MORE STABLE

ARCHES

FAIR FINES

DRAW

POOR FINES

DRAW

Figure 16-Shapes

STABLE

ARCHES

HIGHER

BETTER

ARCH FAILURE

of major apex/pillars

The Joumal of The South African Institute of Mining and Metallurgy

OCTOBER

1994

289

...

Cave mining-the state of the art

Inclination

- 40'

DIP

12

15

18

Spacing.

Figure

STRIKE

10

12

12/15

VERTICAL

10

12.5

15

17-An example of the layout of an inclined drawpoint

A. Production Level Layout Detail

I~-

E!

EI~

I

I

I

I

I

I

--~--r

__~__L

C. Isometric View of

Blockcaving with LHD

r-~--L_~---

B. Cross Section

Figure 18-LHD

290

layout at El Teniente

OCTOBER

1994

The Joumal

of The South Afncan Insmute of Mining and Metallurgy

Cave mining-the

state of the art

In the past it was considered that the height

of the undercut had a significant influence on

caving and, possibly, the flow of ore. The

asbestos mines in Zimbabwe had unoercuts of

30 m with no resultant improvement in caving or

fragmentation. The long time involved in

completing the undercut often led to groundcontrol problems. Good results are obtained with

undercuts of minimum height provided that

complete undercutting is achieved. Where

gravity is needed for the flow of blasted undercut

ore, the undercut height needs to be only half

the width of the major apex. This results in an

angle of repose of 45 degrees and allows the ore

to flow freely.

Support Requirements

In areas of high stress, weak rock will

plastically and strong rock will exhibit

often violent, failure. If there is a large

between the RMR and MRMR, yielding

systems are required. This is explained

Figure 21.

Figure 19-1sometric

view of a panel-cave

deform

brittle,

difference

support

in

operation

Blasted Hor. Holes

~ =-

- --

Narrow

Undercut

m---

~=- ~

.~~

A. Very High Stress

Production Drift

Supporte~

Production

Level

Narrow

Undercut

Only

~ly

'--=

B. High Stress

Production Drift

and Drawpoint

~---

Fully

Supported

Production

Level

-----

Narrow

Undercut

C. Medium/Low

~Stress Weak Ground

Production

The Joumal

c;

Drift

Drawpoint and

Drawbell Drift

Figure ~ifferent

.!;

.:!

f;'j

~Fully~

Supported

Temporary

Supported

--- Full y --Supported

sequences of advanced undercutting

of The South African Institute of Mining and Metallurgy

OCTOBER

1994

291

....

Cave mining-the state of the art

20

10

40

50

30

Pre-stressed cables have little application in

underground situations unless it is to stabilize

fractured rock in a low-stress environment. The

need for effective lateral constraint of the rock

and of lining surfaces such as concrete cannot be

too highly emphasized. Support techniques are

illustrated in Table IV.

R

60

70

80

90

100

SYSTEMS

20

Conclusions

30

High

R

40

Cavability can be assessed provided

accurate geotechnical data are available

and the geological variations are

recognized. The mining rockmass rating

(MRMR) system provides the necessary

data for the empirical definition of the

undercut dimension in terms of the

hydraulic radius.

Numerical modelling can assist the

engineer in understanding and defining

the stress environment.

Fragmentation is a major factor in an

assessment of the feasibility of cave

mining in large competent orebodies.

Programs are being developed for the

determination of fragmentation. and even

the less sophisticated programs provide

good design data. The economic viability

of caving in competent orebodies is

determined by LHD productivity and the

cost of breaking large fragments.

Failure

stress

R 50

60

70

80

90

RIGID SUPPORT

SYSTEMS

.

. .. .

i'

100

Figure 21-Support

requirements for caving operations

Acknowledgements

This paper presents an update

of the technology of cave

mining. It is not possible to

quote references since the

Table IV

bulk of the data supporting

the contents of this paper

have not been published and

the basic concepts are known

to mining engineers.

However, it is appropriate to

acknowledge the contributions

Support techniques

Low stress

(0,33 W x F)

= 1m +

=1 m

Rigid rebar

=

from discussions with the

following people in canada,

Chile, South Africa, and

0,5 mm x 100 mm aperture

Zimbabwe: R. Alvarez, P.).

Bartlett, N.).W. Bell, T. Carew,

Cables = 1 m + 1,5 W

A.R. Guest, C. Page,

D. Stacey, and A. Susaeta.

Thanks are due to

P.). Bartlett for assisting in the

Mesh-reinforced

final preparation

shotcrete

Rigid steel arches

Massive concrete

of the paper.

The simulation program for

the calculation of primary and

secondary fragmentation

Large washers

Tendon straps

(triangles)

referred to in the text was

25 mm rope-cable

writtenby

G.5. Esterhuizen

at Pretoria

slings

Birdcage cables from undercut

Inclined pipes

University.

level

Grouting

Extra bolts and cables

Plates, straps, and arches

W is the span of the tunnel and F is based on

MRMR 21-30: F 1,30

MRMR = 0-20: F = 1,4

=

=

MRMR=51-60: F= 1,05

MRMR=41-50: F= 1,1

292

OCTOBER

1994

MRMR = 31-40: F = 1,2

MRMR > 61

: F = 1,0

The Joumal of The South African Institute of Mining and Metallurgy

Cave mining-the state of the art

~

The Journal

of The

South

African

Institute

DrawpoinUdrawzone spacings for coarser

material need to be examined in terms of

recovery and improved mining

environments. Spacings must not be

increased to lower operating costs at the

expense of ore recovery.

The interactive theory of draw and the

diameter of the isolated drawzone can be

used in the design of drawzone spacing.

Complications occur when the drawzone

spacing is designed on the primary

fragmentation and the secondary fragmentation is significantly different. .

of Mining

and

Metallurgy

OCTOBER

1994

293

....

Potrebbero piacerti anche

- Development of A Multiple Level Underground Limestone MineDocumento5 pagineDevelopment of A Multiple Level Underground Limestone MineMuhammad ReyhandNessuna valutazione finora

- Planning For Narrow Vein Mines: G GemellDocumento4 paginePlanning For Narrow Vein Mines: G GemellBendigo BanksNessuna valutazione finora

- State of The Art - LaubscherDocumento21 pagineState of The Art - LaubscherAndres Condore VásquezNessuna valutazione finora

- Ground Support in Karstified ConditionsDocumento14 pagineGround Support in Karstified ConditionswjzabalaNessuna valutazione finora

- HESLOP - A Review of Geotechnical Considerations in Narrow Vein MiningDocumento10 pagineHESLOP - A Review of Geotechnical Considerations in Narrow Vein MiningAshanti UtahelNessuna valutazione finora

- Journal of Rock Mechanics and Geotechnical Engineering: Amin Manouchehrian, Ming CaiDocumento10 pagineJournal of Rock Mechanics and Geotechnical Engineering: Amin Manouchehrian, Ming CaiPaul MatshonaNessuna valutazione finora

- IADC/SPE 59121 When Rock Mechanics Met Drilling: Effective Implementation of Real-Time Wellbore Stability ControlDocumento13 pagineIADC/SPE 59121 When Rock Mechanics Met Drilling: Effective Implementation of Real-Time Wellbore Stability ControlCAMILO ANDRES BOHORQUEZ ESPARZANessuna valutazione finora

- Three-Dimensional Simulation of Cave Initiation, Propagation and Surface Subsidence Using A Coupled Finite Difference-Cellular Automata SolutionDocumento16 pagineThree-Dimensional Simulation of Cave Initiation, Propagation and Surface Subsidence Using A Coupled Finite Difference-Cellular Automata SolutionMatías Ignacio Fuentes BustamanteNessuna valutazione finora

- An Operational Approach To Ground Co - 2022 - Journal of Rock Mechanics and Geot PDFDocumento15 pagineAn Operational Approach To Ground Co - 2022 - Journal of Rock Mechanics and Geot PDFRsmoothNessuna valutazione finora

- A Practical Manual On Block Caving PDFDocumento525 pagineA Practical Manual On Block Caving PDFJorge Ariel Osorio GuzmanNessuna valutazione finora

- Chapter 2: Literature ReviewDocumento14 pagineChapter 2: Literature ReviewShahadat HossainNessuna valutazione finora

- 14EE MiningTechnology-CavingSlopeInteractionModellingDocumento9 pagine14EE MiningTechnology-CavingSlopeInteractionModellingMezamMohammedCherifNessuna valutazione finora

- Measurement-While-Drilling Technique PDFDocumento9 pagineMeasurement-While-Drilling Technique PDFWilkhen ChuraNessuna valutazione finora

- Rock Mechanics Challenges in Underground Construction and MiningDocumento16 pagineRock Mechanics Challenges in Underground Construction and MiningyashwanthNessuna valutazione finora

- Journal of Rock Mechanics and Geotechnical Engineering: Manchao HeDocumento15 pagineJournal of Rock Mechanics and Geotechnical Engineering: Manchao HeMilton TeranNessuna valutazione finora

- Behaviors of Overlying Strata in Extra Thick Coal Seams Using Top Coal Caving Method 2016 Journal of Rock Mechanics and Geotechnical EngineeringDocumento10 pagineBehaviors of Overlying Strata in Extra Thick Coal Seams Using Top Coal Caving Method 2016 Journal of Rock Mechanics and Geotechnical Engineeringkatta_sridharNessuna valutazione finora

- Engineering Characterisation of The Glaciofluvial Gravels of Cork CityDocumento13 pagineEngineering Characterisation of The Glaciofluvial Gravels of Cork CityAnonymous VcSQvILHmENessuna valutazione finora

- Mathematical Programming Application in Sublevel Caving Production SchedulingDocumento12 pagineMathematical Programming Application in Sublevel Caving Production SchedulingCamila Ordenez OlivaresNessuna valutazione finora

- Jurnal Teknologi: Discrete Element Modelling of Complex Failure Mechanism at Quarry SlopeDocumento9 pagineJurnal Teknologi: Discrete Element Modelling of Complex Failure Mechanism at Quarry SlopeFebry Aulia TonangNessuna valutazione finora

- Application of The Q-System To Australian Underground Metal MinesDocumento12 pagineApplication of The Q-System To Australian Underground Metal MinesCraig ThomasNessuna valutazione finora

- Ubicacion Optima de La BandaDocumento9 pagineUbicacion Optima de La BandaCarlos Pretell RodriguezNessuna valutazione finora

- Basic Ground-Water Hydrology: by Ralph C. HeathDocumento88 pagineBasic Ground-Water Hydrology: by Ralph C. HeathJerome MosquedaNessuna valutazione finora

- Establishing A Site Specific Mining Geotechnical Logging AtlasDocumento9 pagineEstablishing A Site Specific Mining Geotechnical Logging AtlasVinodh Kumar YallaNessuna valutazione finora

- Stop e Performance Villae Scusa 04Documento10 pagineStop e Performance Villae Scusa 04luisparedesNessuna valutazione finora

- Mine PlanningDocumento14 pagineMine PlanningFebri Ruswandi Anggara PutraNessuna valutazione finora

- Introduction To Karst and CavesDocumento22 pagineIntroduction To Karst and CavesJuan Cruz HarasimiukNessuna valutazione finora

- Fookes Et Al 1985 QJEG Dubai Etc EvaporitesDocumento27 pagineFookes Et Al 1985 QJEG Dubai Etc EvaporitesJohan Van Staveren100% (1)

- Ansell - 2004 - in Situ Testing of Young Shotcrete Subjected To Vibrations From Blasting PDFDocumento10 pagineAnsell - 2004 - in Situ Testing of Young Shotcrete Subjected To Vibrations From Blasting PDFUnurbayar EnkhbaatarNessuna valutazione finora

- Decline Design in Underground Mines Using Constrained Path OptimisationDocumento8 pagineDecline Design in Underground Mines Using Constrained Path OptimisationJhan HuayraNessuna valutazione finora

- A Laboratory Study of Rock Properties Affecting The Penetration Rate of Pneumatic Top Hammer DrillsDocumento10 pagineA Laboratory Study of Rock Properties Affecting The Penetration Rate of Pneumatic Top Hammer DrillsFelipe MilhomemNessuna valutazione finora

- Strategic Mine Planning Under UncertaintyDocumento13 pagineStrategic Mine Planning Under UncertaintyIsrael MogrovejoNessuna valutazione finora

- 0.1 BawdenDocumento18 pagine0.1 BawdenedwinsNessuna valutazione finora

- TecMecRoc-L2 - Dimensioning Crown PillarsDocumento8 pagineTecMecRoc-L2 - Dimensioning Crown PillarsAnonymous cMBxGANessuna valutazione finora

- Use of Pre-Splitting Technique As An Alternative Approach ToDocumento4 pagineUse of Pre-Splitting Technique As An Alternative Approach Toalvaroaac4Nessuna valutazione finora

- Bulletin 10 ADEQ (1978)Documento332 pagineBulletin 10 ADEQ (1978)markurban100% (2)

- Business Dynamics and Diversification PlanningDocumento6 pagineBusiness Dynamics and Diversification PlanningrannscribdNessuna valutazione finora

- ISRM-Is-2000-013 - Rock Slopes in Civil and Mining EngineeringDocumento16 pagineISRM-Is-2000-013 - Rock Slopes in Civil and Mining Engineeringcastille1956Nessuna valutazione finora

- Techn of WaterResourc Invest. Met Determ Inorg Subst in Water & Fluv Sedim USGS PDFDocumento560 pagineTechn of WaterResourc Invest. Met Determ Inorg Subst in Water & Fluv Sedim USGS PDFMárcio Antônio Mendonça de SousaNessuna valutazione finora

- Underhand Cut and Fill Mining As Practiced in Therr Deeo Hard Rock Mines in The Unired States PDFDocumento11 pagineUnderhand Cut and Fill Mining As Practiced in Therr Deeo Hard Rock Mines in The Unired States PDFwcamilo015Nessuna valutazione finora

- SPE-188138-MS Application of Geomechanics and Hybrid Metaheuristics in Designing An Optimized Well PathDocumento19 pagineSPE-188138-MS Application of Geomechanics and Hybrid Metaheuristics in Designing An Optimized Well PathehsanNessuna valutazione finora

- Practical Applications of Geology To Resource Reserve EstimationDocumento9 paginePractical Applications of Geology To Resource Reserve EstimationcmollinedoaNessuna valutazione finora

- Porphyry Copper Deposits of The World - Database, Map, and Grade and Tonnage ModelsDocumento3 paginePorphyry Copper Deposits of The World - Database, Map, and Grade and Tonnage ModelsDerlis CalderonNessuna valutazione finora

- BenchFill VillaescusaDocumento10 pagineBenchFill VillaescusaFredd_AlvaroNessuna valutazione finora

- IJEMS 5 (4) 223-235 WTPDocumento13 pagineIJEMS 5 (4) 223-235 WTPratneshkumar2004Nessuna valutazione finora

- TP 141 PDFDocumento24 pagineTP 141 PDFWilliam ProvidoNessuna valutazione finora

- Hunt 2014 Tunneling in Cobbles and Boulders, FDocumento38 pagineHunt 2014 Tunneling in Cobbles and Boulders, FswhuntNessuna valutazione finora

- f094 PDFDocumento4 paginef094 PDFAnshuman SinghNessuna valutazione finora

- Cavin RockfieldDocumento8 pagineCavin RockfieldrNessuna valutazione finora

- Crockford A., Diederichs M., Heinz H. (2011) - TBM Selection and Performance Prediction For Shallow Tunnels in Interbedded Sandstones and SiltstonesDocumento6 pagineCrockford A., Diederichs M., Heinz H. (2011) - TBM Selection and Performance Prediction For Shallow Tunnels in Interbedded Sandstones and SiltstonesAndres Mujica MorovicNessuna valutazione finora

- NATMTunnelinginSoftRocknSanDiego APTA2003 HawleyDocumento12 pagineNATMTunnelinginSoftRocknSanDiego APTA2003 Hawleyرياض عصادNessuna valutazione finora

- Feasibility StudiesDocumento4 pagineFeasibility StudiesyudakurniaawanNessuna valutazione finora

- Karst Eng Classn QJ2003Documento19 pagineKarst Eng Classn QJ2003Rachel OpiyoNessuna valutazione finora

- Practical Application of Ground Support & Reinforcement To Address Weak Rock Mass in Underground MinesDocumento16 paginePractical Application of Ground Support & Reinforcement To Address Weak Rock Mass in Underground MinesAlain CubaNessuna valutazione finora

- Mining Cutoff Grade Strategy To Optimise NPV Based On Multiyear GRG Iterative FactorDocumento7 pagineMining Cutoff Grade Strategy To Optimise NPV Based On Multiyear GRG Iterative FactorluisparedesNessuna valutazione finora

- Managing Risk For Grouting in Karst FDocumento12 pagineManaging Risk For Grouting in Karst Fmjbyle100% (1)

- Sedimentary Basins of Continental Margins and CratonsDa EverandSedimentary Basins of Continental Margins and CratonsM.H.P. BottValutazione: 5 su 5 stelle5/5 (2)

- Fault Mechanics and Transport Properties of RocksDa EverandFault Mechanics and Transport Properties of RocksNessuna valutazione finora

- Modeling The Earth For Oil Exploration: Final Report of the CEC's Geoscience I Program 1990-1993Da EverandModeling The Earth For Oil Exploration: Final Report of the CEC's Geoscience I Program 1990-1993Nessuna valutazione finora

- Is 1904Documento20 pagineIs 1904chandra chandu100% (2)

- GCE AS/A Level: Geology and The Human EnvironmentDocumento10 pagineGCE AS/A Level: Geology and The Human EnvironmentEhmedagaNessuna valutazione finora

- WRD Copperwood Call and Nicholas Geomechanical Report 404826 7Documento38 pagineWRD Copperwood Call and Nicholas Geomechanical Report 404826 7Jotha WallNessuna valutazione finora

- Cy 7 Assesssment1Documento9 pagineCy 7 Assesssment1ken adams100% (1)

- DRRR ModuleDocumento148 pagineDRRR Modulemichael hobayanNessuna valutazione finora

- A Perspective On The Levee Failures in New Orleans From Hurricane KatrinaDocumento12 pagineA Perspective On The Levee Failures in New Orleans From Hurricane KatrinaMUHAMMAD ALINessuna valutazione finora

- Ground SubsidenceDocumento11 pagineGround SubsidenceAngel MadroneroNessuna valutazione finora

- Modeling Block Cave Subsidence at The Molycorp Inc Questa Mine A Case StudyDocumento14 pagineModeling Block Cave Subsidence at The Molycorp Inc Questa Mine A Case StudyDiego NunesNessuna valutazione finora

- Analysis of Ground Movement Due To Metro Station Driven With Enlarging Shield Tunnels Under Building and Its Parameter Sensitivity Analysis 2012 TunneDocumento10 pagineAnalysis of Ground Movement Due To Metro Station Driven With Enlarging Shield Tunnels Under Building and Its Parameter Sensitivity Analysis 2012 Tunnezimbazimba75Nessuna valutazione finora

- Downdrag On Piles, Laterally Loaded Pile, Spread Footings On Sand, Large Mat On Stiff ClayDocumento66 pagineDowndrag On Piles, Laterally Loaded Pile, Spread Footings On Sand, Large Mat On Stiff Claysvs dmrNessuna valutazione finora

- Vertical Sided Excavations and Support StructuresDocumento18 pagineVertical Sided Excavations and Support StructuresZaid AlsarayrehNessuna valutazione finora

- Mat FoundationDocumento28 pagineMat FoundationHesam Copak100% (1)

- Natural Hazards and Disasters 4Th Edition Hyndman Solutions Manual Full Chapter PDFDocumento27 pagineNatural Hazards and Disasters 4Th Edition Hyndman Solutions Manual Full Chapter PDFCatherineMontesgsai100% (11)

- Gypsumanhydrite Some Engineering Problems s100640000071Documento4 pagineGypsumanhydrite Some Engineering Problems s100640000071qgliangNessuna valutazione finora

- The Environmental Impact of Mining and Its CountermeasuresDocumento7 pagineThe Environmental Impact of Mining and Its CountermeasuresAlejandro Guerrero LaverdeNessuna valutazione finora

- What Is The Difference Between A Sinkhole and Ground Subsidence?Documento3 pagineWhat Is The Difference Between A Sinkhole and Ground Subsidence?Saige RedNessuna valutazione finora

- Rock Characterization at El Teniente Mine PDFDocumento15 pagineRock Characterization at El Teniente Mine PDFEmanuel NicolásNessuna valutazione finora

- MINE SUBSIDENCE-Rev 1Documento97 pagineMINE SUBSIDENCE-Rev 1Srijan Pathak80% (5)

- Backfill 2Documento190 pagineBackfill 2Amilton filhoNessuna valutazione finora

- Sinkholes and Subsidence in South AfricaDocumento34 pagineSinkholes and Subsidence in South AfricaZé Guilherme100% (1)

- 6189 16107 1 SMDocumento12 pagine6189 16107 1 SMNur SNessuna valutazione finora

- Ppr2015.0184ma PilingDocumento9 paginePpr2015.0184ma PilingIzam FatimaNessuna valutazione finora

- A Short Note On COASTAL SUBSIDENCE AND SEA-LEVEL RISE (Impacts On Sundarban Coast at The Bay of Bengal)Documento6 pagineA Short Note On COASTAL SUBSIDENCE AND SEA-LEVEL RISE (Impacts On Sundarban Coast at The Bay of Bengal)Shahadat Hossain BiplabNessuna valutazione finora

- Coal Geology Research ProgressDocumento254 pagineCoal Geology Research ProgressIvica PavičićNessuna valutazione finora

- Imwa2000 16Documento15 pagineImwa2000 16MezamMohammedCherifNessuna valutazione finora

- Soil Piping Final ReportDocumento204 pagineSoil Piping Final ReportMithran NsNessuna valutazione finora

- Room-And-pillar Panel Design MethodDocumento6 pagineRoom-And-pillar Panel Design MethodDaniel SantanaNessuna valutazione finora

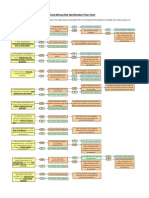

- Coal Mining Risk Identification Flow ChartDocumento1 paginaCoal Mining Risk Identification Flow ChartZ Babar Khan100% (1)

- Ground Shrinking and Swelling: UK Geohazard NoteDocumento4 pagineGround Shrinking and Swelling: UK Geohazard NoteIvan BurtovoyNessuna valutazione finora

- EXAM in DRRRDocumento6 pagineEXAM in DRRRjennilyn bulaonNessuna valutazione finora