Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Reducing Valve R 8

Caricato da

Cristian Adrian ACopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Reducing Valve R 8

Caricato da

Cristian Adrian ACopyright:

Formati disponibili

Reducing valve R 8

PN 16 DN 25 - 125

Water 150 C

Pneumatic spring

Closes at increasing pressure at the outlet

R8

Advantages

Setting of outlet pressure from 0 to 16 bar without

any spring change.

High accuracy.

Low noise operation.

Very long life of diaphragm, because it always works

with low differential pressure of approx. 20 kPa.

Maximal security. In case of diaphragm rupture the

auxiliary spring instantly tightly closes the valve.

Wrong adjustment of safety valve is not possible if

connected to the same pressure vessel as reducing

valve.

Function

The regulator consists of a valve (1), an actuator (3) and a

pressure vessel (8). The fluid pressure at valve's outlet acts

through the impulse pipe (2) to the top side of the diaphragm (5),

and attempts to close the valve together with the force of the

auxiliary spring (4). The pressure of compressed air (9) in the

pressure vessel acts through the connection pipe (6) to the

bottom side of diaphragm, and attempts to open the valve. As

long as the forces on the diaphragm are balanced, the valve's

plug stands still. If the fluid pressure increases, the valve closes

until the new balance is reached. In case of diaphragm rupture,

pressure of fluid on top side and compressed air on the bottom

side of the diaphragm are equalized, and auxiliary spring

instantly tightly closes the valve. The force of the auxiliary spring

corresponds to the pressure of approx. 20 kPa.

Installation

Install the valve into a horizontal pipeline with the actuator body

below. The direction of flow is shown with an arrow on the valve

body. Installation of a strainer in front of the valve is

recommended. At the first filling, vent actuator body a couple of

times by vent screw (12). If the regulated fluid is steam, or the

temperature exceeds 130 C, a cooling vessel (OH 150) must

be installed in the impulse pipe (2). Prior to operation, fill the

cooling vessel with cold water and vent it. For impulse pipe (2)

and connection pipe (6) use copper pipe 10x1.

TA-Regulator Orlika 13, Breice, Slovenia Phone: +386 7 496 14 17 Fax: +386 7 496 20 40 www.ta-regulator.com

2/06

Combination of reducing and safety valve

If reducing valve R8 and safety valve V8 are connected to the

same pressure vessel, the reducing valve will be normally open,

and safety valve tightly closed. If the reducing valve is forced to

close completely, but the pressure at the outlet accidentally

rises for any reasons by additional 15 kPa, the safety valve

starts to open. Pressure difference between acting ranges of

both valves depends on forces of auxiliary springs.

R8

Pressure vessel installation

The pressure vessel has a spherical form with two hooks for

mounting on the wall. The vessel type TP 310 is provided with a

filling valve (10) and one connection (6) for the connecting pipe.

The vessel type TPM 310 is additionally provided with a

manometer connection (11). Type TPD 310 is provided two

connections (6,7) for the connecting pipe, and type TPDM 310

has a manometer connection in addition. Prior to mounting of

the connecting pipe and manometer, check the sealing surfaces

and clean them if necessary. Install very carefully and check

tightness with soap or spray. Make sure to use only original

rubber seals. Never use hemp or teflon tape. Install the vessel

as far away from hot surfaces as possible.

Pressure adjustment

Fill the pressure vessel with compressed air or nitrogen. The

pressure in the vessel must be by approx. 20 kPa higher then

the desired pressure of regulated fluid.

Size selection

It is recommended to choose the flow speed of water within 0,5

to 2 m/s. Optimal speed is approx. 1 m/s. Control the pressure

drop in valve by formula: Dp = 100V2 / KVS2 [kPa], where V is flow

in m3/h.

Ordering data

Reducing valve type R8 DN .... PN16, valve body ...., with

pressure vessel type TP 310.

Specifications

Nominal pressure

PN 16

Maximal differential pressure in valve

16 bar

Maximal pressure at outlet

16 bar

Maximal water temperature

150 C

Accuracy approx.

kPa

Flanges

DIN 2501

Valve body

PN 16

cast iron (GG-25)

PN 16

ductile iron (GGG-40.3)

Actuator body

cast iron (GG-25)

Diaphragm

NBR

Valve seat

stainless steel

Valve plug

stainless steel with EPDM insert

Dimensions

Nominal size

KVS

Length

Height

Height

Diameter

Diameter

Weight

DN

L

H

h

D

F

M

mm

m3/h

mm

mm

mm

mm

mm

kg

25

9

160

435

80

330

115

38

32

17

180

450

95

330

140

39

40

19

200

450

95

330

150

40

50

32

230

460

105

330

165

46

65

50

290

545

125

375

185

68

80

80

310

555

135

375

200

78

100

110

350

600

165

375

220

98

125

120

400

610

175

375

250

106

All specifications can be changed without prior notice.

TA-Regulator Orlika 13, Breice, Slovenia Phone: +386 7 496 14 17 Fax: +386 7 496 20 40 www.taregulator.com

Potrebbero piacerti anche

- p100 - 13 Could BeDocumento4 paginep100 - 13 Could BeEudaldo SaltosNessuna valutazione finora

- ACM619 Anesthesia Machine Service ManualDocumento14 pagineACM619 Anesthesia Machine Service ManualSn DayanidhiNessuna valutazione finora

- Pm512 en MainDocumento8 paginePm512 en MainDusan GordicNessuna valutazione finora

- Differential Pressure TransmittersDocumento36 pagineDifferential Pressure TransmittersgagandeepsinghgxdNessuna valutazione finora

- SPM Full Bore Emergency Unloading Valve Manual PDFDocumento9 pagineSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNessuna valutazione finora

- Regulator de Presiune 41-23Documento6 pagineRegulator de Presiune 41-23Cornel DumitruNessuna valutazione finora

- PT-104 Pumping Trap Installation and MaintenanceDocumento12 paginePT-104 Pumping Trap Installation and MaintenancevkumaranNessuna valutazione finora

- Ariston 600 Europrisma Manual V2.1Documento16 pagineAriston 600 Europrisma Manual V2.1ciohaniNessuna valutazione finora

- Ta-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsDocumento16 pagineTa-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsCatalin DinuNessuna valutazione finora

- Avoiding Cavitation in Control Valves: ASHRAE JournalDocumento4 pagineAvoiding Cavitation in Control Valves: ASHRAE JournalTONNessuna valutazione finora

- Engineering Technical Bulletins: Selecting Valves and Piping CoilsDocumento4 pagineEngineering Technical Bulletins: Selecting Valves and Piping Coilsforevertay2000Nessuna valutazione finora

- Proportional Electro-Hydraulic ControlsDocumento31 pagineProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Dry ValveDocumento12 pagineDry ValveSayed MohamedNessuna valutazione finora

- FH5 E OpinsDocumento2 pagineFH5 E OpinsbabjihanumanthuNessuna valutazione finora

- FIRE HOSE TESTER OPERATING INSTRUCTIONSDocumento2 pagineFIRE HOSE TESTER OPERATING INSTRUCTIONSbabjihanumanthuNessuna valutazione finora

- Samson Tip 41-23Documento6 pagineSamson Tip 41-23ALISAMET92Nessuna valutazione finora

- Full Bore Emerg Unloading Valve O&m - 02-24-2011Documento9 pagineFull Bore Emerg Unloading Valve O&m - 02-24-2011Enrique AssmannNessuna valutazione finora

- Procedures for safely conducting shutdown activities at CTP inlet and outletDocumento4 pagineProcedures for safely conducting shutdown activities at CTP inlet and outleteng20072007Nessuna valutazione finora

- Ariston 30L - EuroprismaDocumento16 pagineAriston 30L - EuroprismaPaulo FonsecaNessuna valutazione finora

- VPT-Kalatjari (Sazeh Engineering Consultants)Documento16 pagineVPT-Kalatjari (Sazeh Engineering Consultants)cristianNessuna valutazione finora

- Self-Operated Pressure Regulators Type 41-73 Universal Excess Pressure ValveDocumento8 pagineSelf-Operated Pressure Regulators Type 41-73 Universal Excess Pressure ValvecartarNessuna valutazione finora

- The Anesthesia MachineDocumento99 pagineThe Anesthesia Machineramanrajesh8386% (7)

- Pipe Friction LossDocumento6 paginePipe Friction LossHoongNessuna valutazione finora

- Cavitation CarlsonDocumento4 pagineCavitation CarlsonjimborenoNessuna valutazione finora

- Liquid Withdrawal Device: For Liquid Nitrogen 25LD, 35LD, 35LD-T and 50LD DewarsDocumento4 pagineLiquid Withdrawal Device: For Liquid Nitrogen 25LD, 35LD, 35LD-T and 50LD DewarsmarcelloairesNessuna valutazione finora

- Adams ValveDocumento5 pagineAdams ValveSuresh KumarNessuna valutazione finora

- VCLDocumento5 pagineVCLoutlander2008Nessuna valutazione finora

- TA-FUSION-P EN LowDocumento20 pagineTA-FUSION-P EN LowradudolNessuna valutazione finora

- Calculating Pump HeadDocumento8 pagineCalculating Pump HeadPascal SayahNessuna valutazione finora

- Cepde - Valve Sizing (U16ch036, U16ch037, U16ch083)Documento15 pagineCepde - Valve Sizing (U16ch036, U16ch037, U16ch083)VRUSHABHNessuna valutazione finora

- Control Valve PresentDocumento120 pagineControl Valve PresentShoeb Ali KhanNessuna valutazione finora

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocumento15 pagineViking Series 90 Operating & Maintenance Instructions: FiltersninatenaNessuna valutazione finora

- ZTV ZTR PRSH enDocumento4 pagineZTV ZTR PRSH enmustafa Al AsfourNessuna valutazione finora

- Shutdown Isolation ProceduresDocumento3 pagineShutdown Isolation Procedureseng20072007Nessuna valutazione finora

- 980a2542 PDFDocumento58 pagine980a2542 PDFMichael DavenportNessuna valutazione finora

- TA-FUSION-C EN LowDocumento16 pagineTA-FUSION-C EN LowTroi LauraNessuna valutazione finora

- CM 013 001 01 1Documento1 paginaCM 013 001 01 196791359Nessuna valutazione finora

- Armstrong Solving StallDocumento9 pagineArmstrong Solving StallsaverrNessuna valutazione finora

- Vane Presiune DN40 - DN250Documento28 pagineVane Presiune DN40 - DN250iza66bellNessuna valutazione finora

- KVDN../2/ : Unit Through Valve (Regulating), PN 16Documento5 pagineKVDN../2/ : Unit Through Valve (Regulating), PN 16Jonathan GrechNessuna valutazione finora

- Pump Head CalculationDocumento15 paginePump Head CalculationYashapuja100% (1)

- thermCA en Stand 2013 03 18Documento56 paginethermCA en Stand 2013 03 18mohamed ghareebNessuna valutazione finora

- Control Valve SizingDocumento9 pagineControl Valve Sizingjmclaug502Nessuna valutazione finora

- Series 1170, LF1170, L1170 and LFL1170 Installation InstructionsDocumento4 pagineSeries 1170, LF1170, L1170 and LFL1170 Installation InstructionsWattsNessuna valutazione finora

- Vent Manifold Flare Manifold DesignDocumento10 pagineVent Manifold Flare Manifold Designahsan888Nessuna valutazione finora

- Series: 2 Port Solenoid Valve For Dust CollectorDocumento10 pagineSeries: 2 Port Solenoid Valve For Dust Collectorcveas1980Nessuna valutazione finora

- 14742101Documento1 pagina14742101Vinod YbNessuna valutazione finora

- Technical Notes: Air Vents, Vacuum Relief Valves, and Pressure Relief Valves in Pressurized PipelinesDocumento10 pagineTechnical Notes: Air Vents, Vacuum Relief Valves, and Pressure Relief Valves in Pressurized PipelinesKyriakos MichalakiNessuna valutazione finora

- Pur-15-02 - Air Purger Type PurDocumento4 paginePur-15-02 - Air Purger Type PurAnderson Giovanny Herrera DelgadoNessuna valutazione finora

- TCP Perforating ProgrammeDocumento3 pagineTCP Perforating ProgrammeYougchu LuanNessuna valutazione finora

- 3B - Inst - Control ValveDocumento31 pagine3B - Inst - Control ValveMystic AamirNessuna valutazione finora

- PRS09 TC V PDFDocumento4 paginePRS09 TC V PDFengp3077Nessuna valutazione finora

- 1172132997-Oe Combined Prds ValvesDocumento21 pagine1172132997-Oe Combined Prds ValvesmayurjannuNessuna valutazione finora

- Experiment No 7Documento7 pagineExperiment No 7Faizan Ahmed67% (3)

- Sur-Flo Products Control Valve Liquid Turbine Meter RunDocumento40 pagineSur-Flo Products Control Valve Liquid Turbine Meter RunCheng HuangNessuna valutazione finora

- Addis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringDocumento10 pagineAddis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringEskiasNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Din 2448Documento3 pagineDin 2448Cristian Adrian ANessuna valutazione finora

- Air Handling UnitsDocumento58 pagineAir Handling UnitsCristian Adrian ANessuna valutazione finora

- Air Handling UnitsDocumento58 pagineAir Handling UnitsCristian Adrian ANessuna valutazione finora

- Installatii electrice si sistem de protectie pentru birouri nou construiteDocumento2 pagineInstallatii electrice si sistem de protectie pentru birouri nou construiteCristian Adrian ANessuna valutazione finora

- VRF DC Inverter V4 and UnitaryDocumento6 pagineVRF DC Inverter V4 and UnitaryCristian Adrian ANessuna valutazione finora

- CH-PVDF-1018: Socket FittingsDocumento7 pagineCH-PVDF-1018: Socket FittingsAlejandro MartinezNessuna valutazione finora

- Week5 Analysis of Pipe NetworksDocumento16 pagineWeek5 Analysis of Pipe Networkselif sNessuna valutazione finora

- Drip Irrigation Parts List: FiltersDocumento4 pagineDrip Irrigation Parts List: FiltersAkshay MirashiNessuna valutazione finora

- Ashirvad UndergroundDocumento27 pagineAshirvad Undergroundjinalshah1012713Nessuna valutazione finora

- Safety Relief Valves - Installation and MaintenanceDocumento3 pagineSafety Relief Valves - Installation and MaintenanceBramJanssen76Nessuna valutazione finora

- PVC CPVC Pipes Pressures D 79Documento3 paginePVC CPVC Pipes Pressures D 79Cheann LayaNessuna valutazione finora

- Pipe LossesDocumento30 paginePipe LossesAbdullah ButtNessuna valutazione finora

- Dimensions and Weights of Plain End Steel Pipes To ANSI B36.10-1979Documento46 pagineDimensions and Weights of Plain End Steel Pipes To ANSI B36.10-1979freddycito21247Nessuna valutazione finora

- INS 306 (Y&Z) Hydraulics: Reynolds ExperimentDocumento5 pagineINS 306 (Y&Z) Hydraulics: Reynolds ExperimentAbdulrazzaqAL-MalikyNessuna valutazione finora

- Den Jet Accessory Catalog 2018Documento52 pagineDen Jet Accessory Catalog 2018RusmansyahNessuna valutazione finora

- Industrial Solenoid ValvesDocumento36 pagineIndustrial Solenoid Valvesศตวรรษ ฉิมวัยNessuna valutazione finora

- Double Pipe Heat Exchanger Project #3 CalculationsDocumento12 pagineDouble Pipe Heat Exchanger Project #3 CalculationsJames Buser100% (1)

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Documento6 paginePCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroNessuna valutazione finora

- Hydraulic Services Design Guide 1st Edition April 2014optDocumento204 pagineHydraulic Services Design Guide 1st Edition April 2014optHopeNessuna valutazione finora

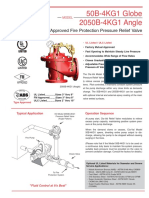

- 50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveDocumento2 pagine50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveNazrul IslamNessuna valutazione finora

- Afwall Millenium Flowise 1.1 GPF Flushometer Toilet System: ® ® Selectronic Exposed Ac Flush ValveDocumento2 pagineAfwall Millenium Flowise 1.1 GPF Flushometer Toilet System: ® ® Selectronic Exposed Ac Flush ValveisaacgamezNessuna valutazione finora

- 73241234Documento3 pagine73241234Anandan HrNessuna valutazione finora

- Din-2848-Pr - de enDocumento32 pagineDin-2848-Pr - de enAhmed AbidNessuna valutazione finora

- Flow, KV Values and Zeta Values For Gate Valves, Resilient Seated Appendix 6Documento3 pagineFlow, KV Values and Zeta Values For Gate Valves, Resilient Seated Appendix 6Imtiyaz KhanNessuna valutazione finora

- Contractor's Material and Test Certificate For Aboveground PipingDocumento3 pagineContractor's Material and Test Certificate For Aboveground Pipinglijo joyNessuna valutazione finora

- Boiler Fittings and AccessoriesDocumento30 pagineBoiler Fittings and Accessorieskowsar0221Nessuna valutazione finora

- Piping Connection ConsiderationsDocumento11 paginePiping Connection ConsiderationsGrundfosEgyptNessuna valutazione finora

- Poclain Valves A52142bDocumento228 paginePoclain Valves A52142bRafalNessuna valutazione finora

- Steam Boilers ME 1103 Introduction To MeDocumento27 pagineSteam Boilers ME 1103 Introduction To MePriyadarshee ShaswatNessuna valutazione finora

- British Standards for Piping and ValvesDocumento3 pagineBritish Standards for Piping and ValvesPradeep Sharma100% (1)

- 1611.16 - Liquid Contaminant, Dye RetentionDocumento4 pagine1611.16 - Liquid Contaminant, Dye Retentionsmupy.122Nessuna valutazione finora

- Cast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Documento5 pagineCast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Andri AjaNessuna valutazione finora

- Documentos FisherDocumento8 pagineDocumentos FisherErnestoNessuna valutazione finora

- Pressure Control ValveDocumento38 paginePressure Control ValvePrasanna KumarNessuna valutazione finora

- GROHE Specification Sheet 32553DC2Documento2 pagineGROHE Specification Sheet 32553DC2aliNessuna valutazione finora