Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

0 Deec 51 Ec 02 C 556 e 15000000

Caricato da

Surya TejTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

0 Deec 51 Ec 02 C 556 e 15000000

Caricato da

Surya TejCopyright:

Formati disponibili

See

discussions, stats, and author profiles for this publication at: http://www.researchgate.net/publication/228616243

Capacity loss in an organically fouled anion

exchanger

ARTICLE in DESALINATION MARCH 2006

Impact Factor: 3.76 DOI: 10.1016/j.desal.2005.07.012

CITATIONS

10

4 AUTHORS:

Zeren Beril Gnder

Yasemin Kaya

Istanbul University

Istanbul University

12 PUBLICATIONS 115 CITATIONS

16 PUBLICATIONS 154 CITATIONS

SEE PROFILE

SEE PROFILE

Ilda Vergili

Hulusi Barlas

Istanbul University

Istanbul University

14 PUBLICATIONS 115 CITATIONS

24 PUBLICATIONS 339 CITATIONS

SEE PROFILE

SEE PROFILE

Available from: Ilda Vergili

Retrieved on: 12 October 2015

Desalination 189 (2006) 303307

Capacity loss in an organically fouled anion exchanger

Z. Beril Gnder*, Yasemin Kaya, Ilda Vergili, Hulusi Barlas

Environmental Engineering Department, Faculty of Engineering, Istanbul University, 34320 Avcilar-Istanbul, Turkey

email: bgonder@istanbul.edu.tr

Received 27 April 2005; accepted 29 July 2005

Abstract

One of the most important contaminants that ion-exchange resins are exposed to is fouling by organic materials.

Especially, anion-exchange resins are more sensitive to fouling by organic materials. The fouling of anion-exchange

resins by organic materials is primarily caused by the degradation of products of cation ion exchangers and humic and

fulvic acids. Organic fouling causes product water with low quality and few anion exchangers and shortens the service

time. Also the need for rinsing water and the use of regeneration chemicals increase. Operating capacity losses

occurring due to the fouling of anion-exchange resin by humic acid were quantitatively determined. SAK254 (Spektraler

Absorptions Koeffizient = spectral absorption coefficient), DFZ436 (DurchsichtsFarbZahl = indexes of transparency),

conductivity and sulfate measurements were made to determine capacity losses, which were obtained as 21%, 23%,

25% and 30% after the fouling studies of anion-exchange resin by the amounts of 0.13, 0.25, 0.5 and 1.0 mg/L humic

acid, respectively. It was found that even small concentrations of humic acid resulted in a considerable amount of

capacity losses in anion-exchange resin.

Keywords: Organic fouling; Humic acid; DFZ436; SAK254; Operating capacity

1. Introduction

Very high quality water is needed through

various stages of processing in many industries

(e.g., semiconductor, pharmaceutical, chemical,

etc.). Ion-exchanger systems currently have widespread use for this purpose. Some problems are

encountered during their use (loading, backwashing and regeneration), which affect the

performance of ion-exchange resins. The most

important one amongst these problems is the

fouling of ion-exchange resins [1,2].

Fouling with organic materials is the most

important one that ion-exchange resins encounter.

Organic fouling is an irreversible fixation of organic materials to the ion-exchange resin. Especially, anion exchange resins are more sensitive to

fouling with organic materials [3].

*Corresponding author.

0011-9164/06/$ See front matter 2006 Elsevier B.V. All rights reserved

304

Z. Beril Gnder et al. / Desalination 189 (2006) 303307

The fouling of anion-exchange resins by

organic materials is primarily caused by the

degradation products of cation exchangers and

humic and fulvic acids. Organic fouling results in

production of low-quality (high conductivity, low

pH), low amounts of water and some great problems such as early breakthrough and long washing periods after regeneration. The capacity of the

ion-exchanger bed decreases and water with

desired quality is not produced due to the fouling

that was not removed fully by means of regeneration and backwashing [3,4].

Natural waters contain organic, inorganic and

biological compounds in various ratios. Organic

materials have a high share amongst these compounds. Sources of organic materials in these

waters are decomposition products of wood and

leaves or industrial and domestic wastes [5].

Organic materials are largely composed of humic

materials. Humic materials are classified into

three groups according to their solubilities in

water [6]: (1) humin, that is the part which is not

soluble at any pH value; (2) humic acid, that is

the part which is not soluble in (pH <2) acidic

medium but is soluble at high pH values; (3) fulvic acid, that is the part which is soluble in all pH

values.

It is believed that the chemical structure of

these three fractions are alike. They appear to

differ in molecular weight and functional group

content. Fulvic acid probably has a lower molecular weight but more hydrophilic functional

groups than humic acid [7].

According to McCoy [8], soluble organic

materials such as humic and fulvic acids foul

anion-exchange resins primarily with ion exchange. The chloride ions or hydroxyl anions

within the humic acid structure are exchanged

with the chloride, sulfate or hydroxyl anion on

the quarternary amine that is grafted to the backbone of the anion-exchange resin molecule [9].

These fouling materials do not diffuse into the

resin due to their molecular dimensions. They

rather prevent ions moving into the resin by

accumulating physically onto the resin surface

and blocking the ion-exchange points [4].

Organic materials make ion-exchange resin

hydrophobic. Because of this, the moisture content of resins which fouled by organic materials

decreases. This is a case which is to be avoided

because it results in the decrease of porosity

volume. As a result, the diffusion rate of counter

ions and operating capacity decrease while the

washing period and rinse water needed increase.

Organic materials may also cause silicate leakage

in anion exchangers where the silicate removal

process is carried on. Silicate accumulates at the

bottom of the anion-exchanger bed because the

flow of water into resin is slowed down due to the

blockage of resin pores by organic materials

having high molecular weights [10].

There are some methods used for the purpose

of cleaning of anion-exchange resins fouled by

organic metarials. Washing with a caustic salt

solution is the most used amongst other methods.

This cleaning procedure is implemented by using

10% salt solution containing 2% NaOH of three

times volume of bed volume [11].

The application of pretreatment processes is

proposed before the ion-exchange system in order

to protect the resins against organic fouling.

Coagulationflocculation, adsorption with actived

carbon, membrane processes and oxidation/ biofiltration processes are used as pretreatment

processes in the removal of organic materials

[12]. In addition, the most resistant resin type

must be chosen against fouling with organic

materials. Acrylic-based resins are more resistant

than styrene-based resins because they have a

larger hydrophilic structure and ease the passage

of high molecular organic materials from the

resin due to their aliphatic structure. Organic

materials could be removed effectively from the

acrylic-based resins during regeneration [13].

2. Materials and methods

Changes in resin capacity were determined

Z. Beril Gnder et al. / Desalination 189 (2006) 303307

quantitatively by searching fouling of resin with

humic acid which is a fraction of humic material.

Lewatit M 500, frequently used in demineralisation applications, was chosen as the strongly

basic anion exchanger. Technical specifications

of the resin (Lewatit M 500), provided from

Bayer Leverkusen, are given in Table 1.

A laboratory-scale glass column with a 2 cm

diameter and 45 cm height was used throughout

the experiments. The column was filled with a

strong anion-exchange resin of 50 mL in volume.

Synthetic water, prepared by dissolving Na2SO4

in distilled water with appropriate amounts resulting 150 mg/L SO42! content, was used. The synthetic water was supplied to the system by using

a peristaltic pump (Prominent) and the feed rate

was adjusted to V = 5.0 m/h (specific flow rate =

31 bed volume/h). A humic acid solution was

used in the fouling studies. This solution was

prepared according to the Urano method: 1 g

humic acid was dissolved in 100 mL 0.1 N NaOH

solution and then distilled water was added up to

1 L after waiting for 1 day [14].

The following method was used for the determination of changes occuring in ion-exchange

capacity in the studies performed for the fouling

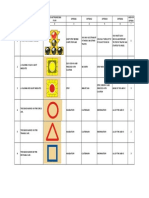

Table 1

Technical specifications of the strongly basic anion

exchanger (Lewatit M 500)

Properties

Strongly basic

anion exchanger

Ionic form

Functional group

Cl!

Quarternary amine,

Type 1

Gel

1.4

0.47

40

NaOH

100

24

Structure

Total capacity, min. eq /L

Bead size, mm

Flow rate, max. m/h

Regenerant

Regenerant level, g/L

Regenerant con., %

305

of ion-exchange resins. The method is based upon

the comparison of resin after being regenerated

with a new resin sample [15,16]. In this study this

method is taken as a reference.

Changes in resin capacity during the fouling

of the anion-exchange resin were determined by

using humic acid in the amounts of 0.13, 0.25, 0.5

and 1.0 mg/L. The amount of 15 mg/L SO42! value

was taken as the breakthrough point and column

loading was continued until this value was

reached at the outlet. SAK254 (Spektraler AbsorptionsKoeffizient = spectral absorption coefficient)

[17], DFZ (Durchsichts Farbzahl = indexes of

transparency) [18] and conductivity measurements were performed for the samples taken from

the column outlet during fouling.

SAK254 and DFZ436 measurements were made

by using Jenway UV-Vis (model 6105) and

Pharmacia LKB-Novaspec II spectrophotometers,

respectively. Conductivity measurements were

carried out by a WPA CM35 conductivity device.

Sulphate measurements were implemented

according to the turbidimetric method as defined

in Standard Methods [19].

A 4% NaOH (12 bed volume/h) solution of

300 mL (6 bed volume) in volume was used for

the strong anion-exchange resin regeneration.

Cocurrent regeneration was carried out in the

study. The regenerated resin was backwashed

with distilled water until the conductivity of the

effluent was less than 1 S/cm.

3. Results and discussion

A strong basic anion-exchanger was fouled

with 0.13, 0.25, 0.5 and 1.0 mg/L humic acid and

raw water was passed through after regeneration.

The capacity of the ion exchanger was calculated

by obtaining breakthrough curves belonging to

the cycles of raw water passed through fresh ionexchanger resin and through ion-exchanger resin

fouled with humic acid and subsequently regenerated (see Figs. 14).

306

Z. Beril Gnder et al. / Desalination 189 (2006) 303307

Fig. 1. Breakthrough curves obtained from the fouling of

strong anion exchanger with 0.13 mg/L humic acid.

(a) raw water, (b) raw water containing 0.13 mg/L humic

acid, (c) raw water after regeneration.

Fig. 2. Breakthrough curves obtained from the fouling of

strong anion exchanger with 0.25 mg/L humic acid.

(a) raw water, (b) raw water containing 0.25 mg/L humic

acid, (c) raw water after regeneration.

Fig. 3. Breakthrough curves obtained from the fouling of

strong anion exchanger with 0.5 mg/L humic acid.

(a) raw water, (b) raw water containing 0.5 mg/L humic

acid, (c) raw water after regeneration.

Fig. 4. Breakthrough curves obtained from the fouling of

strong anion exchanger with 1.0 mg/L humic acid.

(a) raw water, (b) raw water containing 1.0 mg/L humic

acid, (c) raw water after regeneration.

The capacity loss was found to be 21% for the

fouling of anion-exchange resin with 0.13 mg/L

humic acid. In this case, organic material causes

high capacity losses even in small amounts. The

capacity losses were found to be 23% and 25%

for the humic acid amounts of 0.25 and 0.5 mg/L,

respectively. A 30% capacity loss was observed

as the humic acid amount reached 1.0 mg/L

value. The capacity losses are shown in Fig. 5.

Capacity losses increased as the humic acid

amounts increased. The reason for this is that

humic acid which is a high molecular organic

material blocks the pores of anion exchange resin

which in turn prevents ions moving into the resin.

This situation could not to be ceased even by the

regeneration process [4].

DFZ436 and SAK254 parameters measured for

the samples taken from the outlet of the ionexchange column were evaluated during fouling

studies. DFZ was measured as zero for the

samples taken up to 15 mg/L SO4= value which

was chosen as the breakthrough point during the

fouling studies made with 0.13, 0.25, 0.5 and

1.0 mg/L humic acid values. In other words, no

colour was observed in the samples taken from

the column outlet. SAK254 values were determined to be zero for samples taken up to the

breakthrough point during the fouling of anion-

Z. Beril Gnder et al. / Desalination 189 (2006) 303307

Fig. 5. Capacity losses occurring in strong anion

exchange.

exchange resin with 0.13 and 0.25 mg/L humic

acid. When the humic acid amount was 0.5 mg/L,

SAK254 values were observed for the samples

taken from column outlet after the passage of

15.3 L water fouled by humic acid (bed volume

= 306). SAK254 value was measured as 0.9 m!1 at

the breakthrough point. When the humic acid

amount was 1.0 mg/L, SAK254 values were

observed for the samples from the column outlet

after the passage of 14.5 L water fouled by humic

acid (bed volume = 290), and this value became

2.6 m!1 at the breakthrough point. The reason for

this is the blockage of ion-exchange points

existing in ion-exchangers structure by a large

amount of humic acid. As a result, the capacity of

resin decreases.

References

[1] F.N. Kemmer, Ion Exchange, Nalco Water Handbook, 2nd ed., Mc Graw-Hill, New York, 1988,

pp. 12.112.45.

[2] P.N. Cheremisinoff and N.P. Cheremisinoff, Water

Treatment and Waste Recovery: Advanced Technology and Applications, Prentice Hall, Englewood,

NJ, 1993, pp. 288289.

[3] K. Dorfner, Ion Exchange Types, Ion Exchangers

Properties and Applications, 2nd ed., Ann Arbor

Science, Michigan, 1972, pp. 168170.

307

[4] G.C. Lee, G.L. Foutch and A. Aranuchalam, Reactive Func. Polym., 35(10) (1997) 5573.

[5] H. Yldrm, Contribution of ionic strength to the

interaction of natural organic matter and metal oxide

surface, Masters Thesis, Bogazici University, Istanbul, Turkey, 2000.

[6] APHA-AWWA-WEF, Standard Methods for the

Examination of Water and Wastewater, 19th ed.,

Washington, 1995, pp. 5.275.28.

[7] S.A. Suphandag, Adsorption capacity of natural

organic matter on semi-conductor powders, Master

Thesis, Bogazici University, Istanbul, Turkey, 1998.

[8] M. McCoy, Ion Exchange, Ultrapure Water, Tall

Oaks, Littleton, CO, 1996, pp. 2031.

[9] R.G. Alther, Preventing Resin and Membrane

Fouling with Clay Prepolish, Biomin, MI, 2000.

[10] W. Bornak, Resin Analysis and Chemical Cleaning,

39th Liberty Bell Water Treatment Course, Atlantic

City, New Jersey, 2001.

[11] Purolite Company, The fouling of ion exchange

resins and methods of cleaning, Purolite Technical

Bulletin, 1998.

[12] H. degard, B. Eikbrokk and R. Storhaug, Water

Sci. Technol., 40 (1999) 3746.

[13] J.F. Desilva, Removing organics with ion exchange

resin, Water Conditioning Purification, (1997) 13.

[14] S.C. Uyguner, Trace-level metals and natural organic

matter interactions: Oxidative/adsorptive removal

pathways, Master Thesis, Bogazici University,

Istanbul, Turkey, 1999.

[15] Deutsche norm, DIN 54 402: Bestimmung der

Totalen Kapazitt von Anionenaustauschern, Beuth,

Berlin, 1982.

[16] Deutsche norm, DIN 54 403: Bestimmung der

Totalen Kapazitt von Kationenaustauschern, Beuth,

Berlin, 1982.

[17] DIN 38404, Deutsche einheitsverfahren zur wasser-,

abwasser-und schlammuntersuchung- physikalischchemische kenngren (gruppe C), Teil 3: Bestimmung der absorption im bereich der UV-strahlung;

spektraler absorptionskoeffizient (C3), Beuth, Berlin,

2003.

[18] H. Barlas and T. Akgun, Fresenius Environ. Bull., 9

(2000) 597602.

[19] APHA-AWWA-WEF, Standard Methods for the

Examination of Water and Wastewater, 19th ed.,

Washington, 1995, pp. 4.1364.137.

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Structural Analysis and Design of Process EquipmentDocumento360 pagineStructural Analysis and Design of Process EquipmentSurya Tej88% (8)

- Symble, Formula & ValencyDocumento16 pagineSymble, Formula & Valencykawsar2250% (4)

- On PreheatingDocumento22 pagineOn PreheatingYYNessuna valutazione finora

- Cooling Tower TheoryDocumento3 pagineCooling Tower TheoryRanjivemadhuNessuna valutazione finora

- BSK 46 Materials - For - Automobiles11Documento62 pagineBSK 46 Materials - For - Automobiles11shuklahouse100% (1)

- SilicaDocumento2 pagineSilicaSurya TejNessuna valutazione finora

- Watertech Mar 04Documento4 pagineWatertech Mar 04Junnaid NissarNessuna valutazione finora

- XMSDS Sodium Hexametaphosphate 9924995Documento6 pagineXMSDS Sodium Hexametaphosphate 9924995Surya TejNessuna valutazione finora

- Learning Licence Test Road-signs-EnglishDocumento15 pagineLearning Licence Test Road-signs-Englishu2mailrahulNessuna valutazione finora

- LLR Test General Driving Principles EnglishDocumento23 pagineLLR Test General Driving Principles Englishu2mailrahulNessuna valutazione finora

- MQP-Design and Analysis of An Absorption Refrigeration SystemDocumento117 pagineMQP-Design and Analysis of An Absorption Refrigeration SystemSurya TejNessuna valutazione finora

- Sachin Tendulkar's CVDocumento3 pagineSachin Tendulkar's CVhemant117100% (1)

- 25 Years of Time Series ForecastingDocumento31 pagine25 Years of Time Series ForecastingFarhat IqbalNessuna valutazione finora

- Continuous Ideal Reactors: A. Sarath BabuDocumento49 pagineContinuous Ideal Reactors: A. Sarath BabuSurya TejNessuna valutazione finora

- Natural Gas Processing SaadDocumento9 pagineNatural Gas Processing SaadAlexander SashaNessuna valutazione finora

- Amendment No 2 - 11112014 Fo IS226 To IS2062 PDFDocumento2 pagineAmendment No 2 - 11112014 Fo IS226 To IS2062 PDFasa_aha789Nessuna valutazione finora

- Chapter-5ppt1 (1) - Converted-MergedDocumento409 pagineChapter-5ppt1 (1) - Converted-MergedMosesNessuna valutazione finora

- Starch: Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. All Rights ReservedDocumento18 pagineStarch: Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. All Rights ReservedAndalib TabassumNessuna valutazione finora

- EWC 333 Introduction To Wastewater EngineeringDocumento24 pagineEWC 333 Introduction To Wastewater EngineeringAzgar AliNessuna valutazione finora

- Submitted By: CARL JORICH P. DURIA Submitted To: MS. MARIEL S. REDONDO Date Submitted: September 26, 2019Documento2 pagineSubmitted By: CARL JORICH P. DURIA Submitted To: MS. MARIEL S. REDONDO Date Submitted: September 26, 2019anon_435077119Nessuna valutazione finora

- Learn: Subject: Science Class: ViiiDocumento3 pagineLearn: Subject: Science Class: ViiidgrsriNessuna valutazione finora

- Solubility of Ferulic Acid in Supercritical Carbon Dioxide WithDocumento3 pagineSolubility of Ferulic Acid in Supercritical Carbon Dioxide WithJonatas LopesNessuna valutazione finora

- Acid Adsorption and Stability of Nitrocellulose J. Phys. Chem., 1931, 35 (2), PP 536-539Documento4 pagineAcid Adsorption and Stability of Nitrocellulose J. Phys. Chem., 1931, 35 (2), PP 536-539Alexey GuskovNessuna valutazione finora

- Lab Report Organic Chemistry (Experiment 5) Lim Wey LoonDocumento15 pagineLab Report Organic Chemistry (Experiment 5) Lim Wey LoonWEY LOON LIMNessuna valutazione finora

- CPI - Specialty Gas - Brochure - Single - Pages - ARDocumento4 pagineCPI - Specialty Gas - Brochure - Single - Pages - ARElton TimmNessuna valutazione finora

- Hydrocarbons All DPPDocumento24 pagineHydrocarbons All DPPakashgoswami9310Nessuna valutazione finora

- Peracetic Acid Fact SheetDocumento2 paginePeracetic Acid Fact SheetJainil PanchalNessuna valutazione finora

- Chem 1206 - Chapt 1Documento5 pagineChem 1206 - Chapt 1Djaimee Joyce NimesNessuna valutazione finora

- 184.2 BeX - 009Documento112 pagine184.2 BeX - 009Neeraj SinhaNessuna valutazione finora

- Properties of Self-Compacting Concrete Prepared With Coarse and Fine Recycled Concrete AggregatesDocumento6 pagineProperties of Self-Compacting Concrete Prepared With Coarse and Fine Recycled Concrete AggregatesCristine RussellNessuna valutazione finora

- TICKET To VICTORY BIO C7 - C9 F4Documento41 pagineTICKET To VICTORY BIO C7 - C9 F4rohaizi rastamNessuna valutazione finora

- Astm 4590Documento3 pagineAstm 4590Gyna SH67% (3)

- Durability and Mechanical Properties of High Strength Concrete IncorporatingDocumento7 pagineDurability and Mechanical Properties of High Strength Concrete IncorporatingDouglas AlexandreNessuna valutazione finora

- Mix Design For PQCDocumento34 pagineMix Design For PQCSAMRADDHI PRAJAPATINessuna valutazione finora

- Platinum Alloys For Shape Memory ApplicationsDocumento15 paginePlatinum Alloys For Shape Memory ApplicationsKursalNessuna valutazione finora

- Revisionworksheet D22-Jun-2023Documento8 pagineRevisionworksheet D22-Jun-2023Prit mistryNessuna valutazione finora

- Iso 683 14 en PDFDocumento11 pagineIso 683 14 en PDFRiesma TasomaraNessuna valutazione finora

- Poly (Acrylic Acid)Documento10 paginePoly (Acrylic Acid)Rashid WattooNessuna valutazione finora

- Tensile Strength and Elongation at Yield - ASTM D638Documento7 pagineTensile Strength and Elongation at Yield - ASTM D638Silverio AcuñaNessuna valutazione finora

- PHA611 LAB-Group4 Lab ReportDocumento2 paginePHA611 LAB-Group4 Lab ReportAcuCJamNessuna valutazione finora

- Atomic Spectroscopy - A Guide To Selecting The Appropriate Technique and System PDFDocumento16 pagineAtomic Spectroscopy - A Guide To Selecting The Appropriate Technique and System PDFAdamu OnakpaNessuna valutazione finora