Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Led 5mm RGB Cambio Lento

Caricato da

Kevin StrongTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Led 5mm RGB Cambio Lento

Caricato da

Kevin StrongCopyright:

Formati disponibili

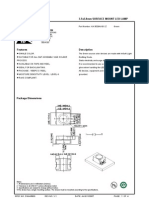

5mm Round full color LED

PART NO.: D+LED-LD5RGBS

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

DISCHARGE

SENSITIVE

DEVICES

Features

Low power consumption

Excellent product quality and reliability

I,c. compatible

Lead-free device.

Applications

Status indicators

Commercial use

Backlights

Advertising Signs

Package Dimensions

Notes:

1. All dimensions are in millimeters.

2. Tolerance is 0.25 unless otherwise noted.

3. Lead spacing is measured where the leads emerge from the package.

4. Specifications are subject to change without notice.

Device Selection Guide

Part No.

Chip

D+LED-LD5RGBS

Lens color

Material

Emitted color

AlGaInP

Red

InGaN

Green

InGaN

Blue

Water clear

Absolute Maximum Ratings at TA=25C

Value

Parameter

Symbol

Power Dissipation

Red

Green

Unit

Blue

PD

150

mW

IF

30

mA

Forward Current

Operating Temperature

Topr

-40C To +85C

Storage Temperature

Tstg

-40C To +85C

Soldering Temperature*2

Tsol

260C For 5 Seconds

Notes:

*1: Pulse width0.1ms, Duty cycle1/10

*2:1.6mm below package base.

Electrical / Optical Characteristics at TA=25C

Symbol

Min.

Typ.

Max

Unit

Red

VF

3.50

5.0

Green

VF

3.50

5.0

Blue

VF

3.50

5.0

Red

625

nm

Green

525

nm

Blue

470

nm

21/2

15

Deg.

Parameter

Forward Voltage

Chromaticity Coordinates

Power Angle

Test Conditions

IF=20mA

IF=20mA

IF=20mA

Remarks:

If special sorting is required (e.g. binning based on forward voltage, luminous intensity, or dominant wavelength),

the typical accuracy of the sorting process is as follows:

1.Dominant Wavelength:+/-1nm

2.Chromatic Coordinates:+/-0.01

3. Luminous Intensity: +/-15%

4. Forward Voltage: +/-0.1V

5.The desiga and working Current for Led is not less than 2mA.

Typical Electrical/Optical Characteristics Curves

( Ta=25 Unless Otherwise Noted )

10

20

30

Output Current VS Periods

40

1.0

50

60

0.8

70

80

90

0.5

SPATIAL DISTRIBUTION

CAUTIONS:

1.Lead Forming & Assembly

Any lead forming or bending must be done before soldering, at normal temperature.

When forming leads, there must be a minimum of 3mm clearance between the base of the

LED lens and the lead bend.

Do not use the base of the lead frame as a fulcrum during lead forming.

Avoid bending the leads at the same point more than once.

During assembly onto PCB, the lead pitch of the LED must match the pitch of the mounting

holes on the PCB during component placement.

2.Cleaning:

Isopropyl alcohol or deionized water are recommended solvents for cleaning. When using other

solvents, it should be confirmed beforehand whether the solvents will dissolve the resin or not.

3.Storage

The storage ambient for the LEDs should not exceed 30 temperature or 70% relative humidity.

It is recommended that LEDs out of their original packaging are used within three months. For

extended storage out of their original packaging, it is recommended that the LEDs be stored in a

sealed container with appropriate desiccant or in desiccators with nitrogen ambient.

4.ESD ( Electrostatic Discharge)

Static Electricity or power surge will damage the LED.

The following procedures may decrease the possibility of ESD damage.

All production machinery and test instruments must be electrically grounded.

Use a conductive wrist band or anti-electrostatic glove when handling these LEDs.

Maintain a humidity level of 50% or higher in production areas.

Use anti-static packaging for transport and storage.

Revision History:

Rev. No.

Change description

Date

A/0

New-made specification

2010/08/23

Prepared by

Checked by

Approved by

Potrebbero piacerti anche

- Ultimate Guide: Wiring, 8th Updated EditionDa EverandUltimate Guide: Wiring, 8th Updated EditionValutazione: 3.5 su 5 stelle3.5/5 (4)

- Ricoh Aficio MP161 SPF Service Manual-93Documento229 pagineRicoh Aficio MP161 SPF Service Manual-93xlongboyNessuna valutazione finora

- Aero 80FP Operator ManualDocumento48 pagineAero 80FP Operator ManualTimmyNessuna valutazione finora

- KP01 Installation ManualDocumento19 pagineKP01 Installation ManualDiradivo Vakaikop100% (1)

- Soldering electronic circuits: Beginner's guideDa EverandSoldering electronic circuits: Beginner's guideValutazione: 4.5 su 5 stelle4.5/5 (9)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDa EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionValutazione: 4.5 su 5 stelle4.5/5 (3)

- 333 2SYGDS530 E2 - DatasheetDocumento7 pagine333 2SYGDS530 E2 - Datasheetvikas_ojha54706Nessuna valutazione finora

- LED Lamp SolderingHandlingDocumento15 pagineLED Lamp SolderingHandlingJimmy SmileyNessuna valutazione finora

- 5mm Infrared LED IR333/H0: FeaturesDocumento8 pagine5mm Infrared LED IR333/H0: FeaturesEversonSelbachNessuna valutazione finora

- Arpl 30WDocumento6 pagineArpl 30WProvera RaspolaganjaNessuna valutazione finora

- Product Specification: PLBT3-WDRG2613Documento6 pagineProduct Specification: PLBT3-WDRG2613api-62031994Nessuna valutazione finora

- Especificacion Tecnica LEDDocumento10 pagineEspecificacion Tecnica LEDJorge Herrero GarcíaNessuna valutazione finora

- D+led-Ld5rDocumento6 pagineD+led-Ld5rJulia EchazarretaNessuna valutazione finora

- T-1 3/4 (5Mm) Full Color Led Lamp: AttentionDocumento9 pagineT-1 3/4 (5Mm) Full Color Led Lamp: AttentionAdindanvrynNessuna valutazione finora

- Mini TOP Views LEDsDocumento11 pagineMini TOP Views LEDsRicky CoxNessuna valutazione finora

- A561E 7 SegmentosDocumento5 pagineA561E 7 SegmentosRaulJoseRainieriNessuna valutazione finora

- 82DS 82000MBDocumento83 pagine82DS 82000MBfebriNessuna valutazione finora

- Philips DVD Player Dvp3000,3005,3010Documento48 paginePhilips DVD Player Dvp3000,3005,3010Malay K GhoshNessuna valutazione finora

- Property of Lite-On Only FeaturesDocumento11 pagineProperty of Lite-On Only FeaturesBLUEE009Nessuna valutazione finora

- Lmt100 and Lmt110 SensorDocumento12 pagineLmt100 and Lmt110 SensorbeiudientuNessuna valutazione finora

- NXT4 Bia e 1Documento24 pagineNXT4 Bia e 1Felipe AchurraNessuna valutazione finora

- 42HP16 Toshiba Manual de ServicioDocumento89 pagine42HP16 Toshiba Manual de ServicioDaniel AvecillaNessuna valutazione finora

- Kingbright RGB Round LedDocumento8 pagineKingbright RGB Round LedcybertechnicoNessuna valutazione finora

- Led 5mm yDocumento6 pagineLed 5mm yMarcos PainenahuelNessuna valutazione finora

- ToshibaDocumento69 pagineToshibaJuan Carlos Canul ArenaNessuna valutazione finora

- LG l1917sDocumento30 pagineLG l1917simmortalwombatNessuna valutazione finora

- P2 Application NotesDocumento11 pagineP2 Application NotesPablo KuziwNessuna valutazione finora

- Preliminary Spec: 3.5X2.8Mm Surface Mount Led LampDocumento4 paginePreliminary Spec: 3.5X2.8Mm Surface Mount Led LampBab AbaNessuna valutazione finora

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesDocumento2 pagineData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaNessuna valutazione finora

- ServiceManual W1542SDocumento32 pagineServiceManual W1542ScapullopelonNessuna valutazione finora

- UM GDS-3000-GDP Probe EDocumento20 pagineUM GDS-3000-GDP Probe Eturbo385Nessuna valutazione finora

- View6L ManualDocumento52 pagineView6L ManualThuy NguyenNessuna valutazione finora

- SVC6100Documento135 pagineSVC6100Christopher CollinsNessuna valutazione finora

- Service Manual: PhilipsDocumento39 pagineService Manual: PhilipsRogerio E. SantoNessuna valutazione finora

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetDocumento6 pagineLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaNessuna valutazione finora

- Service ManualDocumento36 pagineService ManualEu ToteuNessuna valutazione finora

- DVDR3570H - SB KL Ex Si - 1221814332Documento54 pagineDVDR3570H - SB KL Ex Si - 1221814332olomouc7267Nessuna valutazione finora

- Va1912 M A Ma-Led-1 Ug EngDocumento27 pagineVa1912 M A Ma-Led-1 Ug EngSaša RašetaNessuna valutazione finora

- Ricoh - mp5000 S.M.Documento836 pagineRicoh - mp5000 S.M.Nikolaos Mavridis100% (1)

- Philips Bdp3380Documento35 paginePhilips Bdp3380boroda24100% (1)

- Toshiba 42wlt66 (SM) (PL)Documento191 pagineToshiba 42wlt66 (SM) (PL)roadrash100Nessuna valutazione finora

- DS-0035 3W PM2L-3LLx-SD v1.6Documento13 pagineDS-0035 3W PM2L-3LLx-SD v1.6Pavan KumarNessuna valutazione finora

- 42HL57 SVMDocumento39 pagine42HL57 SVMfuwenhuiNessuna valutazione finora

- Wp103gdt Green LedDocumento6 pagineWp103gdt Green LedLuis LopezNessuna valutazione finora

- Arowana Series - EX-proof LedDocumento7 pagineArowana Series - EX-proof LedJames YoungNessuna valutazione finora

- Toshiba 47hl167Documento23 pagineToshiba 47hl167Mike HadenNessuna valutazione finora

- Philips BDP 3000 SMDocumento43 paginePhilips BDP 3000 SMJose Koc GongoraNessuna valutazione finora

- BEKO PDP CH L6BDocumento129 pagineBEKO PDP CH L6BvideosonNessuna valutazione finora

- BEKO L6B PDP Service ManualDocumento121 pagineBEKO L6B PDP Service Manualvideoson100% (2)

- Citizen Systems Idp 3550 User ManualDocumento160 pagineCitizen Systems Idp 3550 User ManualGabriel MendezNessuna valutazione finora

- Beko P7 PDPDocumento125 pagineBeko P7 PDPwajkNessuna valutazione finora

- Toshiba 46rv530u SM (ET)Documento16 pagineToshiba 46rv530u SM (ET)titoritomexNessuna valutazione finora

- 333 2SDRD S530 A3 DatasheetDocumento6 pagine333 2SDRD S530 A3 Datasheetvikas_ojha54706Nessuna valutazione finora

- Toshiba 32av500uDocumento24 pagineToshiba 32av500uGeko NageNessuna valutazione finora

- 9582中英文操作手册Documento76 pagine9582中英文操作手册guoliang gNessuna valutazione finora

- Digital LED Thermometer with Microcontroller AVR ATtiny13Da EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Valutazione: 5 su 5 stelle5/5 (1)

- Excel Arrives Excel Sort of Evolved From MultiPlanDocumento1 paginaExcel Arrives Excel Sort of Evolved From MultiPlanKevin StrongNessuna valutazione finora

- Scripts de Formularios 01Documento4 pagineScripts de Formularios 01Kevin StrongNessuna valutazione finora

- Chapter 18 Working With ChartsDocumento2 pagineChapter 18 Working With ChartsKevin StrongNessuna valutazione finora

- Displaying A Data FormDocumento2 pagineDisplaying A Data FormKevin StrongNessuna valutazione finora

- A Function That Returns An Error ValueDocumento2 pagineA Function That Returns An Error ValueKevin StrongNessuna valutazione finora

- Customizing The ToolboxDocumento2 pagineCustomizing The ToolboxKevin StrongNessuna valutazione finora

- Excel® 2010 Power Programming With VBA: Contents at A GlanceDocumento2 pagineExcel® 2010 Power Programming With VBA: Contents at A GlanceKevin StrongNessuna valutazione finora

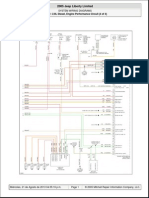

- AntitheftDocumento11 pagineAntitheftKevin StrongNessuna valutazione finora

- UserForm Code ReferenceDocumento4 pagineUserForm Code ReferenceKevin StrongNessuna valutazione finora

- Printing From OnDemand5 4Documento1 paginaPrinting From OnDemand5 4Kevin StrongNessuna valutazione finora

- Table of Contents (1) : TitleDocumento42 pagineTable of Contents (1) : TitleKevin StrongNessuna valutazione finora

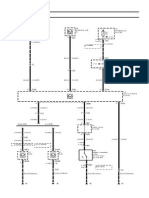

- Electronic Circuit Inspection Procedure: Introduction - How To Troubleshoot Ecu Controlled SystemsDocumento5 pagineElectronic Circuit Inspection Procedure: Introduction - How To Troubleshoot Ecu Controlled SystemsKevin StrongNessuna valutazione finora

- Finishing EnglDocumento49 pagineFinishing EnglSalim NgaosNessuna valutazione finora

- Interleaved Memory Organisation, Associative MemoDocumento19 pagineInterleaved Memory Organisation, Associative MemoGourav SallaNessuna valutazione finora

- Alpha New Trader GuideDocumento9 pagineAlpha New Trader GuideChaitanya ShethNessuna valutazione finora

- Structural SteelDocumento17 pagineStructural SteelliNessuna valutazione finora

- In Context: Subject Area: Organic Chemistry Level: 14-16 Years (Higher) Topic: Addition Polymers Source: RSC - Li/2GrwsijDocumento5 pagineIn Context: Subject Area: Organic Chemistry Level: 14-16 Years (Higher) Topic: Addition Polymers Source: RSC - Li/2GrwsijRajlaxmi JainNessuna valutazione finora

- NRC RG 1.99 Rev. 2 PDFDocumento10 pagineNRC RG 1.99 Rev. 2 PDFlalitNessuna valutazione finora

- Quarter I Subject: GENERAL Mathematics Date: - Content Standard Performance Standard Learning Competency M11GM-Ia-4Documento4 pagineQuarter I Subject: GENERAL Mathematics Date: - Content Standard Performance Standard Learning Competency M11GM-Ia-4PatzAlzateParaguyaNessuna valutazione finora

- Calculation and Adjustment of Silica (Sio) Scaling For Reverse OsmosisDocumento3 pagineCalculation and Adjustment of Silica (Sio) Scaling For Reverse OsmosismerksssNessuna valutazione finora

- DE SHORT METHODS - RevisedDocumento4 pagineDE SHORT METHODS - RevisedWilma NaderaNessuna valutazione finora

- Importance of ForecastingDocumento37 pagineImportance of ForecastingFaizan TafzilNessuna valutazione finora

- Keseimbangan Benda TegarDocumento18 pagineKeseimbangan Benda TegarNur Cholis MajidNessuna valutazione finora

- Res2dinvx32 PDFDocumento173 pagineRes2dinvx32 PDFWahyu Sutrisno0% (1)

- 1768 Compactlogix Controllers, Revision 20: Release NotesDocumento26 pagine1768 Compactlogix Controllers, Revision 20: Release NotesedeconsysNessuna valutazione finora

- Physics Midterm Review PacketDocumento6 paginePhysics Midterm Review PacketJasper SendraNessuna valutazione finora

- Mech CVTDocumento15 pagineMech CVTsachin guptaNessuna valutazione finora

- C++ Project For Graphic Scientific CalculatorDocumento34 pagineC++ Project For Graphic Scientific CalculatorManish DeyNessuna valutazione finora

- As Level Biology Summary Notes (2022-2024 Syllabus)Documento5 pagineAs Level Biology Summary Notes (2022-2024 Syllabus)ElisaNessuna valutazione finora

- SanternoDocumento468 pagineSanternoFrank DicksonNessuna valutazione finora

- Open Development EnvironmentDocumento16 pagineOpen Development EnvironmentMihaiNeacsuNessuna valutazione finora

- Computer Shortcut Keys SystemDocumento5 pagineComputer Shortcut Keys SystemNo RebelNessuna valutazione finora

- BCA Self Assessment English and TagalogDocumento3 pagineBCA Self Assessment English and TagalogReymundo Pantonial Tugbong JrNessuna valutazione finora

- Binomial Theorem: Theory and Exercise BookletDocumento8 pagineBinomial Theorem: Theory and Exercise BookletEr. Narender SinghNessuna valutazione finora

- Colgate PalmoliveDocumento8 pagineColgate PalmoliveRahul MaddikuntaNessuna valutazione finora

- Physics ProjectDocumento11 paginePhysics ProjectDimpySurya44% (25)

- FM TransmitterDocumento38 pagineFM TransmitterTushar Goel100% (1)

- Calculus IIIvectorcalculus 2011Documento82 pagineCalculus IIIvectorcalculus 2011Alfi LouisNessuna valutazione finora

- Pig Iron Blast Furnace: Mcqs Preparation For Engineering Competitive ExamsDocumento20 paginePig Iron Blast Furnace: Mcqs Preparation For Engineering Competitive ExamschauhanNessuna valutazione finora

- 1.0 Intro To Aircon (Properties of Moist Air) With Sample ProblemDocumento10 pagine1.0 Intro To Aircon (Properties of Moist Air) With Sample ProblemRenneil De PabloNessuna valutazione finora

- Minggu 5 Teori AktDocumento69 pagineMinggu 5 Teori AktHILDANessuna valutazione finora

- 17-File Utama Naskah-96-1-10-20210301Documento8 pagine17-File Utama Naskah-96-1-10-20210301Angga DwNessuna valutazione finora