Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Valvula Chek Cameron PDF

Caricato da

elisanaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Valvula Chek Cameron PDF

Caricato da

elisanaCopyright:

Formati disponibili

MS Check Valve

API Styles, Featuring

Metal-to-Metal

Sealing

The Cameron MS Check Valve

API Styles, Featuring Metal-to-Metal Sealing

When well conditions require a

check valve for high pressure or

high temperature service - where

elastomer seals would deteriorate - the Cameron MS Check

Valve from Cooper Oil Tool provides dependable metal-to-metal

sealing.

Primary applications for the

MS Check Valve are high pressure

mud choke manifolds and high

pressure Christmas tree injection

and kill lines.

Low Maintenance Operation

The MS Check Valve is nonlubricated and requires no

routine maintenance.

Forged Steel Construction

MS Check Valves are made

from forged steel with Cooper

quality assurance behind them.

MS Check Valve Features:

Standard Sizes and Pressure Ratings for MS Check Valves

Metal-to-Metal Seals

Metal sealing offers advantages over elastomeric seals in

applications where chemical

and well fluid attack and

extremes of temperature are

factors.

Streamlined Valve Seat

Streamlined valve seat area

results in less flow turbulence

and improves body longevity.

MS Check Valves can be used

with oil, gas, water or drilling

fluids. They are available in all

material and temperature classes

Size

3000 psi

5000 psi

10,000 psi

15,000 psi

20,000 psi

1-13/16"

2-1/16"

2-9/16"

3-1/16"

4-1/16"

5-1/8"

7-1/16"

as well as product specification

levels (PSL) as specified in API

6A. End-to-end measurements

are in accordance with API 6A.

Connections can be flanged,

clamp, butt weld or combination.

MS Check Valves can be supplied to special customer specifications. Standard pressure

ratings range from 3000 to 20,000

psi. Bore sizes range from

1-13/16" to 7-1/16".

Note: Pressure downrating may be required for service temperatures greater than 250F.

Standard Trim Materials for MS Check Valves

API 6A Materials

Classification

Body & Bonnet

Material

Stem Retainer

Material

Poppet

Material

Seat

Material

AA-General Service

Low alloy steel

AISI 410 SST

AISI 410 SST

AISI 410 SST

BB-General Service

Low alloy steel

AISI 410 SST

AISI 410 SST

AISI 410 SST

CC-General Service

AISI 410 SST

AISI 410 SST

AISI 410 SST

AISI 410 SST

DD-Sour Service*

Low alloy steel

AISI 410 SST

Alloy 718

Alloy 718

EE-Sour Service*

Low alloy steel

AISI 410 SST

Alloy 718

Alloy 718

FF-Sour Service*

AISI 410 SST

AISI 410 SST

Alloy 718

Alloy 718

HH-Sour Service*

Alloy 718 or low alloy

steel clad with alloy 625

Alloy 718

Alloy 718

Alloy 718

* as defined by NACE standard MR-01-75

Notes: 1. Specifications subject to change without notice.

2. Special trims available upon request.

3. Pressure downrating may be required for service temperatures greater than 250F.

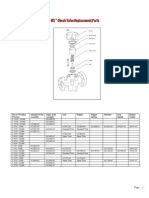

Bonnet

Poppet

Poppet Spring

Seat Retainer

Seat Spring

Bonnet Gasket

Forged Steel Body

Metal Seat

SD-6555

MS Check Valve

Sales and Service Locations

Domestic

Bakersfield, California

Woodland, California

Denver, Colorado

Lafayette, Louisiana

New Orleans, Louisiana

Mount Pleasant, Michigan

Laurel, Mississippi

Oklahoma City, Oklahoma

Corpus Christi, Texas

Dallas, Texas

Houston, Texas

Longview, Texas

Odessa, Texas

Casper, Wyoming

Evanston, Wyoming

International

Buenos Aires, Argentina

Perth, Australia

Kuala Belait, Brunei

Calgary, Canada

Grande Prairie, Canada

Punta Arenas, Chile,

Pointe-Noire, Congo

Cairo, Egypt,

Great Yarmouth, England

London, England

Paris, France

Pau, France

Port Gentil, Gabon

Jakarta, Indonesia

Tokyo, Japan

Kuala Lumpur, Malaysia

Miri, Malaysia

Terengganu, Malaysia

Ciudad Del Carmen, Mexico

Mexico CIty, Mexico

Villahermosa, Mexico

The Hague, The Netherlands

Papakura, New Zealand

Lagos, Nigeria

Warri, Nigeria

Bergen, Norway

Muscat, Oman

Moscow, Russia

Al Khobar, Saudi Arabia

Abu Dhabi, U.A.E.

Maracaibo, Venezuela

Manufacturing Plants and Aftermarket Facilities

Domestic

Anchorage, Alaska

Berwick, Louisiana

Patterson, Louisiana

Ville Platte, Louisiana

Oklahoma City, Oklahoma

Brookshire, Texas

Liberty, Texas

International

Zarate, Argentina

Melbourne, Australia

Edmonton, Canada

Leeds, England

Beziers, France

Celle, Germany

Longford, Ireland

Veracruz, Mexico

Hoogezand, The Netherlands

Port Harcourt, Nigeria

Stavanger, Norway

Singapore, Republic of Singapore

Aberdeen, Scotland

This list includes major manufacturing and sales locations. Contact your nearest Cameron

representative for locations not included on this list.

CAMERON is a registered trademark of Cooper Cameron Corporation

Cooper Cameron Corporation, Cameron Division, TC1010, PDF4/96

Cameron

P.O. Box 1212

Houston, TX 77251-1212

Telephone: 713/939-2211

Fax: 713/939-2620

Potrebbero piacerti anche

- Types of ValvesDocumento31 pagineTypes of ValvesZarnab Rauf78% (9)

- DS32 01 Pump Stations Borehole MechanicalDocumento71 pagineDS32 01 Pump Stations Borehole MechanicalZerathan OmaeNessuna valutazione finora

- Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFDocumento2 pagineChiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFCikalong Yard100% (1)

- Laurus As Built BOP Part Numbers - UnlockedDocumento166 pagineLaurus As Built BOP Part Numbers - UnlockedEstuardo OlanNessuna valutazione finora

- Valves HCR CameronDocumento5 pagineValves HCR CameronmanuelperdomotNessuna valutazione finora

- Cameron DL Packer Assembly 11in - TC9609 - E-22Documento1 paginaCameron DL Packer Assembly 11in - TC9609 - E-22Marcos ChavarriaNessuna valutazione finora

- Maintenance and Operation Manual: Ultra Flow Type 'E-Fc' Gate ValvesDocumento32 pagineMaintenance and Operation Manual: Ultra Flow Type 'E-Fc' Gate ValvesNeilton Junior100% (2)

- Model FC PDFDocumento22 pagineModel FC PDFAbde Esselam100% (1)

- Ds Shearing Blind Ram Tc1399Documento2 pagineDs Shearing Blind Ram Tc1399Gregory StewartNessuna valutazione finora

- AOT Tubular HandlingDocumento112 pagineAOT Tubular HandlingrolandNessuna valutazione finora

- Check Valve MS PDFDocumento4 pagineCheck Valve MS PDFazeazeazeNessuna valutazione finora

- GX Annular Blowout PreventerDocumento2 pagineGX Annular Blowout PreventerCarlos Munizaga100% (1)

- Hydraulic System (Control Valve) PDFDocumento26 pagineHydraulic System (Control Valve) PDFMarco Fam's100% (4)

- Regulator3 4 DSDocumento4 pagineRegulator3 4 DSargaNessuna valutazione finora

- Tc148-2 Manual GV O&mDocumento20 pagineTc148-2 Manual GV O&mFam Escalante OnofreNessuna valutazione finora

- DL Annular Blowout Preventer 21-1/4" 3000 Psi WPDocumento27 pagineDL Annular Blowout Preventer 21-1/4" 3000 Psi WPJeneesh Shanmughan100% (1)

- Gate Valve CameronDocumento13 pagineGate Valve CameronJohn Jairo Simanca100% (1)

- Cameron EB 538 D Rev D2 - Shear Rams - Op & MaintDocumento7 pagineCameron EB 538 D Rev D2 - Shear Rams - Op & MaintCanrig RamdeNessuna valutazione finora

- Towsend CatalogoDocumento98 pagineTowsend CatalogoLuis Enrique Rico100% (3)

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDocumento6 pagineCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Documento18 pagineOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNessuna valutazione finora

- Cameron MBO Multi-Bowl Wellhead SystemDocumento6 pagineCameron MBO Multi-Bowl Wellhead SystemiswantmachooNessuna valutazione finora

- 2P36784, Plug ValveDocumento34 pagine2P36784, Plug ValveEdwin HernandezNessuna valutazione finora

- Axon-Type50u Ram BopDocumento4 pagineAxon-Type50u Ram BopMohie Khosravani0% (1)

- Direct and Indirect Cold Water Supply SystemDocumento14 pagineDirect and Indirect Cold Water Supply SystemBoyi Enebinelson100% (1)

- Operacion y Manual de HCR 5000 Psi (Actuador Hidraulico)Documento22 pagineOperacion y Manual de HCR 5000 Psi (Actuador Hidraulico)Juan Miguel Robledo100% (2)

- Westrom Cameron PartsDocumento22 pagineWestrom Cameron PartsEd CalheNessuna valutazione finora

- Drainage Pumps: Catalogue Drainage and SewageDocumento90 pagineDrainage Pumps: Catalogue Drainage and SewageStefanNessuna valutazione finora

- Cameron Dual Bore FLEXPACKERDocumento1 paginaCameron Dual Bore FLEXPACKERTitanBOPNessuna valutazione finora

- HRSB 13 5.8 - 10M PDFDocumento33 pagineHRSB 13 5.8 - 10M PDFJuan Felipe Garza GNessuna valutazione finora

- Heshka Oil Catalog 2019Documento16 pagineHeshka Oil Catalog 2019Michael PerschkeNessuna valutazione finora

- Swaco' Style Drilling Choke PartsDocumento1 paginaSwaco' Style Drilling Choke PartsBodega 3001Nessuna valutazione finora

- 719638-6A3-MAN - Rev 01 - 719638-6A3-MANDocumento52 pagine719638-6A3-MAN - Rev 01 - 719638-6A3-MANFam Escalante OnofreNessuna valutazione finora

- GE HY Kellyguard FS 080709-2Documento2 pagineGE HY Kellyguard FS 080709-2caballero_tigreNessuna valutazione finora

- LEAR JET 30S MANUAL - OdpDocumento201 pagineLEAR JET 30S MANUAL - Odpeb100% (2)

- 8.3 Description of The Hydraulic System: 8.3.1 Technical DataDocumento14 pagine8.3 Description of The Hydraulic System: 8.3.1 Technical DatahectorNessuna valutazione finora

- Catálogo Cameron Bop Novo 2004-2005Documento162 pagineCatálogo Cameron Bop Novo 2004-2005Edmo Virgens100% (1)

- Cameron Manual Gate Valve FLDocumento2 pagineCameron Manual Gate Valve FLEnrique HortaNessuna valutazione finora

- DPC PDFDocumento94 pagineDPC PDFjquevedo8237Nessuna valutazione finora

- Secondary Steering System (HMU Steering) 966Documento9 pagineSecondary Steering System (HMU Steering) 966Ahmed RezkNessuna valutazione finora

- Annular Bop Packing Elements: Otu Se (Axs)Documento2 pagineAnnular Bop Packing Elements: Otu Se (Axs)JoseManuelDominguezHuertaNessuna valutazione finora

- Tandem Booster m100Documento12 pagineTandem Booster m100Leonardo Alvarez100% (1)

- Tank Filling SystemsDocumento16 pagineTank Filling SystemsVenkatesh MuraliNessuna valutazione finora

- DSQ4 10M SidedoorDocumento15 pagineDSQ4 10M SidedoorДудла СтаніславNessuna valutazione finora

- BoilerDocumento426 pagineBoilerVitor Santos Soares SoaresNessuna valutazione finora

- Pumps - Positive Displacement - Rotary - Waukesha Universal Service ManualDocumento81 paginePumps - Positive Displacement - Rotary - Waukesha Universal Service ManualLuis Jara Tolentino100% (1)

- Anson E Typs Gate Valve With Fail Safe Closed ActuatorDocumento12 pagineAnson E Typs Gate Valve With Fail Safe Closed ActuatorWeniton Oliveira0% (1)

- 13.62 5K Model 7022 Manual PDFDocumento30 pagine13.62 5K Model 7022 Manual PDFPato GonzalezNessuna valutazione finora

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Documento28 pagine21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNessuna valutazione finora

- Annular Bops D Bop DL Bop: To Contents PageDocumento6 pagineAnnular Bops D Bop DL Bop: To Contents PageDavid OrtegaNessuna valutazione finora

- Shaffer NOV Type 72 ShearsDocumento2 pagineShaffer NOV Type 72 ShearsTitanBOP100% (1)

- Bimetallic Steam Traps (Velan)Documento36 pagineBimetallic Steam Traps (Velan)Ebn egg100% (1)

- Hydril GK Annular DataDocumento2 pagineHydril GK Annular DataAndrés Ramírez100% (3)

- Technical Notes and Specifications Part CDocumento29 pagineTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- T NFPA 20 T Chapter 4 General Requirements: Section 4.28Documento2 pagineT NFPA 20 T Chapter 4 General Requirements: Section 4.28AnoirNessuna valutazione finora

- COS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronDocumento5 pagineCOS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronYudaNessuna valutazione finora

- Check Valve MS and Type R CameronDocumento2 pagineCheck Valve MS and Type R CameronRuben Dario Conde LeonNessuna valutazione finora

- Wellhead Equipment CatalogDocumento29 pagineWellhead Equipment CatalogDewy PambayunNessuna valutazione finora

- T 81 Bop Technical Data SheetDocumento2 pagineT 81 Bop Technical Data SheetDimitri Elitist BlessNessuna valutazione finora

- FMC Flowline Product CatalogDocumento80 pagineFMC Flowline Product CatalogRodrigo França100% (2)

- M60eh44 Man 001Documento40 pagineM60eh44 Man 001Riski KurniawanNessuna valutazione finora

- IRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Documento68 pagineIRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Tanyawat Sahsakmontri100% (2)

- Stripper TOT 2.50 10M DS34 TechMan1146Documento13 pagineStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaNessuna valutazione finora

- Parveen Well HeadDocumento25 pagineParveen Well HeadGerman PinedaNessuna valutazione finora

- Retsco/Demco Mud Guns: Bottom TypeDocumento1 paginaRetsco/Demco Mud Guns: Bottom TypeGregory StewartNessuna valutazione finora

- NXT-M Bop TMSDocumento1 paginaNXT-M Bop TMSSasan Abbasi100% (1)

- Core International QuicklistDocumento10 pagineCore International QuicklistJonathan SumimsaNessuna valutazione finora

- Patterson RentalDocumento295 paginePatterson RentalTiffany DacinoNessuna valutazione finora

- Mud Guns: Bottom Type Mud GunDocumento1 paginaMud Guns: Bottom Type Mud GunPrime Energy Warehouse-YemenNessuna valutazione finora

- Choke and Kill 4 Inch 10K 4 Inch 5K of NOVDocumento2 pagineChoke and Kill 4 Inch 10K 4 Inch 5K of NOV刘 建Nessuna valutazione finora

- Model 950 Knife Gate Valve: Product Datasheet - 950Documento2 pagineModel 950 Knife Gate Valve: Product Datasheet - 950Carlos GutierrezNessuna valutazione finora

- Model 940 Knife Gate Valves: Product Datasheet - 940Documento2 pagineModel 940 Knife Gate Valves: Product Datasheet - 940Carlos GutierrezNessuna valutazione finora

- WKM HP Butterfly BrochureDocumento28 pagineWKM HP Butterfly BrochureAarthi PadmanabhanNessuna valutazione finora

- Manual de Bolsillo FM MantenimientoDocumento94 pagineManual de Bolsillo FM MantenimientoCristhian D CaicedoNessuna valutazione finora

- Schedule of Rates 2018-19 PDFDocumento327 pagineSchedule of Rates 2018-19 PDFNagarjuna Kuncham40% (5)

- CL 604-Pneumatic SystemDocumento16 pagineCL 604-Pneumatic SystemJamesNessuna valutazione finora

- 22 12 DDocumento1 pagina22 12 Dsheikh karimNessuna valutazione finora

- Runner Pitch Diameter (In)Documento6 pagineRunner Pitch Diameter (In)FedericoNessuna valutazione finora

- Ejprescott Valve and Tapping Product GuideDocumento34 pagineEjprescott Valve and Tapping Product GuideTarik JazoulNessuna valutazione finora

- MICON EngineeringDocumento39 pagineMICON EngineeringAnbalagan AnbaNessuna valutazione finora

- SS5 Parts Book 2002Documento24 pagineSS5 Parts Book 2002RUN GONessuna valutazione finora

- Grundfos Submersible Deep Well - Motor - Acc - SP a-SPDocumento104 pagineGrundfos Submersible Deep Well - Motor - Acc - SP a-SPIlyas Kurniawan100% (2)

- Moduflow SeriesDocumento14 pagineModuflow SeriesfernandoNessuna valutazione finora

- Air Dryer CheckDocumento4 pagineAir Dryer CheckCristhian Samuel Yacila OrdinolaNessuna valutazione finora

- Building Utilities Reviewer ComprehensiveDocumento3 pagineBuilding Utilities Reviewer ComprehensiveReynald HarrisNessuna valutazione finora

- 461 LMI P5 Serie Ibv EngDocumento24 pagine461 LMI P5 Serie Ibv EngsunanNessuna valutazione finora

- Cissell - HD 125 DryerDocumento63 pagineCissell - HD 125 DryerMaria K RizzoNessuna valutazione finora

- In-Line Balanced Pressure Proportioning SystemDocumento4 pagineIn-Line Balanced Pressure Proportioning SystemsenkuttuvanNessuna valutazione finora

- Check Valve Ball Poppet Type Direct Acting SAE-10 Cartridge - 350 BarDocumento2 pagineCheck Valve Ball Poppet Type Direct Acting SAE-10 Cartridge - 350 BarJuan Santiago RojasNessuna valutazione finora