Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gas (Amine) Sweetening Process - Jonell Filtration Applications GasSweet 1015

Caricato da

Bob PeppingCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gas (Amine) Sweetening Process - Jonell Filtration Applications GasSweet 1015

Caricato da

Bob PeppingCopyright:

Formati disponibili

Filtration

Applications in

Gas (Amine)

Sweetening Systems

The most common filtration problems in an amine

unit are foaming and fouling. Foaming will reduce

effective absorption in the contactor tower resulting

in high amine carryover rates and replacement costs.

Treatment of the gas extraction will dramatically

decrease resulting in reduced flow and the injection

of costly foaming inhibitors to regain control of the

amine system.

Gas Sweetening is a critical procedure in gas

processing facilities. To meet sales specifications and

maintain efficient operation, natural gas goes through

a sweetening process to remove contaminants;

primarily H2S because of its corrosiveness and C02

for its lack of heating value. Amine solvents are widely

used to remove these contaminants from natural gas

or lighter hydrocarbon products. Typical industries

that perform gas sweetening includes: gas production

sites, gas processing plants, refineries, LNG facilities,

petrochemicals, etc.

Fouling occurs from excessive particulate

concentrations and can lead to poor amine/feed gas

contacting and off-spec gas. Resulting problems

include: tray plugging in the absorber and regenerator

towers, heat exchanger/reboiler failure, carbon bed

fouling, etc. In addition, corrosive contaminants can

degrade amine strength, decrease gas treatment

capacity, increase energy usage, and lower

equipment life.

Because of its highly corrosive and contaminant laden

environment, amine processes require an optimum

filtration/separation system to operate properly. Seldom

is a single contaminant responsible for amine system

operating problems. These contaminants can include

fine solid particulates such as iron sulfides and liquid

hydrocarbons in aerosol form.

The Benefits of an

Optimum Filtration/Separation

System include:

Ability to meet sales gas specification

and maintain efficient operation

Reduction in absorber (contactor) plugging

Prevention of amine foaming

Reduces the use of costly

anti-foaming inhibitors

Reduction in equipment fouling

Increase carbon bed life

Reduced amine consumption

Lower operating and maintenance costs

www.jonellinc.com | sales@jonellinc.com

254.559.7591

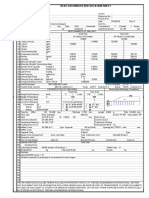

Jonell Filtration Solutions for Gas (Amine) Sweetening Process

9

Sweet Gas

Jonell Micro-DEP and

Micro-LOK Series

Liquid/Gas Coalescer Elements

TM

Acid Gas

TM

Cooler

TM

TM

Reflex Drum

AB SO RB ER

Rich Amine

Jonell LiquiPleat Series

Liquid Filter Elements

TM

REGEN ERAT O R

Sour Gas/

Acid Gas

Jonell CarboPUR

Activated Carbon

Canisters

TM

Jonell Micro-DEP

and Micro-LOK

Series Liquid/Gas

Coalescer Elements

TM

TM

Jonell LiquiPleat Series

Liquid Filter Elements

TM

6

Rich

Amine

Lean Amine

Slip Stream

Reflux Pump

Reflux

This schematic should be viewed as a general example of where

filtration systems could be located within a Gas Sweetening Process.

These processes will vary between companies and facilities. As such,

each application should be reviewed and considered individually in

order to choose the correct system technology.

Steam

Vapor

Fuel Gas

Jonell Micro-DEP

and Micro-LOK

Series Liquid/Gas

Coalescer Elements

Flash Tank

Reboiler

TM

TM

Lean Amine

3

Jonell LiquiPleat Series

Liquid Filter Elements

TM

L/R Heat

Exchanger

Jonell

CarboPUR

Activated Carbon

Canisters

TM

Lean Amine

Jonell LiquiPleat Series

Liquid Filter Elements

TM

Inlet gas enters the bottom of the absorber/contactor column flowing

upwards through a series of trays and is countercontacted

with the aqueous amine solution absorbing the acid gas in the amine.

Purified (sweet) gas exits at the top of the absorber/contactor column.

Rich amine solution, which has H2S and CO2 molecules attached,

leaves the absorber and flows to a flash tank then passes through a

Lean/Rich cross exchanger to the upper section of the regenerator/

stripper column.

The rich amine is heated in the regenerator/stripper column by

contacting hot vapors from the reboiler causing the acid gas molecules

to be stripped from the amine, thereby regenerating the solution.

Location

Jonell Micro-DEP

and Micro-LOK

Series Liquid/Gas

Coalescer Elements

Condenser

Make-Up

Water

10

Condensate

Lean Amine Pump

Steam and acid gases separated from the rich amine are condensed

and cooled.

The stripped acid gas typically flows to a sulfur plant for further

processing.

The condensed water is separated in the reflux accumulator and

returned to the still.

The hot lean amine from the reboiler is circulated back to the absorber/

contactor after passing through the lean/rich amine cross exchanger

and a lean solution cooler.

Jonell Filter Solution

Filter Purpose

Filter Benefit

Micro-DEP and Micro-LOK

Series Coalescer Elements

Removal of hydrocarbon, water, and other

liquids and solids from sour gas feed.

Reduces absorber foaming and fouling, increases

absorption and carbon bed efficiency.

Micro-DEP and Micro-LOK

Series Coalescer Elements

Removal of carried over amine, water,

and heavy hydrocarbons.

Maintains fuel gas quality and protects

downstream equipment.

LiquiPleat Series Liquid

Filter Elements

Removal of scale and solid contaminants

and protect the carbon filter system.

Prevents carbon bed plugging, fouling in the reboiler

and heat exchanger, and reduces foaming problems.

CarboPUR Series Activated

Carbon Canisters

Removal of of dissolved organic acids produced by

amine degradation and trace liquid hydrocarbons.

Reduces amine foam in the regenerator (stripper)

and degradation in the reboiler.

LiquiPleat Series Liquid

Filter Elements

Removal of carbon bed fines.

Protects downstream equipment. Prevents heat

exchanger and reboiler fouling.

LiquiPleat Series Liquid

Filter Elements

Removal of scale and solid contaminants including

iron sulfites and protect the carbon filter system.

Reduces foaming problems, prevents carbon bed

plugging, and prevents absorber fouling.

CarboPUR Series Activated

Carbon Canisters

Removal of dissolved organic acids produced by

amine degradation and trace liquid hydrocarbons.

Reduces system corrosion and foaming tendency,

and maintains solvent activity.

LiquiPleat Series Liquid

Filter Elements

Removal of carbon bed fines.

Protects downstream equipment and prevents fouling

in the absorber.

Micro-DEP and Micro-LOK

Series Coalescer Elements

Removal of carried over amine.

Protects downstream equipment and processes.

10

Micro-DEP and Micro-LOK

Series Coalescer Elements

Removal of water, amine, and liquid hydrocarbons.

Protects downstream equipment. Reduces maintenance

and downtime costs at sulfur recovery unit.

GasSweet 10/15

Potrebbero piacerti anche

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionDa EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionValutazione: 5 su 5 stelle5/5 (1)

- Model 10 10fb 11 Carbon HousingsDocumento4 pagineModel 10 10fb 11 Carbon HousingsrezNessuna valutazione finora

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisDa EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisValutazione: 5 su 5 stelle5/5 (1)

- Filter Separator English LetterDocumento2 pagineFilter Separator English Lettermarcoo8Nessuna valutazione finora

- Cone Design ToolDocumento1 paginaCone Design ToolPramod KumarNessuna valutazione finora

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Documento10 pagineDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182Nessuna valutazione finora

- JEWEL T Hydrocarbon Dew Point ControlDocumento2 pagineJEWEL T Hydrocarbon Dew Point ControljojeecaresNessuna valutazione finora

- Petrogas Filtration CatalogueDocumento12 paginePetrogas Filtration Catalogueleandroperao5374Nessuna valutazione finora

- 0203 KSS Marker StripDocumento1 pagina0203 KSS Marker StripAgus Heri TulasnoNessuna valutazione finora

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFDocumento8 pagine503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14Nessuna valutazione finora

- Activated CarbonDocumento3 pagineActivated CarbonHerik AziziNessuna valutazione finora

- Seprasol Plus: Liquid/Gas CoalescersDocumento4 pagineSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiNessuna valutazione finora

- BETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsDocumento6 pagineBETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsVinothkumarNessuna valutazione finora

- Gas Treatment SLDocumento68 pagineGas Treatment SLwahyuriansyahNessuna valutazione finora

- Filtration in HydrotreatingDocumento2 pagineFiltration in Hydrotreatingck196548400% (1)

- EX Firetube Boiler Changed by Advances in Design TechnologyDocumento7 pagineEX Firetube Boiler Changed by Advances in Design TechnologyXamir Suarez AlejandroNessuna valutazione finora

- Standard Hook-Up Wires & Cables For ElectronicsDocumento124 pagineStandard Hook-Up Wires & Cables For ElectronicsdlstoneNessuna valutazione finora

- Adsorption PDFDocumento8 pagineAdsorption PDFReza JabbarzadehNessuna valutazione finora

- Indirect Fired HeaterDocumento2 pagineIndirect Fired HeaterJoshua CollierNessuna valutazione finora

- FItrLTERS PDFDocumento4 pagineFItrLTERS PDFAriz Joelee ArthaNessuna valutazione finora

- Eclipse HandbookDocumento118 pagineEclipse Handbook23Otter100% (1)

- Steam HXDocumento1 paginaSteam HXrajachemNessuna valutazione finora

- Va1 Dec 00100 I M1D Pid 0001 PDFDocumento2 pagineVa1 Dec 00100 I M1D Pid 0001 PDFAnonymous JtYvKt5XENessuna valutazione finora

- Indirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhDocumento6 pagineIndirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhMuhammad AhsanNessuna valutazione finora

- Automated Operation of Topsoe Steam Reformers LTMDocumento8 pagineAutomated Operation of Topsoe Steam Reformers LTMrajuNessuna valutazione finora

- Process Flow DiagramDocumento11 pagineProcess Flow DiagramNikhil UdainiyaNessuna valutazione finora

- Dai SeminarDocumento36 pagineDai SeminardocrafiNessuna valutazione finora

- Random Packing Article PDFDocumento88 pagineRandom Packing Article PDFAbizer Jamali100% (1)

- Gas Filter Separators 4Documento8 pagineGas Filter Separators 4Anonymous bHh1L1Nessuna valutazione finora

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocumento1 paginaC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNessuna valutazione finora

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Documento14 pagineFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024Nessuna valutazione finora

- Flare Gas Recovery Data Sheet PDFDocumento1 paginaFlare Gas Recovery Data Sheet PDFMohamed AdelNessuna valutazione finora

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocumento2 pagineAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanNessuna valutazione finora

- Foam Behaviour of An Aqueous Solution of Piperazine Nmethyldiethanolamine Mdea Blend As A Function of The Type of Impurities and ConcentrationsDocumento6 pagineFoam Behaviour of An Aqueous Solution of Piperazine Nmethyldiethanolamine Mdea Blend As A Function of The Type of Impurities and ConcentrationsFraz RizviNessuna valutazione finora

- MAHLE IF PremiumSelectElements ENDocumento6 pagineMAHLE IF PremiumSelectElements ENJamin SmtpngNessuna valutazione finora

- Bunner ControlDocumento19 pagineBunner ControlHai NguyenNessuna valutazione finora

- Ekoplastik PPR Catalogue of Products PDFDocumento36 pagineEkoplastik PPR Catalogue of Products PDFnamNessuna valutazione finora

- Binh Nen Khi 3000 Lit-Rk Project-23122015Documento1 paginaBinh Nen Khi 3000 Lit-Rk Project-23122015Van DiepNessuna valutazione finora

- Special Closures Literature2Documento2 pagineSpecial Closures Literature2ruben'sNessuna valutazione finora

- Amine PKGDocumento18 pagineAmine PKGRathinavel PerumalNessuna valutazione finora

- Biogas From ADDocumento88 pagineBiogas From ADoscarbtt36530% (1)

- Heater P&IdDocumento1 paginaHeater P&Idjcarlosherrerac7Nessuna valutazione finora

- 4 Fundamentals of Gas Sweetening by K F Butwell and L Kroop PDFDocumento32 pagine4 Fundamentals of Gas Sweetening by K F Butwell and L Kroop PDFnasreenakhtariNessuna valutazione finora

- Water Bath Heater Writeup PDFDocumento2 pagineWater Bath Heater Writeup PDFJayesh SanganiNessuna valutazione finora

- Perhitungan Pressure Vessel LengkapDocumento70 paginePerhitungan Pressure Vessel LengkapReo Aditya MahesaNessuna valutazione finora

- Quick-Opening Closures SurveyDocumento13 pagineQuick-Opening Closures SurveyAjmi HmidaNessuna valutazione finora

- VBE - Aug2008 Pressure Loss CalculatorDocumento9 pagineVBE - Aug2008 Pressure Loss Calculatorakhilendraa4074Nessuna valutazione finora

- Carbon Molecular Sieve DataDocumento6 pagineCarbon Molecular Sieve DataShashank RaiNessuna valutazione finora

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocumento10 pagineRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1Nessuna valutazione finora

- FL1627Documento2 pagineFL1627Isaac Montero BarreraNessuna valutazione finora

- Safety Valve Technical DetailsDocumento5 pagineSafety Valve Technical DetailsvineethvskkdNessuna valutazione finora

- Foaming in A Mine SystemsDocumento16 pagineFoaming in A Mine SystemsAhmad FarooqNessuna valutazione finora

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Documento31 pagineDesign of Shell & Tube HX (Unprotected For Expert Excel Users)Sameer ChaturvediNessuna valutazione finora

- Hydrogen BroucherDocumento16 pagineHydrogen BroucherIvo Padua100% (1)

- 10.0 Troubleshooting Gas Dehydration Operational Problems: F P C C ADocumento7 pagine10.0 Troubleshooting Gas Dehydration Operational Problems: F P C C AHiep LeNessuna valutazione finora

- Eg 21 019Documento155 pagineEg 21 019agaricusNessuna valutazione finora

- Filtration and Separation in RefineriesDocumento30 pagineFiltration and Separation in RefineriesprogerNessuna valutazione finora

- Best Practice: Saudi Aramco Desktop StandardsDocumento19 pagineBest Practice: Saudi Aramco Desktop Standardssethu1091100% (4)

- ngoài lề đồ án chuyên ngànhDocumento5 paginengoài lề đồ án chuyên ngànhTu LaiNessuna valutazione finora

- CPM3700 Acid Gas Removal PlantsDocumento32 pagineCPM3700 Acid Gas Removal PlantsFawaz AlsaifNessuna valutazione finora

- Groundwater Hydrology Tutorial PDFDocumento20 pagineGroundwater Hydrology Tutorial PDFJames K. KirahukaNessuna valutazione finora

- Vamsi (1) Water Company InternshipDocumento30 pagineVamsi (1) Water Company InternshipVamshi KrishnaNessuna valutazione finora

- The Value of Surface Tension of A Liquid at Critical Temperature IsDocumento10 pagineThe Value of Surface Tension of A Liquid at Critical Temperature Issagarchidre114Nessuna valutazione finora

- PressureDocumento1 paginaPressureAshish KumarNessuna valutazione finora

- Diffusion Uops2Documento8 pagineDiffusion Uops2John Philip AyoNessuna valutazione finora

- Experiment 3: Determination of The Coefficient of Discharge With Outflow Under Constant Head ObjectiveDocumento5 pagineExperiment 3: Determination of The Coefficient of Discharge With Outflow Under Constant Head ObjectiveUsman AhmadNessuna valutazione finora

- Data Sheet Filter Drier With Interchangeable Solid Core Type DCRDocumento8 pagineData Sheet Filter Drier With Interchangeable Solid Core Type DCRDima ArfNessuna valutazione finora

- Angeles - Momentum TransferDocumento16 pagineAngeles - Momentum TransferJaden BrownNessuna valutazione finora

- Air Pollution ControlDocumento35 pagineAir Pollution ControlPraveen YadavNessuna valutazione finora

- Reviewer TopicsDocumento3 pagineReviewer Topicshoneylet tayactac0% (2)

- Present Chiller 3 Log SheetDocumento5 paginePresent Chiller 3 Log SheetMadan TiwariNessuna valutazione finora

- Inland Aquaculture EngineeringDocumento222 pagineInland Aquaculture Engineeringsheil.cogay100% (1)

- Compressible Flow 12batchDocumento74 pagineCompressible Flow 12batchSirajul IslamNessuna valutazione finora

- College Physics 9th Edition Serway Test BankDocumento35 pagineCollege Physics 9th Edition Serway Test Bankshannonsellersdfrjxwiabt100% (34)

- Complete Water Treatment Plant ProjectDocumento79 pagineComplete Water Treatment Plant ProjectRAHUL MAHAJAN100% (1)

- RWH School - Climate Change Control Team - Presentation PDFDocumento16 pagineRWH School - Climate Change Control Team - Presentation PDFAsif AhmedNessuna valutazione finora

- ROP Perennial Crop Support Series - Irrigation (Aug 18 2008Documento120 pagineROP Perennial Crop Support Series - Irrigation (Aug 18 2008Atiqur RahmanNessuna valutazione finora

- Basic Properties of Fluid Flow (EU - 2)Documento15 pagineBasic Properties of Fluid Flow (EU - 2)Jake Nathaniel R. AbadNessuna valutazione finora

- Che111p Quiz 2ot - 3Q1516Documento1 paginaChe111p Quiz 2ot - 3Q1516Rejed VillanuevaNessuna valutazione finora

- Equilibrium Study of K2CO3, KHCO3, CO2 and WaterDocumento27 pagineEquilibrium Study of K2CO3, KHCO3, CO2 and Waterbmeghani100% (5)

- 2nd Stage Separator: For Production Conditions / The Process Can Be AchievedDocumento5 pagine2nd Stage Separator: For Production Conditions / The Process Can Be AchievedihsansepalmaNessuna valutazione finora

- 4 Bernoulli'S Theorem Demonstration: Mapúa UniversityDocumento11 pagine4 Bernoulli'S Theorem Demonstration: Mapúa Universityqwert qwertyNessuna valutazione finora

- Separators and FiltersDocumento15 pagineSeparators and FilterstrpacNessuna valutazione finora

- Kishanganga Hydroelectric PlantDocumento3 pagineKishanganga Hydroelectric PlantAbirami BaskaranNessuna valutazione finora

- States of MatterDocumento29 pagineStates of MatterAndy GacuyaNessuna valutazione finora

- M24L40Documento7 pagineM24L40Andenet AshagrieNessuna valutazione finora

- Performance and Efficiency Test of Mini-Ice PlantDocumento23 paginePerformance and Efficiency Test of Mini-Ice PlantVanessa M. Martinez100% (2)

- Thermal Properties of Matter - 1Documento17 pagineThermal Properties of Matter - 1Nik AshrafNessuna valutazione finora

- Thermodynamics-II Practical Final Exam & VIVA: InstructionsDocumento4 pagineThermodynamics-II Practical Final Exam & VIVA: InstructionsUzair BukhariNessuna valutazione finora

- Asme PTC 1986Documento4 pagineAsme PTC 1986AmalAhmed0% (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDa EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionValutazione: 4.5 su 5 stelle4.5/5 (3)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeDa EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeValutazione: 5 su 5 stelle5/5 (1)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDa EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincValutazione: 3.5 su 5 stelle3.5/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDa EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeValutazione: 5 su 5 stelle5/5 (4)

- The Laws of Thermodynamics: A Very Short IntroductionDa EverandThe Laws of Thermodynamics: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDa EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseValutazione: 4.5 su 5 stelle4.5/5 (51)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactDa EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactValutazione: 5 su 5 stelle5/5 (5)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDa EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisValutazione: 4 su 5 stelle4/5 (2)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDa EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNessuna valutazione finora

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideDa EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNessuna valutazione finora

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDa EverandSodium Bicarbonate: Nature's Unique First Aid RemedyValutazione: 5 su 5 stelle5/5 (21)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDa Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideValutazione: 3.5 su 5 stelle3.5/5 (7)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeDa EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeValutazione: 4 su 5 stelle4/5 (1)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeDa EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNessuna valutazione finora

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsDa EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNessuna valutazione finora

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyDa EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyValutazione: 5 su 5 stelle5/5 (1)

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDa EverandChemistry for Breakfast: The Amazing Science of Everyday LifeValutazione: 4.5 su 5 stelle4.5/5 (90)