Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Shell and Tube Heat Exchanger Design Using CFD Tools

Caricato da

Chockalingam AthilingamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Shell and Tube Heat Exchanger Design Using CFD Tools

Caricato da

Chockalingam AthilingamCopyright:

Formati disponibili

SHELL AND TUBE HEAT EXCHANGER DESIGN USING

CFD TOOLS

OBJECTIVE: The main objective of this project is designing and

simulation of shell and tube heat exchanger with helical baffle

using Ansys tools.

ABSTRACT;

In present day shell and tube heat exchanger is the most

common type heat exchanger widely use in oil refinery and other

large chemical process, because it suits high pressure application.

The process in solving simulation consists of modeling and

meshing the basic geometry of shell and tube heat exchanger

using CFD package ANSYS 13.0. The objective of the project is

design of shell and tube heat exchanger with helical baffle and

study the flow and temperature field inside the shell using ANSYS

software tools. The heat exchanger contains 7 tubes and 600 mm

length shell diameter 90 mm. The helix angle of helical baffle will

be varied from 0 0 to 200 . In simulation will show how the

pressure vary in shell due to different helix angle and flow rate.

The flow pattern in the shell side of the heat exchanger with

continuous helical baffles was forced to be rotational and helical

due to the geometry of the continuous helical baffles, which

results in a significant increase in heat transfer coefficient per unit

pressure drop in the heat exchanger.

Computational Fluid Dynamics (CFD):

CFD is a sophisticated computationally-based design and analysis

technique. CFD software gives you the power to simulate flows of

gases and liquids, heat and mass transfer, moving bodies,

multiphase physics, chemical reaction, fluid-structure interaction

and

acoustics

through

computer

modelling.

This

software

can also build a virtual prototype of the system or device before

can be apply to real-world physics and chemistry to the model,

and the software will provide with images and data, which predict

the performance of that design. Computational fluid dynamics

(CFD) is useful in a wide variety of applications and use in

industry. CFD is one of the branches of fluid mechanics that uses

numerical methods and algorithm can be used to solve and

analyse problems that involve fluid flows and also simulate the

flow over a piping, vehicle or machinery. Computers are used to

perform the millions of calculations required to simulate the

interaction of fluids and gases with the complex surfaces used in

engineering. More accurate codes that can accurately and quickly

simulate even complex scenarios such as supersonic and

turbulent flows are on going research. Onwards the aerospace

industry has integrated CFD techniques into the design, R & D

and manufacture of aircraft and jet engines. More recently the

methods have been applied to the design of internal combustion

engine, combustion chambers of gas turbine and furnaces also

fluid flows and heat transfer in heat exchanger (Figure 1).

Furthermore, motor vehicle manufactures now routinely predict

drag

forces,

underbonnet

air

flows

and

surrounding

car

environment with CFD. Increasingly CFD is becoming a vital

component in the design of industrial products and processes. fig

2.1 Fluid flow simulation for a shell and tube exchanger. 7 2.4

APPLICATION OF CFD: CFD not just spans on chemical industry,

but a wide range of industrial and nonindustrial application areas

which is in below :

Aerodynamics of aircraft and vehicle. Combustion in IC

engines and gas turbine in power plant. Loads on offshore

structure in marine engineering. Blood flows through arteries

and vein in biomedical engineering. Weather prediction in

meteorology. Flow inside rotating passages and diffusers in

turbo-machinery. External and internal environment of buildings

like wind loading and heating or Ventilation system. Mixing and

separation or polymer moldings in chemical process engineering.

Distribution

of

pollutants

engineering. 2.5 ANSYS:

and

effluent

in

environmental

Potrebbero piacerti anche

- Chlorine: International Thermodynamic Tables of the Fluid StateDa EverandChlorine: International Thermodynamic Tables of the Fluid StateNessuna valutazione finora

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- He SelectionDocumento7 pagineHe SelectionKaizerNessuna valutazione finora

- Isothermal ReactorDocumento58 pagineIsothermal ReactorRoxanna LevineNessuna valutazione finora

- Heat Exchanger Design OptimizationDocumento27 pagineHeat Exchanger Design OptimizationUsama AkramNessuna valutazione finora

- Jacketed Vessel Heat Transfer Coeff and Delta PDocumento4 pagineJacketed Vessel Heat Transfer Coeff and Delta Pyamen-691904Nessuna valutazione finora

- Chapter One: Introdution To ProjectDocumento21 pagineChapter One: Introdution To Projectabiy balkewNessuna valutazione finora

- Plate Column Distillation EfficiencyDocumento7 paginePlate Column Distillation EfficiencyVijay PrasadNessuna valutazione finora

- ChemSepTutorial MulticomponentDistillationDocumento16 pagineChemSepTutorial MulticomponentDistillationavailme100% (1)

- Janna Engineering Heat Transfer (BookFi) - 492-496Documento5 pagineJanna Engineering Heat Transfer (BookFi) - 492-496Daniela Mancipe PuinNessuna valutazione finora

- Kettle Reboilers Chemical Engineering Design Ray SinnoyDocumento6 pagineKettle Reboilers Chemical Engineering Design Ray SinnoyFederico BogettiNessuna valutazione finora

- Biruk Endale Design On Heat Exchanger-1Documento32 pagineBiruk Endale Design On Heat Exchanger-1nigus gereziherNessuna valutazione finora

- Heat Transfer Assignment QuestionsDocumento2 pagineHeat Transfer Assignment QuestionsMurali KrishnaNessuna valutazione finora

- Excel Unit Op Tutorial for Modeling a MixerDocumento11 pagineExcel Unit Op Tutorial for Modeling a MixerEleazar RodriguezNessuna valutazione finora

- Ahmad, Linnhoff, Smith - Design of Multipass Heat Exchangers - An Alternative Approach (ASME) PDFDocumento6 pagineAhmad, Linnhoff, Smith - Design of Multipass Heat Exchangers - An Alternative Approach (ASME) PDFjdgh1986Nessuna valutazione finora

- TUBESHEETDocumento5 pagineTUBESHEETMehta MehulNessuna valutazione finora

- More ExercisesDocumento3 pagineMore ExercisesAnas Shatnawi100% (1)

- RCMDocumento15 pagineRCMAdzamNessuna valutazione finora

- Evaporation TutorialDocumento2 pagineEvaporation TutorialjayaprinaNessuna valutazione finora

- Design of Shell and Tube Heat ExchangerDocumento4 pagineDesign of Shell and Tube Heat ExchangerIqra Safdar100% (1)

- An Mon2Documento5 pagineAn Mon2KHÁNH VÕ ĐĂNGNessuna valutazione finora

- 1/2Documento3 pagine1/2konainglincho001Nessuna valutazione finora

- Fermenter design specificationsDocumento38 pagineFermenter design specificationsMilton Dela Rosa JrNessuna valutazione finora

- CBE 417 FlashDrumSizing Wankat PDFDocumento7 pagineCBE 417 FlashDrumSizing Wankat PDFAbdul RehmanNessuna valutazione finora

- Impeller Design For Mixing of SuspensionsDocumento16 pagineImpeller Design For Mixing of SuspensionsFaycel OuerdienNessuna valutazione finora

- Sizing Sheet for 2-phase separator as per API 12J standardsDocumento5 pagineSizing Sheet for 2-phase separator as per API 12J standardsWickyNessuna valutazione finora

- Plate Heat Exchangers Calculation Methods For Singleand Two Phase Flow PDFDocumento12 paginePlate Heat Exchangers Calculation Methods For Singleand Two Phase Flow PDFFrandhoni UtomoNessuna valutazione finora

- Insulation For SCI ReactorDocumento12 pagineInsulation For SCI ReactorJogender DhayalNessuna valutazione finora

- Mechanical Design (Compile Draft 1)Documento87 pagineMechanical Design (Compile Draft 1)IRIZREENNessuna valutazione finora

- Prediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent CorrelationDocumento18 paginePrediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent Correlationcamilo_ortiz_6Nessuna valutazione finora

- Section 3Documento5 pagineSection 3Aduchelab AdamsonuniversityNessuna valutazione finora

- Solubility of Calcium Carbonate in WaterDocumento2 pagineSolubility of Calcium Carbonate in WaterKEHALI AbdelheqNessuna valutazione finora

- HTRIDocumento1 paginaHTRIDhanny MiharjaNessuna valutazione finora

- Alcohol DistillationDocumento4 pagineAlcohol DistillationprocesspipingdesignNessuna valutazione finora

- Design and analysis of waste water treatment processesDocumento53 pagineDesign and analysis of waste water treatment processesMuddasar ShaikhNessuna valutazione finora

- Process Equipment Design Chapter 4 - Pressure Vessel Part 2Documento84 pagineProcess Equipment Design Chapter 4 - Pressure Vessel Part 2Naresh GanisonNessuna valutazione finora

- King Abdulaziz University Mechanical Engineering Heat Exchanger DesignDocumento65 pagineKing Abdulaziz University Mechanical Engineering Heat Exchanger DesignMuhammad HaidiNessuna valutazione finora

- 05 - Test On Linear ActuatorsDocumento3 pagine05 - Test On Linear ActuatorsShubham SatheNessuna valutazione finora

- Lab 3Documento16 pagineLab 3Paen Zulkifli100% (1)

- Agitation and Mixing FlowDocumento9 pagineAgitation and Mixing FlowSasitharan MNessuna valutazione finora

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocumento8 pagineVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNessuna valutazione finora

- Heat Exchangers Design: Effectiveness - NTU MethodDocumento35 pagineHeat Exchangers Design: Effectiveness - NTU MethodSaurabh SengarNessuna valutazione finora

- Heat Exchanger Networks: (Continued) Slide-2Documento44 pagineHeat Exchanger Networks: (Continued) Slide-2Adheep DasNessuna valutazione finora

- 39 Algal Oil Production 1Documento21 pagine39 Algal Oil Production 1Sai Srivathsava UdathuNessuna valutazione finora

- Solution Manual 1.45-1.46 KernDocumento2 pagineSolution Manual 1.45-1.46 KernJonesHutaurukNessuna valutazione finora

- Lab With Index1Documento35 pagineLab With Index1Labdhi ShahNessuna valutazione finora

- CE 3003 Advanced Process Design - Individual Project: Executive SummaryDocumento88 pagineCE 3003 Advanced Process Design - Individual Project: Executive SummaryLee Junming100% (1)

- MSD Report Pressure Vessel DRAFT 1Documento26 pagineMSD Report Pressure Vessel DRAFT 1prabhaakarNessuna valutazione finora

- Batch Reactive DistillationDocumento7 pagineBatch Reactive DistillationChalmer BelaroNessuna valutazione finora

- Energy Performance Assessment of Heat ExchangersDocumento22 pagineEnergy Performance Assessment of Heat ExchangersShailesh PatelNessuna valutazione finora

- Homework 1Documento9 pagineHomework 1AgithaNessuna valutazione finora

- HEAT TRANSFER EQUIPMENT DESIGN AND TYPESDocumento26 pagineHEAT TRANSFER EQUIPMENT DESIGN AND TYPESJazer Mari CantosNessuna valutazione finora

- CHE3044F Reactor Design Tutorial ProblemsDocumento4 pagineCHE3044F Reactor Design Tutorial ProblemsnmhatityeNessuna valutazione finora

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Da EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Valutazione: 5 su 5 stelle5/5 (1)

- Corrosion Failures: Theory, Case Studies, and SolutionsDa EverandCorrosion Failures: Theory, Case Studies, and SolutionsNessuna valutazione finora

- Practical Chemical Thermodynamics for GeoscientistsDa EverandPractical Chemical Thermodynamics for GeoscientistsNessuna valutazione finora

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Da EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Nessuna valutazione finora

- Thermal engineering A Clear and Concise ReferenceDa EverandThermal engineering A Clear and Concise ReferenceNessuna valutazione finora

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDa EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNessuna valutazione finora

- Mixer GrinderDocumento29 pagineMixer GrinderChockalingam AthilingamNessuna valutazione finora

- Box Shift Conveyor 2018Documento2 pagineBox Shift Conveyor 2018Chockalingam AthilingamNessuna valutazione finora

- Scotch Yoke Hacksaw Sriram Engg ReportDocumento67 pagineScotch Yoke Hacksaw Sriram Engg ReportChockalingam Athilingam100% (1)

- Safety For Motorised Sheet Forming 2018Documento3 pagineSafety For Motorised Sheet Forming 2018Chockalingam AthilingamNessuna valutazione finora

- Project List With Cost Details 2018 2019 Panimalar PolyDocumento8 pagineProject List With Cost Details 2018 2019 Panimalar PolyChockalingam AthilingamNessuna valutazione finora

- Manual Bi Folding Gate PRINTCOPY SBDDocumento50 pagineManual Bi Folding Gate PRINTCOPY SBDChockalingam AthilingamNessuna valutazione finora

- Project Titles NC 2018 Cs Fea RDDocumento9 pagineProject Titles NC 2018 Cs Fea RDChockalingam AthilingamNessuna valutazione finora

- Bottling Plant PLC 2019Documento4 pagineBottling Plant PLC 2019Chockalingam AthilingamNessuna valutazione finora

- 11 Foldable Bridge 2017 PrintDocumento48 pagine11 Foldable Bridge 2017 PrintChockalingam AthilingamNessuna valutazione finora

- Shock Absorber Failure 2018Documento3 pagineShock Absorber Failure 2018Chockalingam AthilingamNessuna valutazione finora

- Block Diagram of Carbon Level IndicatorDocumento1 paginaBlock Diagram of Carbon Level IndicatorChockalingam AthilingamNessuna valutazione finora

- 6.design and Fabrication of Length Adjustable Belt Conveyor-1Documento3 pagine6.design and Fabrication of Length Adjustable Belt Conveyor-1Chockalingam AthilingamNessuna valutazione finora

- Scotck Yoke PPT Veltech 2016Documento29 pagineScotck Yoke PPT Veltech 2016Chockalingam Athilingam50% (2)

- Gas Cutting DeviceDocumento3 pagineGas Cutting DeviceChockalingam AthilingamNessuna valutazione finora

- Pneumatic Sand SlingerDocumento1 paginaPneumatic Sand SlingerChockalingam AthilingamNessuna valutazione finora

- Sand Slinger MC Pneumatic 2016 VeltechDocumento47 pagineSand Slinger MC Pneumatic 2016 VeltechChockalingam AthilingamNessuna valutazione finora

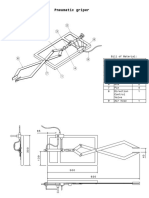

- Pneumatic GriperDocumento2 paginePneumatic GriperChockalingam AthilingamNessuna valutazione finora

- Plastic Injection Manual 2016 Amk PolyDocumento43 paginePlastic Injection Manual 2016 Amk PolyChockalingam AthilingamNessuna valutazione finora

- Abs 127two - Axes - Drill 2016 ReviewDocumento3 pagineAbs 127two - Axes - Drill 2016 ReviewChockalingam AthilingamNessuna valutazione finora

- HTTP FOR ENGINEERINGDocumento1 paginaHTTP FOR ENGINEERINGChockalingam AthilingamNessuna valutazione finora

- Lorry Trailor Lifter CostDocumento1 paginaLorry Trailor Lifter CostChockalingam AthilingamNessuna valutazione finora

- MOTORISED Press Durga Poly 2016Documento76 pagineMOTORISED Press Durga Poly 2016Chockalingam AthilingamNessuna valutazione finora

- Pneumatic Elevator Abs 20124Documento3 paginePneumatic Elevator Abs 20124Chockalingam AthilingamNessuna valutazione finora

- Air Brake PROJECT REPORTDocumento52 pagineAir Brake PROJECT REPORTChockalingam Athilingam72% (18)

- F T ZL 6L: 4 - RLT TTJ R5 !.1Documento1 paginaF T ZL 6L: 4 - RLT TTJ R5 !.1Chockalingam AthilingamNessuna valutazione finora

- Electronic ComparatorDocumento1 paginaElectronic ComparatorChockalingam AthilingamNessuna valutazione finora

- HonningDocumento1 paginaHonningChockalingam AthilingamNessuna valutazione finora

- IR Sensor UnitDocumento1 paginaIR Sensor UnitChockalingam AthilingamNessuna valutazione finora

- Amk SymbolDocumento6 pagineAmk SymbolChockalingam AthilingamNessuna valutazione finora

- The Transformation of Metaphysical ScienceDocumento7 pagineThe Transformation of Metaphysical ScienceblavskaNessuna valutazione finora

- Journal 082013Documento100 pagineJournal 082013Javier Farias Vera100% (1)

- War, Rivalry An State Building in Latin AmericaDocumento16 pagineWar, Rivalry An State Building in Latin AmericaPablo Andrés Garrido GonzálezNessuna valutazione finora

- OM - Rieter - UNIMix A76Documento321 pagineOM - Rieter - UNIMix A76Phineas FerbNessuna valutazione finora

- NewTrendsInLeadershipandManagement ArikkokDocumento32 pagineNewTrendsInLeadershipandManagement Arikkoksocofem288Nessuna valutazione finora

- The Seven Kings of Revelation 17Documento9 pagineThe Seven Kings of Revelation 17rojelio100% (1)

- Dental System SoftwareDocumento4 pagineDental System SoftwareHahaNessuna valutazione finora

- Electronics HubDocumento9 pagineElectronics HubKumaran SgNessuna valutazione finora

- Philip Larkin: The Art of Poetry 30Documento32 paginePhilip Larkin: The Art of Poetry 30Telmo RodriguesNessuna valutazione finora

- Sight Reduction Tables For Marine Navigation: B, R - D, D. SDocumento12 pagineSight Reduction Tables For Marine Navigation: B, R - D, D. SGeani MihaiNessuna valutazione finora

- Philippine Politics Concepts ExplainedDocumento3 paginePhilippine Politics Concepts ExplainedAngel Lyn A Lacerna100% (1)

- Mini Centre CatalogDocumento26 pagineMini Centre CatalogJohn EarleyNessuna valutazione finora

- Organizing and Delivering A Memorized SpeechDocumento9 pagineOrganizing and Delivering A Memorized SpeechJanice L. Langit100% (4)

- Re: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesDocumento1 paginaRe: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesMayada OsmanNessuna valutazione finora

- Beyond VaR OfficialDocumento76 pagineBeyond VaR OfficialmaleckicoaNessuna valutazione finora

- Nataraja Stotram - A Hymn Without 'CharaNa' and 'ShRi~NgaDocumento8 pagineNataraja Stotram - A Hymn Without 'CharaNa' and 'ShRi~NgaSiva Krishna100% (1)

- Writing A Formal Letter To The PresidentDocumento1 paginaWriting A Formal Letter To The PresidentPiaAnaisNessuna valutazione finora

- Measures of CentralityDocumento13 pagineMeasures of CentralityPRAGASM PROGNessuna valutazione finora

- Variolink Esthetic Brochure 673400Documento6 pagineVariolink Esthetic Brochure 673400wuhan lalalaNessuna valutazione finora

- MF-QA-001 PDIR ReportDocumento2 pagineMF-QA-001 PDIR ReportBHUSHAN BAGULNessuna valutazione finora

- CE ProblemDocumento5 pagineCE ProblemJho FNessuna valutazione finora

- Andrew Linklater - The Transformation of Political Community - E H Carr, Critical Theory and International RelationsDocumento19 pagineAndrew Linklater - The Transformation of Political Community - E H Carr, Critical Theory and International Relationsmaria luizaNessuna valutazione finora

- Explanation of Four Ahadeeth From Imaam Al-Bukhaaree's Al-Adab-Ul-MufradDocumento4 pagineExplanation of Four Ahadeeth From Imaam Al-Bukhaaree's Al-Adab-Ul-MufradMountainofknowledgeNessuna valutazione finora

- Gregory University Library Assignment on Qualities of a Reader Service LibrarianDocumento7 pagineGregory University Library Assignment on Qualities of a Reader Service LibrarianEnyiogu AbrahamNessuna valutazione finora

- Pmls 1 Final Exam Reviewer: Clinical Chemistry ContDocumento14 paginePmls 1 Final Exam Reviewer: Clinical Chemistry ContPlant in a PotNessuna valutazione finora

- Economics and The Theory of Games - Vega-Redondo PDFDocumento526 pagineEconomics and The Theory of Games - Vega-Redondo PDFJaime Andrés67% (3)

- List of PEGA Interview Questions and AnswersDocumento33 pagineList of PEGA Interview Questions and Answersknagender100% (1)

- C++ NotesDocumento129 pagineC++ NotesNikhil Kant Saxena100% (4)

- Business Plan1Documento38 pagineBusiness Plan1Gwendolyn PansoyNessuna valutazione finora

- BBRC4103 - Research MethodologyDocumento14 pagineBBRC4103 - Research MethodologySimon RajNessuna valutazione finora