Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

01 Samss 010 PDF

Caricato da

Anonymous ZxJZoUDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

01 Samss 010 PDF

Caricato da

Anonymous ZxJZoUCopyright:

Formati disponibili

Materials System Specification

01-SAMSS-010

Fabricated Steel Piping

7 April 2013

Document Responsibility: Materials and Corrosion Control Standards Committee

Saudi Aramco DeskTop Standards

Table of Contents

Previous Issue: 25 May 2011

Scope............................................................. 2

Conflicts and Deviations................................. 2

References..................................................... 2

Purchase Order Information........................... 4

Material Requirements................................... 4

Requirements for Design,

Cutting and Fitting.................................. 6

Bending.......................................................... 9

Welding.......................................................... 9

Inspection and Tests...................................... 9

10

Product Marking and

Preparation for Shipment..................... 10

Next Planned Update: 11 May 2014

Page 1 of 11

Primary contact: Al-Anezi, Mohammed Ali on +966-3-8809528

CopyrightSaudi Aramco 2013. All rights reserved.

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

01-SAMSS-010

Fabricated Steel Piping

Scope

1.1

This specification defines the minimum mandatory requirements governing the

fabrication of steel pipe spools, including welding, heat treatment, and threading

of pipes.

1.2

This specification may be used for piping made of high strength special steel or

alloy steels for low and high temperature applications. In this case, exceptions

and additions to this specification will be stated in the Purchase Order or its

attachments.

1.3

The governing code shall be ASME B31.3 unless B31.1, B31.4 or B31.8 is

specified in the Purchase Order as required.

Conflicts and Deviations

2.1

Any conflicts between this specification and other applicable Saudi Aramco

Materials System Specifications (SAMSSs), Engineering Standards (SAESs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

Direct all requests to deviate from this specification in writing to the Company

or Buyer Representative, who shall follow internal company procedure |

SAEP-302 and forward such requests to the Manager, Consulting Services

Department of Saudi Aramco, Dhahran.

References

The selection of material and equipment, and the design, construction, maintenance, and

repair of equipment and facilities covered by this specification shall comply with the

latest edition of the references listed below, unless otherwise noted.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a Mandatory

Saudi Aramco Engineering Requirement

Saudi Aramco Engineering Standards

SAES-W-011

Welding Requirements for On-plot Piping

SAES-W-012

Welding Requirements for Pipelines

Page 2 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

01-SAMSS-010

Fabricated Steel Piping

Saudi Aramco Materials System Specifications

01-SAMSS-035

API Line Pipe

01-SAMSS-038

Small Direct Charge Purchase of In-Plant Pipe

01-SAMSS-039

Induction and Furnace Hot Pipe Bends

02-SAMSS-005

Butt Welding Pipe Fittings

02-SAMSS-011

Forged Steel Weld Neck Flanges for Low,

Intermediate and High Temperature Service

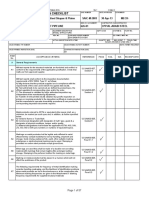

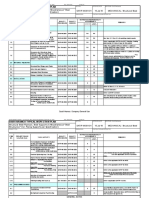

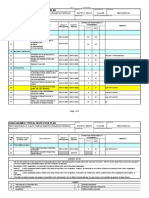

Saudi Aramco Inspection Requirements

Form 175-013100

Fabricated Carbon Steel Piping

Saudi Aramco Standard Drawings

3.2

AB-036227

Piping Symbols

AB-036521

Bridge Weld and Typical Brace Seal Welded and

Socket Welded Valves on Process Lines

AB-036719

Reinforcement of Welded Branch Connections

AE-036175

Welding Boss for Threaded Connections

AD-036643

Welding Boss for Socket Weld Connections

Industry Codes and Standards

American Petroleum Institute

API SPEC 5L

Specification for Line Pipe

American Society of Mechanical Engineers

ASME B1.20.1

Pipe Threads, General Purpose (Inch)

ASME B16.11

Forged Steel Fittings, Socket-Welding and Threaded

ASME B16.5

Pipe Flanges and Flanged Fittings

ASME B16.9

Factor-made Wrought Buttwelding Fittings

ASME B16.25

Buttwelding Ends

ASME B16.47

Large Diameter Steel Flanges

ASME B31.1

Power Piping

ASME B31.3

Process Piping

ASME B31.4

Pipeline Transportation Systems for Liquid

Hydrocarbons and Other Liquids

Page 3 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

01-SAMSS-010

Fabricated Steel Piping

ASME B31.8

Gas Transmission and Distribution Piping Systems

ASME SEC V

Nondestructive Examination

International Organization for Standardization

NACE MR0175/ISO 15156

Petroleum and Natural Gas Industries Materials

for Use in H2S-Containing Environments in

Oil and Gas Production, 2002 edition

Manufacturers Standardization Society

MSS-SP-83

Carbon Steel Pipe Unions, Socket-Welding and

Thread Ends

Purchase Order Information

The Purchase Order will include the following:

a)

The applicable code (ASME B31.1, B31.3, B31.4, or B31.8).

b)

Detailed Isometric Drawings or Piping Detail.

c)

Service conditions.

d)

Post-weld heat treatment, if required by service conditions (otherwise, it shall be

governed by the applicable code).

e)

Materials to be supplied by the Vendor.

f)

Materials to be supplied by the Buyer to the Vendor, if any.

g)

Inspection Requirements - Form 175-013100 plus any additional requirements.

h)

Minimum I.D. dimension, if required to permit passage of instrumented scraper or

maintenance scraper.

i)

Impact testing requirements.

j)

Non-material Requirements (NMR) form for fabricated pipe bend(s) if applicable.

k)

Surface preparation and paint or coating requirements.

Material Requirements

All materials supplied by the Vendor for piping elements or structural attachments shall

conform to the requirements of the applicable code and shall be traceable to mill

certificates. Used or reclaimed materials or materials of unknown specification are not

permitted.

Page 4 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

5.1

5.3

Fabricated Steel Piping

Pipe

5.1.1

The Pipe material shall be according to the Purchase Order.

5.1.2

Unless otherwise specified in the Purchase Order, the allowable

materials for carbon steel are:

5.1.3

5.2

01-SAMSS-010

1)

API SPEC 5L Grade B through X65, PSL 2 either seamless or

single seam submerged arc welded pipe, conforming to

01-SAMSS-035 or 01-SAMSS-038.

2)

ASTM A53 seamless Grade B or A106 Grade B conforming to

01-SAMSS-035 or 01-SAMSS-038.

ERW pipe (electric resistance welded) shall not be used for process

piping designed to ASME B31.3.

Pipe Nipples

5.2.1

Nipples shall be Schedule 80 minimum. Threads shall be in accordance

with ASME B1.20.1 taper pipe thread.

5.2.2

Pipe sizes of 1-inch and smaller in vibration service, shall have bracing

in accordance with Standard Drawing AB-036521. Where bracing cannot

be effectively provided, nipples with Schedule 160 shall be installed.

Flanges

Flanges shall be ASME weld neck type in accordance with 02-SAMSS-011.

Flange specification, rating, and facing shall be as specified in the Purchase

Order.

5.4

Unless otherwise shown on the Purchase Order drawings, the pipe fittings shall

be as follows:

5.4.1

Butt welding pipe fittings shall be used for nominal pipe sizes 2-inch and

larger. Butt welding pipe fittings shall be in accordance with

02-SAMSS-005. The material grade of butt welding fittings shall match,

or be equivalent in strength to, that of the adjoining pipe.

5.4.2

Forged steel threaded or socket-welding fittings 1 and smaller shall

conform to ASME B16.11, pressure class 3000 and ASTM A105.

5.4.3

All unions shall conform to MSS-SP-83, Class 3000 for nominal pipe

sizes 1 and smaller. The material shall be carbon steel per

ASTM A105, ASTM A350 or alloy steel per ASTM A182.

Page 5 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

5.4.4

5.5

01-SAMSS-010

Fabricated Steel Piping

For nominal pipe sizes 1 and smaller, forged steel welding bosses

shall conform to either Standard Drawing AE-036175 or AD-036643 or

be equivalent to A105 integrally reinforced fittings, pressure class 3000

minimum.

Reinforcing and Attachments

Steel plate used for reinforcing pads, sleeves, saddles and other structural

attachments shall conform to a code listed plate material with specified

minimum yield strength of 241.3 MPa (35,000 psi) or greater.

All reinforcing and attachment welds shall be continuous. Skip or stitch

welding is not permitted.

5.6

Additional material requirements for sour service.

5.6.1

Pipes shall meet the requirements of Annexes K & H of API SPEC 5L.

5.6.2

Flanges and fittings shall be in accordance with NACE MR0175.

Requirements for Design, Cutting and Fitting

6.1

6.2

Drawings

6.1.1

The Vendor shall prepare detailed shop fabrication drawings based on

the Purchase Order drawings. The shop drawings shall be submitted to

the Buyer for approval prior to fabrication.

6.1.2

Any details not shown on Buyer's drawings shall be designed by the

Vendor in accordance with the applicable ASME B31 code.

6.1.3

Standard piping symbols used on Piping Detail Sheets and Isometric

Detail Sheets are identified on Standard Drawing AB-036227.

6.1.4

Approval of Vendor's drawings by the Buyer does not relieve the Vendor

of the responsibility for compliance with the code, this specification and

the Purchase Order requirements.

Reinforcement Pads

6.2.1

The reinforcement pad shall be in accordance with the Standard Drawing

AB-036719.

6.2.2

A 3-6 mm weep hole shall be provided for each reinforcing. The weep

hole shall not be mechanically plugged nor seal welded but can be

plugged with grease

Page 6 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

6.3

01-SAMSS-010

Fabricated Steel Piping

Mitered Joints and Bends

Mitered bends or miter pipe joints are not permitted. A mitered joint is defined

as a joint with an angular offset larger than three degrees.

6.4

6.5

Pipe Joints

6.4.1

For butt-weld connections of wall thickness ratio of joined pipes greater

than 1.5, end preparations and geometry shall comply with ASME B16.25.

6.4.2

Threaded and socket welded joints shall be 1-1/2 and smaller.

For socket-welded connections, the axial gap between male and female

component, as shown in Figure 328.5.2C of ASME B31.3 code, shall be

maximum of 3 mm and minimum of 1.5 mm.

6.4.3

Seal welding is required of all threaded joints up to the first block valve

except in the following services:

a)

Thermowells

b)

Bar stock plugs downstream of a seal-welded block valve.

c)

Special devices such as access fittings and scraper signals.

d)

Joints which require frequent disassembly and are located

downstream of a seal welded block valve, e.g., sample connections.

e)

Instrument piping downstream of the primary instrument isolation

valve.

f)

Pipe union ring threads and joints with elastomer o-rings.

g)

Threaded joints, downstream of a seal welded root valve, which

discharge directly to an open drainage system or to the atmosphere.

h)

Extended body valves with integrally reinforced welding end per

API STD 602.

Pipe Components

6.5.1

Pipe unions shall not be installed in the pipe section between the main

pipe run and root valve.

6.5.2

Integrally reinforced fittings shall be designed to abut the pipe wall with

a full penetration weld.

6.5.3

Couplings and half-couplings shall not be used as integrally reinforced

fittings. Couplings are not permitted between the header and root valve.

Page 7 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

6.6

6.7

01-SAMSS-010

Fabricated Steel Piping

6.5.4

The use of LokRing coupling is limited to piping 2 inch maximum for

instrument air, nitrogen gas, and water service.

6.5.5

Bushings with one size reduction shall not be used. Only hex head steel

bushings shall be used. Flush steel bushings are not permitted.

Ends for Field Welding

6.6.1

The ends of pipe and pipe spools to be joined by girth welds during field

installation, shall be prepared and matched to facilitate fit-up in the field

unless it is indicated in the drawing where extra length is to be cut back

in the field for adjustment. Corresponding welding ends shall be clearly

marked.

6.6.2

All welding ends shall be beveled with an angle of 35 degrees, 5 degrees,

and a root face of 1.6 mm. The bevels shall be either machine-cut bevels

or smooth, clean, slag-free flame cut. The end plane shall be normal to the

pipe axis as defined on the piping drawing, within 0.25 degrees.

Dimensional Tolerances

6.7.1

The tolerance for axial dimensions, face-to-face, center-to-face and

location of attachments shall be 3 mm maximum.

6.7.2

Lateral offset of branches and connections from centerline of run shall

not exceed 1.6 mm.

6.7.3

Flange bolt holes shall straddle the established centerlines. Rotation of

flanges, measured as the offset between elevation of bolt holes on

opposite sides of a flange centerline shall not exceed 1.6 mm.

6.7.4

The tilt of a flange measured at the periphery across any diameter shall

not exceed 1 mm from the square position.

6.7.5

When a minimum I.D. dimension is specified by the Purchase Order

(spool with pipe bend), the pipe spool shall be checked by the Vendor by

passing a gauging scraper through the finished spool. The diameter of

the gauging scraper shall be equal to the I.D. dimension specified and the

length shall be approximately one-half of the nominal diameter.

6.7.6

Pipe spools and bends shall be checked and corrected after heat

treatment to assure proper alignment of flanges and correct centerline

dimensions.

6.7.7

Bend tolerances are: bend angle 0.5 degree and bend radius 1% unless

otherwise indicated on Company drawing or Purchase Order.

Page 8 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

01-SAMSS-010

Fabricated Steel Piping

Bending

7.1

Hot Bends

Furnace hot bends or induction bends shall comply with the requirement of

01-SAMSS-039.

7.2

Cold Bending

Cold bending is not permitted for in-plant piping.

Welding

8.1

8.2

All welding, heat treating, and non-destructive testing shall be in accordance

with the following specifications:

a)

SAES-W-011 for ASME B31.3 applications.

b)

SAES-W-012 for ASME B31.4 and ASME B31.8 applications.

Repairs

Unsuccessful weld repairs after the second attempt shall be cut out as a cylinder

and shall be replaced with a new section of pipe and/or fittings.

8.3

Radiography

8.3.1

The non-mandatory appendix to ASME SEC V, Article 2 shall be used

in determining the required number and location of radiographs for

circumferential joints.

8.3.2

Progressive examinations and other additional radiography resulting

from rejected or repaired welds shall be at Vendor's expense.

8.3.3

Progressive examinations and other additional radiography resulting

from rejected or repaired welds shall not be included in the minimum

percentage specified to be radiographed.

Inspection and Tests

All inspection and testing shall be performed as per Saudi Aramco Inspection

Requirements Form 175-013100.

9.1

Hydrostatic Tests

9.1.1

When all openings on a pipe spool are either flanged or threaded, the

spool shall be hydrostatically tested. When no test pressure is indicated

Page 9 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

01-SAMSS-010

Fabricated Steel Piping

in the Purchase Order, the hydrostatic test pressure shall be based on the

flange rating as shown in ASME B16.5, but not less than the minimum

test pressure per ASME B31.3 paragraph 345.4.2.

No paint or primer shall be applied over the girth welds prior to

hydrostatic testing.

9.2

9.1.2

The Vendor shall provide the necessary blind flanges, plugs, caps, or

plates required for the hydrotest.

9.1.3

Piping spools which have welding ends shall not be pressure tested

unless provisions for test ends have been indicated in the Purchase Order

documents. For piping spools which are not to be pressure tested, all

weld joints shall be 100% inspected by using the NDT methods specified

in the Purchase Order.

Inspection

The Vendor shall give an advance notice in writing to the Buyer for all tests

required for the fabrications. All materials, certificates, fabrication, testing and

examinations shall be subjected to verification by Buyer's Inspector in

accordance with ASME B31.3 Chapter VI for full compliance with this

Specification and the Purchase Order drawings and other requirements.

Inspection shall be carried out at the place of manufacture.

10

Product Marking and Preparation for Shipment

10.1

Identification

10.1.1

Each spool shall be marked with the purchase order number and spool

number painted at the ends as shown on the drawings. The numbers

shall not be less than 25 mm in height. In addition, the spool number

shall be die-stamped on the rim of each flange.

10.1.2

Pipe bends, delivered as separate components, shall be marked by paint

stenciling with the following additional information:

a)

Vendor name or trademark

b)

Outside diameter and nominal wall thickness

c)

Grade per API SPEC 5L or ASTM

d)

Bend angle and radius

e)

Point of tangency, both ends

f)

Tempering heat treatment identification

Page 10 of 11

Document Responsibility: Materials and Corrosion Control Standards Committee

Issue Date: 7 April 2013

Next Planned Update: 11 May 2014

g)

10.2

01-SAMSS-010

Fabricated Steel Piping

Sour service or non-sour service

Cleaning

All loose foreign material and weld spatter shall be removed from the inside and

outside of the spool. The spool shall be clean and dry.

10.3

Painting

Unless otherwise specified in the Purchase Order the pipe spools shall not be

painted or coated.

10.4

11 May 2010

25 May 2011

7 April 2013

Protection

10.4.1

When spools are supplied with blind flanges, they shall be bolted on

with the specified gaskets and stud bolts. Other flange faces shall be

protected by a suitable cover bolted to the flange.

10.4.2

Threaded bosses shall be fitted with steel bar stock plugs. Threaded pipe

ends shall be provided with steel or malleable iron pipe caps as

temporary closure. Threads shall be coated with a graphite and oil paste.

10.4.3

Welding ends shall be protected against damage during handling and

shipment by means of a securely fastened bevel protector.

10.4.4

Pipe and fittings shall not be stored directly on the ground.

10.4.5

Stacking shall be done in a manner to avoid damage to pipes, fittings

or coatings.

10.4.6

All material shall be handled with care to prevent damage.

10.4.7

Lined and coated pipe and fittings shall be lifted with wide fabric or

rubber-covered slings.

Revision Summary

Major revision.

Editorial revision to remove the committee list.

Editorial revision to transfer the document responsibility from Piping Standards Committee to

the Materials and Corrosion Control Standards Committee.

Page 11 of 11

Potrebbero piacerti anche

- Saep 347Documento27 pagineSaep 347Qaiser Mahmood100% (2)

- Saep 85Documento24 pagineSaep 85fawad ali25% (4)

- Saep 321Documento28 pagineSaep 321brecht1980Nessuna valutazione finora

- Juan Martin Garcia System Dynamics ExercisesDocumento294 pagineJuan Martin Garcia System Dynamics ExercisesxumucleNessuna valutazione finora

- SAIC-L-2035 Rev 6Documento2 pagineSAIC-L-2035 Rev 6biplabpal2009Nessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento15 pagineSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- SAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageDocumento8 pagineSAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageMuhammad Farukh Manzoor0% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNessuna valutazione finora

- Ad 036821 001Documento1 paginaAd 036821 001AmolNessuna valutazione finora

- 01 Samss 044 PDFDocumento11 pagine01 Samss 044 PDFAbdul Rahim ShaikhNessuna valutazione finora

- SAEP-352 - Welding Procedures Review and Approval PDFDocumento14 pagineSAEP-352 - Welding Procedures Review and Approval PDFsilvrsurfr637Nessuna valutazione finora

- 01 Samss 010Documento12 pagine01 Samss 010Ahmed Shaban KotbNessuna valutazione finora

- 01 Samss 035Documento28 pagine01 Samss 035Cherukunnon Jubu100% (2)

- Materials System SpecificationDocumento21 pagineMaterials System Specificationnadeem shaikhNessuna valutazione finora

- 175 320300Documento1 pagina175 320300sridhar100% (1)

- Saep 1145Documento20 pagineSaep 1145Amit shah100% (1)

- Saudi Aramco piping inspection planDocumento2 pagineSaudi Aramco piping inspection planMuhammad Farukh ManzoorNessuna valutazione finora

- Saudi Aramco Test ReportDocumento4 pagineSaudi Aramco Test Reportkarthi51289Nessuna valutazione finora

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Documento4 pagine1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- Saic L 2008 PDFDocumento4 pagineSaic L 2008 PDFHesham HelalNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocumento12 pagineSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNessuna valutazione finora

- SAIC-M-2003 Rev 7Documento57 pagineSAIC-M-2003 Rev 7yugandhar100% (1)

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocumento19 pagineSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocumento2 pagineSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saudi Aramco Typical Inspection PlanDocumento11 pagineSaudi Aramco Typical Inspection PlanAhdal NoushadNessuna valutazione finora

- 01 Samss 029Documento15 pagine01 Samss 029Cherukunnon Jubu100% (1)

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocumento12 pagineSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNessuna valutazione finora

- Saudi Aramco PMI checklist ensures alloy purityDocumento5 pagineSaudi Aramco PMI checklist ensures alloy puritykarioke mohaNessuna valutazione finora

- Materials System SpecificationDocumento9 pagineMaterials System SpecificationFAPM1285Nessuna valutazione finora

- SAIC-A-2008 Rev 0Documento3 pagineSAIC-A-2008 Rev 0Kristine Caye DatarioNessuna valutazione finora

- Saep 352 PDFDocumento15 pagineSaep 352 PDFRami ElloumiNessuna valutazione finora

- 09 Samss 089-2016Documento26 pagine09 Samss 089-2016lhanx2Nessuna valutazione finora

- Materials System SpecificationDocumento7 pagineMaterials System Specificationaanouar77Nessuna valutazione finora

- Saep 1151Documento13 pagineSaep 1151fero67% (3)

- SAIC-A-2009 Rev 2Documento5 pagineSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Saic H 1003Documento2 pagineSaic H 1003Hussain Nasser Al- NowiesserNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento3 pagineSaudi Aramco Inspection ChecklistphilipyapNessuna valutazione finora

- SAER1972Documento9 pagineSAER1972zamil2008Nessuna valutazione finora

- SAUDI ARAMCO UPGRADE WATER SYSTEMDocumento3 pagineSAUDI ARAMCO UPGRADE WATER SYSTEMLeopoldo TalandatoNessuna valutazione finora

- Saes-L-108, 10112010Documento27 pagineSaes-L-108, 10112010Sathishkumar DhamodaranNessuna valutazione finora

- SAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARDocumento7 pagineSAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARZahidRafiqueNessuna valutazione finora

- SAUDICHECK - WELD TRACKING DATABASEDocumento5 pagineSAUDICHECK - WELD TRACKING DATABASEManoj KumarNessuna valutazione finora

- Saep 324Documento8 pagineSaep 324brecht1980100% (3)

- Saudi Aramco tank inspection requirementsDocumento2 pagineSaudi Aramco tank inspection requirementssridhar100% (1)

- Satr H 1003Documento2 pagineSatr H 1003Thouseef MaNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento5 pagineSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist (SAIC) Title: ElectricalDocumento11 pagineSaudi Aramco Inspection Checklist (SAIC) Title: ElectricalBhaskar Pitchika100% (1)

- 34-Samss-010 2018Documento9 pagine34-Samss-010 2018asimazami69Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocumento3 pagineSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNessuna valutazione finora

- SatipDocumento5 pagineSatipMuhammad Abdul Kadher100% (3)

- Saudi Aramco Typical Inspection PlanDocumento2 pagineSaudi Aramco Typical Inspection PlanMAZHARULNessuna valutazione finora

- Welding Standards for Corrosion-Resistant Piping MaterialsDocumento10 pagineWelding Standards for Corrosion-Resistant Piping MaterialsRaj AryanNessuna valutazione finora

- Saudi Aramco Typical Inspection PlanDocumento10 pagineSaudi Aramco Typical Inspection Plankarthi51289Nessuna valutazione finora

- Saic L 2007 PDFDocumento7 pagineSaic L 2007 PDFHesham HelalNessuna valutazione finora

- 01 Samss 010Documento11 pagine01 Samss 010biplabpal2009Nessuna valutazione finora

- 01 Samss 010Documento12 pagine01 Samss 010inatt101Nessuna valutazione finora

- 01 Samss 010Documento12 pagine01 Samss 010aamirtec301Nessuna valutazione finora

- Pipe JointDocumento12 paginePipe Jointimrankhan22Nessuna valutazione finora

- Materials System SpecificationDocumento8 pagineMaterials System Specificationnadeem shaikhNessuna valutazione finora

- 01 Samss 010Documento12 pagine01 Samss 010이진영Nessuna valutazione finora

- Materials System SpecificationDocumento15 pagineMaterials System SpecificationZubair RaoofNessuna valutazione finora

- 7890 Parts-Guide APDocumento4 pagine7890 Parts-Guide APZia HaqNessuna valutazione finora

- Draft Initial Study - San Joaquin Apartments and Precinct Improvements ProjectDocumento190 pagineDraft Initial Study - San Joaquin Apartments and Precinct Improvements Projectapi-249457935Nessuna valutazione finora

- g4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDocumento144 pagineg4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDevin DickenNessuna valutazione finora

- Front Wheel Steering System With Movable Hedlights Ijariie5360Documento6 pagineFront Wheel Steering System With Movable Hedlights Ijariie5360Ifra KhanNessuna valutazione finora

- PDFViewer - JSP 3Documento46 paginePDFViewer - JSP 3Kartik ChaudharyNessuna valutazione finora

- SRS Design Guidelines PDFDocumento46 pagineSRS Design Guidelines PDFLia FernandaNessuna valutazione finora

- Accomplishment Report Yes-O NDCMC 2013Documento9 pagineAccomplishment Report Yes-O NDCMC 2013Jerro Dumaya CatipayNessuna valutazione finora

- ML AiDocumento2 pagineML AiSUYASH SHARTHINessuna valutazione finora

- Apollo TyresDocumento78 pagineApollo TyresADITYA33% (3)

- NDE Procedure - Radiographic TestingDocumento43 pagineNDE Procedure - Radiographic TestingJeganeswaranNessuna valutazione finora

- Sayre Materia Medica-3Documento87 pagineSayre Materia Medica-3ven_bams5840Nessuna valutazione finora

- Private Schools Provide Better EducationDocumento2 paginePrivate Schools Provide Better EducationcitraNessuna valutazione finora

- Traffic Violation Monitoring with RFIDDocumento59 pagineTraffic Violation Monitoring with RFIDShrëyãs NàtrájNessuna valutazione finora

- A Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastDocumento82 pagineA Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastJacques LeBlanc100% (18)

- 24.postpartum Period-Physiological Changes in The MotherDocumento16 pagine24.postpartum Period-Physiological Changes in The MotherHem KumariNessuna valutazione finora

- Patent for Fired Heater with Radiant and Convection SectionsDocumento11 paginePatent for Fired Heater with Radiant and Convection Sectionsxyz7890Nessuna valutazione finora

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualDocumento18 pagineKAC-8102D/8152D KAC-9102D/9152D: Service ManualGamerAnddsNessuna valutazione finora

- IEEE T&D Insulators 101 Design CriteriaDocumento84 pagineIEEE T&D Insulators 101 Design Criteriasachin HUNessuna valutazione finora

- Chapter 10 AP GP PDFDocumento3 pagineChapter 10 AP GP PDFGeorge ChooNessuna valutazione finora

- T9001 T9002 T9003 T9004: Tecn# Originator Title Aging Status of TecnDocumento2 pagineT9001 T9002 T9003 T9004: Tecn# Originator Title Aging Status of TecnThanalachmy GopiNessuna valutazione finora

- SB Z Audio2Documento2 pagineSB Z Audio2api-151773256Nessuna valutazione finora

- Chain Surveying InstrumentsDocumento5 pagineChain Surveying InstrumentsSachin RanaNessuna valutazione finora

- Entrepreneurship Project On Jam, Jelly & PicklesDocumento24 pagineEntrepreneurship Project On Jam, Jelly & Picklesashish karshinkarNessuna valutazione finora

- Idioms & Phrases Till CGL T1 2016Documento25 pagineIdioms & Phrases Till CGL T1 2016mannar.mani.2000100% (1)

- 2018-04-12 List Mold TVSDocumento5 pagine2018-04-12 List Mold TVSFerlyn ValentineNessuna valutazione finora

- Tds G. Beslux Komplex Alfa II (25.10.19)Documento3 pagineTds G. Beslux Komplex Alfa II (25.10.19)Iulian BarbuNessuna valutazione finora

- Advanced Ultrasonic Flaw Detectors With Phased Array ImagingDocumento16 pagineAdvanced Ultrasonic Flaw Detectors With Phased Array ImagingDebye101Nessuna valutazione finora

- HVCCI UPI Form No. 3 Summary ReportDocumento2 pagineHVCCI UPI Form No. 3 Summary ReportAzumi AyuzawaNessuna valutazione finora