Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Open Safety Dialogue (OSD), Dialogue, Delivery and Commitment

Caricato da

mohamadi42Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Open Safety Dialogue (OSD), Dialogue, Delivery and Commitment

Caricato da

mohamadi42Copyright:

Formati disponibili

SPE 86625

Open Safety Dialogue (OSD), Dialogue, Delivery and Commitment

Terje Lvby and Tor Alrik Dahl, Statoil ASA

Copyright 2004, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at The Seventh SPE International Conference on

Health, Safety, and Environment in Oil and Gas Exploration and Production held in Calgary,

Alberta, Canada, 2931 March 2004.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in a proposal submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to a proposal of not more than 300

words; illustrations may not be copied. The proposal must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Acknowledgements

We would like to thank Mr. Alan Hammer QAC Manager,

Operations Coflexip Stena Offshore. Mr. Stacy P. Payne,

Manager International HS&E, Global Marine. Dr. Mark

Fleming, Chartered Psychologist The Keil Centre. They all

shared extensively from their vast knowledge and experience,

and provided both encouragement and guidance at the outset

of our project. We truly believe that their valuable input so far

has enabled us to avoid the worst pitfalls in such programs.

Proposal

This paper describes the introduction of a management tool for

behavior modification implemented in Statoils E&P operations

over the past two years.

A large number of executives, managers and supervisors1 have

been trained, in small groups, to use a structured methodology

for work site interaction with staff aimed at reducing at risk

behavior in our plants and facilities. Our training program

have been highly standardized and at the same time focused on

stimulation of dialogue and creation of consensus amongst the

participants.

Our Open Safety Dialogue (OSD) introduction program has

been conducted in the shortest possible time span. Each

supervisor has been put under mild pressure to apply the OSD

methodology at completion of her/his training.

We will briefly describe the OSD methodology, our training

program and the tools and techniques we have developed and

applied to achieve our objectives.

Supervisor is used as a generic term for executives,

managers, supervisors and foremen in the rest of the text.

The main objective is to share our experiences with respect to:

Culture conflicts encountered

How to ensure usage and compliance

Reporting and statistics

Managerial style elements

Opposing forces

Employee reactions

The requirements and tools for continued pressure and long

term commitment

Surprises and rewards

We will also present our plans for OSD follow up activities

and our related peer program; which are now in progress.

OSD methodology

As in most behavioral safety programs we apply elements of

scientific psychology, labeled as coaching, in our program.

The central element of OSD is that two supervisors invite

employees who are at worki to engage in an open, honest and

friendly dialogue aimed at having the employees themselves

realize and express their at risk behaviors, as well as the

potentional consequences to themselves, with respect to

ongoing work at the actual work sites.

It is mandatory for the supervisors in an OSD to demonstrate a

100 % no blame attitude. This in recognition of the fact that a

significant percentage of individual at risk behaviors are

unconscious, and to avoid provoking a counterproductive

defensive reaction from the employees.

The dialogue is closed with a formal agreement of behavioral

change, when such changes are required. These agreements

are followed up. Supervisors will not use OSD in situations

where they observe gross violations of safety rules and

regulations that qualify directly for disciplinary action.

Dupont have, in a recent report to Statoilr1, stated: It is

clearly recognized that the OSD program is a copy of previous

versions of Duponts STOP for Supervisors program.

Even though our program and STOP, and a series of similar

programs, have the same basic foundation in psychology we

beg to differ from this is a copy of assessment

We have sourced our methodology from several different

existing programs (some of them recognized in industry as

based on Duponts HSE programs; such as STOP, START,

ABS, ASA etc.) as well as published papers and reports.

It was however imperative to our objective to tailor our final

solution both to complement existing corporate HSE standards

and systems, as well as to be adapted to the Norwegian work

culture.

We feel that this is clearly acknowledged in Duponts report

where it is stated. It is, however, recognized that as an

internally developed program there are a number of variances,

both in terms of concept and implementation when compared

with Dupont best practice. (We will identify some of our

variances from Dupont best practice throughout this paper.)

Training program

Our formal training is conducted as a one day course at sites /

plants and offshore platforms with a small group of

supervisors per instructor. The theory part addresses both the

deficiencies of previously applied HSE supervisory techniques

and the reasons why we are convinced that correctly applied

coaching (i.e. OSD) will have the desired effect, over time.

Our structured dialogue methodology is then introduced step

by step. Each step is justified by referring both back to the

participants own knowledge and experiences and psychology

explained in previous sessions.

The theoretical part of the training is concluded by role-plays

based on photos of realistic work situations selected from the

course participants own areas of responsibility.

The practical part of the course requires the participants to

engage in real life dialogues based on what they have learned

so far. Each of the participants typically gets the benefit of

participating in 2 4 OSDs, under instructor supervision and

guidance.

All the course participants are invited to establish their own

personal target for how many OSD they will try to participate

in during the coming year, at course closure. They do this by

filling in an agreement with the CEO of our company at the

end of the course. (Fig.1). (The instructor copies these for data

recording, and the participants keep their original agreement

as a course diploma).

SPE 86625

The OSD training is complemented by a documentation

package. This is only distributed to course participants. It was

not intended, nor developed, as self-study documentation but

as a reminder and supplement to what was explained during

the course.

Our experiences

The project team who initiated this program in late 2001

highlighted that the only true measure of success for a

behavioral modification program would be a continuous and

significant reduction in LTA and injury frequency over a long

period of time (years).

It was also realized that a broad and significant change in

safety culture was a critical success criteria. And that such

changes require both top-down and across the board focus

and involvement, as well as time.

The project teams postulate was that it would take at least 3

5 years of dedicated work before true and significant results

would materialize. It is therefore far to early in the project to

assess and report measurable (true) achievements.

We have however already observed several interesting issues

we will like to share with our readers.

Although most of these observations ()2 are of empirical

nature, we do believe we are in a unique position to state some

of these as facts because a low number of instructorsii have

trained 3700 supervisors in small groups over a period of less

than two years. The same instructors have also coached a

significant number of the same supervisors in use of OSD in

their work environment. (This coaching typically follows 8

10 months after their initial OSD training).

As we have trained and coached a large number of supervisors

from our main contractor companies in addition to our own

employees, representing a multitude of professional

backgrounds, nationalities, and corporate cultures, we truly

feel that our observations are representative not only for

different companies but also for different nationalitiesiii.

Our observations and experiences are in other words of a multi

nationality and a multi company nature and therefore not in

any regard only limited to our own company.

Culture conflicts encountered

Norwegian organizational culture r2

The overall Norwegian business organization culture and

managerial styles have been developed and refined over the

last 5 6 decades. A society founded on broadly accepted

social democratic principles has had a strong impact on the

way we organize managerial structures and workforce

relations in the Norwegian industry.

Fig. 1 Personal OSD ambition agreement

We have used this marker () throughout the rest of our text

to identify our main observation- / solution statements.

SPE 86625

The supervisors and employees in Norway are considered

equal, particularly with respect to matters that directly impact

the workforce.

Unions and collaborative bodies within the organization are

considered to be viable channels for appeal of managerial

decisions.

The supervisors true authority is to a large extend dependent

on the individuals professional skills and contact network and

not so much on rank and position.

Supervisors may as a result of this be questioned, and even

interrogated, from multiple levels and directions in the

organization, even on minor issues.

Direct orders and demand for loyal adherence to procedures,

standards, and (to a degree) even laws, are out of fashion in

Norway as involvement and consensus are the overall

recommended managerial styles in our country.

--We also have, to a large extent, abandoned the use of

disciplinary actions in enforcing good safety regulations and

procedures.

It is generally believed in Norway that Norwegians are able to

practice open and candid communication techniques in all

matters at all levels (as long as it does not involve very

personal feelings and relations).

We were therefore greatly surprised to find that most

Norwegian supervisors reverted to the old HSE inspector and

fault finding technique when their objective was to guide

their employees, in a positive manner, to assess their own at

risk behavior and the potentional worse personal impact, if an

incident happened.

The much praised openness and informality in Norway do

not ensure that supervisors are visible at the work sites.

Steadily increasing parts of their time are spent as desk

jockeys, or in meetings. Even when the message from the

companys executive board, combined with the OSD program,

are that more visible leadership is required supervisors

themselves tend to ease back into the same office work most

of them claim to detest.

We know, from direct communication, that this lack of visible

leadership in our plants is both observed and of concern to our

CEO.

How to ensure usage and compliance

Statoil has, as most other companies, experienced previous

well-intended and important HSE initiatives being received

with enthusiasm and motivation both by management, unions

and the work force before they fizzle into a halt for no obvious

reason.

We also had some knowledge about problems in other

organizations behavior modification projects, where each

supervisor was assigned a quota to perform within a set

timeframe. (i.e. projects which turned into pure number

games)

We knew before this project commenced that most of our

supervisors felt that they already had their plate more than

filled with priority tasks. We therefore had to secure across the

organization priority and dedication to the OSD challenge,

while we at the same time did not have available resources to

conduct ongoing on site monitoring of progress and

performance.

It was decided that we would require the supervisors to

report each conducted dialogue. In order to counteract

negative reactions, funded on previous experiences we had to

avoid some of the traps we, and others, had fallen into in

earlier projects:

We require only confirmation of an OSD being

conducted

We made the reporting as efficient as possible

We do not require any reporting of observations iv

We measure performance per organizational unit

only, not by individual supervisor v

We enable extensive reporting for those who so

desire.

We prohibit identification of workforce participants

We established a long term program of coaching and

verification

We experienced a lot of bickering and moaning from

supervisors about yet another reporting system at the outset.

The claim was that they would do the dialogues regardless of

reporting or not, and that the quality of the OSDs would be

better if they did not have to worry about having to report

them.

We therefore waited patiently and did not enforce reporting

initially. Each unit was questioned about their progress after

approx. 3 months, and they admitted, even without probing,

that progress had not been particularly good.

Senior

Management then demanded active reporting; and the worst

objections to this were silenced.

We have been extremely surprised to discover that

supervisor teams in our production facilities and even groups

of supervisors on individual shifts have developed their own

standards of OSD methodology, which in some cases even are

in direct conflict with the detailed and justified instructions

which are given during our structured formal training or in the

documentation. And whats even worse; they claim that their

approach is based on and consistent with the same sources.

We have, based on this observation, decided that OSD

instructors periodically will visit all plants/shifts and perform

coaching of individual supervisors by participating in OSDs

on one-to-one basis.

Its our overall plan to increase this target in a controlled

fashion on an annual basis until we reach a company wide

OSD factor of at least 7.

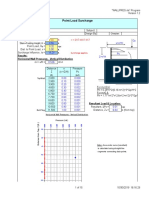

OSD factor 01.11.2003 for

Offshore platforms and onshore plants E&P - NG

2,5

The score limit for year 2003 is set to 2 (meaning 2 and over) to reduce the risk of stimulating a pure numbers competition .

1,5

0,5

Pla

nt B

On

sho

re b

Pr o

a se

jec

( s)

tB

fr o

m

01.0

6.0

3

01

.0 5

.03

6.0

3

orm

fro

m

2 4.0

Pla

nt

A

Pla

tf

01

.04

.03

R fr

om

orm

Pla

tf

Q

orm

fro

m

orm

Pla

tf

Pr o

jec

tA

Pla

tf

3.0

3

orm

2 4.0

Pla

tf

orm

orm

Pla

tf

Pla

tf

10

.03

.03

ro m

fro

m

M

Nf

orm

orm

Pla

tf

Pla

tf

5.0

3

om

01 .0

2 .0

orm

15.0

I f ro

m

orm

orm

Pla

tf

Pla

tf

J fr

G

orm

Pla

tf

orm

Pla

tf

Pla

tf

orm

Pla

tf

orm

C

orm

Pla

tf

orm

0

Pla

tf

We have facilitated extensive reporting features and follow up

assistance for supervisors who want to utilize these. We do

also allow for manual recording and reporting through

assistants (secretaries, planners etc.) if required. The only

thing that is not facilitated, or permitted, is identification of the

employee(s) the supervisors talked with.

We have received much praise for the simplicity of our Lotus

Notes reporting solution.

orm

The reporting is done through a Lotus Notes database form

(Fig 2) where the few mandatory fields are clearly highlighted.

The reporting is made as efficient as possible, and we have

proved through tests that even a first time user needs less than

30 seconds to record their first OSD.

Pla

tf

The only mandatory reporting of an OSD consists of date,

time, plant, area (in plant) and the names of the two

supervisors who initiated the dialogue.

activity between plants/org. units regardless of size as well as

to establish the same target for any level of our organization.

We have established a factor of 2 as a target for the first year

in full operation (2003) and do not report any achievement

higher than this target. (To circumvent any best guy in class

competition between units).

The OSD factor will be/is included in the performance- /

bonus contracts for plant managers.

Pla

tf

Reporting and statistics

We have verified through targeted testing that extraordinary

tasks like OSDs will not get done in large organizations unless

a reporting is required and controlled.

SPE 86625

No. of OSDs

1191

1261

1176

800

540

398

1203

955

104

340

238

598

320

449

237

Factor = No of OSDs per unit/plant divided by man-years employed (same period ).

10.11.2003

475

139

154

378

153

397

205

143

47

Offshore man-year = 1615 hours Onshore man-year = 1820 hours.

OSD 2003 OSD TEAM E&P N HSE

Fig. 3 Monthly executive report, OSD factor

The project team has started assessing which type of statistical

presentations may be useful in the future.

Although it is far to early to interpret any of this as significant

measures we believe that we already see some initial

confirmation of the fact that you have to achieve a minimum

critical mass of OSDs before you can expect to see stable

and positive results from such efforts (Fig 4).

Injury frequency - OSD Factor

Injury ferquency

OSD Factor

30

2

1,8

Fig. 2 Database reporting form

Our company has other systems where the business units in

Statoil report their manpower employed per period, in order to

facilitate multiple types of frequency reporting.

This combination permitted us to develop a management

reporting scheme where we on a monthly basis present the

achieved OSD factor for each plant/org. unit. This shows the

number of OSDs factorized over the number of man-years

employed in the same period. (Fig. 3)

25

1,6

1,4

20

1,2

15

1

0,8

10

0,6

0,4

0,2

0

jan.03

feb.03

mar.03

apr.03

Platform A

mai.03

jun.03

jul.03

Platform B

Fig. 4 A very preliminary observation of results

We dont have any other reporting scheme for the project.

The OSD factor enables the executives to compare OSD

aug.03

sep.03

SPE 86625

Managerial style elements

Our executives and senior managers lecture about safety in

large groups in the correct manner; - they know very well

what to say. But to demonstrate and verify the same gospel by

walking around and stimulate the work force directly has

proved to be quite another and far more challenging task.

This in spite of the fact that the same executives, during OSD

training, agree that the personal positive dialogue, practiced at

work sites may be more effective, also in a wider perspective.

We feel that the paradox most executives face in this regard is

that there always are so many major business issues and tasks

at hand that a few brief and short (although extremely

important) dialogues about worksite safety all times runs a

high risk of being slightly delayed and postponed. Then, as all

executives work periods and site visit programs have a

tendency to be overloaded, it ends up with a repetitive

personal promise of doing a better job in this area at the next

opportunity.

We do however know that our executives are aware of this

situation and are actively doing their best to facilitate

opportunities for OSDs in their schedules during site visits.

Supervisors who have an extensive professional background

within their own area of responsibility seem to be the ones

who struggle the most to make these dialogues about their

employees personal safety natural. This in spite of the fact that

they often have both good and close personal relationships

with their colleagues. They revert very quickly into a dialogue

about purely technical topics or the old finger pointing as

soon as they sense that the communication gets a little

strained.

We have in all our OSD training and coaching highlighted

the fact that it would generate a high risk for overall program

failure if we try to stimulate OSD activities by introducing

quotas per supervisor. Dialogues of this nature is not

something all supervisors, as well as employees, will feel

comfortable with initially. To neglect important this fact will

only stimulate counterproductive reactions and reporting. We

feel that we have successfully argued this case to our top

executives, but are still engaged in an ongoing struggle to

prevent some representatives of our middle management from

applying such negative performance measures within their

area of responsibility.

Quite a number of the supervisors see dialogues such as this

as a strange sort of competition between themselves and their

crewmembers. As a result they engage in pure power plays

where they have to find something at fault (the auditor

syndrome) even when there is nothing truly wrong in the

situation.

The OSD represents an extremely simple, and easy to

understand and justify, dialogue format. In spite of this it

appears to be extremely difficult to learn and practice by

seasoned supervisors.

At the same time when we observe this hard struggle to

learn and be confident in OSD practice by our supervisors

during the practical part of OSD training and coaching we are

surprised by requests for shorter training, light versions and

other quick fix solutions with respect to the formal training

from the very same supervisors who struggles the most.

Opposing forces

We have for a number of years worked diligently to make

individual workers truly realize that they themselves are the

persons most responsible (in charge) for their own personal

safety. It appears now that we, as an undesired side effect of

this effort, may have reduced the feeling of direct

responsibility for the same issues on the supervisors part.

We have also experienced company wide initiatives for cost

cutting and manpower reductions like all the other oil

companies in the world. This has required resources for

project work, process changes, changes in the supervisors

authority and responsibilities and empowerment of workforce

versus supervision.

Introduction of new and powerful

corporate IT systems, which at the same time are more

demanding on the end users, are also tying the supervisors

more than to their offices and PCs. These developments have

reduced the available time for supervisors to visit worksites

and engage themselves in ongoing work activities for their

crews. We expected this to have a significant negative impact

on our project, but this has failed to materialize. On contrary

it seems that the new OSD initiative where supervisors more

frequently visit employees in the plant area and focus on

personal safety and display honest concern for each individual,

to a degree have reduced the anxiety which could have been

caused by the corporate cost cutting ambitions. We have also

recorded frequent feedback, from both parties, to the fact that

OSDs are welcomed as a missed closer level of ongoing

contact between our employees and their supervisors.

Executives, managers and supervisors strongly agree during

OSD training that our failure to use disciplinary action in a

correct fashion as a tool to enforce important safety rules and

procedures is a major obstacle to the development of a good

safety culture in our company.

We have an established practice of handling a few extreme

safety violations through disciplinary actions, but at the same

time have neglected to pursue people who repetitively violate

mandatory safety precautions and procedures through an

orderly application of our disciplinary procedure. It is a

known fact that we, as a result, have people in our

organization who choose to behave in a fashion with respect to

safety where they are a real danger both to themselves as well

as their colleagues.

This has also been identified in the Dupont report mentioned

earlierr1 and is now an important action item in our plan

for 2004.

A significant number of the course participants are very

active during training, subscribe to all the evaluations and

arguments presented, are enthusiastic about the potentional of

the OSD methodology and give the training very high scores

on the course evaluation. (Overall average approx 5,2. On a 1

6 scale).

Even so, a significant number of the supervisors who give the

course top score only commit themselves to carry out 2 5

OSDs per year at course closure.

Employee reactions

The work force is in general very positive to the OSD

experiences they have encountered, partly because they have

truly missed interactions with their supervisors (visits) in the

workplace.

The unions safety delegates are voicing a joint strong opinion

stating that OSD have been a significant and very positive new

approach to safety work in our company.

We have however, through the grapevine, received some,

hopefully isolated, observations of rather disastrous dialogues.

Observations of this nature which have reached the project

team members in person, seems to originate with disloyal

supervisors who choose to display their discontent and

disagreement with the OSD initiative to subordinates instead

of addressing and resolving this with their superiors.

The requirements and tools for continued pressure and

long term commitment

The most important factor, at this stage in the program, in

order to secure long-term commitment and success for our

behavioral safety program, will be to demonstrate solid and

personal top management commitment and engagement.

This is the area where we have struggled the most in the last

two years. Our executives are both dedicated to the program

and actively demanding supervisor performance and OSD

reporting. They monitor the OSD factor on a monthly basis

and both challenge and praise individual managers and units

through direct communication.

We know that our executives are quite good at doing OSDs,

when they manage to find the opportunity and time to perform

them. And it is greatly appreciated by the work force when

they observe members of the executive board and company

presidents through OSDs both being interested in their work

and cautioning them in a friendly manner to take care of

themselves confirming the corporate safety credo We do

always have the required time to work in a safe and controlled

manner

The paradox is that with all these immensely important

factors our executives really struggle to find the time and

opportunity to carry out a few short dialogues with such

potentional and impact, even when they visit plants and sites.

This dilemma have now the required executive attention and

our OSD project team have been requested both to

continuously challenge them on their performance in this

regard as well as to facilitate arrangements where they actively

can demonstrate their OSD dedication. We are therefore

confident that we will see a significant positive development

SPE 86625

with respect to visible behavioral change commitment from

key members of our corporate executive committee.

Surprises and rewards

The biggest surprise has been that we completely underestimated the training requirements. We settled for an one-day

formal course to secure that even the busiest supervisors could

find the time to attend such limited training and because we

thought it would be more than sufficient time to learn to use

and practice a very simple and productive communication

technique.

We train the supervisors to carry out a friendly dialogue with

people they know, which should last no more than 5 minutes,

through the use of four basic questions (which we even

provide on a memory jogger card). As basis for the practical

training we establish a joint understanding as to the basis for

OSD as a powerful tool to improve safety. Understandings the

majority of our course participants subscribes to, and is

enthusiastic about.

In spite of this positive foundation we have experienced that

our supervisors struggle, and require far more training than we

expected when we developed the program.

We are convinced that this to a large degree is caused by the

fact that we previously have trained our supervisors so well in

pure faultfinding and finger pointing methods. Methods

they have practiced for years. We completely overlooked this

need for clean out training, and have to rectify this now,

when the initial OSD training should be approaching an end.

Although we knew that our supervisors over time have been

turned more and more into office workers we did not realize to

which degree this had removed them from hands on

knowledge about what actually goes on at the work sites.

Quite a few of our supervisors have had major eye openers

after they have started practicing OSD.

We are also recording a very high degree of appreciation from

the work force confirming that they have actually missed the

contact with their supervisors out in the field (at their work

sites).

An observation by the OSD instructors, which have

increased in magnitude as the program have progressed, is the

lack of overall consistency in our companys and employees

safety focus. While we consider ourselves quite good in this

regard in our plants and on offshore installations we often talk

about this being carried over to the rest of our organization

as well as our employees private sphere (homes etc.) 24

hours HSE focus. As OSD instructors, traveling around in

the different environments and also talking to supervisors and

staff about their off hours safety focus, we collect the most

incredible observations and stories showing that such safety

carry over effects often are only marginal and even

nonexistent. Gross at risk behaviors, that would have been

addressed immediately at our plants, are often neglected when

they occur in and around our office buildings, even by visiting

plant supervisors. Plant workers and supervisors, who are

recognized as very safety conscious at work, tell numerous

stories about near misses at home due to their own at risk

behavior, within areas they would never fail in at work etc.

SPE 86625

And a number of our supervisors, who know that they should

lead by example at work, admits they tend to do otherwise

when they are at home with their own family.

Safety is not something which is transmitted, it has to be

focused at and worked on at all times, everywhere

One of our immediate and great rewards have been to be

present during OSDs where the dialogue technique used

correctly have revealed unseen but significant at risk behaviors

with a potentional for severe injuries; and where the

employees are truly grateful for having been made aware of

the dangers.

Another reward has been meeting supervisors who states

that this is the best professional experience and leadership

training they have encountered in their professional lives.

We also consider the support and engagement from our

CEO and corporate executive committee members, and their

commitment to long-term focus and push for this project, as a

reward for the project team. As said above, we would like to

see this extended to more direct OSD activities on their part as

well. We do however expect to see a positive and significant

change in this in the near future.

Future plans and activities

OSD follow up activities

We will increase our OSD coaching in order to compensate

both the requirements for more practical training and to

counteract the tendency to develop sub standards locally in our

company.

We will develop and conduct opinion polls aimed at collecting

better information as to how OSD is experienced both by the

workforce and the supervisors. This will be anonymous polls

where we only aim to be able to identify whether the

respondent is a supervisor or employee, and at which plant the

respondent are employed.

We are already in the process of developing an OSD

Newsletter. This is aimed at easing ongoing communication

with our supervisors regarding OSD, and at the same time a

vehicle to enable communication about our company standard

as to the methodology and practice of OSD.

We aim to start a series of motivation efforts. The first

objective is to communicate directly by letter (in a positive

manner!) with supervisors who might believe they have been

completely forgotten about how we might help them to

achieve their personal objectives with regard to the number of

OSDs they aimed to do at the end of training.

The next stage will be to give some sort of recognition to

plants and departments who have achieved the annual OSD

factor and even to give the individuals of these units some sort

of recognition.

The CEO has requested that a parallel program is developed to

train and motivate all senior support personnel (engineers,

purchasers, corporate management, etc.) who through their

actions, or lack of such, may impact the safety of others. As

an important part of this program version we will also increase

our focus at office and off hours safety for all company

employees and environments.

We are also looking into ways and means to introduce some

sort of competition into the OSD program. As we, at all costs,

will avoid stimulating a situation where we focus on the

number of OSDs per individual supervisor our current

thoughts are on rewarding The good OSD or The OSD

with the best experience transfer potentional etc.

Peer program

The project proposal for OSD underscored that this is a top

down program, and stated that it had to be complemented by a

peer program as a crucial part of an overall behavioral safety

program.

The project plan proposed that the peer program was phased in

approximately 1,5 year after the start OSD training. Such a

delay was required both in order to secure that OSD would be

well established before the peer program started, and to avoid

depleting OSD for crucial resources before it reached the half

way mark.

The peer programs objectives include reduction of

communication barriers between colleagues with respect to

dialogue about at risk behaviors, and openness about private

matters that may impact individuals focus and safety. It also

include awareness training as to injury consequence

assessment by documented experiences and highlights the

importance of both taking care of each other and staying

focused so as to ensure that all individuals are going home

from work in equal or better shape as when they came.

Statoils safe behavior peer program is now ongoing.

According to current plans it will engage more than 10,000

company and contract employees over a period of 2 years

participating in large conventions of 2 days duration

complemented by a 4 year program of follow up activities.

The supervisors who have completed OSD training are

important role models and resources in this peer program

There is tight collaboration between the two programs but

because of the unexpected and extended demand for OSD

training a separate project group is in charge our safe behavior

peer program

Afterthought

Old habits die hard,

regardless of whether its managerial styles

or at risk behaviors at the work sites.

In order to have success in a behavioral safety program

both must be changed

References

r1. HSE MANAGEMENT EVALUATION for Statoil ASA,

Stavanger; Norway, March 2003;

(Internal report made for Statoil by Dupont)

r2. Culture and HSE Management, Sigurd K. Berg, Aker

Offshore Partner;

SPE 73993, Society of Petroleum Engineers Inc. 2002.

Endnotes

i

This is one of the areas where we deviate from the way we

have seen Duponts STOP program being practiced. We have

OSD dialogues with people at work, regardless of whether we

observe anything wrong or not. This defuses any anxiety on

the part of the workforce regarding supervisors interrupting

them for such dialogues when they are working.

ii

A very small number of instructors do all the OSD training

in Statoil. The objective is to secure that we present a

consistent message and a structured methodology with

standard elements. We do not permit cascade training in the

OSD program. (This is another area where we deviate from

Duponts standard)

iii

We have trained Norwegians, Danes, Swedes, Germans,

Dutchmen, Portuguese, Spaniards, Americans, Englishmen,

Scots and Chinese from more than 30 different companies.

iv

This is an area were we clearly deviate from Duponts

best practice.

We do not collect STOP cards and process them by HSE

committees etc.

We are of the opinion that the intended result of the dialogue

(that the individual workers realize that they should focus on

eliminating their own at risk behaviors) far outweighs any

potentional for organizational learning through committees.

Another reason for this policy is that we feel that a practice

of handling such reports in HSE committees will pose a high

risk of violation of our no name no blame ambition.

We have another incident reporting system (Synergy) that aim

to facilitate important experience transfer and we do not feel

that its advisable to have multiple reporting and

administrative systems with the same objectives.

v

We have established a measure of performance where we

compute the number of OSDs per man-year employed for the

same period. For our first year of full operation we set the

target for all operational units to factor 2. It is our ambition to

increase this target over time until we reach an OSD factor of

at least 7 for all units.

The individual ambitions of each supervisor are only known to

themselves, and the project team. It is never reported to

management.

We encourage unit managers to apply balanced measures of

motivation (leadership) and recognize and respect the fact

that there are always different strokes for different folks, and

that this technique is something most, but not all, supervisors

will be able to utilize in a constructive manner.

SPE 86625

Potrebbero piacerti anche

- Transfer of Training in Organisations: (Learning & Development in Organisations series #12)Da EverandTransfer of Training in Organisations: (Learning & Development in Organisations series #12)Nessuna valutazione finora

- OrientationDocumento2 pagineOrientationVishakha ChandraNessuna valutazione finora

- A Survey of Architecture Design RationaleDocumento46 pagineA Survey of Architecture Design RationaleEdward CardenasNessuna valutazione finora

- Flexpip4 PDFDocumento16 pagineFlexpip4 PDFdevpal78Nessuna valutazione finora

- 6th Sem 2 Civil Engg PDFDocumento39 pagine6th Sem 2 Civil Engg PDFLeigh HudsonNessuna valutazione finora

- Apparent Weight in A LiftDocumento18 pagineApparent Weight in A LiftInn Ain100% (1)

- 7-Solving Quadratic Equations by Completing The SquareDocumento17 pagine7-Solving Quadratic Equations by Completing The SquareArchana RajuNessuna valutazione finora

- Chemistry Paper Form 2 Term 1 Exam 2017Documento8 pagineChemistry Paper Form 2 Term 1 Exam 2017Godfrey MuchaiNessuna valutazione finora

- Aci Concrete Design Mix ProcedureDocumento4 pagineAci Concrete Design Mix ProcedureLan CorpuzNessuna valutazione finora

- SAFETYDocumento53 pagineSAFETYKunal JaiswalNessuna valutazione finora

- Live LoadsDocumento1 paginaLive Loadsjojo_323Nessuna valutazione finora

- Assessment of The Effects of Keta Sea Defence Project On The Livelihoods of The People in The Keta Municipality, Volta Region, GhanaDocumento13 pagineAssessment of The Effects of Keta Sea Defence Project On The Livelihoods of The People in The Keta Municipality, Volta Region, GhanaPremier PublishersNessuna valutazione finora

- Design For Shear According To Bs8110-1997: Paneled Beams (B4)Documento1 paginaDesign For Shear According To Bs8110-1997: Paneled Beams (B4)مصطفى عبدالرحيمNessuna valutazione finora

- Proportionality (Mathematics)Documento4 pagineProportionality (Mathematics)OmarGarciaNessuna valutazione finora

- Weep Hole Part Elevation Section: Drawn: Checked: Approved: Date: Horz. Scale: CAW None 2/17/2017Documento1 paginaWeep Hole Part Elevation Section: Drawn: Checked: Approved: Date: Horz. Scale: CAW None 2/17/2017eduardox11Nessuna valutazione finora

- Structural Steelwork Design 2012-2013 Calculation SheetDocumento3 pagineStructural Steelwork Design 2012-2013 Calculation SheetIbnuyusoff77Nessuna valutazione finora

- Disaster Risk Reduction Education in Indonesia ChaDocumento18 pagineDisaster Risk Reduction Education in Indonesia ChaNovitaNessuna valutazione finora

- Design HakeemDocumento3 pagineDesign Hakeemg4goharNessuna valutazione finora

- Tapiwa EvaluationDocumento72 pagineTapiwa EvaluationProto Proffesor TshumaNessuna valutazione finora

- Bending Moment, Shear Force and Deflection of Beams and FramesDocumento14 pagineBending Moment, Shear Force and Deflection of Beams and FramesronyNessuna valutazione finora

- Offshore StructureDocumento12 pagineOffshore Structureg4goharNessuna valutazione finora

- Near Miss Temple FormDocumento1 paginaNear Miss Temple FormSantos RexNessuna valutazione finora

- Evaluation of World Bank Group's Strate in LiberiaDocumento218 pagineEvaluation of World Bank Group's Strate in LiberiaIndependent Evaluation GroupNessuna valutazione finora

- Engineering Services AgreementDocumento2 pagineEngineering Services AgreementdesignbaseNessuna valutazione finora

- ASCE710IDocumento15 pagineASCE710IMina MagdyNessuna valutazione finora

- Concrete TechnologyDocumento186 pagineConcrete Technologysmg26thmayNessuna valutazione finora

- RET. WALL OriginalDocumento15 pagineRET. WALL OriginalSupun Aravinda JayawardhaneNessuna valutazione finora

- 002 Engineering and PM Services PresentationDocumento9 pagine002 Engineering and PM Services PresentationjakalegawaNessuna valutazione finora

- Country Assistance Program Evaluation For AfghanistanDocumento223 pagineCountry Assistance Program Evaluation For AfghanistanIndependent Evaluation at Asian Development BankNessuna valutazione finora

- Calculating Load As Per Snip4Documento29 pagineCalculating Load As Per Snip4pektophNessuna valutazione finora

- Section - 1 Introduction To Quadratic Expressions: Locus Locus Locus Locus LocusDocumento58 pagineSection - 1 Introduction To Quadratic Expressions: Locus Locus Locus Locus LocusNíkhíl Bansal100% (1)

- Report - Review Local Disaster Risk Reduction Fund in BD - Findings and Recommendations - 2011Documento16 pagineReport - Review Local Disaster Risk Reduction Fund in BD - Findings and Recommendations - 2011CDMP BangladeshNessuna valutazione finora

- Design Loads & ConditionsDocumento11 pagineDesign Loads & ConditionsAnonymous ZMLlQvBopNessuna valutazione finora

- Fixed Moment Condition Design Based On ACI 318-14: Input Data & Design SummaryDocumento1 paginaFixed Moment Condition Design Based On ACI 318-14: Input Data & Design SummaryEnrike GarciaNessuna valutazione finora

- Steel BuildingsDocumento41 pagineSteel BuildingsAb van AlfenNessuna valutazione finora

- Bridge Proper SL Item of Work Cl. No. of Unit Qty No. Mort & H'S Specification 1 2 3 4 5Documento8 pagineBridge Proper SL Item of Work Cl. No. of Unit Qty No. Mort & H'S Specification 1 2 3 4 5Hoque joynulNessuna valutazione finora

- Painting Safety TipsDocumento2 paginePainting Safety Tipsatisz333Nessuna valutazione finora

- RCC31R Rigorous One-Way SlabsDocumento389 pagineRCC31R Rigorous One-Way SlabsCioabla BogdanNessuna valutazione finora

- BoQ EstimasiDocumento22 pagineBoQ EstimasiHidma RofiNessuna valutazione finora

- Design and Coonstruction of Cruise Berth For Colon 2000, PanamaDocumento8 pagineDesign and Coonstruction of Cruise Berth For Colon 2000, PanamaAlirezaNessuna valutazione finora

- Basement Column Supporting Lateral Resisting Frame Based On ACI 318-08 Input Data & Design SummaryDocumento3 pagineBasement Column Supporting Lateral Resisting Frame Based On ACI 318-08 Input Data & Design SummaryAnonymous fLgaidVBhzNessuna valutazione finora

- RCC72 Stairs & Landings - MultipleDocumento3 pagineRCC72 Stairs & Landings - MultipleMohammad Twaha JaumbocusNessuna valutazione finora

- RTPR-ENG-REP-00XX - A Steelwork Transfer E3D To Shop Detailing Testing ReportDocumento27 pagineRTPR-ENG-REP-00XX - A Steelwork Transfer E3D To Shop Detailing Testing ReportJustine Lloyd Bautista100% (1)

- Wage Rate Calculation For Direct & Indirect LaborsDocumento6 pagineWage Rate Calculation For Direct & Indirect LaborsABAMELANessuna valutazione finora

- Cv-Sreenath (T&i)Documento5 pagineCv-Sreenath (T&i)sreenaths100% (1)

- 07-Mathcad Wall Spread SoilDocumento17 pagine07-Mathcad Wall Spread SoilLevent KurtulduNessuna valutazione finora

- Tutorial Retaining WallDocumento14 pagineTutorial Retaining WallAnonymous 7oXNA46xiNNessuna valutazione finora

- Wall Presure AnalysisDocumento6 pagineWall Presure Analysisbuffyto5377Nessuna valutazione finora

- Roof DeckDocumento2 pagineRoof DeckRayodcNessuna valutazione finora

- Calculation of Snow Load Multi-Span RoofsDocumento3 pagineCalculation of Snow Load Multi-Span Roofstecon ploiestiNessuna valutazione finora

- Design of Solid Wood PanelsDocumento6 pagineDesign of Solid Wood PanelsJerome BartalouNessuna valutazione finora

- Residential Wiring GuideDocumento32 pagineResidential Wiring GuideEgbo EseNessuna valutazione finora

- Disaster Risk Reduction Architecture Key Practices For ImplementersDocumento48 pagineDisaster Risk Reduction Architecture Key Practices For ImplementersSeijinNessuna valutazione finora

- A Checklist For Building Organizational Evaluation CapacityDocumento5 pagineA Checklist For Building Organizational Evaluation Capacityyassir971Nessuna valutazione finora

- Appendix B - Tree Felling Procedure PDFDocumento5 pagineAppendix B - Tree Felling Procedure PDFAmani Katotola AyubuNessuna valutazione finora

- Generating Wind Loads For Other StructuresDocumento35 pagineGenerating Wind Loads For Other Structuresfv79772zhxNessuna valutazione finora

- Daniel Tian Li: Design CriteriaDocumento32 pagineDaniel Tian Li: Design Criteriacurlyjockey100% (1)

- Organizational Change Development PlanDocumento20 pagineOrganizational Change Development PlanjacintaNessuna valutazione finora

- Graduate Business Start-Ups Project Report: StudiesDocumento53 pagineGraduate Business Start-Ups Project Report: StudiesEhsan MahmoodNessuna valutazione finora

- Dof Hseq Workbook WebDocumento180 pagineDof Hseq Workbook WebvhlactaotaoNessuna valutazione finora

- Modeling of Transient Cuttings TransportDocumento11 pagineModeling of Transient Cuttings Transportmohamadi42Nessuna valutazione finora

- A New Comprehensive, MechanisticDocumento10 pagineA New Comprehensive, Mechanisticmohamadi42Nessuna valutazione finora

- A New Wellbore Position Calculation Method: C.R. Chia, SPE, W.J. Phillips, SPE, and D.L. Aklestad, SPE, SchlumbergerDocumento5 pagineA New Wellbore Position Calculation Method: C.R. Chia, SPE, W.J. Phillips, SPE, and D.L. Aklestad, SPE, Schlumbergermohamadi42Nessuna valutazione finora

- Propagation of Chromium (III) AcetateDocumento7 paginePropagation of Chromium (III) Acetatemohamadi42Nessuna valutazione finora

- The Slug Suppression System in OperationDocumento5 pagineThe Slug Suppression System in Operationmohamadi42Nessuna valutazione finora

- Predicting Permeability From Well Logs inDocumento11 paginePredicting Permeability From Well Logs inmohamadi42Nessuna valutazione finora

- Lateral Buckling of Pipe With ConnectorsDocumento14 pagineLateral Buckling of Pipe With Connectorsmohamadi42Nessuna valutazione finora

- Asphaltene Precipitation and AlterationDocumento6 pagineAsphaltene Precipitation and Alterationmohamadi42Nessuna valutazione finora

- IMPES Stability Selection ofDocumento7 pagineIMPES Stability Selection ofmohamadi42Nessuna valutazione finora

- Maximizing Yibal's Remaining ValueDocumento9 pagineMaximizing Yibal's Remaining Valuemohamadi42Nessuna valutazione finora

- Benchmarking The Formation Damage of Drilling FluidsDocumento11 pagineBenchmarking The Formation Damage of Drilling Fluidsmohamadi42Nessuna valutazione finora

- Waterflooding in Low NG Fluvial Environment - Thai Shell ExperienceDocumento7 pagineWaterflooding in Low NG Fluvial Environment - Thai Shell Experiencemohamadi42Nessuna valutazione finora

- A Geomechanical Modeling Approach in Deep Horizontal Well Development Designs PDFDocumento11 pagineA Geomechanical Modeling Approach in Deep Horizontal Well Development Designs PDFmohamadi42Nessuna valutazione finora

- Propellant Perforation Breakdown Technique Eastern Venezuela Field ApplicationsDocumento15 paginePropellant Perforation Breakdown Technique Eastern Venezuela Field Applicationsmohamadi42Nessuna valutazione finora

- Massive Hydraulic Fracturing - A Case History in Western Siberia, RussiaDocumento12 pagineMassive Hydraulic Fracturing - A Case History in Western Siberia, Russiamohamadi42Nessuna valutazione finora

- Gas-Lift Instability Resulted Production Loss and Its Remedy by Feedback ControlDocumento9 pagineGas-Lift Instability Resulted Production Loss and Its Remedy by Feedback Controlmohamadi42Nessuna valutazione finora

- Pore Scale Network Modeling of Relative Permeability in Chemical FloodingDocumento6 paginePore Scale Network Modeling of Relative Permeability in Chemical Floodingmohamadi42Nessuna valutazione finora

- SPE 84842 Comparing Fracture Simulation Design To Radioactive Tracer Field Results: A Case HistoryDocumento9 pagineSPE 84842 Comparing Fracture Simulation Design To Radioactive Tracer Field Results: A Case Historymohamadi42Nessuna valutazione finora

- A Geomechanical Modeling Approach in Deep Horizontal Well Development Designs PDFDocumento11 pagineA Geomechanical Modeling Approach in Deep Horizontal Well Development Designs PDFmohamadi42Nessuna valutazione finora

- Application of A New Class of Surfactants in Stimulation TreatmentsDocumento10 pagineApplication of A New Class of Surfactants in Stimulation Treatmentsmohamadi42Nessuna valutazione finora

- Change of Subject-To Principal HVMDocumento3 pagineChange of Subject-To Principal HVMPrantik SealNessuna valutazione finora

- GE Power System and Corporate ExpressDocumento8 pagineGE Power System and Corporate ExpressdollieNessuna valutazione finora

- Masterfile - Archer & Bull - UG 2022 - IITMDocumento9 pagineMasterfile - Archer & Bull - UG 2022 - IITMSam TyagiNessuna valutazione finora

- Heat ExchangersDocumento29 pagineHeat ExchangerscooLkiD1412Nessuna valutazione finora

- 18 SSBDocumento162 pagine18 SSBapi-3806887Nessuna valutazione finora

- Exadata Technical Whitepaper 134575Documento31 pagineExadata Technical Whitepaper 134575Jyothi JohnNessuna valutazione finora

- Alternative ADHD TreatmentDocumento3 pagineAlternative ADHD TreatmentCindy VanegasNessuna valutazione finora

- ESE 18 Cut Offs English PDFDocumento1 paginaESE 18 Cut Offs English PDFkishan singhNessuna valutazione finora

- Quadratic EquationsDocumento40 pagineQuadratic EquationsWeb Books100% (6)

- Werewere FelaDocumento17 pagineWerewere FelaStacy HardyNessuna valutazione finora

- Gui 0001 EngDocumento102 pagineGui 0001 EngBalaji MysoreNessuna valutazione finora

- Chap05 JOHN W. CRESWELLDocumento27 pagineChap05 JOHN W. CRESWELLMuhammad Bilal100% (2)

- Eindhoven University of Technology: Award Date: 2008Documento65 pagineEindhoven University of Technology: Award Date: 2008Jay Mark VillarealNessuna valutazione finora

- Literacy Lesson PlanDocumento5 pagineLiteracy Lesson Planapi-437974951Nessuna valutazione finora

- 5 HPHT API 6x - FowlerDocumento13 pagine5 HPHT API 6x - Fowlerchau nguyenNessuna valutazione finora

- IU BIM Execution Plan TemplateDocumento12 pagineIU BIM Execution Plan TemplateAyman KandeelNessuna valutazione finora

- Sample TestDocumento2 pagineSample TestSarah Guimary PelarisNessuna valutazione finora

- Lessons Electric Circuits 1 PDFDocumento530 pagineLessons Electric Circuits 1 PDFStefano SintoniNessuna valutazione finora

- Google Calendar Integrator - v2.0Documento21 pagineGoogle Calendar Integrator - v2.0Sumedh KakdeNessuna valutazione finora

- Photo-Realistic 3D Model Extraction From Camera Array CaptureDocumento11 paginePhoto-Realistic 3D Model Extraction From Camera Array CaptureJohn NaylorNessuna valutazione finora

- Stress in CompoundsDocumento3 pagineStress in CompoundsEmma PeelNessuna valutazione finora

- A Study On Customer Relationship Management Practices of Commercial Banks in Thanjavur DistrictDocumento6 pagineA Study On Customer Relationship Management Practices of Commercial Banks in Thanjavur DistrictarcherselevatorsNessuna valutazione finora

- Interpersonel Need of Management Student-Acilitor in The Choice of ElectivesDocumento180 pagineInterpersonel Need of Management Student-Acilitor in The Choice of ElectivesnerdjumboNessuna valutazione finora

- Talent Acquisition ChallengeDocumento12 pagineTalent Acquisition ChallengeSue Marks100% (3)

- Chemistry 102 Experiment 8 ColorimetryDocumento7 pagineChemistry 102 Experiment 8 ColorimetryDaniel MedeirosNessuna valutazione finora

- 8102 Lifespan ProjectDocumento8 pagine8102 Lifespan Projectapi-346419959Nessuna valutazione finora

- An Overview On Co-Operative Societies in BangladeshDocumento11 pagineAn Overview On Co-Operative Societies in BangladeshAlexander DeckerNessuna valutazione finora

- Strut & Tie ModelDocumento67 pagineStrut & Tie Modelahmed adel100% (9)

- Psy 1 Chap 3 Human DevelopmentDocumento24 paginePsy 1 Chap 3 Human Developmentjeanette8riosNessuna valutazione finora

- Case Study ResearchDocumento20 pagineCase Study ResearchManish PuttyahNessuna valutazione finora

- LIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionDa EverandLIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionValutazione: 4 su 5 stelle4/5 (404)

- Master Your Emotions: Develop Emotional Intelligence and Discover the Essential Rules of When and How to Control Your FeelingsDa EverandMaster Your Emotions: Develop Emotional Intelligence and Discover the Essential Rules of When and How to Control Your FeelingsValutazione: 4.5 su 5 stelle4.5/5 (322)

- The Stoic Mindset: Living the Ten Principles of StoicismDa EverandThe Stoic Mindset: Living the Ten Principles of StoicismValutazione: 4.5 su 5 stelle4.5/5 (12)

- The Power of Now: A Guide to Spiritual EnlightenmentDa EverandThe Power of Now: A Guide to Spiritual EnlightenmentValutazione: 4.5 su 5 stelle4.5/5 (4125)

- The 7 Habits of Highly Effective People: The Infographics EditionDa EverandThe 7 Habits of Highly Effective People: The Infographics EditionValutazione: 4 su 5 stelle4/5 (2475)

- Becoming Supernatural: How Common People Are Doing The UncommonDa EverandBecoming Supernatural: How Common People Are Doing The UncommonValutazione: 5 su 5 stelle5/5 (1482)

- Summary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesDa EverandSummary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesValutazione: 5 su 5 stelle5/5 (1636)

- Indistractable: How to Control Your Attention and Choose Your LifeDa EverandIndistractable: How to Control Your Attention and Choose Your LifeValutazione: 3 su 5 stelle3/5 (5)

- Summary: The Laws of Human Nature: by Robert Greene: Key Takeaways, Summary & AnalysisDa EverandSummary: The Laws of Human Nature: by Robert Greene: Key Takeaways, Summary & AnalysisValutazione: 4.5 su 5 stelle4.5/5 (30)

- Think This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeDa EverandThink This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeValutazione: 2 su 5 stelle2/5 (1)

- How To Win Friends and Influence People by Dale Carnegie - Book SummaryDa EverandHow To Win Friends and Influence People by Dale Carnegie - Book SummaryValutazione: 5 su 5 stelle5/5 (557)

- The 5 Second Rule: Transform your Life, Work, and Confidence with Everyday CourageDa EverandThe 5 Second Rule: Transform your Life, Work, and Confidence with Everyday CourageValutazione: 5 su 5 stelle5/5 (12)

- The One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsDa EverandThe One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsValutazione: 4.5 su 5 stelle4.5/5 (709)

- Control Your Mind and Master Your Feelings: This Book Includes - Break Overthinking & Master Your EmotionsDa EverandControl Your Mind and Master Your Feelings: This Book Includes - Break Overthinking & Master Your EmotionsValutazione: 4.5 su 5 stelle4.5/5 (74)

- The Science of Self Discipline: How Daily Self-Discipline, Everyday Habits and an Optimised Belief System will Help You Beat Procrastination + Why Discipline Equals True FreedomDa EverandThe Science of Self Discipline: How Daily Self-Discipline, Everyday Habits and an Optimised Belief System will Help You Beat Procrastination + Why Discipline Equals True FreedomValutazione: 4.5 su 5 stelle4.5/5 (867)

- The 16 Undeniable Laws of Communication: Apply Them and Make the Most of Your MessageDa EverandThe 16 Undeniable Laws of Communication: Apply Them and Make the Most of Your MessageValutazione: 5 su 5 stelle5/5 (73)

- The Courage Habit: How to Accept Your Fears, Release the Past, and Live Your Courageous LifeDa EverandThe Courage Habit: How to Accept Your Fears, Release the Past, and Live Your Courageous LifeValutazione: 4.5 su 5 stelle4.5/5 (253)

- Leadership and Self-Deception: Getting out of the BoxDa EverandLeadership and Self-Deception: Getting out of the BoxValutazione: 5 su 5 stelle5/5 (156)

- The Slight Edge: Turning Simple Disciplines into Massive Success and HappinessDa EverandThe Slight Edge: Turning Simple Disciplines into Massive Success and HappinessValutazione: 4.5 su 5 stelle4.5/5 (118)

- Summary of The Art of Seduction by Robert GreeneDa EverandSummary of The Art of Seduction by Robert GreeneValutazione: 4 su 5 stelle4/5 (46)

- The Silva Mind Method: for Getting Help from the Other SideDa EverandThe Silva Mind Method: for Getting Help from the Other SideValutazione: 5 su 5 stelle5/5 (51)

- The War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesDa EverandThe War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesValutazione: 4.5 su 5 stelle4.5/5 (274)

- Empath: The Survival Guide For Highly Sensitive People: Protect Yourself From Narcissists & Toxic Relationships. Discover How to Stop Absorbing Other People's PainDa EverandEmpath: The Survival Guide For Highly Sensitive People: Protect Yourself From Narcissists & Toxic Relationships. Discover How to Stop Absorbing Other People's PainValutazione: 4 su 5 stelle4/5 (95)

- The Motive: Why So Many Leaders Abdicate Their Most Important ResponsibilitiesDa EverandThe Motive: Why So Many Leaders Abdicate Their Most Important ResponsibilitiesValutazione: 5 su 5 stelle5/5 (225)

- The Miracle Morning by Hal Elrod: A Summary and AnalysisDa EverandThe Miracle Morning by Hal Elrod: A Summary and AnalysisValutazione: 4.5 su 5 stelle4.5/5 (55)