Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

How Does It Work - Cryogenic Valves

Caricato da

bisworupm0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

81 visualizzazioni3 paginecryogenic valves

Titolo originale

How Does It Work_ Cryogenic Valves

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentocryogenic valves

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

81 visualizzazioni3 pagineHow Does It Work - Cryogenic Valves

Caricato da

bisworupmcryogenic valves

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

8/19/2015

Howdoesitwork:CryogenicValves

Search

Menu

How does it work: Cryogenic Valves

It generally is accepted in the oil and gas industry that the cryogenic temperature range

starts at -238 F (-150 C). In addition to this temperature range, certain gases are

considered cryogenic because they take more than just an increase in pressure to

compress their volume. Anything warmer than the cryogenic range up to 37 F (3 C) is

called refrigeration.

Understanding where cryogenic temperatures start is very important to valve selection.

There are a number of things to understand about cold temperatures when considering

how to select a valve that will work over a long period of time.

The valve industry is conservative, Nathaniel Paxton, Cameron product manager for

TBV ball valves, said. A general rule is that continuous temperatures less than -100

F (-73 C) are considered cryogenic service and warrant specific valve preparation.

Problems With Transporting Cryogenic Media

Cryogen leakage is not only dangerous, but also very expensive, especially when one

considers the cost to make a gas into a cryogen in the first place.

As it pertains to the valve, it has been said many times that thermal swings can be the

Achilles heel for any valve, and severe temperature variations of a cryogenic nature take

this to a new level, Paxton said.

The components of any valve (body, bonnet, stem, stem seals, ball, seats, etc.) will

contract and expand at different rates because of different material composition or the

amount of time exposed to the cryogen.

Heat gains from the environment are a constant battle when dealing with cryogens,

hence the reason for valve and piping insulation. One has to remember that, during gas

processing, we are dealing with the physical properties of gases, such as liquefied natural

gas (LNG), nitrogen, oxygen, argon, and helium. These liquids do not want to be

liquids at atmospheric pressure and, if allowed, can violently transform to gases in a

heartbeat, Paxton said.

In the normal processing of cryogens, there always is the buildup of pressure because of

this heat gain from the environment and the subsequent vapor formation. There needs

to be special consideration in designing the valve/piping system to allow for this pressure

build up.

Other big problems with cryogenic services include seat leakage potential. The linear and

radial growth of the stem in relation to the body often can be underestimated. Selecting

the correct valve can help avoid the problems mentioned above.

https://www.cam.com/productsandservices/valves/valveacademy/howdoesitworkcryogenicvalves

1/3

8/19/2015

Howdoesitwork:CryogenicValves

Selecting a Valve for Cryogenic Service

While there are not strict guidelines for valve type in cryogenic service, there is a trend to

select quarter-turn ball valves for their tight shut-off capabilities. This quarter-turn

motion is also found in high-performance and triple offset butterfly valves. For larger

valve sizes, gate valves often are utilized over ball valves, because ball valves can be more

costly. However, with a ball valve, you pay more up front, but will save more later on in

terms of valve performance over time. As for the type of piping connections, flange and

welded configurations are used mostly for cryogenic service, although customer

preference typically determines which type is used.

Valves intended for cryogenic service should be assembled in a clean room and be

lubricant free, or utilize lubricants compatible with cold service. The valves should not

have machine oils, grease, dirt, or any foreign material in the valve for the clean service.

Any unnecessary matter can inhibit the valve performance at cryogenic temperatures

meaning, if something gets in between the ball and seat sealing, problems can occur.

When buying a valve for cryogenic service, you should insist to see documented

procedures for cleaning and verify the procedures are being followed during the

assembly process, Paxton advised.

Cameron is willing to rigorously prepare valve components for clean room assembly and

take the precautions to keep components contaminant free to the standards required by

the industry. Our TBV line of ball valves has been a recognized leader for cryogenic

service since 1978. In addition, our in-house clean room, quality processes, and testing

help ensure that TBV valves will perform when you need them to. With numerous stem

seal designs, soft or metal seats, and two-piece and three-piece body construction,

Camerons TBV valves offer a range of options for a variety of cryogenic applications.

CONTACT US

Valve Academy

Valve Academy

+1.281.499.8511

valveacademy@c-a-m.com

Challenges

Products & Services

Company

Resource Library

https://www.cam.com/productsandservices/valves/valveacademy/howdoesitworkcryogenicvalves

2/3

8/19/2015

Howdoesitwork:CryogenicValves

Contact Us

OneSubsea

Transact Login

Investors

Locations

Careers

Tradeshows

Follow Us

Privacy Policy

Terms of Service

Site Map

LinkedIn

2015 Cameron. All rights reserved.

https://www.cam.com/productsandservices/valves/valveacademy/howdoesitworkcryogenicvalves

3/3

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Letter of Introduction To GAR Corporation - 107 - Dt. 10.5.22Documento3 pagineLetter of Introduction To GAR Corporation - 107 - Dt. 10.5.22bisworupmNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Letter of Introduction To Ashoka Builders Private Limited - 108 - Dt. 21.5.22Documento3 pagineLetter of Introduction To Ashoka Builders Private Limited - 108 - Dt. 21.5.22bisworupmNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Letter of Introduction To Bhavya Constructions PVT Ltd. - 122 Dt. 22.06.22Documento3 pagineLetter of Introduction To Bhavya Constructions PVT Ltd. - 122 Dt. 22.06.22bisworupmNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Letter of Introduction To Colliers (KDPL Mall Project) - 118 Dt. 08.06.22Documento3 pagineLetter of Introduction To Colliers (KDPL Mall Project) - 118 Dt. 08.06.22bisworupmNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Letter of Introduction To Colliers (KDPL Mall Project) - 119 Dt. 09.06.22Documento3 pagineLetter of Introduction To Colliers (KDPL Mall Project) - 119 Dt. 09.06.22bisworupmNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Letter of Introduction To Ark Group - 134 Dt. 30.06.22Documento3 pagineLetter of Introduction To Ark Group - 134 Dt. 30.06.22bisworupmNessuna valutazione finora

- 005 Elect - Light Distribuiton Board Components PDFDocumento64 pagine005 Elect - Light Distribuiton Board Components PDFbisworupmNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Troilokyanath Mukhopadhyay RachanasangrahaDocumento882 pagineTroilokyanath Mukhopadhyay RachanasangrahabisworupmNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- 003 Elect - Electrical Earthing System Installation PDFDocumento110 pagine003 Elect - Electrical Earthing System Installation PDFbisworupmNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Medium Voltage SwitchgearDocumento6 pagineMedium Voltage Switchgearmealysr100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Shamsur Rahman Kobita Samagra PDFDocumento716 pagineShamsur Rahman Kobita Samagra PDFbisworupm100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Chap Versus PapDocumento2 pagineChap Versus PapbisworupmNessuna valutazione finora

- 0031NG011795F2 PDFDocumento1 pagina0031NG011795F2 PDFbisworupmNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Check ValvesDocumento4 pagineCheck ValvesALP69Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Ladder 1Documento1 paginaLadder 1bisworupmNessuna valutazione finora

- Annexure-VIII DVC Safety Clause of O&M ContractDocumento5 pagineAnnexure-VIII DVC Safety Clause of O&M ContractbisworupmNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Is - 2062.2011 PDFDocumento17 pagineIs - 2062.2011 PDFN GANESAMOORTHYNessuna valutazione finora

- Annex 17 - Piping Support Erection STDDocumento28 pagineAnnex 17 - Piping Support Erection STDbisworupm100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Disclosure To Promote The Right To InformationDocumento33 pagineDisclosure To Promote The Right To InformationbisworupmNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Annex 14 - Piping SpecDocumento18 pagineAnnex 14 - Piping SpecbisworupmNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Volume Ia General Conditions of Contract 1485001735Documento21 pagineVolume Ia General Conditions of Contract 1485001735bisworupmNessuna valutazione finora

- High Pressure Carbon Dioxide Fire Suppression System: Data/SpecificationsDocumento4 pagineHigh Pressure Carbon Dioxide Fire Suppression System: Data/SpecificationsbisworupmNessuna valutazione finora

- General TechnicalDocumento194 pagineGeneral TechnicalSutama ChowdhuryNessuna valutazione finora

- Aerosol Smoke Detector Testers FSE Magazine PDFDocumento4 pagineAerosol Smoke Detector Testers FSE Magazine PDFbisworupmNessuna valutazione finora

- Buckeye Catalogo - 2013Documento28 pagineBuckeye Catalogo - 2013Marco Antonio Zelada HurtadoNessuna valutazione finora

- Attachment 5 - Valve Design Table PDFDocumento8 pagineAttachment 5 - Valve Design Table PDFbisworupmNessuna valutazione finora

- Civil Spec - NTPC, RamagundamDocumento41 pagineCivil Spec - NTPC, Ramagundambisworupm100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- 015 - 21!04!2015 - Fire Protection Detection System - SterlingDocumento4 pagine015 - 21!04!2015 - Fire Protection Detection System - SterlingbisworupmNessuna valutazione finora

- FM 200Documento1 paginaFM 200bisworupmNessuna valutazione finora

- Obel-P Adapter Unit NewsDocumento4 pagineObel-P Adapter Unit NewswalleyranNessuna valutazione finora

- The Role and Objectives of The BIPMDocumento15 pagineThe Role and Objectives of The BIPMJune AlapaNessuna valutazione finora

- Pip Veeta001 Tank Selection Guide: VesselsDocumento29 paginePip Veeta001 Tank Selection Guide: VesselsPankaj AdhikariNessuna valutazione finora

- Plumbing Code QuestionsDocumento3 paginePlumbing Code QuestionsJhay DomdomNessuna valutazione finora

- Webdispatcher TimeoutsDocumento9 pagineWebdispatcher Timeoutsowl meadowNessuna valutazione finora

- As 5804.4-2010 High-Voltage Live Working Barehand WorkDocumento7 pagineAs 5804.4-2010 High-Voltage Live Working Barehand WorkSAI Global - APACNessuna valutazione finora

- Adobe Acrobat Reader DC: Help and TutorialsDocumento35 pagineAdobe Acrobat Reader DC: Help and TutorialsPras OnezatNessuna valutazione finora

- Unilever CaseDocumento2 pagineUnilever CaseElly DangNessuna valutazione finora

- Safety Observer DefinitionsDocumento6 pagineSafety Observer DefinitionsWarwick AudetNessuna valutazione finora

- Draft Short Form of Jps Metering PolicyDocumento7 pagineDraft Short Form of Jps Metering Policydenzil_1000Nessuna valutazione finora

- Ac500 Web Server Lvd-eotn121u-En - RevaDocumento5 pagineAc500 Web Server Lvd-eotn121u-En - RevaBui Xuan DuongNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Art of Programming ContestDocumento219 pagineArt of Programming ContestshilswapanNessuna valutazione finora

- Pip Adg001 Specification For Developing Practices: Work ProcessesDocumento21 paginePip Adg001 Specification For Developing Practices: Work ProcessesJohn BuntalesNessuna valutazione finora

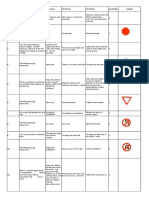

- Traffic SymbolDocumento27 pagineTraffic SymbolraviNessuna valutazione finora

- Wipro SampleDocumento8 pagineWipro SampleArghya GuhaNessuna valutazione finora

- Safety Assessment of Foreign Aircraft - NotesDocumento8 pagineSafety Assessment of Foreign Aircraft - NotesBasharat UllahNessuna valutazione finora

- Grading and ReportingDocumento25 pagineGrading and ReportingLcc-dnc BedNessuna valutazione finora

- Ul 94Documento2 pagineUl 94ParagNessuna valutazione finora

- Pr1605020007en 9500 MPR Mss Family r6-1 Ansi DatasheetDocumento2 paginePr1605020007en 9500 MPR Mss Family r6-1 Ansi DatasheetToh Pyie SheinNessuna valutazione finora

- Social Media PolicyDocumento1 paginaSocial Media PolicyDavid SpoonerNessuna valutazione finora

- Voip PBX Quotation 2012 - ChimaDocumento1 paginaVoip PBX Quotation 2012 - ChimaJaime Luis SalinasNessuna valutazione finora

- Arduino and Visual Basic Part 2 - Receiving Data From The Arduino - Martyn CurreyDocumento26 pagineArduino and Visual Basic Part 2 - Receiving Data From The Arduino - Martyn CurreysabteleNessuna valutazione finora

- AbstractDocumento4 pagineAbstractVaibhav GawandeNessuna valutazione finora

- Cabo de Rede Cat6 Branco LSZH Amp CommscopeDocumento3 pagineCabo de Rede Cat6 Branco LSZH Amp CommscopeHudson MatosNessuna valutazione finora

- Mss sp-73 1991 PDFDocumento5 pagineMss sp-73 1991 PDFChotiwan RattanasatienNessuna valutazione finora

- Cat 3516 1600 KW Emcp2Documento6 pagineCat 3516 1600 KW Emcp2Jose Merardo ParraNessuna valutazione finora

- Sure Signal OverviewDocumento13 pagineSure Signal Overviewram4uintpt2Nessuna valutazione finora

- Vol39No7 Full PDFDocumento68 pagineVol39No7 Full PDFdeviationzNessuna valutazione finora

- DIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFDocumento5 pagineDIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFnoraafshin100% (2)

- Ekahau Wireless Site Survey ToolDocumento2 pagineEkahau Wireless Site Survey ToolHugh Haskell-ThomasNessuna valutazione finora

- The Laws of Thermodynamics: A Very Short IntroductionDa EverandThe Laws of Thermodynamics: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (10)

- Oil and Gas Pipelines: Integrity and Safety HandbookDa EverandOil and Gas Pipelines: Integrity and Safety HandbookNessuna valutazione finora

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDa EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseValutazione: 4.5 su 5 stelle4.5/5 (51)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDa EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNessuna valutazione finora