Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1 s2.0 S1877705812045146 Main

Caricato da

Javier Alejandro RodriguezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1 s2.0 S1877705812045146 Main

Caricato da

Javier Alejandro RodriguezCopyright:

Formati disponibili

Available online at www.sciencedirect.

com

Procedia Engineering 46 (2012) 97 104

1st International Symposium on Innovation and Technology in the Phosphate Industry

[SYMPHOS 2011]

Operation of Surface Miner: Retrospect of a Decade Journey in India

Kaushik Deya, Jayanta Bhattacharyab *

a

Assistant Professor, Mining Engineering, Indian Institute of Technology, Kharagpur, India,

b

Professor, Mining Engineering, Indian Institute of Technology, Kharagpur, India

Abstract

Surface miners made their debut in Indian surface mining industry in 1996 on a limestone deposit. The application of surface miner was

extended for coal mining in the year 1999. Presently, more than 100 surface miners are working in Indian surface mines owing to its

higher productivity and environment-friendliness. Presently, surface miner is also experimented for excavation of different deposits,

namely, bauxite, hematite, sandstone, shale etc.

Initially, the surface miners were being deployed largely on trial and error basis or on the basis of in-field experimental runs.

Manufacturers evaluated the applicability of surface miners based on compressive strength of rock. Recently, a cuttability index has been

developed to predict the applicability and performance of surface miners for different application condition. This enables the user to select

a suitable machine as per their requirement.

Surface miner completely eliminates drilling blasting and primary crushing unit and thus reduces their associated environmental hazards.

Apart from this, the sized excavated material increases the transport/conveying efficiency and thus saves the energy requirement in

transportation.

Application of surface miner with proper planning yields better efficiency. The planning can be categorized into two parts, namely, short

term and long term planning. Short term planning is within the control of field engineer and is carried out to achieve the steady production

rate and quality control. Short term planning is carried out to select the operating mode, place of operation etc. Surface miner can allow a

steep slope angle. As the blasting (short term stress) is eliminated the factor of safety for the pit slope can be kept low. This reduces the

stripping ratio and increases the overall productivity of the mine. These are the essential consideration for long term planning with surface

miner. This present paper would discuss the Indian experience of surface miner operation on the above issues. The benefits of the

deployment and the challenges faced during operation have been discussed in this paper. The recent research and development carried out

in this area is also highlighted.

2012 The

The Authors.

Authors.Published

Publishedby

byElsevier

ElsevierLtd.

Ltd.Selection

Selectionand/or

and/or

peer-review

under

responsibility

of the

Scientifi

c /or

peer-review

under

responsibility

of the

Selection

and

peer-review of

under

responsibility

the access

scientific

oflicense

SYMPHOS

2011.

under committee

CC BY-NC-ND

.

Committee

SYMPHOS

2011ofOpen

Keywords: surface miner; cuttability; mine planning; environmental impact.

Nomenclature

CI

L*

Mc

Is

Jv

cuttability index

production or cutting performance (bcm/h)

rated capacity of the machine (bcm/h)

rating for point load index

rating for volumetric joint count

* Corresponding author* . Tel.: +91-8906536801; fax: +91-3222-283728.

E-mail address: kausdey@yahoo.co.uk

1877-7058 2012 The Authors. Published by Elsevier Ltd. Selection and/or peer-review under responsibility of the Scientific Committee of SYMPHOS 2011

Open access under CC BY-NC-ND license. doi:10.1016/j.proeng.2012.09.451

98

Aw

Js

M

Kaushik Dey and Jayanta Bhattacharya / Procedia Engineering 46 (2012) 97 104

rating for abrasivity of rock

rating for direction of cutting with respect to major joints

rating for machine power

1. Introduction

Surface miner was first developed in 1970s owing the design concept of road milling machines, which cuts the old road

surface for road construction (Dey and Ghose, 2008)[1]. Since then, surface miners have gained in popularity with improved

design of cutting drum and higher machine power. Presently, more than 300 surface miners are working over the world with

competitive cost and eco-friendliness (Ghose, 2008)[2]. In India,Gujrat Ambuja Cement Ltd. was the first to introduce this

technology in one of their limestone mine in 1995 by deploying a SM-1900 machine. The reason behind this deployment

was strategic. Due to the depletion of near surface deposits, the surface mines are becoming deeper and thus, the

requirement of operating surface area is becoming larger. India is a densely populated country and the available land for

mining is less as compared to countrys mineral demand. Thus, the operating surface mines are becoming closer to the

inhabitancy and conventional drilling and blasting technique is prohibited due to threat of the inhabitant from fly rock and

ground vibration (Dey, 1999)[3]. This makes surface miner a popular mining excavation technique and presently, around 105

surface miners are working in Indian surface mines. This paper would discuss operation of surface miner, selection of

surface miner, planning with the surface miner and its environment-friendliness.

2. Surface Miner

Based on the cutting principle, surface miner can be categorized as (i) multi-bucket cutting drum located in front of the

machine ( e.g. Krupp Surface Miner), (ii) bucketless cutting drum positioned either in front of the machine (e.g. Vermeer

surface miner) or in between front and rear crawler (e.g. Wirtgen surface miner). In India, only the second type of surface

miner (i.e. bucketless cutting drum type) is used. Bucketless cutting drum, in general, is equipped with point attack tool.

Cutting drum rotates either in up cutting direction (Wirtgen surface miner) or in complimentary direction (Vermeer surface

miner). Surface miner is a compact equipment, which cuts, crushes and loaded the material simultaneously and thus,

achieves the advantages of continuous mining system. Surface Miner is a crawler mounted machine. It has a milling drum,

positioned below the machine in between front and rear crawler and rotates in up-cutting direction. Drum is equipped with

cutting picks in a double helix manner, so that all the cut materials are directed towards the centre of the drum where the

primary conveyor is located. A scraper plate is located behind the drum to leave a smooth after cut surface. There are three

major operations done by the machine:

Cutting material.

Size reduction of the cut material

Conveying and loading of the material

By the rotation of cutting drum in upward cutting the cutting picks shear out the insitu material. As the cutting drum is

positioned at the bottom, the machine weight is the added advantage in cutting operation. Size reduction of cut material is

mainly achieved during the movement of the cut material through the double helix arrangement of picks. Further size

reduction takes place by self-attrition during the conveying through the primary conveyor and the discharge conveyor.

Discharge conveyor directly loads on to the dumper or tipper (Dey et.al, 2000)[4]. Some of the commercially available

surface miners are listed in Table 1 along with their specifications.

99

Kaushik Dey and Jayanta Bhattacharya / Procedia Engineering 46 (2012) 97 104

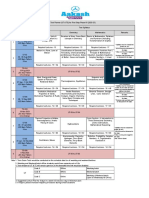

Table 1 Major specifications of some commercially available surface miner [5,6,7,8]

Wirtgen GmbH

Vermeer

L&T

TAKRAF GmbH

Bitelli

Rated

capacity

(m3/h)

Maximum

Cutting

depth (mm)

Operating

gradient

(1 in %)

Maximum

cutting speed

(m/min)

Drum

width (m)

Machine

power (kW)

Operating

weight (ton)

SM 2100

2.0

448

41

550

250

25

SM2200

2.2

671

49

668

350

84

SM2500

2.5

783

100

845

600

25

SM3500

3.5

895

137

1900

470

25

12

SM4200

4.2

1194

184

2400

600

20

T855

2.5

281

40.8

NA

812

28

NA

T955

3.4

309

56.7

NA

812

20

NA

T1055

3.4

317

61.2

NA

812

16

NA

T1255

3.7

447

99.8

NA

610

12

NA

KSM223

2.2

597

NA

NA

350

83

KSM304

3.0

895

100

NA

400

20

MTS180

3.3

500

NA

180

700

NA

NA

MTS300

4.0

750

NA

300

875

NA

NA

MTS500

4.9

1650

NA

500

1050

NA

NA

MTS800

5.6

2000

NA

800

1225

NA

NA

MTS1250

6.5

2500

NA

1250

1400

NA

NA

MTS2000

7.4

2500

NA

2000

1575

NA

NA

SF202

2.0

515

43

180

250

NA

NA

Parameters

However, surface miner has some major limitations, which should be considered before adopting the equipment (Dey

and Sen, 2008)[9]. These limitations are

performance of surface miners depends largely on the length of cut area,

abrasivity has significant influence on the cost of excavation and

performance decreases with increase in the rock strength.

Despite these limitations, very often, surface miner is required to be deployed apart from becoming the most feasible

technique if

blasting is prohibited and

requirement of selective mining of thin seams for grade control requirement.

3. Selection of Surface Miners

Selection of proper surface miner is crucial for project economics. For economical rock excavation, therefore, using

surface miners, there are two basic elements to be considered the machine and the rockmass. A machine is the product of

human ingenuity and can be modified to suit a specific requirement (Eskikaya S. and Tuncdemir H., 2007)[10]. However,

100

Kaushik Dey and Jayanta Bhattacharya / Procedia Engineering 46 (2012) 97 104

rockmass is a natural component in the earths crust and is thus immutable. It is imperative, therefore, to understand the

rock to be excavated prior to selection of the machine and based on that a suitable excavating machine should be adopted.

For the selection of suitable surface miner in India, a rockmass classification system (called rockmass cuttability

classification) has been developed. This classification considers three rockmass parameters, one machine parameter and one

application parameter. The suitable weightage is given for each parameters and the sum of the rating gives the cuttability

classification(Dey and Ghose, 2008)[1]. The details of the cuttability classification are given in Table 2.

Table 2 Rating of the parameters of rockmass cuttability classification

Class

Point load index (Is50)

Rating (Is)

Volumetric joint count (no/m3)

Rating (Jv)

Abrasivity

Rating (Aw)

Direction of cutting respect to major joint direction

Rating (Js)

Machine power (kW)

Rating (M)

II

III

IV

< 0.5

5

> 30

5

< 0.5

3

720 - 900

3

> 1000

4

0.5 1.5

10

30 10

10

0.5 1.0

6

540 - 720

6

800 1000

8

1.5 2.0

15

10 3

15

1.0 2.0

9

360 - 540

9

600 800

12

2.0 3.5

20

31

20

2.0 3.0

12

180 - 360

12

400 600

16

> 3.5

25

1

25

> 3.0

15

00 - 180

15

< 400

20

Thus, the rockmass cuttability classification (CI) is the sum of the rating of above five parameters

CI = I s + J v + Aw + J s + M

(1)

Based on this cuttability classification, the ease of excavation of rockmass using surface miner can be classified as given

below

Table 3 Assessment of excavatability of surface miner based on cuttability index

Excavatability index

50 > CI

50 < CI < 60

60 < CI < 70

70 < CI < 80

CI > 80

Possibility of ripping

Very easy excavation

Easy excavation

Economic excavation

Difficult excavation, may be not economic

Surface miner should not be deployed

Production rate of a surface miner can be estimated as follow

CI

L* = 1

kM c

100

(2)

where,

L* = production or cutting performance (bcm/h),

Mc = rated capacity of the machine (bcm/h),

CI = cuttability index ,

k = a factor for consideration of influence of specific cutting condition and is a function of pick lacing (array), pick

shape, atmospheric condition etc. and varies from 0.5 1.0.

The rockmass cuttability classification provides a handy tool for decision making on the applicability and selection of

surface miners. The classification also gives a first hand idea about the GO NO GO criterion on applicability of surface

miner apart from an estimated performance.

101

Kaushik Dey and Jayanta Bhattacharya / Procedia Engineering 46 (2012) 97 104

4. Planning Surface Miner Operation

Application of surface miner with proper planning not only yields better efficiency but also gives better control over the

product grade. In general the planning is carried out in two phases, namely long term and short term planning. Long term

planning basically dictates the year-wise pit size, grade control, bench slope control etc. In case of surface miner, the higher

bench slope can be designed using lower factor of safety due to elimination of blasting . This significantly reduces the

stripping ratio, especially, for deep surface mines. The second important factor is the variation in rockmass characteristics

with the strata/depth. This changes the performance of the deployed surface miner. For example, a surface miner suitable for

coal may not be suitable for the overburden/parting rock strata say of sandstone or shale. Thus, year-wise individual face

planning is essentially recommended.

Short term planning is within the control of field engineer and is carried out to achieve the steady production rate and

quality control. For mining with surface miner, short term planning is carried out to select the operating mode, place of

operation etc. A surface miner can work in three operating method, namely, harvesting/continuous method, turn back

method and empty travel back method. In each operating method, a surface miner can operate either in conveyor loading

mode or in windrowing mode (Fig. 1).

Surface

miner

Based on

loading

option

Direct

loading

Front

loading

Based on

movement

Indirect

loading

Rear

loading

Windrowing

Sidecasting

Empty

travel back

Conveyor

loading

Windrowing

Turn back

Conveyor

loading

Windrowing

Fig. 1 Surface miner modes of operation.

For the short term planning with the surface miner, a software is being developed to assist the field engineers to select

suitable operating mode (Pradhan and Dey, 2009[11] and Dey and Ghose, 2009 [12]). The developed software can be used to

select the operating mode for the surface miner to achieve optimum production under following geo-mining conditions: compressive strength of the rock is less than 120 MPa,

the effect of gradient of the working bench on the production is not considered, thus it is considered to be flat or gently

inclined,

special applications like, selective mining of thin seams/dirt bands, ramp construction etc., are not considered,

decision is made considering the productivity, not the financial appraisal.

The snap shot of the software is given below

102

Kaushik Dey and Jayanta Bhattacharya / Procedia Engineering 46 (2012) 97 104

Fig. 2 Snap shot of software SM1.0 used for selection of surface miner

5. Environmental Gain

In terms of new technology the Surface Miner, wherever applicable, may be of great use as it is inherently less adverse to

environment. This is concluded considering the adverse effect of the blasting, which is eliminated by the surface miner.

However, being a rock cutting machine the surface miner has some inherent environmental hazards like generation of dust,

noise etc. A comparative environmental study has been carried out for surface miner and conventional mining system (Dey

et. al., 2000)[4]. The results are discussed below

5.1. Noise

Conventional surface mining system deploying drill, shovel, dumper introduces more noise sources to the pit. As a result

both work-site noise level and the far-field environmental noise level may increase beyond permissible limit. Surface miner

is a hydraulically controlled machine and work with minimum structural vibration as a result noise generated is

comparatively less. The elimination of drills and replacement of dump trucks by conveyors also contribute to the reduction

of noise levels. Figure 3 shows that surface miner works with less noise generation and the noise level at the cabin, 1 m

distance, 10 m distance and 100 m distance from this machine is comparatively less than other machines.

Kaushik Dey and Jayanta Bhattacharya / Procedia Engineering 46 (2012) 97 104

103

90

85

Noise Level (dBA)

80

75

70

65

60

55

50

At Cabin

1m Distance

45

10m Distance

100m Distance

CH

PH

CH I

EC

P-3

IV

H 43

EC Sh

o

-3

89 vel

S

RE ho

CP vel

RE 1 D

CP rill

Su 2 D

r il

rfa

l

c

H

EC e M

in

-3

er

33

Sh

D ove

oz

l

Pa er-6

y

61

D

um Lo

ad

pe

er

r

D

um (50 -6

t

)pe

1

r(

50 02

t)

-1

IR 24

-2

Ti

D

r

pp

D

oz ill

er

e

-M

r-8

P2

99

6D

-0

91

2

40

Fig. 3 Comparison of noise levels from different surface mining machineries

5.2. Dust

Drilling, blasting, loading, transportation operations in a surface mine generate dust and suspended particulate materials.

Their concentrations near different coal mines are given in Table 4. The dust level as monitored in coal mining face

operating with windrowing method is also included in the Table 4.

Table 4 - Level of SPM (

Site

Excavation Workshop

Coal Washery

Site Office

Project Office

Club House (colony)

Mine Office

Workshop

Surface Miner face

Windrowing loading site (FEL)

g/m3 of ambient air) near mines (Dey et. al., 2000)

SPM Concentration

601

728

443

850

943.6

925.2

562

421

772

Season

Winter Season

Winter Season

Winter Season

Summer Season

March (1988)

March (1988)

Day Time

Winter season

Winter season

The table indicates conventional surface mining machinery, which are liable to cause air pollution by dust generation.

Surface Miner has some advantages over the conventional operation in this respect. This is attributed to the following

reasons:

Surface miner creates an artificial closed chamber (by two side plates, scraper bar and rear scraper plate) around the

milling drum which is the main source of dust and a continuous water spraying facility suppresses the dust at the source.

The sprayed water wets the cut material and minimises the dust generation during conveying and loading. Also auxiliary

water spraying on the conveyor is available for extreme dry conditions.

The sprayed water keeps the cutting tool cool (and hence sharp), which reduces dust generation in cutting operations.

As the surface miner provides a smooth after cut surface the dust generation in inpit transportation is also less. But haul

road transportation is likely to be unaltered for both conventional and Surface Miner face for the same road conditions.

104

Kaushik Dey and Jayanta Bhattacharya / Procedia Engineering 46 (2012) 97 104

6. Conclusions

Presently, surface miner has become one of the most popular mining equipment in Indian surface mines. The

applicability of surface miner depends on the rockmass and machine parameters. The rockmass cuttability classification

provides a handy tool for decision making on the application range of surface miners. This classification also predicts the

probable production rate from which the feasibility of the surface miner deployment can be calculated. Surface miner can

increase its productivity up to 30% with proper planning. It is strongly suggested that prior to deployment a long term

planning should be carried out and if required different types of surface miner should be deployed for different rock types.

The environmental gain of using surface miner is already proved and it must be realized in terms of indirect savings.

References

[1] Dey K. and Ghose A. K., Predicting Cuttability with Surface Miners A Rockmass Classification Approach, Journal of Mines, Metals and Fuels,

Vol.56. No.5 & 6, 2008, 85 - 92.

[2] Ghose A. K., New Technology for Surface Mining in the 21st Century Emerging Role for Surface Miner, Journal of Mines Metals and Fuels, Vol. 56

No. 3 & 4, 2008, 41 43.

[3] Dey K., Performance Analysis of Continuous Surface Miner in Indian surface Coal Mines A Case Study, unpublished M. Tech Thesis, Indian School

of Mines, Dhanbad, 1999, P40.

[4] Dey K., Pathak K. and Sen P., Environmental Acceptability of Wirtgen Surface Miner for Indian Surface Coal Mines, National Seminar on Mining in

the New Millennium, 10 12 November 2000, Hyderabad, 136-142.

[5] Downloaded from www.wirtgenindia.com

[6] Downloaded from www.takraf.com/en/products_services

[7] Personal communication with L & T Kansbahal

[8] Downloaded from www.vermeer.com

[9] Dey K. and Sen P., Continuous Surface Miner in Mining Limestone and Coal in India A Comparative Study, Journal of Mines, Metals and Fuels,

Vol.56. No.3 & 4, 2008, 51 - 54.

[10] Eskikaya S. and Tuncdemir H., , A Handy Tool for Every Type of Tunneling Roadheader, Journal of Mines, Metals & Fuels, Vol. 55, No. 12, 2007,

524 538.

[11] Pradhan P. and Dey K., Productivity Improvement through Selection of Operating Mode of Surface Miner - A Computational Approach, Journal of

Mines, Metals and Fuels, Vol. 57, No 3&4, 2009, 67 75.

[12] Dey K. and Ghose A. K., Selecting A Surface Miner An Algorithm, Journal of Mines, Metals and Fuels, Vol. 57, No 9, 2009, 282 287.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Effect of Cavity Structure On The Risk of Engine Life Limited PartsDocumento11 pagineEffect of Cavity Structure On The Risk of Engine Life Limited PartsJavier Alejandro RodriguezNessuna valutazione finora

- Turbine Blade Tip Leakage Flow Control by Unsteady Periodic Wakes of Upstream Blade RowDocumento14 pagineTurbine Blade Tip Leakage Flow Control by Unsteady Periodic Wakes of Upstream Blade RowJavier Alejandro RodriguezNessuna valutazione finora

- Individual-Related Factors and Management-Related Factors in Aviation MaintenanceDocumento10 pagineIndividual-Related Factors and Management-Related Factors in Aviation MaintenanceJavier Alejandro RodriguezNessuna valutazione finora

- 1 s2.0 S1877705814011606 MainDocumento9 pagine1 s2.0 S1877705814011606 MainJavier Alejandro RodriguezNessuna valutazione finora

- Human-Rating Design of Visual Coding Based On The Airworthiness RequirementsDocumento8 pagineHuman-Rating Design of Visual Coding Based On The Airworthiness RequirementsJavier Alejandro RodriguezNessuna valutazione finora

- Surrogate-Based Sensitivity Analysis For Safety Assessment of General Aviation Heavy-Fueled EnginesDocumento10 pagineSurrogate-Based Sensitivity Analysis For Safety Assessment of General Aviation Heavy-Fueled EnginesJavier Alejandro RodriguezNessuna valutazione finora

- 1 s2.0 S1877705815022286 MainDocumento6 pagine1 s2.0 S1877705815022286 MainJavier Alejandro RodriguezNessuna valutazione finora

- Research On Ranking Evaluation Models of Safety Risk in Productive Enterprises Based On The Perspective of SupervisionDocumento8 pagineResearch On Ranking Evaluation Models of Safety Risk in Productive Enterprises Based On The Perspective of SupervisionJavier Alejandro RodriguezNessuna valutazione finora

- Advanced Electrochemical in Vitro Detection of Superoxide Radicals With Fully Integrated Microsensor SystemDocumento5 pagineAdvanced Electrochemical in Vitro Detection of Superoxide Radicals With Fully Integrated Microsensor SystemJavier Alejandro RodriguezNessuna valutazione finora

- Vulnerability and Resilience Under Effects of Tsunamis: Case of Industrial PlantsDocumento6 pagineVulnerability and Resilience Under Effects of Tsunamis: Case of Industrial PlantsJavier Alejandro RodriguezNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Training Toolbox: Forced Reps - The Real Strength SenseiDocumento7 pagineThe Training Toolbox: Forced Reps - The Real Strength SenseiSean DrewNessuna valutazione finora

- Bfhi Poster A2Documento1 paginaBfhi Poster A2api-423864945Nessuna valutazione finora

- Process of CounsellingDocumento15 pagineProcess of CounsellingSamuel Njenga100% (1)

- A Guide To Effective Project ManagementDocumento102 pagineA Guide To Effective Project ManagementThanveerNessuna valutazione finora

- SHS11Q4DLP 21st CentFinalDocumento33 pagineSHS11Q4DLP 21st CentFinalNOEMI DE CASTRONessuna valutazione finora

- Insung Jung An Colin Latchem - Quality Assurance and Acreditatión in Distance Education and e - LearningDocumento81 pagineInsung Jung An Colin Latchem - Quality Assurance and Acreditatión in Distance Education and e - LearningJack000123Nessuna valutazione finora

- Reflection On Harrison Bergeron Society. 21ST CenturyDocumento3 pagineReflection On Harrison Bergeron Society. 21ST CenturyKim Alleah Delas LlagasNessuna valutazione finora

- Origin of "ERP"Documento4 pagineOrigin of "ERP"kanika_bhardwaj_2Nessuna valutazione finora

- Approach To Vaginal Discharge in ChildrenDocumento12 pagineApproach To Vaginal Discharge in ChildrensujataNessuna valutazione finora

- Describing LearnersDocumento29 pagineDescribing LearnersSongül Kafa67% (3)

- Introduction To Instrumented IndentationDocumento7 pagineIntroduction To Instrumented Indentationopvsj42Nessuna valutazione finora

- Lesson 3 The Prodigal SonDocumento2 pagineLesson 3 The Prodigal Sonapi-241115908Nessuna valutazione finora

- Case Blue Ribbon Service Electrical Specifications Wiring Schematics Gss 1308 CDocumento22 pagineCase Blue Ribbon Service Electrical Specifications Wiring Schematics Gss 1308 Cjasoncastillo060901jtd100% (132)

- Kurukku PadaiDocumento4 pagineKurukku PadaisimranNessuna valutazione finora

- "What Is A Concept Map?" by (Novak & Cañas, 2008)Documento4 pagine"What Is A Concept Map?" by (Novak & Cañas, 2008)WanieNessuna valutazione finora

- MuzicaDocumento3 pagineMuzicaGiurcanas AndreiNessuna valutazione finora

- UT & TE Planner - AY 2023-24 - Phase-01Documento1 paginaUT & TE Planner - AY 2023-24 - Phase-01Atharv KumarNessuna valutazione finora

- Springfield College Lesson Plan Template PHED 237: The Learning and Performance of Physical ActivitiesDocumento5 pagineSpringfield College Lesson Plan Template PHED 237: The Learning and Performance of Physical Activitiesapi-285421100Nessuna valutazione finora

- ESU Mauritius Newsletter Dec 2014Documento8 pagineESU Mauritius Newsletter Dec 2014Ashesh RamjeeawonNessuna valutazione finora

- Business Finance and The SMEsDocumento6 pagineBusiness Finance and The SMEstcandelarioNessuna valutazione finora

- A&P: The Digestive SystemDocumento79 pagineA&P: The Digestive SystemxiaoNessuna valutazione finora

- HW 2Documento2 pagineHW 2Dubu VayerNessuna valutazione finora

- Digital TransmissionDIGITAL TRANSMISSIONDocumento2 pagineDigital TransmissionDIGITAL TRANSMISSIONEla DerarajNessuna valutazione finora

- Lesson Plan Pumpkin Moon SandDocumento3 pagineLesson Plan Pumpkin Moon Sandapi-273177086Nessuna valutazione finora

- Complete PDFDocumento495 pagineComplete PDFMárcio MoscosoNessuna valutazione finora

- Karly Hanson RèsumèDocumento1 paginaKarly Hanson RèsumèhansonkarlyNessuna valutazione finora

- Cat4 Test Practice For Year 11 Level GDocumento6 pagineCat4 Test Practice For Year 11 Level GJoel OkohNessuna valutazione finora

- Thesis FulltextDocumento281 pagineThesis FulltextEvgenia MakantasiNessuna valutazione finora

- SUBSET-026-7 v230 - 060224Documento62 pagineSUBSET-026-7 v230 - 060224David WoodhouseNessuna valutazione finora

- GAJ Mod 18 Ace Your InterviewDocumento12 pagineGAJ Mod 18 Ace Your InterviewAnjela SantiagoNessuna valutazione finora