Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Civil - IJCSEIERD - Seepage in Water Tank

Caricato da

TJPRC PublicationsTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Civil - IJCSEIERD - Seepage in Water Tank

Caricato da

TJPRC PublicationsCopyright:

Formati disponibili

International Journal of Civil, Structural,

Environmental and Infrastructure Engineering

Research and Development (IJCSEIERD)

ISSN(P): 2249-6866; ISSN(E): 2249-7978

Vol. 5, Issue 4, Aug 2015, 73-78

TJPRC Pvt. Ltd.

SEEPAGE REDUCTION IN OVERHEADED WATER TANK

ASHWIN SANJAY BALWAIK

Department of Civil Engineering, GHRCE College of Engineering, Nagpur, Maharashtra, India

ABSTRACT

This paper represents the application of fibre for seepage reduction in over headed water tank. Structures like

dams, retaining walls, canals water tanks are subjected to continuous seepage through there surfaces. These structures are

constructed by concrete. Concrete is a material which cracks over time. And great seepage loss takes place through the

surface of the walls. On the other hand to repair this seepage reconstruction of the water tanks becomes time consuming

and uneconomical. In such cases some remedial techniques shall be used to reduce great seepage of water tank through the

structure. Fibre meshes are mat like material that is applied to the surface of the structures which are used for water storage

purpose. This paper deals with the efficiency of such materials on its application to surfaces of over-head tank with great

seepage loss.

KEYWORDS: Seepage, Fibre Meshes, Flexible, Over-Head Tank, Glass Fibre

INTRODUCTION

Water is scares resource in nature. These days all over the globe water shortage is a major issue. India is tropical

country which has greatly diversified distribution of water. On the other hand there are many storage reservoir and over

headed water tank that are constructed to maintain the supply of water all over a particular area. But it has been observed

that these are mainly constructed of concretes which are subjected to large amount of cracks as a result of which great

amount of water is wasted daily through seepage. In case of dams if seepage is not controlled then there are chances of

erosion of embankment, foundation etc.

Seepage is the slow escape of water through porous structure surface of material. To save this seepage loss it is

not practically possible to reconstruct water tanks because it is time consuming and also resources consuming. There are

many type of material or remedial materials that can help to reduce the seepage loose of water that is faced daily. And

water can be saved. There are n number of fiber materials if are applied to the structure will reduce the seepage to a greater

extent. There are different fibers meshes of different sizes that can be applied for reduction of seepage through water tanks

etc. these are glass fiber mesh for water proofing, fiber mesh, plaster water proofing wire mesh, application of fiber cloth

for water proofing etc.

METHODOLOGY

Methodology includes application of fibre meshes on the surface of the water tank which is an over-head water

tank.

Application of Glass Fibre Mesh

Plaster glass fibre mesh or glass fibre mesh which is made up of woven glass fibre yarn as its basis mesh, and then

coated by alkaline resistant latex. It has fine alkaline-resistant, high strength, etc. As an ideal engineering material in

www.tjprc.org

editor@tjprc.org

74

Ashwin Sanjay Balwaik

construction, it is widely used for

Wall warm keeping,

Wall material

Cement reinforcing,

Surface decorating,

Mosaic back mounting,

Crack repairing and so on.

Following Picture Shows the Images of Glass Fibre Mesh Cloth

Figure 1: Structure of Glass Fibre Mesh

Properties of These Fibre Mesh

High alkali resistance

Glass fiber cloth is used for heat reservation systems

It prevent seepage by protecting and preventing cracks

These are flexible

High tensile strength

Durable for more than 50 years

It has high elastic modulus more than 80.4 Gpa

The Procedure for Application is as Follows

Use 160g / m2 mesh fabric in insulator layer of reinforcement in the mortar

By studying of the shrinkage

and temperature changes provide a space to maintain movement between the

layers

This is to prevent crack and rupture due to shrinkage or temperature change.

Apply the layer.

Impact Factor (JCC): 5.9234

NAAS Rating: 3.01

75

Seepage Reduction in Overheated Water Tank

Keep it to set for 48 hours

The water tank chosen for the treatment was a circular R.C.C water tank the dimensions are shown in figure

Figure 2: Shows Dimensional Details of Circular Water Tank.

As Per the Figure

Internal diameter of circular tank =10.5m

External diameter of tank=12m

Height of tank =3.5m

Thickness of wall= 1.5m

Volume of tank =115.45 cubic meter.

The tank was first emptied.

The surface of wall of excluding free board was applied the layer of fiber mesh.

And left for 72 hours so that it gets completely fixed to the surface.

Then the tank was supplied for the quantity of water it used to store is 115 cubic meter.

ANALYSIS

The circular R.C.C. water tank was under observation for 48 hrs. First of all the measures of seepage were taken.

The initial volume of water supplied to the water is 115 cubic mt. Volume of water was measure after every 6 hrs.

The tank was initially filled with water of 115cubic meter.

Observations are made after every 6 hours of interval. For the decrease in the volume of water by decreased

height of water level is measured.

The lowering level of water is measure by using measuring tape.

Likewise 7 observations are taken upto 48 hr.

Now after the application of glass fiber mesh, tank was filled again with volume of water taken as 115 cubic

meter.

www.tjprc.org

editor@tjprc.org

76

Ashwin Sanjay Balwaik

Then again seepage observations are made after each 6 hrs of interval.

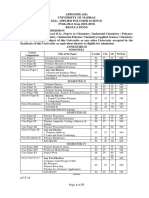

The observations are shown in Table 1

OBSERVATIONS

Table 1: Total Seepage Before and after Application of Glass Fibre

Serial

Number

Time

Interval

(Hours)

1

2

3

4

5

6

7

6

12

18

24

30

36

48

After Application of Glass Fibre

Volume of

Total Seepage

Water

(Cubic Meter)

(Cubic Meter)

110

5

103

11

95

19

88.7

25.3

82

32

75.8

38.2

70

44

Before Application of Glass Fibre

Volume of

Total Seepage

Water

(Cubic Meter)

(Cubic Meter)

113.5

3.5

107.4

7.9

101.1

14

92

17.3

87.7

23

79.8

27

74.3

32.5

The total difference in seepage was found to be:

44-32.5= 11.5 cubic meter

% Difference in seepage = 32.5/44 X 100 = 73.8 74 %

RESULTS

The application of glass fiber mesh to water tank surface resulted in decrease in loss of water as 74%.

The amount of seepage in water tank without fiber mesh is 44 cubic meter.

The amount of seepage after application of fiber mesh is 32.8 cubic meter.

The decrease in loss of water due to seepage resulted in more supply of water.

Total saving in water is up to 11.5 cubic meters.

It saved water up to 74 %

It saved the maintenance cost up to 20%

Bar Chart Shows Total Seepage after and Before Treatment Respectively

Impact Factor (JCC): 5.9234

NAAS Rating: 3.01

77

Seepage Reduction in Overheated Water Tank

Graph 1: Comparison of Seepage Value with Time

For every increase in 6 hrs of the interval the value has been seen to be increasing in the range of 70% to75% or

so.

The value of seepage of untreated R.C.C water tank is more than that of R.C.C tank applied by glass fiber mesh.

CONCLUSIONS

As the technique helped in reduction of seepage of the existing water tank. It can help many other water tanks in

local areas to reduce seepage which will as a whole reduce the loss of water of the city.

There are many types of fibers available based on the suitability it can help in reducing seepage in storage

reservoirs dams, canals also in dwelling units the wall tiles can be applied by using this technique to reduce

dampness and seepage of water through it.

In dams if this technique is used the phenomenon such as slippage of dam, overturning. Piping can be eliminated

to 70%.

Many types of water storage systems can be treated with these techniques to fix the most common problem of

seepage without the total replacement of the existing structures.

This is found to be an effective economical technique.

Also the age of the applied is 50 years. So it is one time investment technique.

REFRENCES

1.

Waterproofing of Water Retaining Structures

2.

23 Years Water Level Monitoring Through Earthfill Dam (Case Study)

3.

Analysis of the Water Resources Potential and Useful Life of the Shiroro Dam, Nigeria

4.

Preliminary analysis method of reservoir leakage based on GIS Bo Xu 1Mowen Xie1, ,Liwei Wang.

5.

Polyacrylamide Treatments For Reducing Seepage In SoilLined Reservoirs: A Field Evaluation R. D. Lentz, D.

C. Kincaid

www.tjprc.org

editor@tjprc.org

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Flame Retardant Textiles For Electric Arc Flash Hazards: A ReviewDocumento18 pagineFlame Retardant Textiles For Electric Arc Flash Hazards: A ReviewTJPRC PublicationsNessuna valutazione finora

- 2 4 1644229496 Ijrrdjun20221Documento10 pagine2 4 1644229496 Ijrrdjun20221TJPRC PublicationsNessuna valutazione finora

- Comparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanDocumento8 pagineComparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanTJPRC PublicationsNessuna valutazione finora

- Baluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaDocumento14 pagineBaluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaTJPRC PublicationsNessuna valutazione finora

- 2 33 1641272961 1ijsmmrdjun20221Documento16 pagine2 33 1641272961 1ijsmmrdjun20221TJPRC PublicationsNessuna valutazione finora

- The Conundrum of India-China Relationship During Modi - Xi Jinping EraDocumento8 pagineThe Conundrum of India-China Relationship During Modi - Xi Jinping EraTJPRC PublicationsNessuna valutazione finora

- 2 29 1645708157 2ijtftjun20222Documento8 pagine2 29 1645708157 2ijtftjun20222TJPRC PublicationsNessuna valutazione finora

- Development and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateDocumento10 pagineDevelopment and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateTJPRC PublicationsNessuna valutazione finora

- 2 44 1653632649 1ijprjun20221Documento20 pagine2 44 1653632649 1ijprjun20221TJPRC PublicationsNessuna valutazione finora

- 2 31 1648794068 1ijpptjun20221Documento8 pagine2 31 1648794068 1ijpptjun20221TJPRC PublicationsNessuna valutazione finora

- 2 52 1642055366 1ijpslirjun20221Documento4 pagine2 52 1642055366 1ijpslirjun20221TJPRC PublicationsNessuna valutazione finora

- 2 52 1649841354 2ijpslirjun20222Documento12 pagine2 52 1649841354 2ijpslirjun20222TJPRC PublicationsNessuna valutazione finora

- 2 51 1656420123 1ijmpsdec20221Documento4 pagine2 51 1656420123 1ijmpsdec20221TJPRC PublicationsNessuna valutazione finora

- Using Nanoclay To Manufacture Engineered Wood Products-A ReviewDocumento14 pagineUsing Nanoclay To Manufacture Engineered Wood Products-A ReviewTJPRC PublicationsNessuna valutazione finora

- 2 51 1647598330 5ijmpsjun202205Documento10 pagine2 51 1647598330 5ijmpsjun202205TJPRC PublicationsNessuna valutazione finora

- Self-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsDocumento8 pagineSelf-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsTJPRC PublicationsNessuna valutazione finora

- Dr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahDocumento12 pagineDr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahTJPRC PublicationsNessuna valutazione finora

- 2 51 1651909513 9ijmpsjun202209Documento8 pagine2 51 1651909513 9ijmpsjun202209TJPRC PublicationsNessuna valutazione finora

- Covid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangDocumento8 pagineCovid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangTJPRC PublicationsNessuna valutazione finora

- An Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaDocumento10 pagineAn Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaTJPRC PublicationsNessuna valutazione finora

- Effect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementDocumento8 pagineEffect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementTJPRC PublicationsNessuna valutazione finora

- Effectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewDocumento14 pagineEffectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewTJPRC PublicationsNessuna valutazione finora

- A Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)Documento8 pagineA Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)TJPRC PublicationsNessuna valutazione finora

- Analysis of Bolted-Flange Joint Using Finite Element MethodDocumento12 pagineAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsNessuna valutazione finora

- 2 67 1645871199 9ijmperdfeb202209Documento8 pagine2 67 1645871199 9ijmperdfeb202209TJPRC PublicationsNessuna valutazione finora

- Vitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019Documento16 pagineVitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019TJPRC PublicationsNessuna valutazione finora

- 2 67 1648211383 1ijmperdapr202201Documento8 pagine2 67 1648211383 1ijmperdapr202201TJPRC PublicationsNessuna valutazione finora

- 2 67 1653022679 1ijmperdjun202201Documento12 pagine2 67 1653022679 1ijmperdjun202201TJPRC PublicationsNessuna valutazione finora

- 2 67 1645017386 8ijmperdfeb202208Documento6 pagine2 67 1645017386 8ijmperdfeb202208TJPRC PublicationsNessuna valutazione finora

- Numerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingDocumento18 pagineNumerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingTJPRC PublicationsNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- )Documento12 pagine)shafaatNessuna valutazione finora

- NFPA - 13 - Tables A.20.4.1-4 - and - Table A.20.4.5.1Documento9 pagineNFPA - 13 - Tables A.20.4.1-4 - and - Table A.20.4.5.1VISHNU LAL VvNessuna valutazione finora

- Resist Dyeing and Its MethodsDocumento2 pagineResist Dyeing and Its MethodsRosheen RahatNessuna valutazione finora

- All The Best NishumaDocumento90 pagineAll The Best NishumaGAGANNessuna valutazione finora

- Technical Terms of Textile Dyeing: Muhammad Awais ImranDocumento19 pagineTechnical Terms of Textile Dyeing: Muhammad Awais ImrantesfayergsNessuna valutazione finora

- Group Assignment Without Rahul PartDocumento22 pagineGroup Assignment Without Rahul PartagungNessuna valutazione finora

- Modified M.SC SyllabusDocumento27 pagineModified M.SC SyllabusAbhishekBanerjeeNessuna valutazione finora

- Santoni SeamlessDocumento2 pagineSantoni SeamlessSudheer SinghNessuna valutazione finora

- Weaving Introduction 1Documento77 pagineWeaving Introduction 1Md Nafis HossainNessuna valutazione finora

- Texture YarnDocumento2 pagineTexture Yarnquochbt100% (1)

- Thesis Tien-TranDocumento75 pagineThesis Tien-TranPhong Nguyễn ThếNessuna valutazione finora

- Medical Non Woven Fabric Manufacturer in India - CkfabricsDocumento2 pagineMedical Non Woven Fabric Manufacturer in India - Ckfabricsvijayindhuri99Nessuna valutazione finora

- Agc1 - 1Documento6 pagineAgc1 - 1Thùy Linh NguyễnNessuna valutazione finora

- SANFORIZINGDocumento7 pagineSANFORIZINGnalinkumar9440% (1)

- Basic Rag QuiltDocumento1 paginaBasic Rag QuiltkaletarbetNessuna valutazione finora

- Introduction of Textile - Impulse FinalDocumento31 pagineIntroduction of Textile - Impulse FinalAniket MaheshwariNessuna valutazione finora

- ETP Leather Garment PDFDocumento100 pagineETP Leather Garment PDFAshish DixitNessuna valutazione finora

- Invatex Lta NewDocumento5 pagineInvatex Lta NewruestchivaNessuna valutazione finora

- SWOT Analysis PaperDocumento10 pagineSWOT Analysis Paperrushilmanchanda07Nessuna valutazione finora

- Supply Chain in Thai Garment Industry: Impact On Women Workers!Documento67 pagineSupply Chain in Thai Garment Industry: Impact On Women Workers!JunyaYimprasert100% (2)

- FDocumento21 pagineFGunjanBhutaniNessuna valutazione finora

- GATE 2016 2018 Textile Engineering and Fibre Science Question Paper and Answer Key PDFDocumento48 pagineGATE 2016 2018 Textile Engineering and Fibre Science Question Paper and Answer Key PDFJAMUNA JournalistNessuna valutazione finora

- Simulation Based Optimization On Mattress Manufacturing LineDocumento9 pagineSimulation Based Optimization On Mattress Manufacturing LineArslan AbbasNessuna valutazione finora

- Quarter 1: Learner'S MaterialDocumento41 pagineQuarter 1: Learner'S MaterialRichard ViseyNessuna valutazione finora

- Final Shahi Report - RohitDocumento61 pagineFinal Shahi Report - Rohitkshama786100% (2)

- Digging DeeperDocumento5 pagineDigging DeeperKristine Joy LomedaNessuna valutazione finora

- Imran Alam 2015Documento6 pagineImran Alam 2015Riti SrivastavaNessuna valutazione finora

- Kovai Vizha - DLDocumento26 pagineKovai Vizha - DLKali MuthuNessuna valutazione finora

- UCSP Q1 Mod4 Significance of Cultural Social Political and Economic Symbols and Practices PDFDocumento16 pagineUCSP Q1 Mod4 Significance of Cultural Social Political and Economic Symbols and Practices PDFTaibor LaborNessuna valutazione finora

- Wearable Computers Seminar ReportDocumento19 pagineWearable Computers Seminar ReportMidhun RaviNessuna valutazione finora