Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Analyzer CFD Overview V1 BV

Caricato da

DharaniDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Analyzer CFD Overview V1 BV

Caricato da

DharaniCopyright:

Formati disponibili

Analyzer

CAE Solutions Pvt. Ltd.

Complete CAE Solutions

CFD Capabilities at Analyzer

Automotive Industry

CFD Capabilities in:

Internal and External

Aerodynamics

Intake/exhaust manifolds

Underhood Analysis

Filtration and Exhaust Systems

External Aerodynamics

Underhood thermal management

Engine Simulation

Filtration System

Electronic Cooling Areas of Expertise

Component

Virtual

Level Analysis

JEDAC Tests

Theta

JA, Theta JC, Theta JB, Theta CA, etc.

Detailed

Modeling

Compact Thermal Model

2R

Board

and DELPHI Model

Level Analysis

Component

Placement

Thermal Vias, Board Cu Layering, etc.

System

Level Analysis

Overall

System Thermal Performance

Casing, Internal Air, and Component Surface Temperature

Parameters

Under Consideration

Peak Temperature/Hot Spots

Air flow rates and temperature

What if? Analysis

Effect of Heat sinks, fans, heat pipes, etc.

Design Optimization

Turbo-machinery Capabilities

Pumps (Single and Multi-Stage)

Compressors and turbines (Single and Multi-stage)

Fans and Blowers

Cavitation Analysis

Automotive Application

Mixed Flow

Axial Flow

Radial Flow

Turbo Chargers

Radiator Fans

Parameters under investigation

Head or Total Pressure Rise

Shaft Power

Efficiency

Stall or Flow Separation

Cooling Water Basin and Pump Sump Analysis

Relative Position of Sluice Gate and Pump Intake:The primary reason of the swirl is the relative

position of sluice gate and pump intake, hence the

position needs to be optimized.

Vortex Breaker:By using appropriate Vortex Breakers,

vortex formation reduces significantly.

Separation Wall:By using Breast wall, overall vortex formation

and hydraulic fluctuations will reduce, this will improve

pump performance.

Introduction of slope:Introduction of Slope rather than step in the sump

pit, reduces flow recirculation and improves pump performance.

Ventilation and Fire/Smoke Simulation

Optimizing the location of fresh air and exhaust

location and number of jet fan required.

Locating the dead regions and high CO

concentration zones and eliminating them.

Tracing Smoke path and formulizing the emergency

evacuation.

Applications in:

Multi Level Car Park Ventilation

Malls and Airports

Tunnels

Commercial buildings

Bus and Railway Stations

Internal and External Building Simulation

CFD Simulation for Internal and External of

Buildings:

CFD Simulation of Airports to determine the thermal

comfort of passengers inside the airport.

Fire and Smoke simulations inside the shopping mall

to determine the location of fresh air and exhaust fan

locations for best performance of system.

Determining the stack effect in tall buildings due to

AHUs place one over another under various wind

speeds and wind directions.

Determining the flow pattern on building and to

predict the effect of rain (Wind Driven Rain) on the

building.

HVAC simulation of Airports

Stack effect prediction due to Outdoor Units

Simulation of Fire Propagation in

Shopping Mall

Flow simulation on Building to determine the wind driven rain

CFD in Process Industry

Spray Dryer

Cyclone

ESP

Bag House

Ducting

Mixing

Ineffective outlets

Key Clients List

Some of the current customers

NAL

ThyssenKrupp

Cunmmins

Ashok Leyland

Atlas Copco

BHEL R&D

Larsen & Toubro Limited

Thank You

External

Aerodynamics of Car

(any vehicle)

Flow through Pump

(Pipes/Valves etc)

IC engine

simulation

CFD

Ventilation and Smoke Simulation

Electronic Cooling

(Transient Simulations)

HVAC in Data Centre

(Car/Buildings etc)

Combustion in Fluidized

Bed (Furnas/Engines

etc)

Aero-Acoustics in Intake Manifold (HVAC

ducts, Mufflers, combustors etc)

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hydraulics JumpDocumento12 pagineHydraulics JumpsyahirabdullahNessuna valutazione finora

- 01 - Head Loss Calculation - 01Documento15 pagine01 - Head Loss Calculation - 01pangit catcatNessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological UniversityMohitSathwara 2609Nessuna valutazione finora

- Column Internals ImagesDocumento10 pagineColumn Internals ImagespandianvijaybharathiNessuna valutazione finora

- FM Landing Valve PDFDocumento1 paginaFM Landing Valve PDFsujs_1Nessuna valutazione finora

- G D C V L P D C V L G P H: Total Total Head (M) 25 % Safty Total With 25 % SaftyDocumento2 pagineG D C V L P D C V L G P H: Total Total Head (M) 25 % Safty Total With 25 % SaftyraifaisalNessuna valutazione finora

- PETREL Simple SimulationDocumento48 paginePETREL Simple SimulationKuala Tambora100% (1)

- Advances in Heat Transfer 2 (1965)Documento469 pagineAdvances in Heat Transfer 2 (1965)alejandro_baro419Nessuna valutazione finora

- Chapter3 Mechproperties Sem1 2820212022 29Documento79 pagineChapter3 Mechproperties Sem1 2820212022 29irdina harissaNessuna valutazione finora

- Forced Convection,,internal FlowDocumento157 pagineForced Convection,,internal FlowZayn AhmedNessuna valutazione finora

- Kinetics Study and Modelling of Steam Methane ReformingDocumento15 pagineKinetics Study and Modelling of Steam Methane ReformingAndreea DobreNessuna valutazione finora

- Energy Conservation BoilerDocumento38 pagineEnergy Conservation Boilervivek rathodNessuna valutazione finora

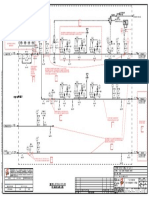

- Fuel Gas Skid Train PDFDocumento1 paginaFuel Gas Skid Train PDFhadNessuna valutazione finora

- Models - Mfl.controlled Diffusion Micromixer PDFDocumento36 pagineModels - Mfl.controlled Diffusion Micromixer PDFvarun singhNessuna valutazione finora

- TECNAIR Serie P PDFDocumento28 pagineTECNAIR Serie P PDFdokundotNessuna valutazione finora

- PP-309 Mass Transfer: Course Facilitator: Nadia Khan Lecture of Week 1 & 2Documento77 paginePP-309 Mass Transfer: Course Facilitator: Nadia Khan Lecture of Week 1 & 2ashas waseem100% (1)

- MBBR DesignDocumento5 pagineMBBR Designsaurabh kushwahaNessuna valutazione finora

- Turnover Rates in Heterogeneous CatalysisDocumento6 pagineTurnover Rates in Heterogeneous CatalysisWahab ChodharyNessuna valutazione finora

- Foster Wheeler Boiler ManualDocumento48 pagineFoster Wheeler Boiler ManualIbrahem HyasatNessuna valutazione finora

- Educational Information For High Expansion Foam Fire Extinguishing SystemDocumento3 pagineEducational Information For High Expansion Foam Fire Extinguishing SystemAjay W DhimanNessuna valutazione finora

- 2101 Solutions VII, 2014Documento11 pagine2101 Solutions VII, 2014mnseftnerNessuna valutazione finora

- Hydraulic Conductivity Compatibility Testing of Soils With Aqueous SolutionsDocumento17 pagineHydraulic Conductivity Compatibility Testing of Soils With Aqueous SolutionsMohanadNessuna valutazione finora

- Lab Manual (Cre)Documento41 pagineLab Manual (Cre)akash100% (1)

- Investigation of Optimum Operating Parameters For BOD & COD Removal Using Activated CarbonDocumento6 pagineInvestigation of Optimum Operating Parameters For BOD & COD Removal Using Activated CarbonafridiNessuna valutazione finora

- 1.2.d Single Reaction in A PFR With Heat Exchange - Solution.2023Documento9 pagine1.2.d Single Reaction in A PFR With Heat Exchange - Solution.2023Bastien KamaraNessuna valutazione finora

- BP Flowback ProceduresDocumento10 pagineBP Flowback ProceduresAlexander KlmNessuna valutazione finora

- Tank Battery Design PDFDocumento4 pagineTank Battery Design PDFdigeca100% (1)

- Agitator Tank Mixers Agitators Chemineer Agitator PRG IrelandDocumento7 pagineAgitator Tank Mixers Agitators Chemineer Agitator PRG IrelandRahul ChandrawarNessuna valutazione finora

- Vacuum PumpsDocumento2 pagineVacuum PumpsStefanVisNessuna valutazione finora

- 2001, Casappa, Flow DividersDocumento20 pagine2001, Casappa, Flow DividersVelibor KaranovićNessuna valutazione finora