Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Delivery Condition: Applicable To Parts: Ring WCFN0055

Caricato da

Balram JiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Delivery Condition: Applicable To Parts: Ring WCFN0055

Caricato da

Balram JiCopyright:

Formati disponibili

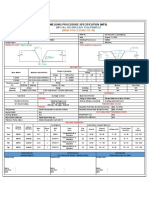

TECHNICAL DELIVERY CONDITION

Customer Wise TDC No.:Material Specification

Customer Name :

TDC No. :

Rev. No.:

Date

:

Page :

VC / TDC / 002

ASTM A-105

VC / TDC 002

00

08.10.2015

01 of 02

Applicable to Parts : Ring WCFN0055

Sr.

No.

Description

Required Parameters

Process / Mfg Route

Refined & Vacuum degassed through EAF, LRF, CCH, EMS & VD

OR VAD

Chemistry

Inspection

Method

%C

0.20 - 0.25

By Spectral

%Si

0.15 ~ 0.35

By Spectral

%Mn

0.85 ~ 1.150

By Spectral

%P

0.035 Max.

By Spectral

%S

0.035 Max.

By Spectral

%Cr

-----

By Spectral

%Al

0.020 ~ 0.040

By Spectral

%Mo

-----

By Spectral

%Cu

-----

By Spectral

%Ni

-----

By Spectral

%Sn

-----

By Spectral

%V

-----

By Spectral

%As

-----

By Spectral

%Sb

-----

By Spectral

%Pb

-----

By Spectral

%Ca

-----

By Spectral

%B

-----

By Spectral

%(Sn+As+Sb

)

-----

By Spectral

Gas Content (PPM)

Max.

---------

Supply Condition

AS ROLLED

Macro-structure

C2,R2,S2 Max. Free from Porosity, Flakes & Excessive

Seggregation

By Acid Etching

Microstructure

Uniform distribution of Ferrite & Pearlite should be free from banding

------

Ultrasonic Testing

100% Inspection by UT with deffect Echo Max. 20% of back wall

Echo

-----

As Per ASTM E-381 Plate-II

As per IS:4163

Inclussion Rating

Grain Size

Pepared By:

Sulphide

Aluminate

Silicate

Oxide

Thin Series

(Max.)

2.0

2.0

2.0

2.0

Thick Series

(Max.)

1.5

1.5

1.5

1.5

ASTM 5 ~ 8 at 100x

By Microscope

As Per ASTM E-112

Approved By:

Format No. QFM/QC/01 Rev 00

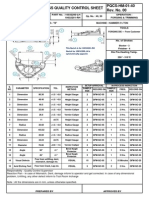

TDC No. :

TECHNICAL DELIVERY CONDITION

Sr.

No.

Description

Required Parameters

10

Jominy Hardenability

------Test Bar

Diameter

(mm)

Test Bar H/T

Status

11

Mechanical Properties

Visual Inspection

00

Rev. No.:

08.10.2015

Date

:

02 of 02

Page :

Inspection

Method

-----

---------

-----

---------

-----

UTS (MPA)

---------

-----

YS (MPA)

---------

-----

% Elongation

10%

-----

% RA

---------

-----

---------

-----

241 BHN Max.

-----

Color Code

Yellow+White

Visual

Heat Code

Written with paint

Visual

Section Size

As per our Purchase order

Vernier Caliper

Surface

Condition

Free From Crack & Seam

Visual

Impact

Strength

As Rolled

Hardness

12

VC / TDC 002

13

Reduction Ratio

-----

14

De-carb Level

-----

-----

15

Acceptable level of

Surface Defects

-----

-----

16

Upsettability Test

Free From Crack & Seam

By Acid Etching

17

Multiple Length

As per our Purchase order

-----

Free From Streaks

As Per IS : 4075 1985

18

19

20

Step down Test

Test Certificates

Chemistry : Gas Content (PPM) Max. ; Macro-structure ; Ultrasonic Testing ; Inclusion Rating ; Grain Size ;

(Required for each Heat

Mechanical Properties ; Color Code ; Heat Code ; Section Size ; Reduction Ratio ; Upsettability Test ;

No.)

Multiple Length ; MPI/Step down Test ; Jominy

Tolerances on Size,

Roundness &

Straightness

Stock Size

(mm)

Tolerance on Size (mm)

Tolerance on out of roundness(mm) Max.

As Per IS:3739 - 1987

NOTE :- Any change in procss parameter to be kept informed to Vikrant Components India Pvt. Ltd.

Pepared By:

Approved By:

Format No. QFM/QC/01 Rev 00

VC / TDC 002

00

08.10.2015

01 of 02

/ 002

-105

Remarks

SOURCE

proved By:

QFM/QC/01 Rev 00

VC / TDC 002

00

08.10.2015

02 of 02

Remarks

Inclusion Rating ; Grain Size ;

n Ratio ; Upsettability Test ;

a Pvt. Ltd.

proved By:

QFM/QC/01 Rev 00

Potrebbero piacerti anche

- Forging SDocumento93 pagineForging SrichardchiamNessuna valutazione finora

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocumento1 paginaWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNessuna valutazione finora

- TWI CSWIP Training Plan - Dynaquest Energy LimitedDocumento2 pagineTWI CSWIP Training Plan - Dynaquest Energy LimitedAdeniyi100% (1)

- Cutting Plan FormatDocumento1 paginaCutting Plan FormatPrinceRaghavNessuna valutazione finora

- Form UT, MT, PT, RTDocumento5 pagineForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Qap Gate ValveDocumento1 paginaQap Gate ValveAjit PatilNessuna valutazione finora

- TDC 004 CS Fittings r0Documento1 paginaTDC 004 CS Fittings r0samkarthik47Nessuna valutazione finora

- In Process QC FormatDocumento9 pagineIn Process QC FormatSunil ChaubeyNessuna valutazione finora

- Surface Preparation & Painting ProcedureDocumento9 pagineSurface Preparation & Painting ProcedureRam ThevarNessuna valutazione finora

- WFP 2 01 Procedure R1Documento8 pagineWFP 2 01 Procedure R1leodavid87Nessuna valutazione finora

- Material Traceability ProcedureDocumento12 pagineMaterial Traceability Procedureqamar qateebNessuna valutazione finora

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocumento1 paginaFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- Painting Report Cd3Documento15 paginePainting Report Cd3sivaNessuna valutazione finora

- Circularity Inspection Report: Shell Course (LW) CW CWDocumento14 pagineCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNessuna valutazione finora

- TopCoreBelco 101 FCDocumento9 pagineTopCoreBelco 101 FCCesar ArellanoNessuna valutazione finora

- T.C.L. Co. - Test & Control LaboratoriesDocumento2 pagineT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNessuna valutazione finora

- WPS-PQR ListDocumento1 paginaWPS-PQR ListSandra SandersNessuna valutazione finora

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocumento1 paginaReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNessuna valutazione finora

- Painting Procedure 4288 Danem 28-04-13Documento24 paginePainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- Welding Repair ProcdureDocumento16 pagineWelding Repair Procdureprem nautiyal100% (1)

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Documento4 pagineAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocumento1 paginaMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNessuna valutazione finora

- SA 387 Grade 91 Class 2Documento4 pagineSA 387 Grade 91 Class 2briang-2Nessuna valutazione finora

- I S 3658 - 1999Documento12 pagineI S 3658 - 1999Subhendu KhantuaNessuna valutazione finora

- Weld Consumables SelectionDocumento3 pagineWeld Consumables SelectionArputharaj Maria LouisNessuna valutazione finora

- 202 1sp 0 Saw Cs CsDocumento8 pagine202 1sp 0 Saw Cs CskrishimaNessuna valutazione finora

- Inspection CertificateDocumento1 paginaInspection CertificateAtanasio PerezNessuna valutazione finora

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocumento5 pagineAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedNessuna valutazione finora

- NDT Request (Template)Documento4 pagineNDT Request (Template)Bethel NdifonNessuna valutazione finora

- QAP Seamless PipeDocumento2 pagineQAP Seamless PipeashokkahirwarNessuna valutazione finora

- Welders ManagementDocumento11 pagineWelders ManagementStanley AlexNessuna valutazione finora

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocumento2 paginePrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Poster Welding P VoxXa PDFDocumento1 paginaPoster Welding P VoxXa PDFAd Man GeTigNessuna valutazione finora

- IZO Appliances (PVT) LTD: Quality Management System Procedure For System of ProductionDocumento7 pagineIZO Appliances (PVT) LTD: Quality Management System Procedure For System of ProductionS M Arif HussainNessuna valutazione finora

- Inspection Report: CPP-RM-PO-0180Documento4 pagineInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- Dimensional Inspection Report: Sample Production Lot/BatchDocumento1 paginaDimensional Inspection Report: Sample Production Lot/BatchCristina TinaNessuna valutazione finora

- WPS14-1 A106 B SmawDocumento4 pagineWPS14-1 A106 B SmawRahul MoottolikandyNessuna valutazione finora

- Qualification RangeDocumento1 paginaQualification RangeSARSAN NDTNessuna valutazione finora

- Wps MainlineDocumento5 pagineWps MainlineAlfian FebriansyahNessuna valutazione finora

- Baking and Drying Temperature of ElectrodesDocumento1 paginaBaking and Drying Temperature of ElectrodesshisNessuna valutazione finora

- Aws N-1 WPS-PQR FormDocumento2 pagineAws N-1 WPS-PQR FormEdwin MariacaNessuna valutazione finora

- 4102 NDT Notes PDFDocumento14 pagine4102 NDT Notes PDFAjay Kumar Reddy KNessuna valutazione finora

- 4 1 1-InsulatingFlangeKits PDFDocumento4 pagine4 1 1-InsulatingFlangeKits PDFKykyRizkyNessuna valutazione finora

- 1662 15Documento117 pagine1662 15RajamanikkamNessuna valutazione finora

- Weld ShrinkageDocumento16 pagineWeld ShrinkageWeff JingNessuna valutazione finora

- DRAFT Sample Welding Procedure GuidebookDocumento3 pagineDRAFT Sample Welding Procedure Guidebookahmad100% (1)

- Fit Up Welding Visual Inspection ReportDocumento2 pagineFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Documento1.913 paginePipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- Welding Procedure Specification (WPS) FormDocumento2 pagineWelding Procedure Specification (WPS) FormEarl Harbert0% (2)

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocumento7 pagineA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNessuna valutazione finora

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Documento1 paginaInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNessuna valutazione finora

- Welding Parameters Control PipelineDocumento1 paginaWelding Parameters Control PipelinemusheerNessuna valutazione finora

- Welding Repair ProcedureDocumento4 pagineWelding Repair ProcedureRiky SumantriNessuna valutazione finora

- TDC 003 - SS Pipes - r0Documento1 paginaTDC 003 - SS Pipes - r0samkarthik47Nessuna valutazione finora

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Documento4 pagineProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNessuna valutazione finora

- Ins-P-021, Long Seam Set UpDocumento4 pagineIns-P-021, Long Seam Set UpDeepak100% (1)

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Documento17 pagineWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNessuna valutazione finora

- Qap 8000ce Reactor - Repat - 1Documento2 pagineQap 8000ce Reactor - Repat - 1AliasgarNessuna valutazione finora

- TDC Tech Spec For PlateDocumento3 pagineTDC Tech Spec For PlateBantoo RajamandiNessuna valutazione finora

- Larsen & Toubro Limited: Ecc DivisionDocumento4 pagineLarsen & Toubro Limited: Ecc Divisionmanu_gite100% (2)

- Tootan Wala KhoohDocumento92 pagineTootan Wala KhoohBalram Ji100% (3)

- Rework Record For Heat Treated Parts: Original Production DetailsDocumento1 paginaRework Record For Heat Treated Parts: Original Production DetailsBalram Ji100% (2)

- Manav Kika HaniDocumento19 pagineManav Kika HaniBalram JiNessuna valutazione finora

- English Short StoriesDocumento9 pagineEnglish Short StoriessharmasumittNessuna valutazione finora

- Handling of InstrumentsDocumento10 pagineHandling of InstrumentsBalram JiNessuna valutazione finora

- Chap-02 Pair ofDocumento9 pagineChap-02 Pair ofBalram JiNessuna valutazione finora

- ABC SocialismDocumento20 pagineABC SocialismsudamailNessuna valutazione finora

- Lea - 5SDocumento1 paginaLea - 5SallanjulesNessuna valutazione finora

- Stavax ESRDocumento13 pagineStavax ESRBalram JiNessuna valutazione finora

- Sae 1038 - Ø36Documento1 paginaSae 1038 - Ø36Balram JiNessuna valutazione finora

- Fundamentals of Heat Treating Ideal DiameterDocumento2 pagineFundamentals of Heat Treating Ideal Diameterozkangurkal100% (1)

- Emissivity 2Documento10 pagineEmissivity 2Les StroupfNessuna valutazione finora

- Oerlikon Checklist 2012Documento14 pagineOerlikon Checklist 2012Balram JiNessuna valutazione finora

- Touch Probe Fixtures enDocumento7 pagineTouch Probe Fixtures enBalram JiNessuna valutazione finora

- Jominy Formula SheetDocumento2 pagineJominy Formula SheetBalram JiNessuna valutazione finora

- PQCS Tube Flange Rough - CuttingDocumento1 paginaPQCS Tube Flange Rough - CuttingBalram JiNessuna valutazione finora

- PQCS Tube Flange Rough - ForgingDocumento1 paginaPQCS Tube Flange Rough - ForgingBalram JiNessuna valutazione finora

- Molygraph Graphol: Technical Data SheetDocumento1 paginaMolygraph Graphol: Technical Data SheetBalram JiNessuna valutazione finora

- Molygraph Graphol: Technical Data SheetDocumento1 paginaMolygraph Graphol: Technical Data SheetBalram JiNessuna valutazione finora

- Ramya Balaji Alloy Pvt. Limited: Record No.: Date: Page 1 of 1 Title: Code of Conduct For Employees (Staff)Documento1 paginaRamya Balaji Alloy Pvt. Limited: Record No.: Date: Page 1 of 1 Title: Code of Conduct For Employees (Staff)Balram JiNessuna valutazione finora

- Shewhart Individuals Control ChartDocumento2 pagineShewhart Individuals Control ChartBalram JiNessuna valutazione finora

- Why SpiritualityDocumento37 pagineWhy SpiritualityBalram JiNessuna valutazione finora

- JG Ja0023Documento1 paginaJG Ja0023Balram JiNessuna valutazione finora

- Kmpnai Ko Inayama: Kma-Caari Ka Naama À Idpat-MaomtDocumento1 paginaKmpnai Ko Inayama: Kma-Caari Ka Naama À Idpat-MaomtBalram JiNessuna valutazione finora

- How To Unprotect An Excel Sheet Without PasswordDocumento6 pagineHow To Unprotect An Excel Sheet Without PasswordBalram JiNessuna valutazione finora

- Work Instructions - Nickel Spot TestDocumento2 pagineWork Instructions - Nickel Spot TestBalram JiNessuna valutazione finora

- Preventive Maintenance PlanDocumento3 paginePreventive Maintenance PlanBalram Ji86% (7)

- Chapter 1Documento1 paginaChapter 1Balram JiNessuna valutazione finora

- Weight Standard FinalDocumento1 paginaWeight Standard FinalBalram JiNessuna valutazione finora

- Audi A4-7Documento532 pagineAudi A4-7Anonymous QRVqOsa5Nessuna valutazione finora

- Sim Uge1Documento62 pagineSim Uge1ALLIAH NICHOLE SEPADANessuna valutazione finora

- 23 Ray Optics Formula Sheets Getmarks AppDocumento10 pagine23 Ray Optics Formula Sheets Getmarks AppSiddhant KaushikNessuna valutazione finora

- MSDS Buffer Solution PH 4.0Documento5 pagineMSDS Buffer Solution PH 4.0Ardhy LazuardyNessuna valutazione finora

- Class 12 Physics Derivations Shobhit NirwanDocumento6 pagineClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniNessuna valutazione finora

- Transportation of CementDocumento13 pagineTransportation of CementKaustubh Joshi100% (1)

- End-Of-Chapter Answers Chapter 7 PDFDocumento12 pagineEnd-Of-Chapter Answers Chapter 7 PDFSiphoNessuna valutazione finora

- Test On Real NumberaDocumento1 paginaTest On Real Numberaer.manalirathiNessuna valutazione finora

- Management PriniciplesDocumento87 pagineManagement Priniciplesbusyboy_spNessuna valutazione finora

- CL Honours Report NamanDocumento11 pagineCL Honours Report NamanNaman VermaNessuna valutazione finora

- Mahindra&mahindraDocumento95 pagineMahindra&mahindraAshik R GowdaNessuna valutazione finora

- Pitch DeckDocumento21 paginePitch DeckIANessuna valutazione finora

- The Pneumatics of Hero of AlexandriaDocumento5 pagineThe Pneumatics of Hero of Alexandriaapi-302781094Nessuna valutazione finora

- MLX90614Documento44 pagineMLX90614ehsan1985Nessuna valutazione finora

- Work Energy Power SlidesDocumento36 pagineWork Energy Power Slidessweehian844100% (1)

- Jurnal Job DescriptionDocumento13 pagineJurnal Job DescriptionAji Mulia PrasNessuna valutazione finora

- Source:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Documento2 pagineSource:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Ian EncarnacionNessuna valutazione finora

- Blake Mouton Managerial GridDocumento3 pagineBlake Mouton Managerial GridRashwanth Tc100% (1)

- Regulasi KampenDocumento81 pagineRegulasi KampenIrWaN Dompu100% (2)

- Template Budget ProposalDocumento4 pagineTemplate Budget ProposalimamNessuna valutazione finora

- File RecordsDocumento161 pagineFile RecordsAtharva Thite100% (2)

- Tomb of Archimedes (Sources)Documento3 pagineTomb of Archimedes (Sources)Petro VourisNessuna valutazione finora

- WWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDocumento8 pagineWWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDestiny EasonNessuna valutazione finora

- Amity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorDocumento23 pagineAmity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorMayank TayalNessuna valutazione finora

- Configuration Guide - Interface Management (V300R007C00 - 02)Documento117 pagineConfiguration Guide - Interface Management (V300R007C00 - 02)Dikdik PribadiNessuna valutazione finora

- Building Material Supplier in GurgaonDocumento12 pagineBuilding Material Supplier in GurgaonRodidustNessuna valutazione finora

- Atmel 46003 SE M90E32AS DatasheetDocumento84 pagineAtmel 46003 SE M90E32AS DatasheetNagarajNessuna valutazione finora

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Documento85 pagineME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNessuna valutazione finora

- White Paper: 1 Definitive Guide To Data QualityDocumento18 pagineWhite Paper: 1 Definitive Guide To Data QualityGonçalo MartinsNessuna valutazione finora

- Static Electrification: Standard Test Method ForDocumento10 pagineStatic Electrification: Standard Test Method Forastewayb_964354182Nessuna valutazione finora